Patents

Literature

39results about How to "Guaranteed composite effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

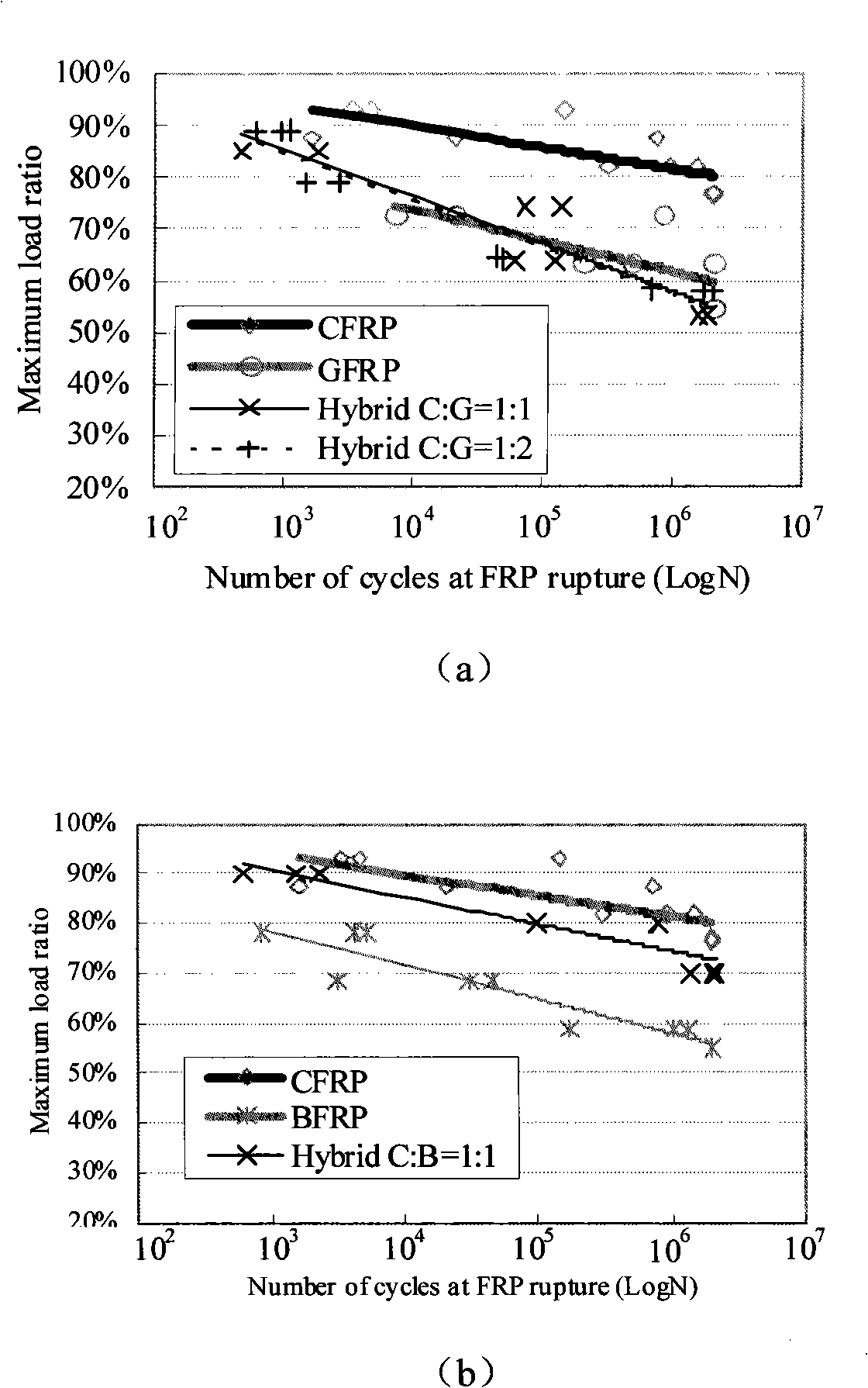

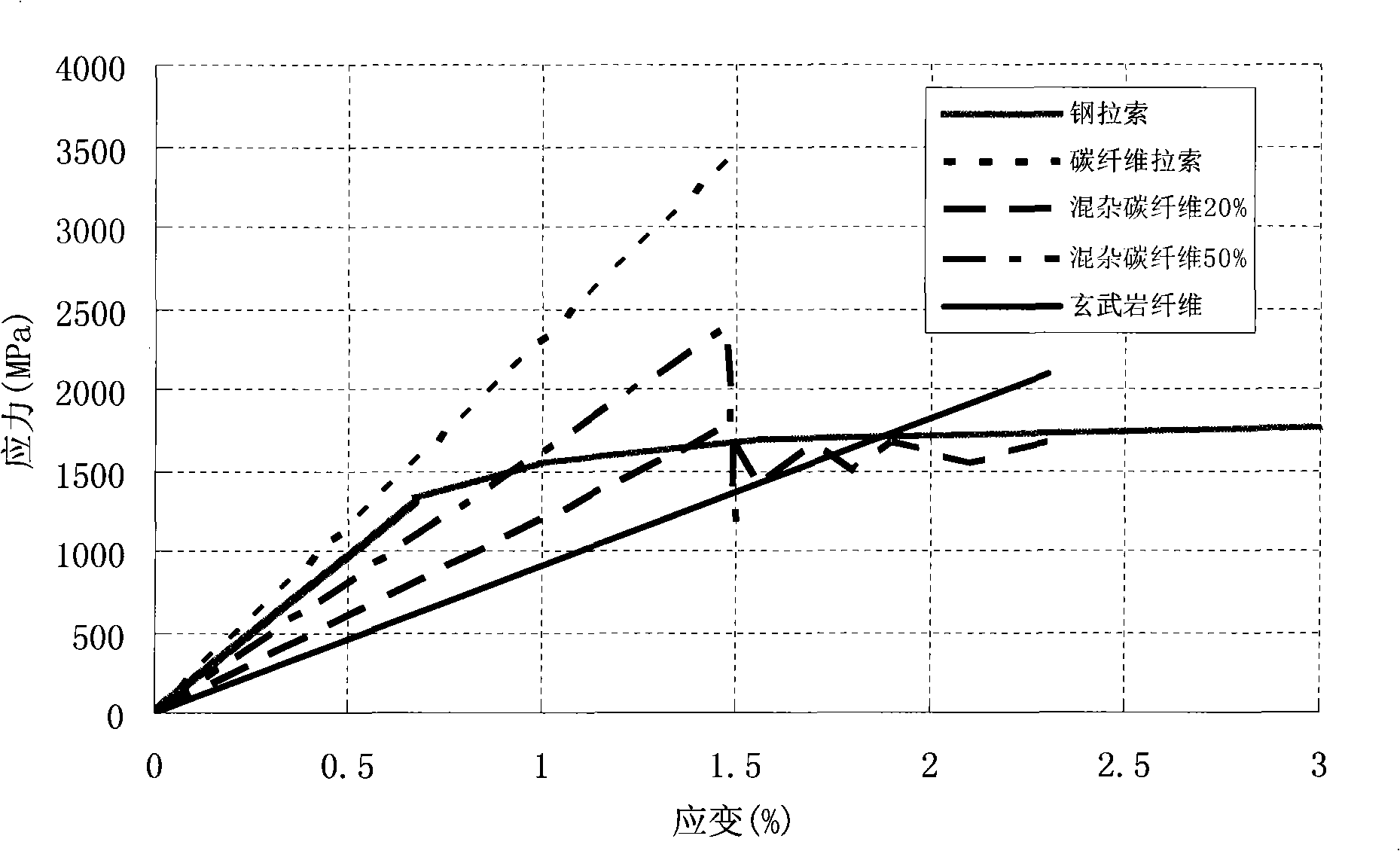

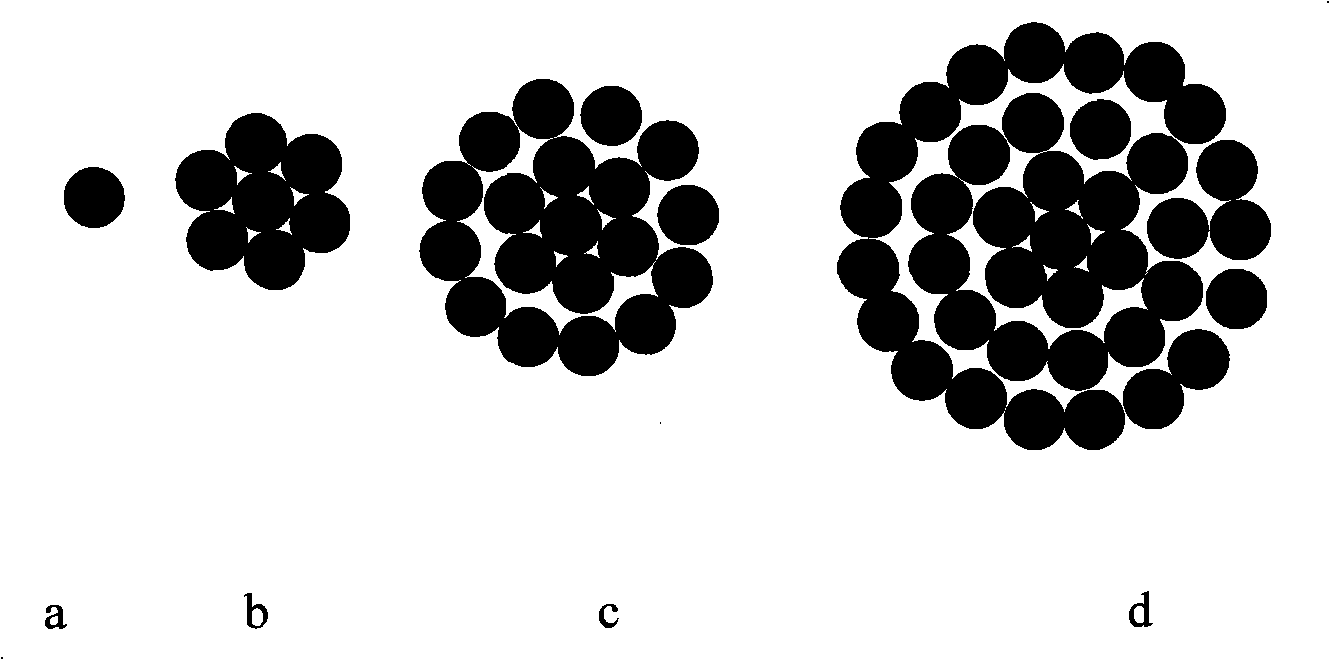

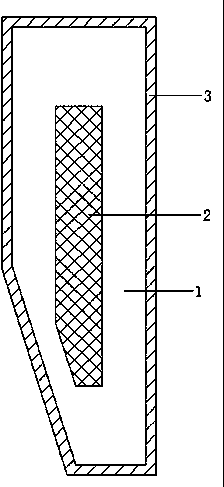

Basalt fibre composite rib and basalt fibre composite inhaul cable

ActiveCN101525864ASmall sag effectImprove air stabilityBridge structural detailsCarbon fibersBasalt fiber

