Dedusting method and dedusting device for concentrating mill screening equipment

A technology for screening equipment and mineral processing plants, applied in separation methods, dust removal, injection devices, etc., can solve the problems of unsuitable, muddy bonding, large water consumption, etc., and achieve reliable performance, small diameter, and small water consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

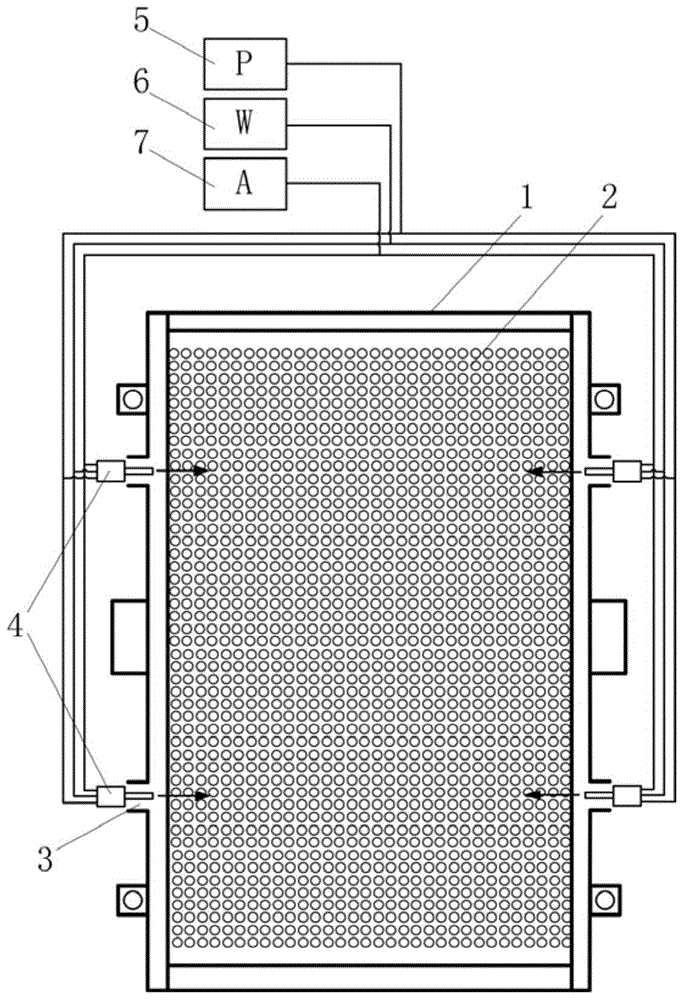

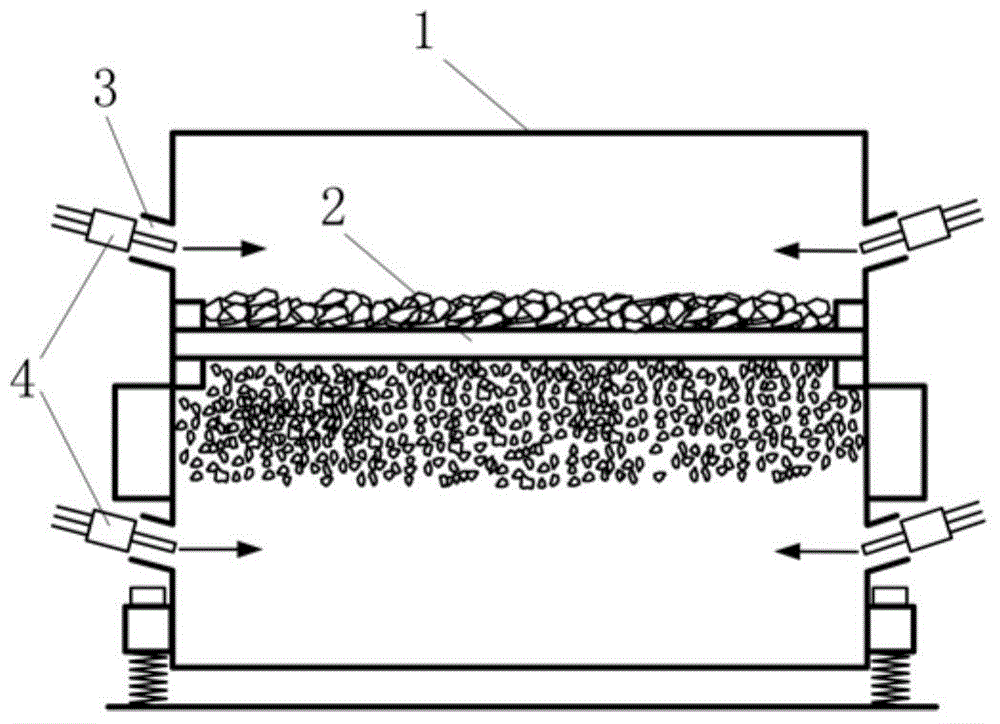

[0035] Using the method described in the present invention, the dust removal experiments were carried out on the vibrating screens of a molybdenum ore dressing plant in Chengde, Hebei, an iron ore dressing plant in Chengde, Hebei, and a lead-zinc ore dressing plant in Wenshan, Yunnan. These three concentrators all use 1800×3600 linear single-layer vibrating screens for material classification. During the test, according to figure 1 and figure 2 In the schematic method, eight atomized water inlets 3 and their piezoelectric ultrasonic atomizing nozzles 4 are arranged on both sides of the vibrating screen 1. Connect the piezoelectric ultrasonic atomizing nozzle 4 with the ultrasonic power supply 5, the water supply system 6, the air pressurization system 7 and other equipment without contacting the body. During the test, the operating frequency of the piezoelectric ultrasonic atomizing nozzle 4 was set to 120 kHz, the water supply system 6 was adjusted to maximize the amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com