Gluing and compounding device for packaging corrugated boards

A technology for gluing and compounding corrugated cardboard, which is applied in the direction of machining/deformation, can solve problems such as uneven gluing and easy deformation of boxboard paper, reduce the amount of gluing, prevent deformation and wrinkles, and improve the efficiency of gluing and compounding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

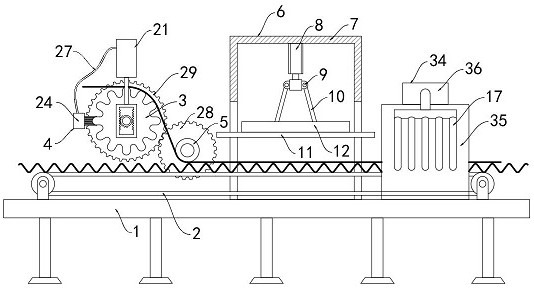

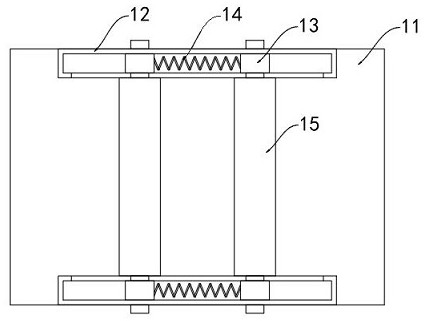

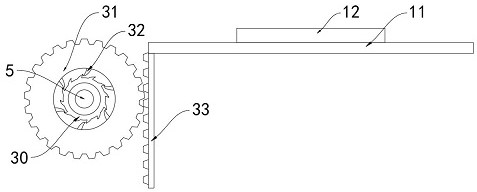

[0027] Such as Figure 1-5 As shown, a packaging corrugated cardboard gluing composite device includes a frame 1, a conveyor belt 2 for conveying corrugated paper is arranged on the frame 1, and a glue roller 3 is arranged on the frame 1. It should be noted that the glue application There are protruding teeth 16 arranged in a circular array on the peripheral side wall of the roller 3, and the protruding teeth 16 extend along the axial direction of the gluing roller 3. When the gluing roller 3 rotates, the protruding teeth 16 are in contact with the surface of the boxboard paper for gluing, so that the box The adhesive on the surface of the cardboard is in strips arranged equidistantly, and is glued together with the protrusions of the corrugated paper to reduce the amount of glue applied and ensure the composite effect and the strength of the cardboard. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com