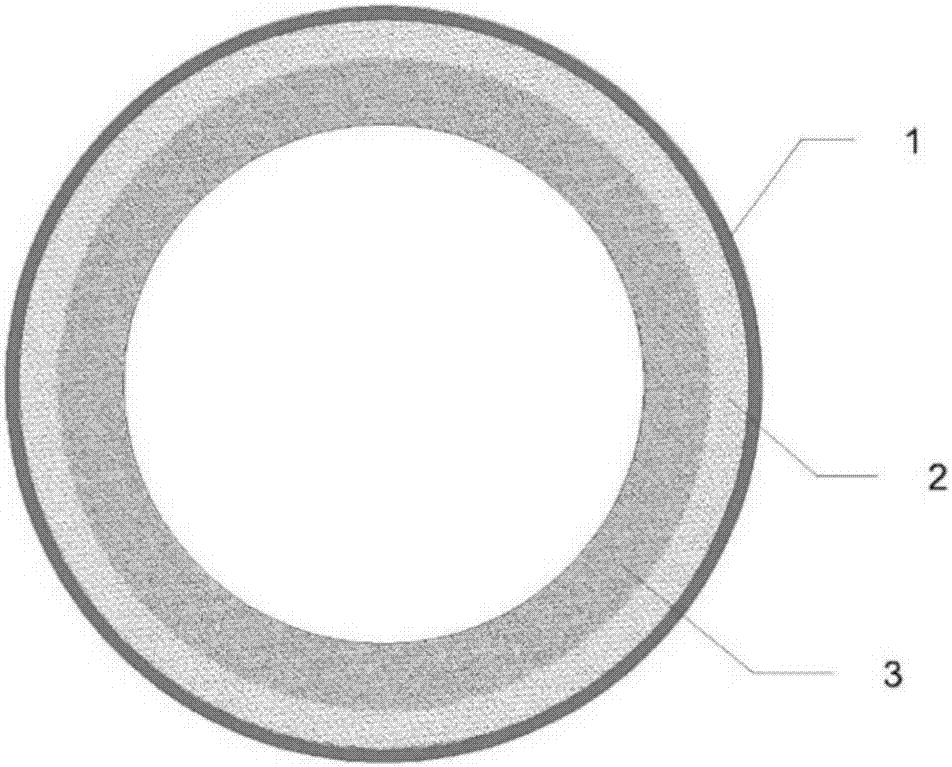

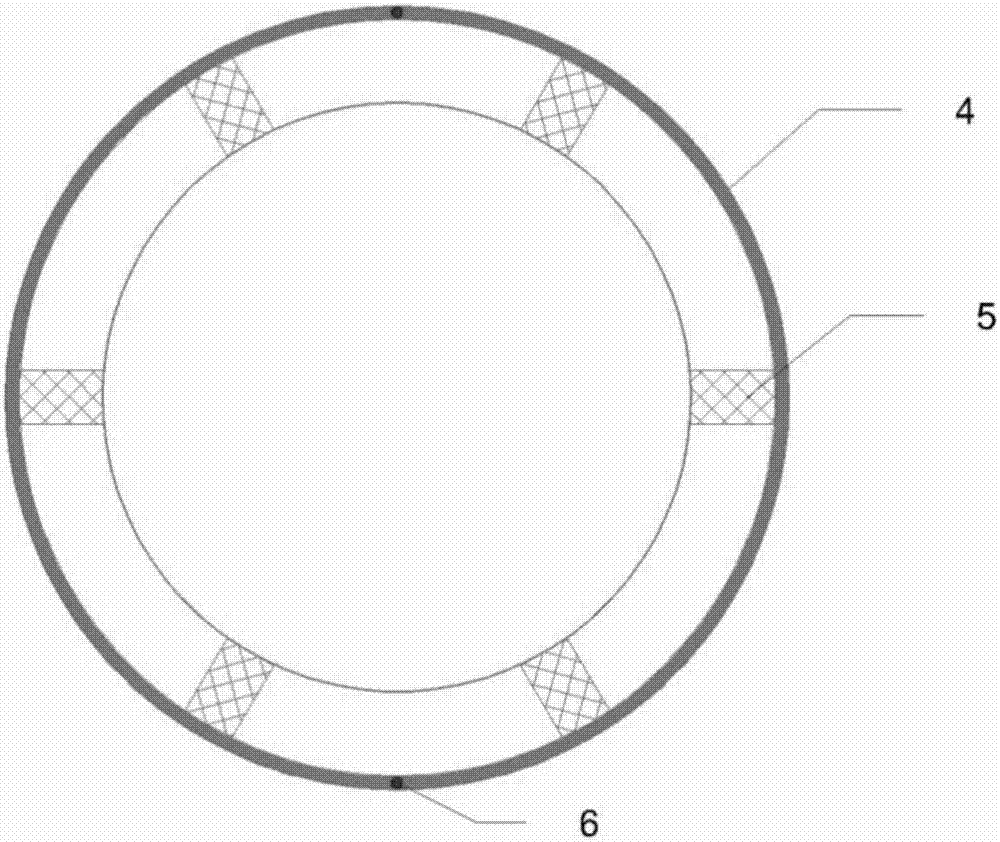

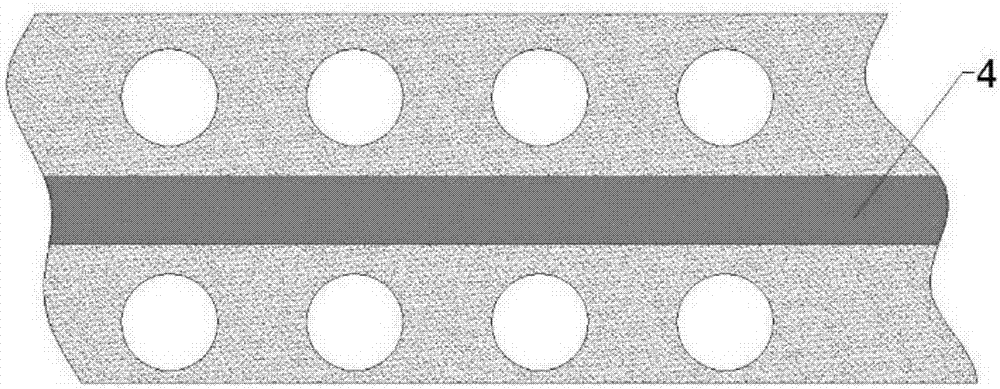

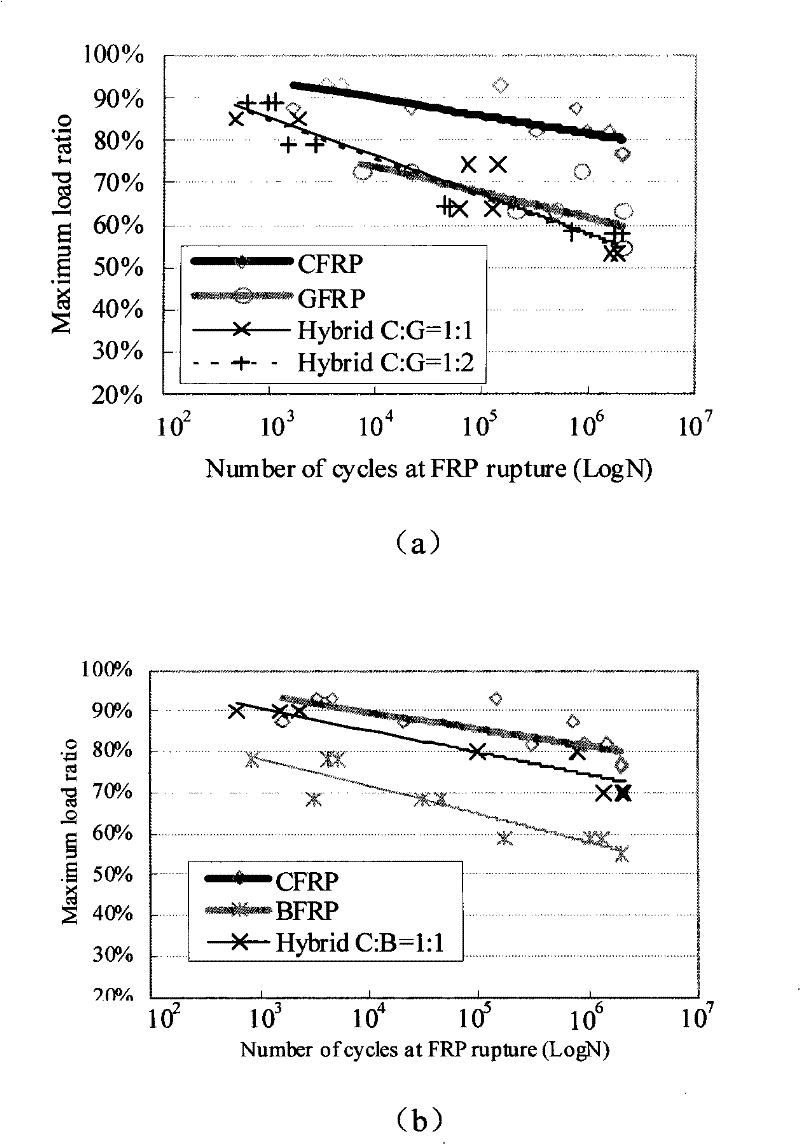

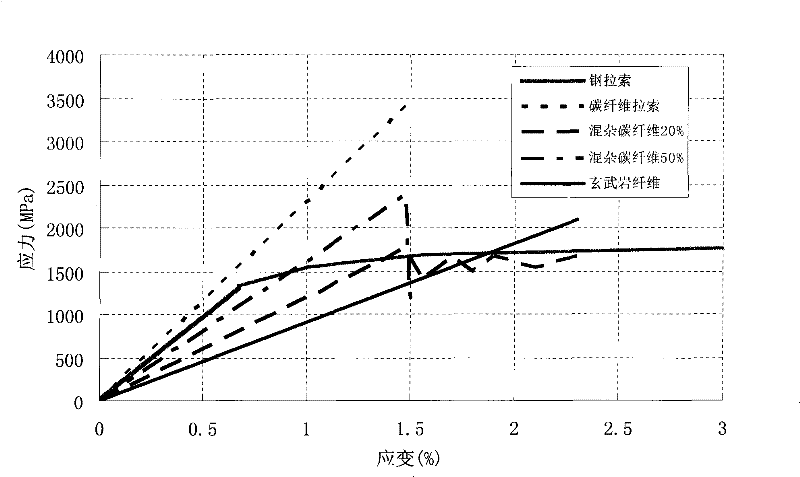

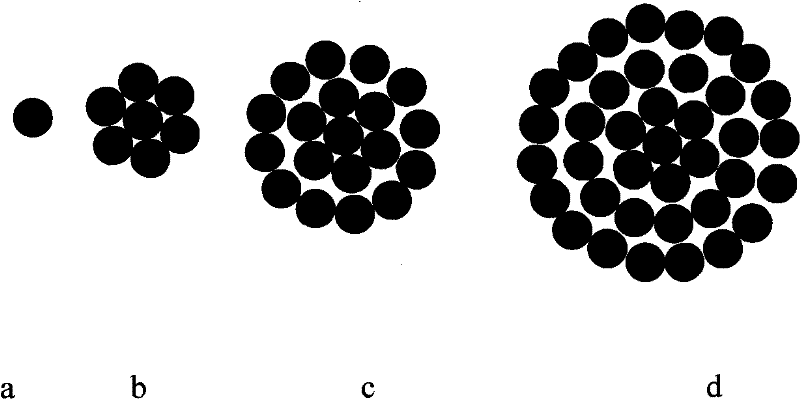

The invention discloses a basalt fibre composite rib and a basalt fibre composite inhaul cable. The composite rib is formed by drawing, extruding, molding and compounding basalt fibre and carbon fibre under the pretension action, and fibre volume ratio is 4:1-1:1; the basalt fibre composite inhaul cable comprises an outer protecting layer and fibre reinforcement material arranged in the outer protecting layer, the fibre reinforcement material comprises a center rib and an outer rib, the center rib is composed of a basalt fibre rib or carbon fibre rib, the outer rib is composed of the basalt fibre composite rib, an adhesive elastic filling layer and an inner sleeve are arranged between the center rib and the outer rib, the inner side of the inner sleeve is connected with the adhesive elastic filling layer, and the outer side of the inner sleeve is connected with the outer rib. In the composite inhaul cable, the carbon fibre content occupies 25-40 percent of total fibre content of the inhaul cable. Compared with the prior art, the composite carbon fibre of the basalt fibre composite inhaul cable in the basalt fibre enables short-period and long-period mechanical property and chemical property of the inhaul integer to be better, and has remarkable economy.

Owner:SOUTHEAST UNIV +2

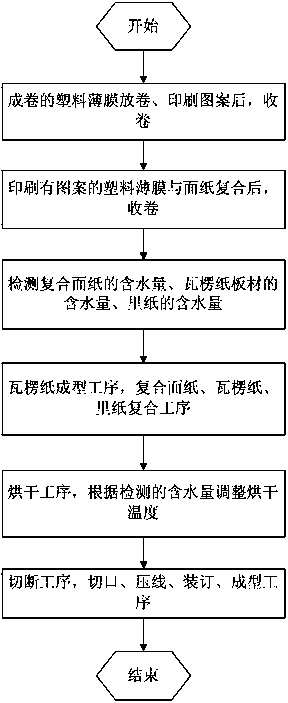

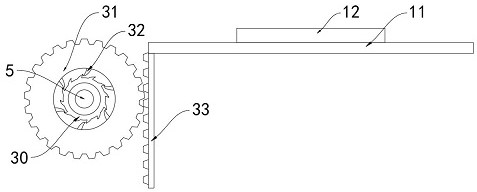

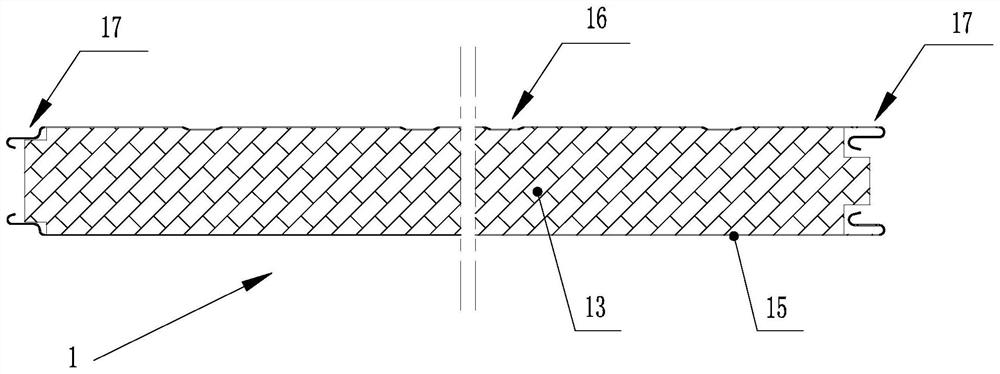

Paper-plastic package box and manufacturing method thereof

InactiveCN103612417ANo pressureAvoid squishingMechanical working/deformationBox making operationsCardboardMolded pulp

The invention provides a paper-plastic package box and a manufacturing method thereof. The manufacturing method of the paper-plastic package box comprises the following steps that a volumed thin film is unwound, and after patterns are printed, the thin film is wound; the thin film printed with the patterns and surface paper are wound after being combined; a forming procedure of corrugated paper is conducted, and a composition procedure of the composite surface paper, the corrugated paper and inner paper is conducted; a cutting-off procedure is conducted, and cutting, line folding, binding and forming procedures are conducted. According to the manufacturing method of the paper-plastic package box, technological processes are simplified, working efficiency is improved, and production cost is reduced. By heating rollers through which the corrugated paper, the compote surface paper and the inner paper pass, bonding firmness of the corrugated paper, the compote surface paper and the inner paper is enhanced. The gap between second compression roller is equal to the sum of the thickness of the composite surface paper, the thickness of the corrugated paper and the thickness of the inner paper, so that the second compression rollers have non compacting force on composite paper boards and only play a traction and composite role, and it is avoided that strength of the composite paper boards is reduced because the corrugated paper is flattened during composition.

Owner:龙口锦昇包装有限公司

Rolling compositing process of aluminum-clad steel pipe material

ActiveCN103599932AGuaranteed composite effectImprove bindingMetal rolling arrangementsCarbon steelSteel tube

The invention provides a rolling compositing process of aluminum-clad steel pipe material. According to the process, aluminum alloy material and carbon steel material are composited well; production cost is low, and composting is effective. According to the technical scheme, the process is characterized in that the carbon steel material and the aluminum alloy material are prepared respectively, the carbon steel material and the aluminum alloy material are stacked and fed into a rolling mill to be rolled, and the aluminum-clad steel pipe material is obtained. Rolling deformation is controlled ranging from 60% to 70% during cold rolling.

Owner:YINBANG CLAD MATERIAL

Process method for preparing wear-resisting extrusion roller sleeve through centrifugal casting

The invention relates to a process method for preparing a wear-resisting extrusion roller sleeve through centrifugal casting, and belongs to the field of metal based composite material. The method includes the steps that firstly, an annular blank with a framework is prepared; and secondly, the blank is spliced to be placed into a centrifugal machine die, metal liquid pouring is carried out, and the wear-resisting roller sleeve is obtained. A composite zone of the roller sleeve is composed of two different ceramic particles, wherein the outer layer ceramic particle is the ceramic particle with good iron liquid wettability, and the inner layer ceramic particle is the oxide ceramic particle. By means of the method, the framework is placed into the blank, the blank strength is improved, containing is facilitated, different ceramic particles are selected, the blank cost is reduced, the roller face composite effect is improved, and the service life of the roller face is greatly improved.

Owner:KUNMING UNIV OF SCI & TECH

Basalt fibre composite rib and basalt fibre composite inhaul cable

ActiveCN101525864BSmall sag effectImprove air stabilityBridge structural detailsCarbon fibersBasalt fiber

The invention discloses a basalt fibre composite rib and a basalt fibre composite inhaul cable. The composite rib is formed by drawing, extruding, molding and compounding basalt fibre and carbon fibre under the pretension action, and fibre volume ratio is 4:1-1:1; the basalt fibre composite inhaul cable comprises an outer protecting layer and fibre reinforcement material arranged in the outer protecting layer, the fibre reinforcement material comprises a center rib and an outer rib, the center rib is composed of a basalt fibre rib or carbon fibre rib, the outer rib is composed of the basalt fibre composite rib, an adhesive elastic filling layer and an inner sleeve are arranged between the center rib and the outer rib, the inner side of the inner sleeve is connected with the adhesive elastic filling layer, and the outer side of the inner sleeve is connected with the outer rib. In the composite inhaul cable, the carbon fibre content occupies 25-40 percent of total fibre content of the inhaul cable. Compared with the prior art, the composite carbon fibre of the basalt fibre composite inhaul cable in the basalt fibre enables short-period and long-period mechanical property and chemical property of the inhaul integer to be better, and has remarkable economy.

Owner:SOUTHEAST UNIV +2

Gluing and compounding device for packaging corrugated boards

PendingCN114228262ALarge and uniform contact areaNot prone to deformation and wrinklesMechanical working/deformationCardboardAdhesive

The invention belongs to the technical field of corrugated board production and processing, and particularly relates to a packaging corrugated board gluing and compounding device which comprises a rack, a conveying belt used for conveying corrugated paper is arranged on the rack, a gluing roller is arranged on the rack, a gluing mechanism is arranged on the gluing roller, a guide roller is arranged on the output side of the gluing roller, and a gluing mechanism is arranged on the guide roller. A compounding mechanism is arranged on the output side of the guide roller; the compounding mechanism comprises a compounding chamber fixed to the rack, an air cylinder is installed on the top face of the compounding chamber, and the output end of the air cylinder is fixedly connected with a hinge base. The gluing mechanism and the compounding mechanism are in close fit operation, the contact area of a pressing plate and corrugated paper is large and uniform, deformation and wrinkles are not prone to occurring, cardboard paper and the corrugated paper are tightly glued and bonded, the product quality is guaranteed, an adhesive is sucked through an adhesive suction barrel and conveyed to a gluing channel, and the production efficiency is improved. And the adhesive is uniformly coated on the convex teeth on the surface of the glue coating roller by the bristles on the brush plate, so that the cardboard paper can be uniformly and effectively glued.

Owner:张美皊

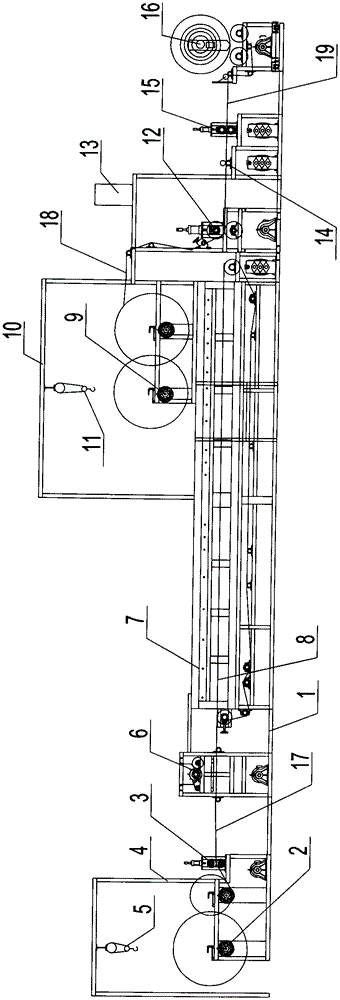

Activated carbon hot melt adhesive dusting compound machine

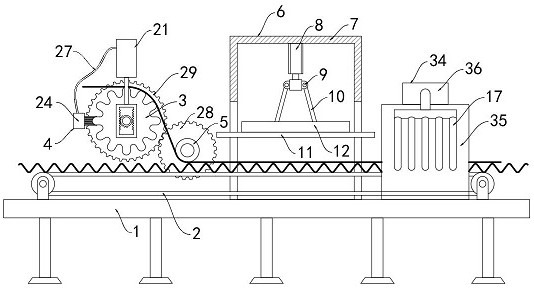

InactiveCN105291542AGuaranteed composite effectGuaranteed product effectLamination ancillary operationsLaminationActivated carbonAgricultural engineering

The invention discloses an activated carbon hot melt adhesive dusting compound machine with a good compound effect. The activated carbon hot melt adhesive dusting compound machine comprises a rack, a bottom fabric double-station emptying device, a front pulling device and a bottom fabric feeding frame are arranged at the front end of the rack, a bottom fabric lifting hooking device is arranged on the ply stratum feeding frame, an activated carbon mixing hot melt adhesive dusting device is arranged on the portion, at the rear end of the ply stratum double-station emptying device, of the rack, a baking device is arranged on the portion, at the rear end of the activated carbon mixing hot melt adhesive dusting device, of the rack, a polytetrafluoroethylene conveying belt is arranged in the baking device, an upper layer fabric double-station emptying device and an upper layer fabric feeding frame are arranged at the rear end of the baking device, an upper layer fabric lifting hooking device is arranged on the upper layer fabric feeding frame, and a compound device, an air cooling device, a cutting device, a rear hulling device and a hydraulic edge-aligning and cloth-rolling device are sequentially arranged on the portion, at the rear end of the baking device, of the rack.

Owner:JIANGSU KUNTAI MACHINERY

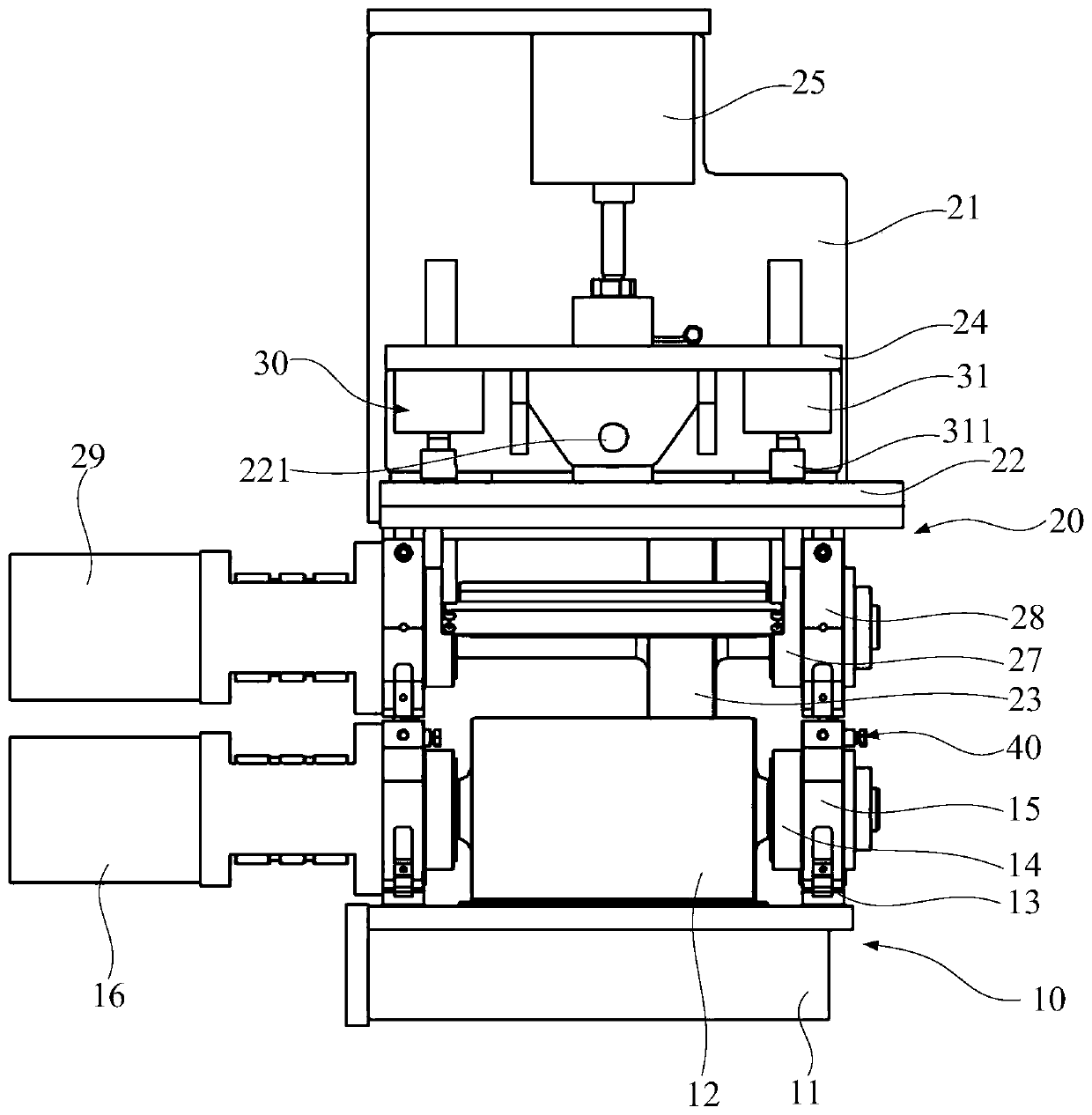

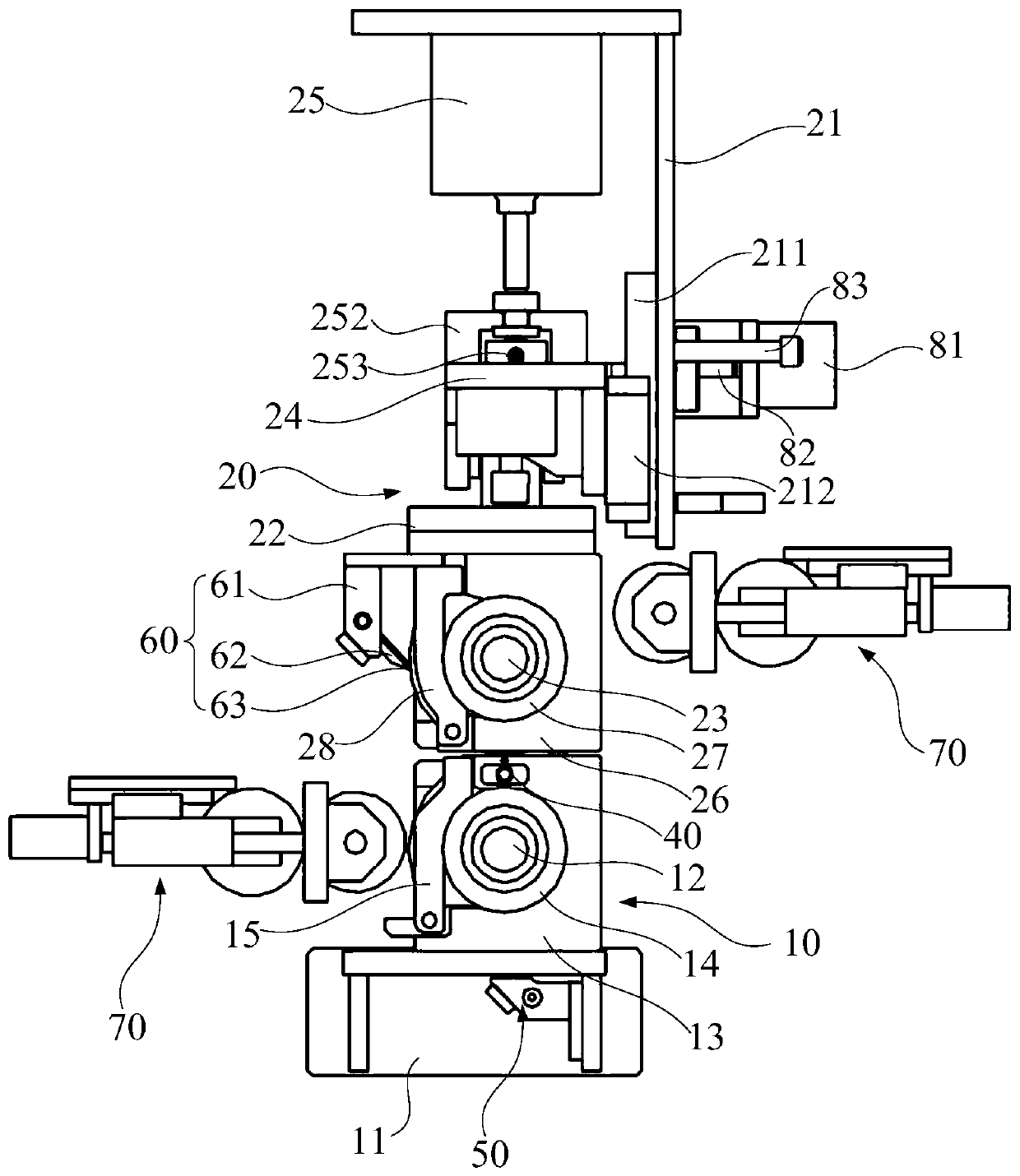

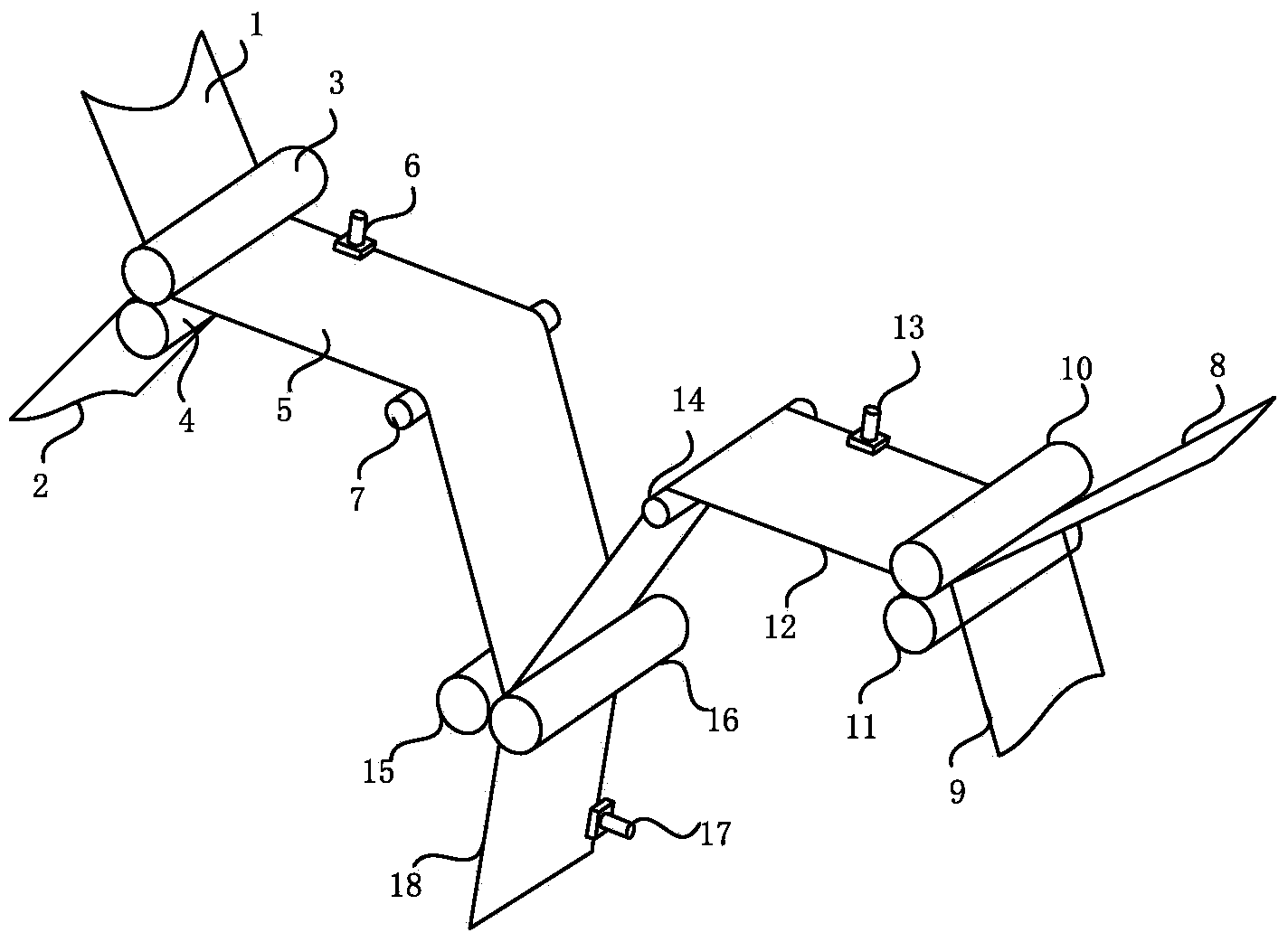

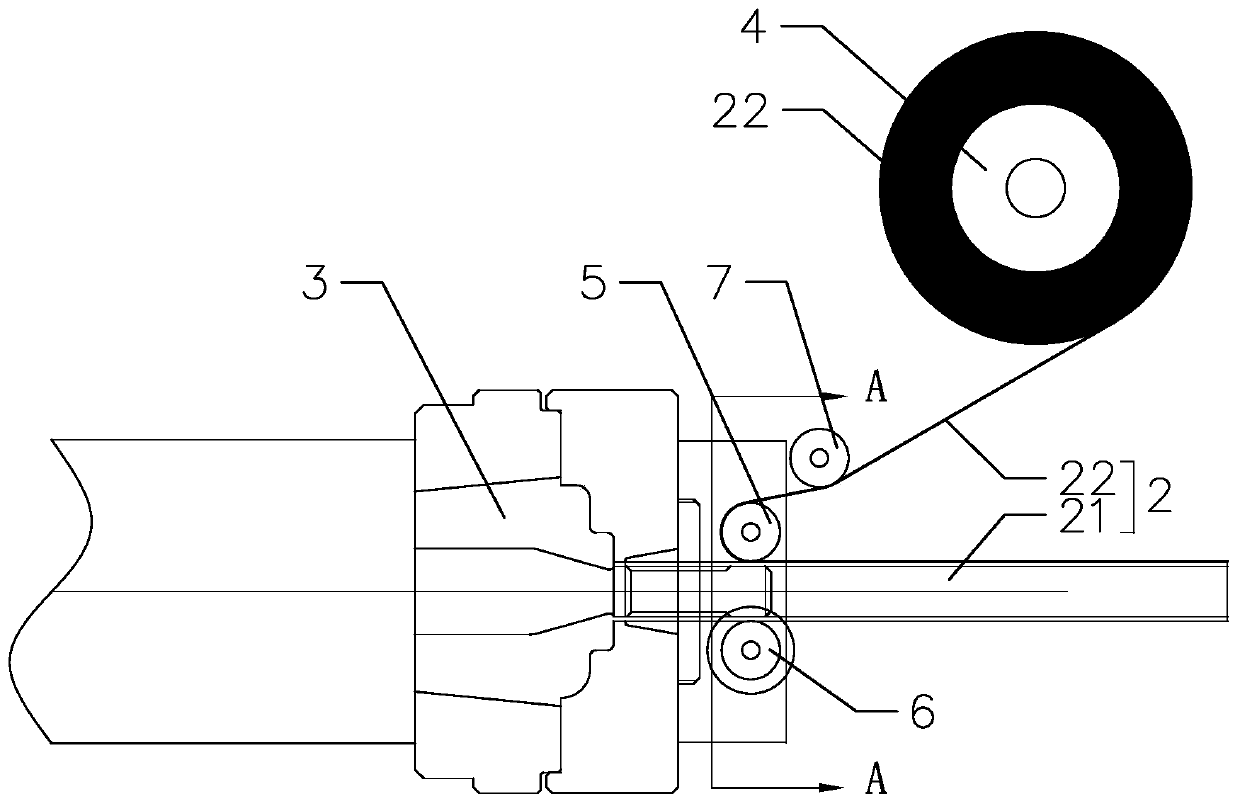

Film material compounding device

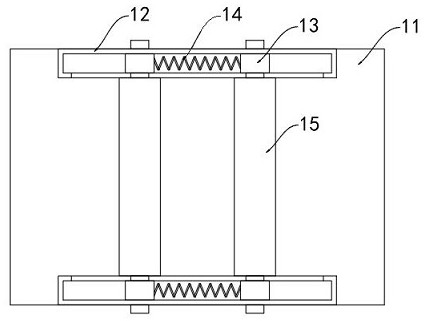

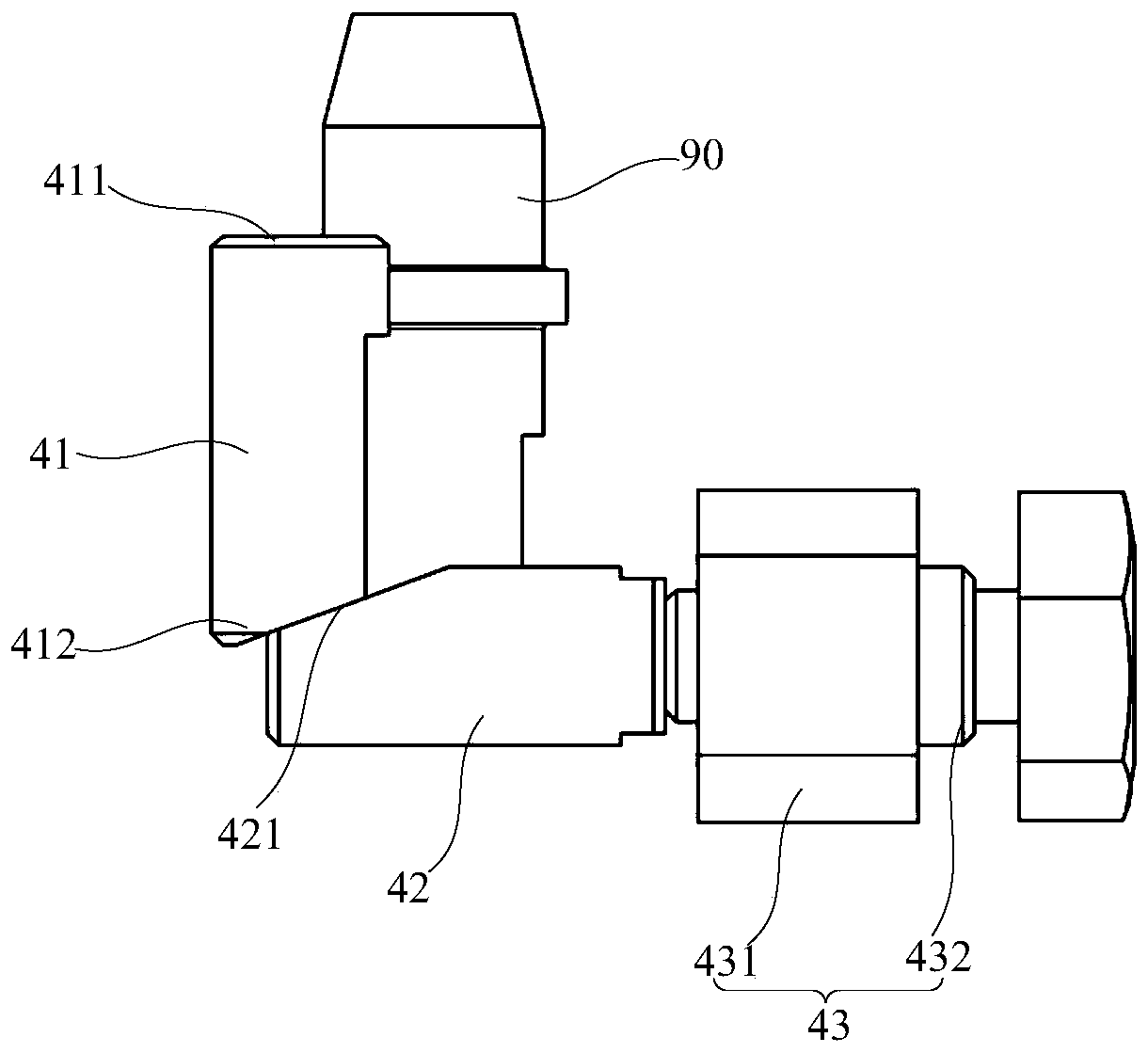

PendingCN111531902AGuaranteed composite effectImprove product qualityDomestic articlesMechanical engineeringFilm material

The invention relates to a film material compounding device. The film material compounding device comprises a first compression roller mechanism, a second compression roller mechanism and a first adjusting mechanism, wherein the first compression roller mechanism comprises a base and a first compression roller rotationally arranged on the base around the axis of the first compression roller, the second compression roller mechanism comprises a fixed support, a swing seat rotationally connected to the fixed support around a rotating axis and a second compression roller rotationally connected tothe swing seat around the axis of the second compression roller, the second compression roller and the first compression roller are arranged in the first direction perpendicular to the axial directionof the first compression roller so as to abut against the two sides of a film material correspondingly, the rotating axis is perpendicular to the first direction and the axial direction of the firstcompression roller, and the first adjusting mechanism is connected with the fixed support and the swing seat and can apply acting force enabling the swing seat to rotate around the rotating axis. Andtherefore, the swing seat can be driven to rotate around the rotating axis through the first adjusting mechanism, then the second compression roller is driven to rotate around the rotating axis relative to the first compression roller, the second compression roller is parallel to the first compression roller, the compounding effect of the film material is favorably ensured, and the product qualityis improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

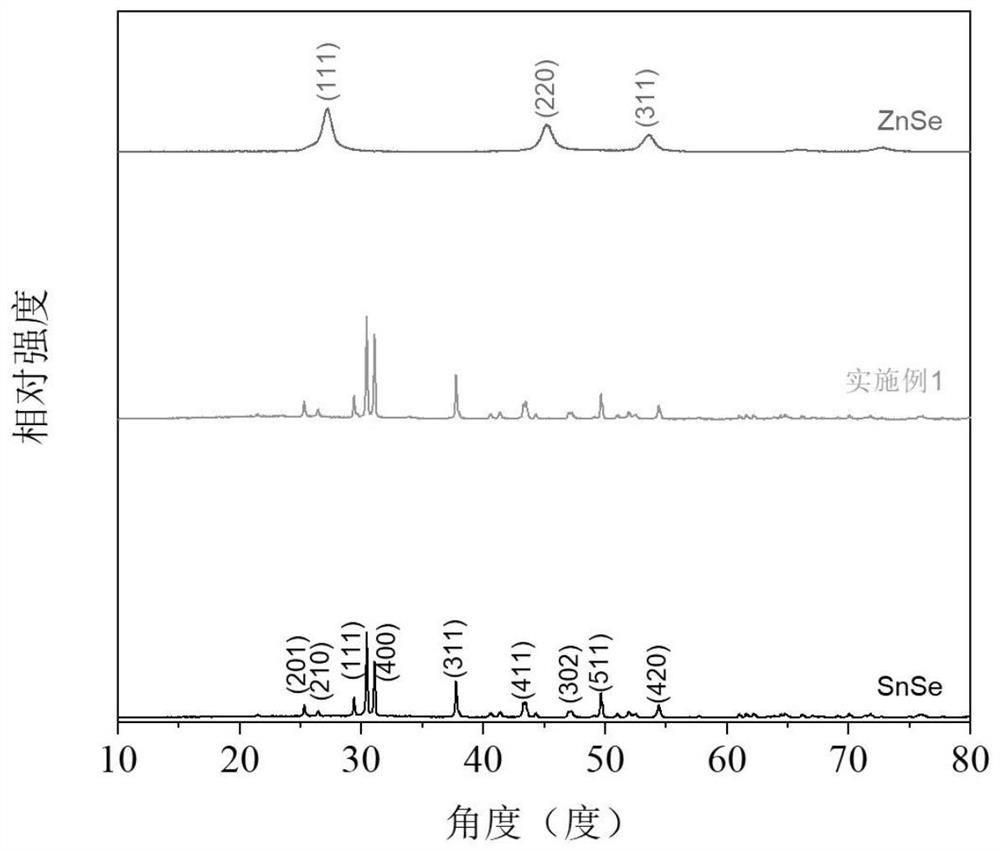

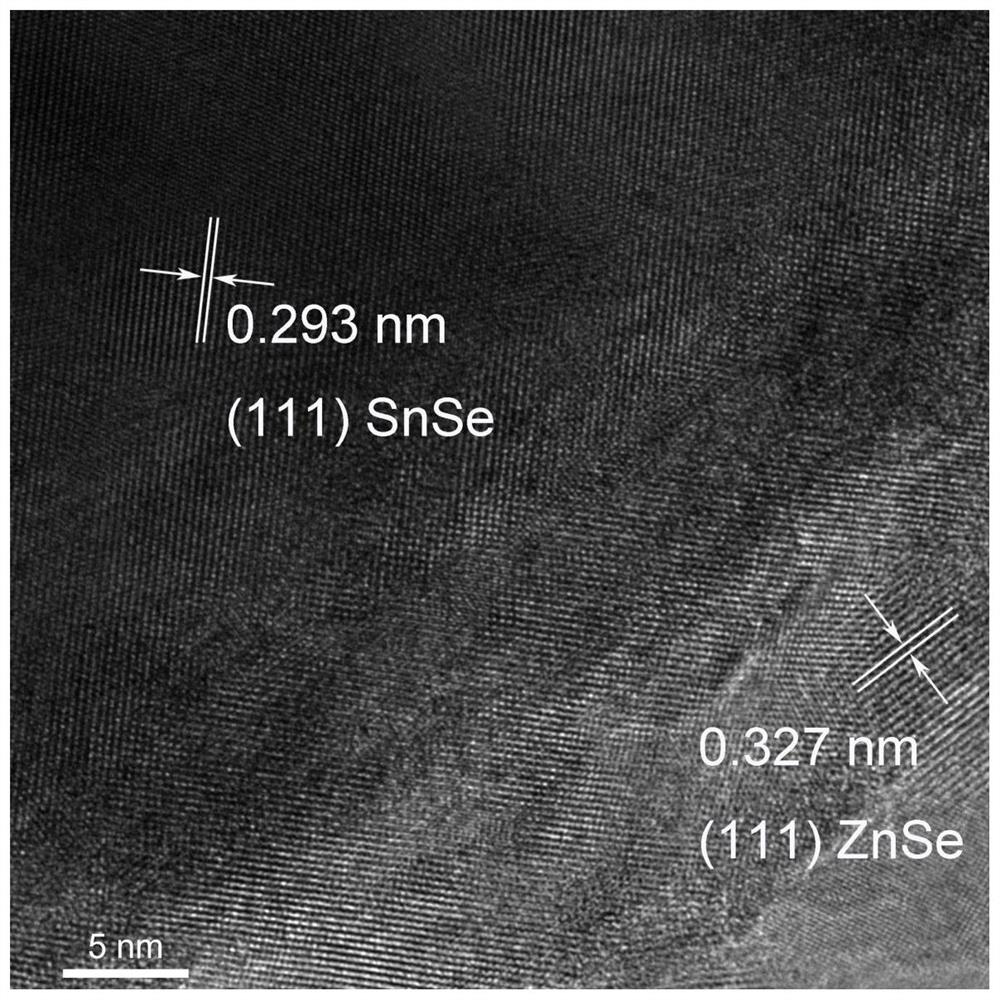

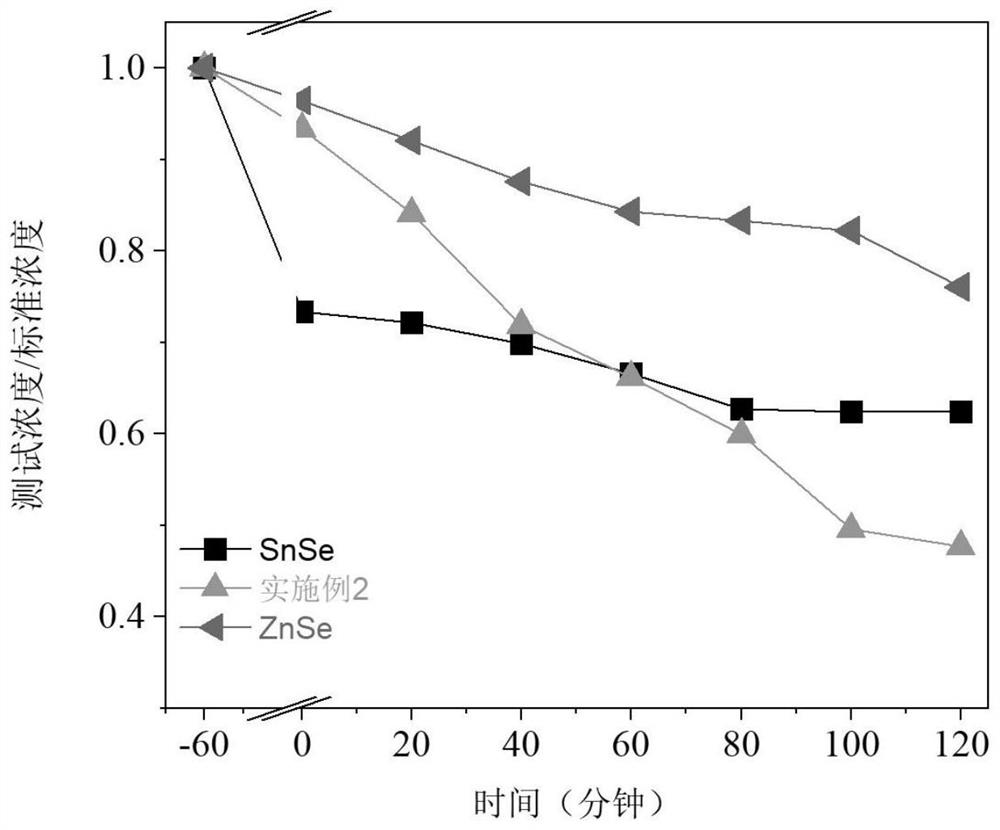

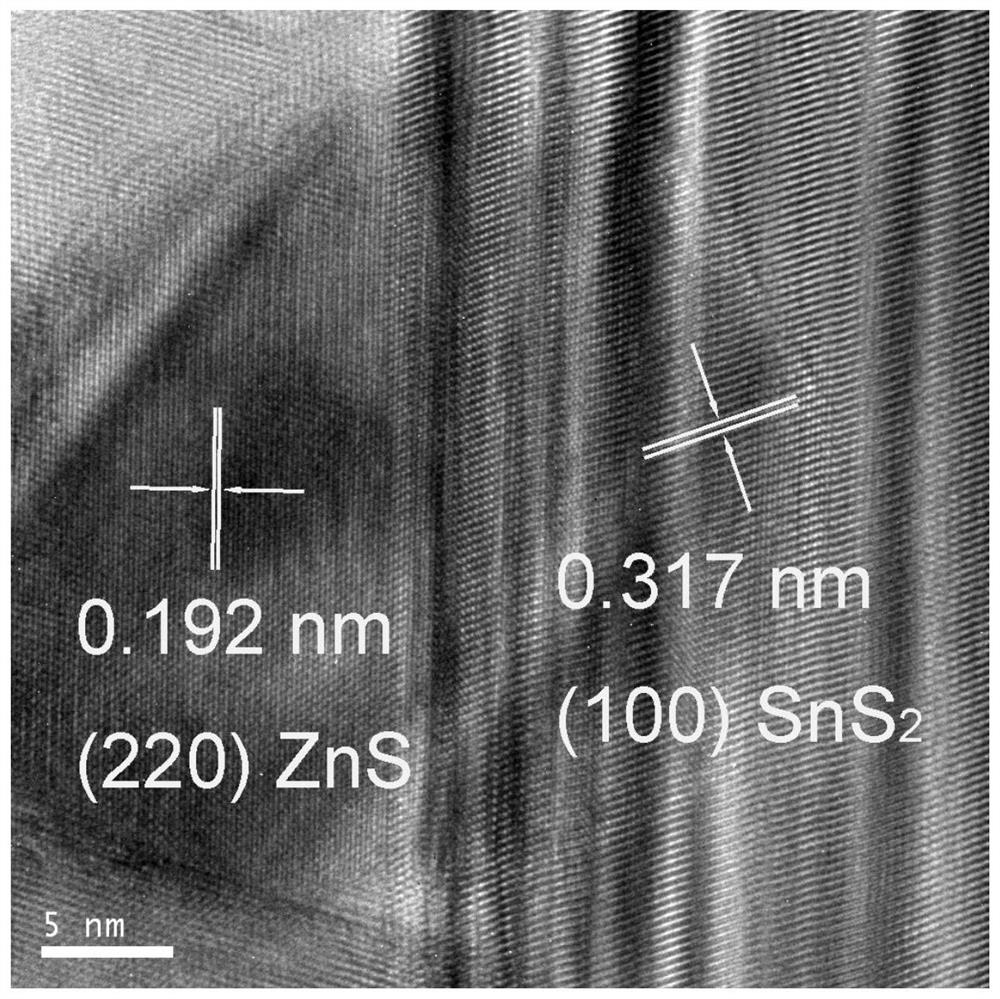

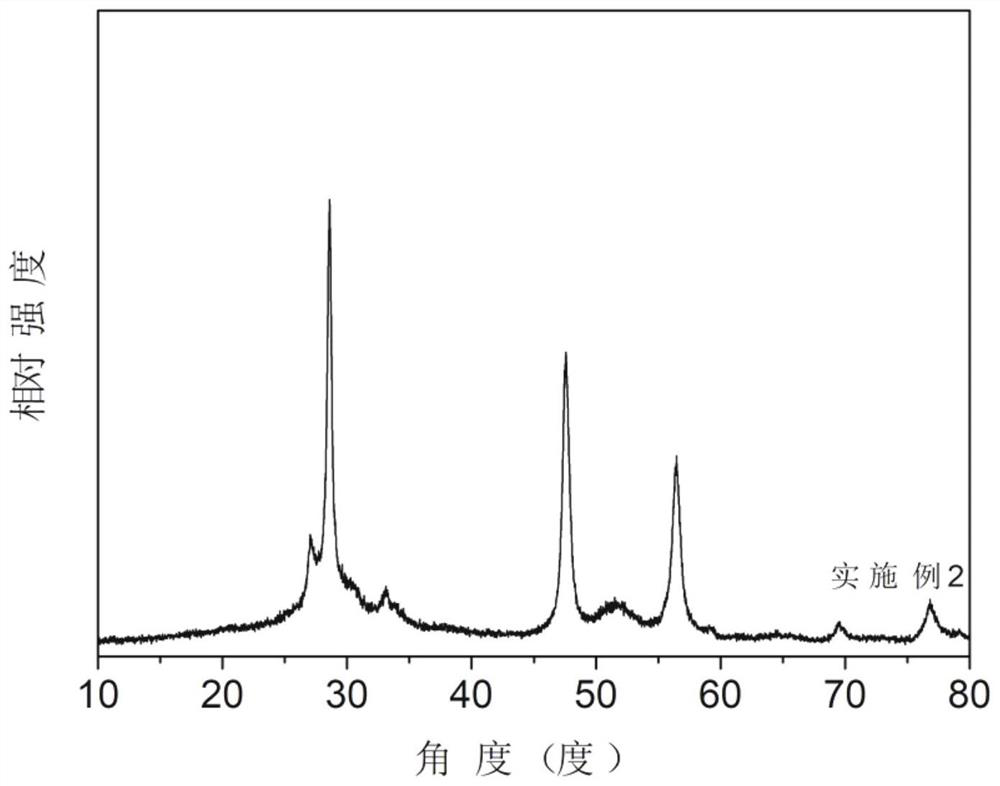

Novel zero-dimensional ZnSe-two-dimensional SnSe heterojunction catalyst and preparation and application thereof

PendingCN114247454ASmall sizeGuaranteed not to break downPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystMeth-

The invention relates to a novel zero-dimensional ZnSe-two-dimensional SnSe heterojunction catalyst as well as preparation and application of the novel zero-dimensional ZnSe-two-dimensional SnSe heterojunction catalyst. The method comprises the following steps: mixing SnCl2, SeO2, oleamide, hydrazine hydrate and water to form a precursor solution, and putting the precursor solution into a hydrothermal reaction kettle for hydrothermal reaction to obtain two-dimensional nano-sheet SnSe; the preparation method comprises the following steps: mixing two-dimensional nano-sheet SnSe, ZnNO3. 6H2O, SeO2, sodium hexadecyl benzene sulfonate, hydrazine hydrate and water to obtain a precursor solution, putting the precursor solution into a hydrothermal reaction kettle, and carrying out secondary hydrothermal reaction to obtain the zero-dimensional ZnSe-two-dimensional SnSe heterojunction catalyst. The photocatalytic degradation performance of the zero-dimensional ZnSe-two-dimensional SnSe heterojunction catalyst prepared by the preparation scheme is obviously enhanced, and the degradation rates of the zero-dimensional ZnSe-two-dimensional SnSe heterojunction catalyst for photocatalytic degradation of methylene blue and levofloxacin are 3.8 times and 1.7 times of those of a single SnSe product respectively. The method is simple in process, easy to control and high in production efficiency.

Owner:HANGZHOU DIANZI UNIV

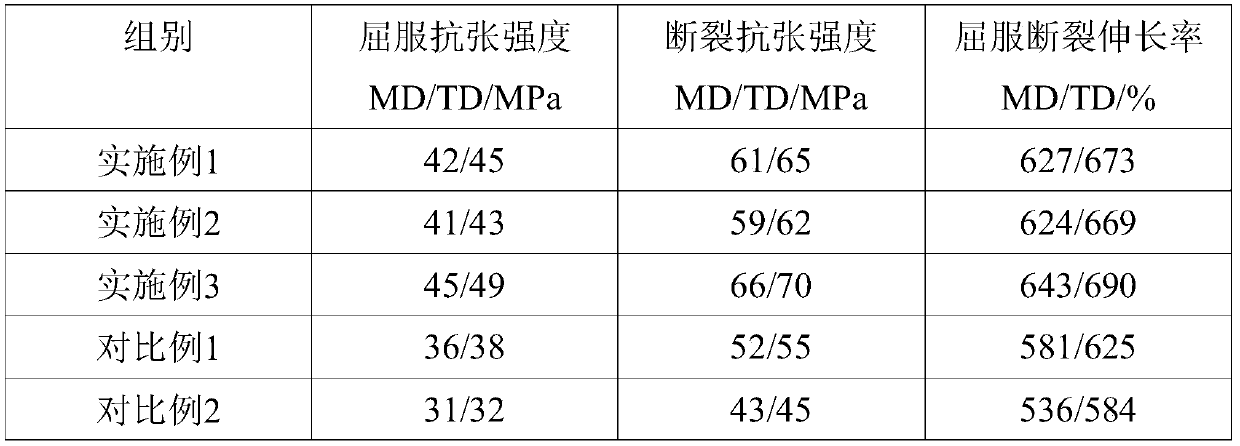

Processing method of NY/RCPP composite film for high-temperature retort pouch

ActiveCN111590988AImprove mechanical propertiesImprove performanceFlexible coversWrappersPolypropylenePolymer chemistry

The invention discloses a processing method of an NY / RCPP composite film for a high-temperature retort pouch, and relates to the technical field of composite films. Nylon and block copolymer polypropylene are used as main materials, an NY / RCPP composite film with a two-layer structure is prepared by adding a processing aid, the prepared composite film has the advantages of both NY and RCPP, the use performance of the prepared composite film is further optimized by adding the processing aid, and the prepared composite film is non-toxic and harmless, has excellent mechanical properties, barrierproperties and heat resistance, and is suitable for being used as a high-temperature retort pouch processing material.

Owner:合肥佛斯德新材料科技有限公司

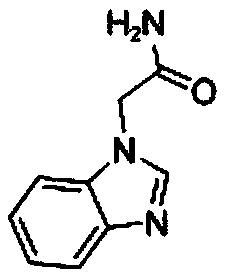

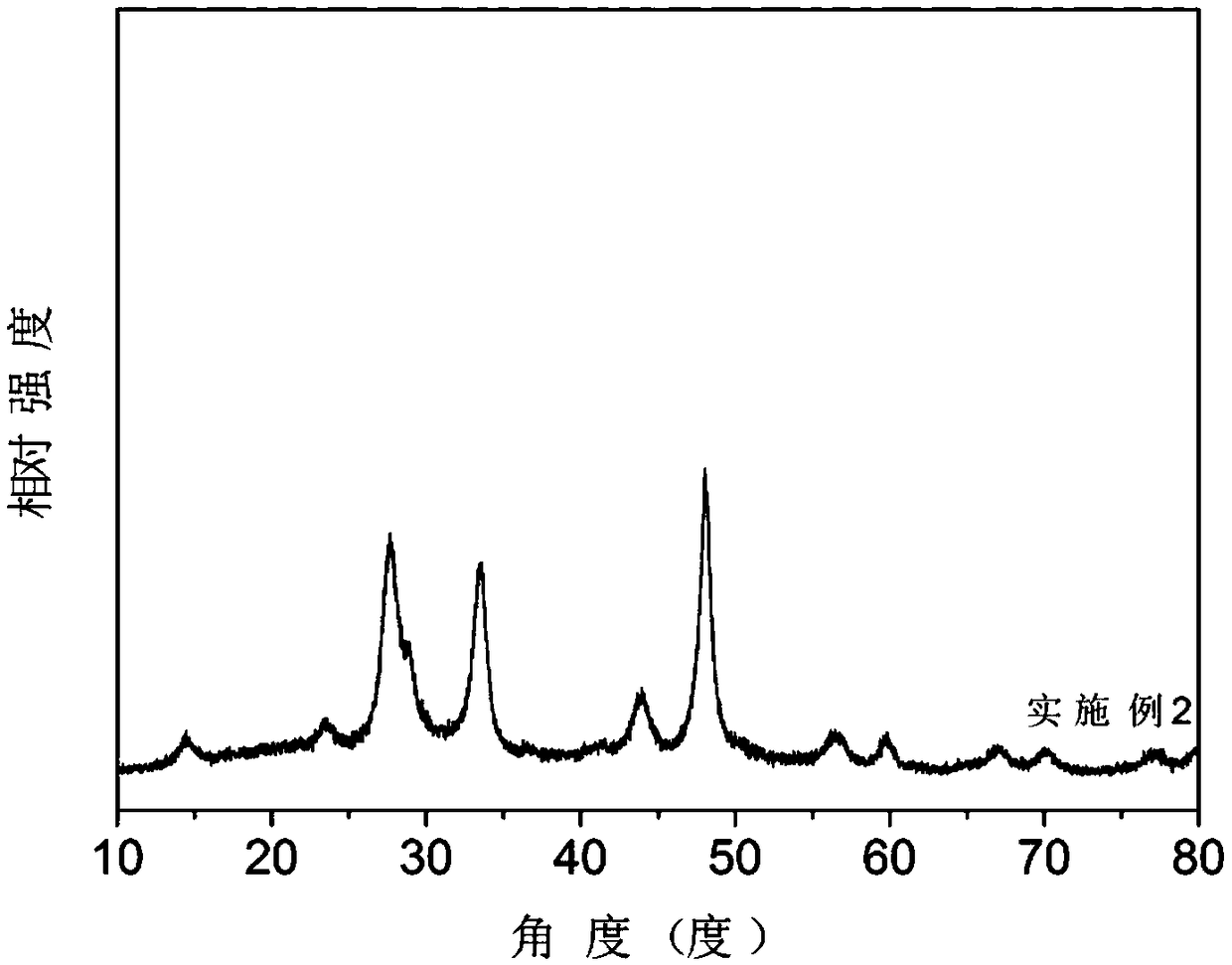

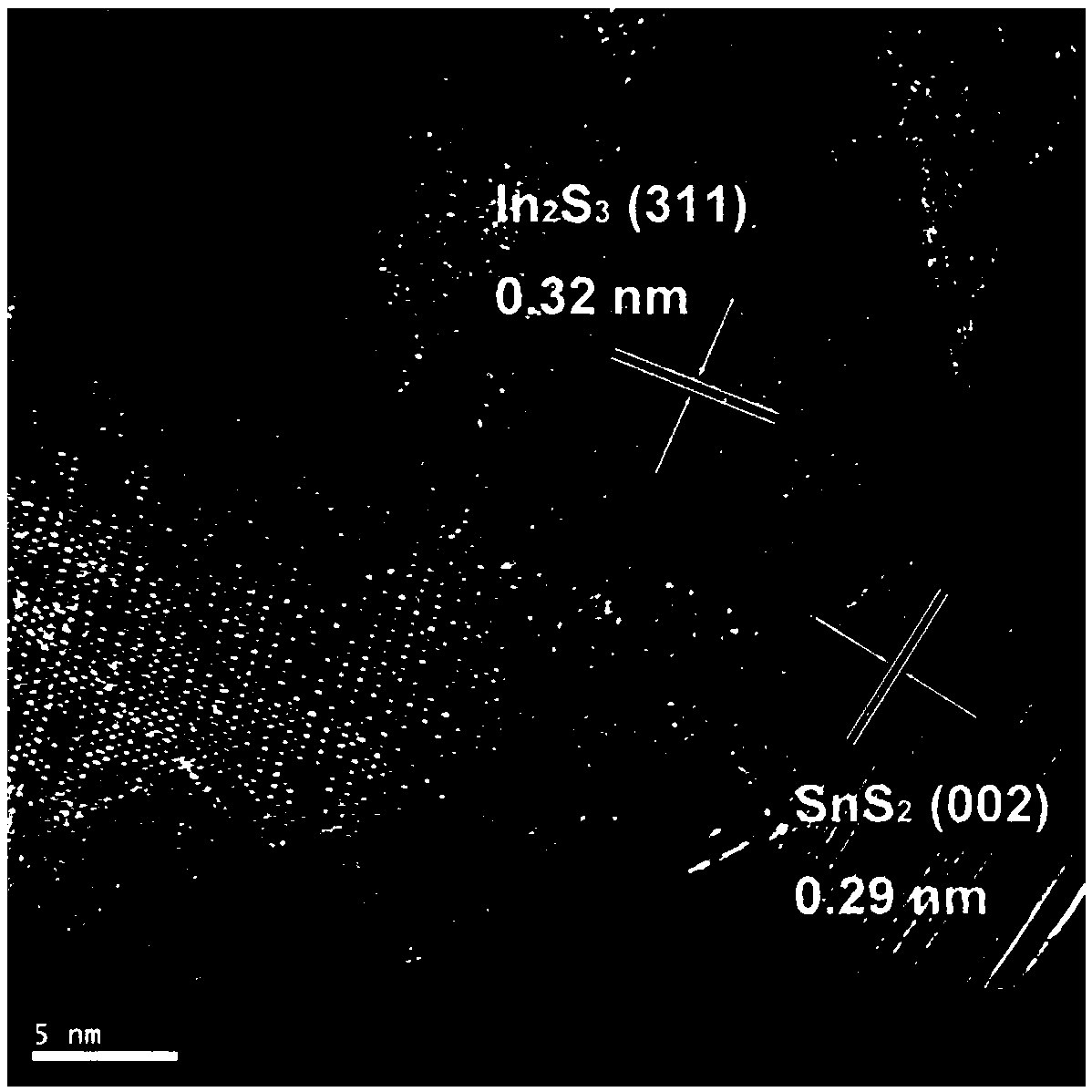

Preparation method of three-dimensional spherical In2S3-SnS2 compound

InactiveCN109046384AWon't breakSmall sizePhysical/chemical process catalystsThioureaSodium borohydride

The invention relates to a preparation method of a three-dimensional spherical In2S3-SnS2 compound. According to the method, indium nitrate, 1-isoleucine, sodium borohydride and water are mixed into precursor liquid, and the precursor liquid is placed in a hydrothermal reaction kettle for hydrothermal reaction to obtain three-dimensional spherical In2S3; the three-dimensional spherical In2S3, SnCl4, thiourea, ethanediamine and water are mixed into precursor liquid, and the precursor liquid is placed in the hydrothermal reaction kettle for secondary hydrothermal reaction to obtain the three-dimensional spherical In2S3-SnS2 compound. The method has the advanges of simple process, easiness in control and high production efficiency.

Owner:HANGZHOU DIANZI UNIV

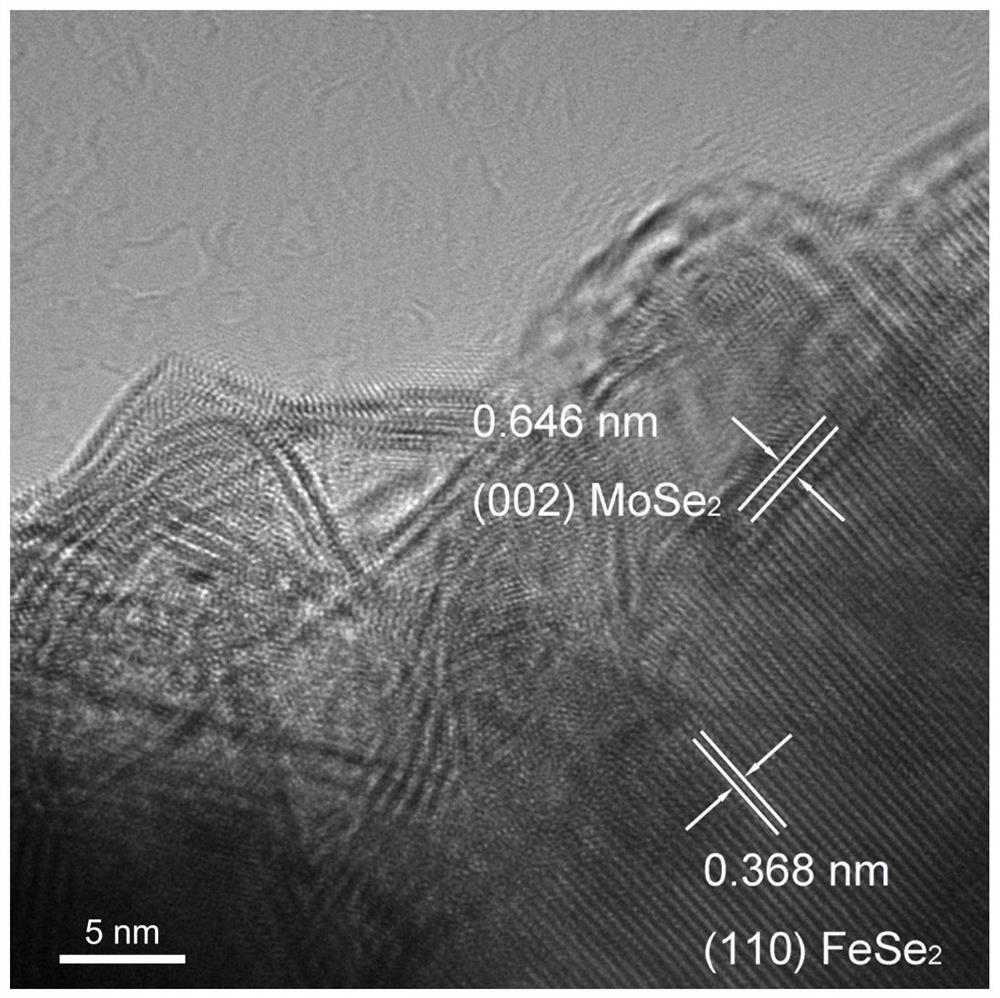

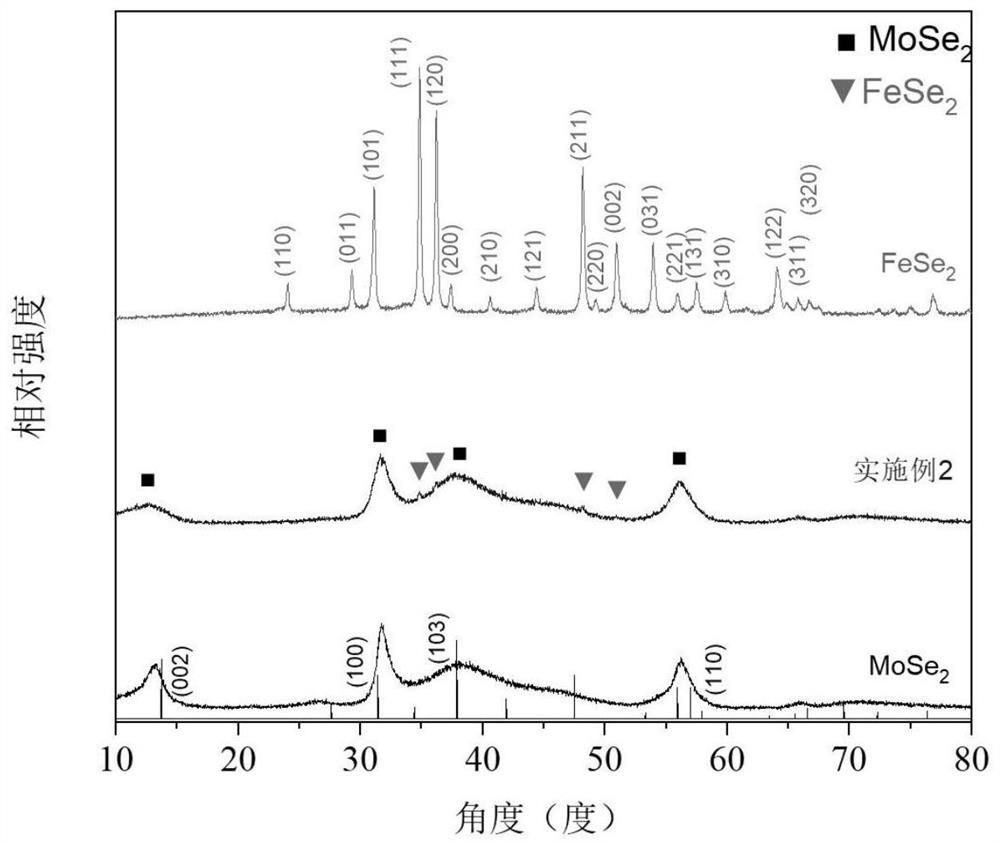

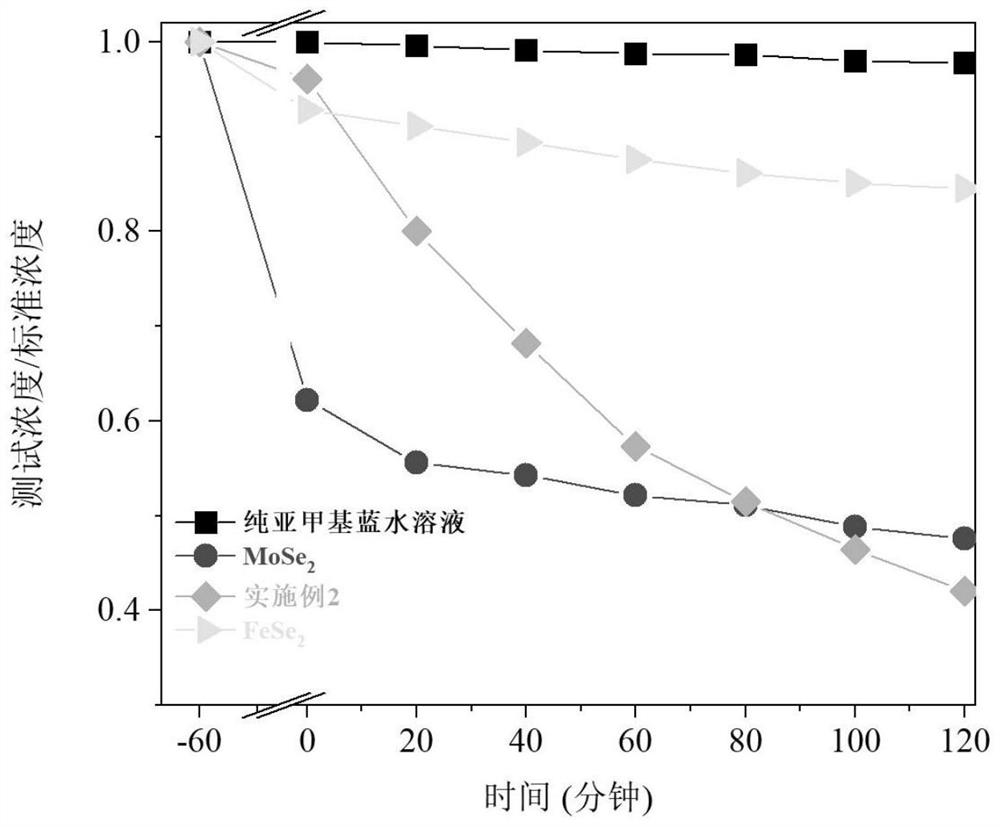

High-performance one-dimensional FeSe2-two-dimensional MoSe2 compound as well as preparation method and application thereof

PendingCN114272940AEasy compoundSmall sizeWater/sewage treatment by irradiationWater contaminantsMeth-Methyl blue

The invention relates to a high-performance one-dimensional FeSe2-two-dimensional MoSe2 compound as well as a preparation method and application thereof. The method comprises the following steps: mixing (NH4) 2MoO4. 2H2O, SeO2, sodium hexadecyl benzene sulfonate, hydrazine hydrate and water to obtain a precursor solution, and putting the precursor solution into a hydrothermal reaction kettle for hydrothermal reaction to obtain two-dimensional nano flaky MoSe2; the preparation method comprises the following steps: mixing two-dimensional nano flaky MoSe2, FeCl3, Na2SeO3, hexadecyl trimethyl ammonium bromide, hydrazine hydrate and water to obtain a precursor solution, and putting the precursor solution into a hydrothermal reaction kettle for secondary hydrothermal reaction. The degradation rate and the photocurrent density of the material for photocatalytic degradation of methylene blue are relatively improved by 245% and 110% respectively, and the photocatalytic performance of the compound is obviously enhanced. The method is simple in process, easy to control and high in production efficiency.

Owner:HANGZHOU DIANZI UNIV

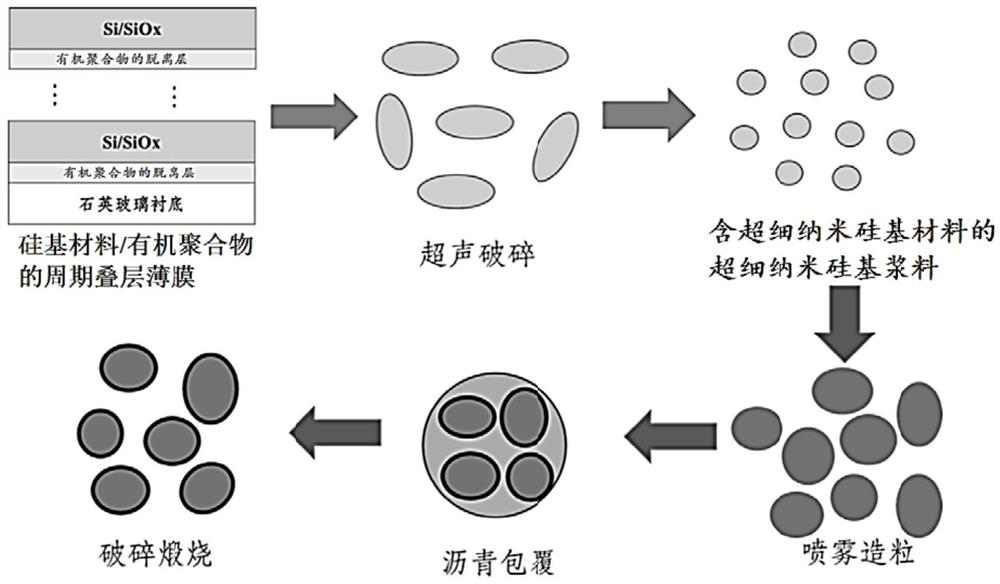

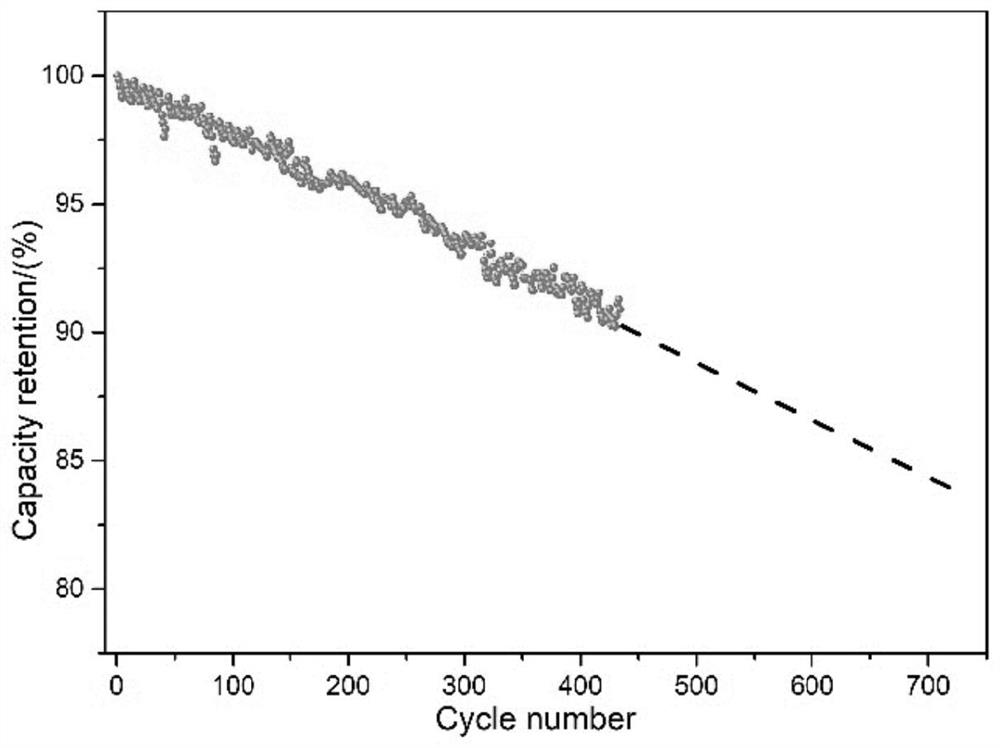

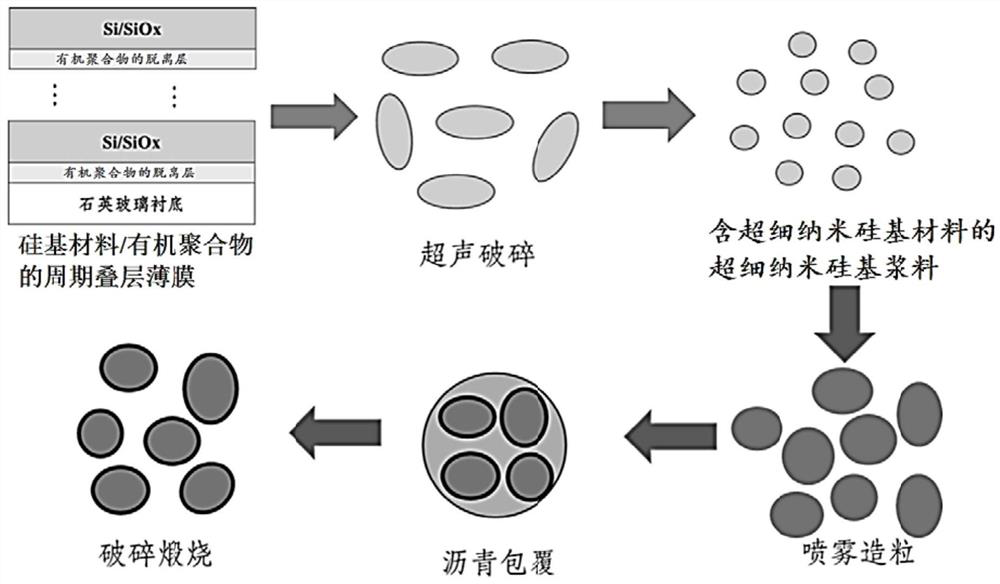

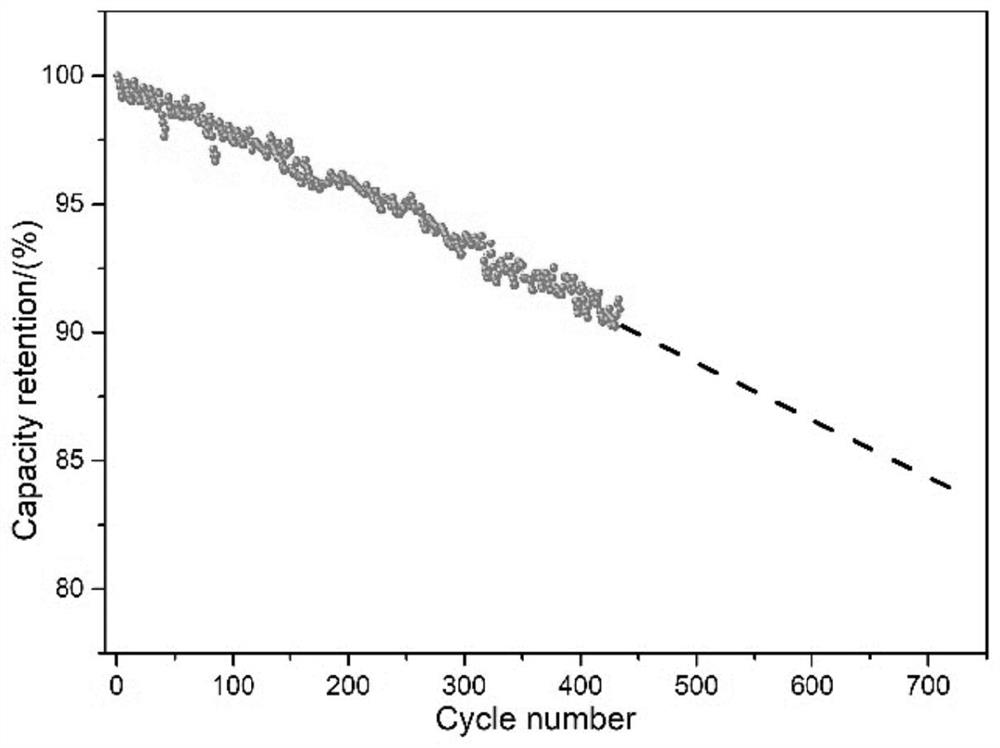

Superfine nano silicon/carbon composite material as well as preparation method and application thereof

ActiveCN112234178AGuaranteed composite effectReduce usage bloat defectsNegative electrodesLi-accumulatorsCarbon compositesPyrrolidinones

The invention discloses a superfine nano silicon / carbon composite material as well as a preparation method and application thereof, which belong to the technical field of preparation of lithium battery negative electrode materials. According to the invention, the superfine nano silicon / carbon composite material is prepared on the basis of superfine nano silicon-based slurry, high-temperature petroleum asphalt and polyvinylpyrrolidone by using a segmented roasting method, the material has excellent electrical property, and the superfine nano silicon-based slurry is prepared by using electron beam evaporation combined with a crushing process. The problems that in the preparation process of the superfine nano silicon / carbon composite material, the problems that nano silicon-based materials such as nano Si and nano SiOx are large in particle size, the oxidation problem is not easy to control, and dispersion is not uniform are solved, and the prepared superfine nano silicon / carbon compositematerial has low expansibility and high cycling stability, and can be used as a battery silicon-based composite negative electrode material.

Owner:SHAANXI COAL & CHEM TECH INST

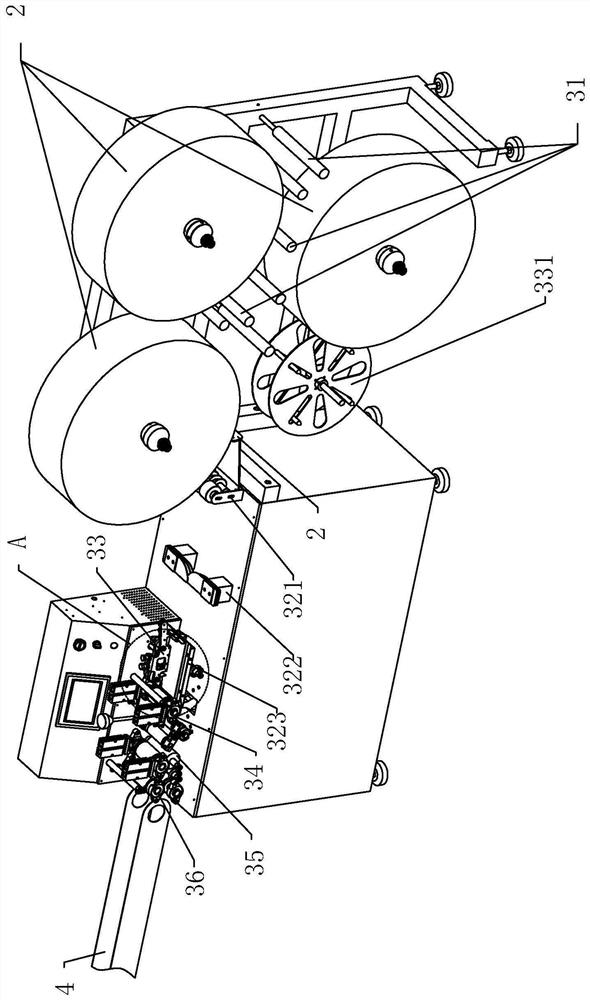

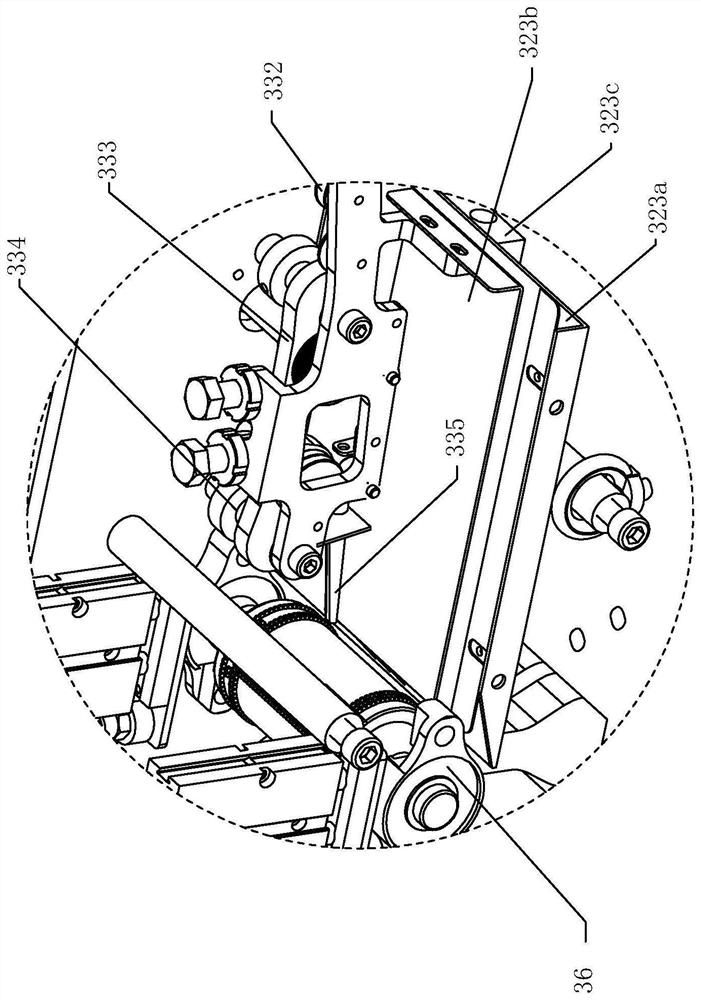

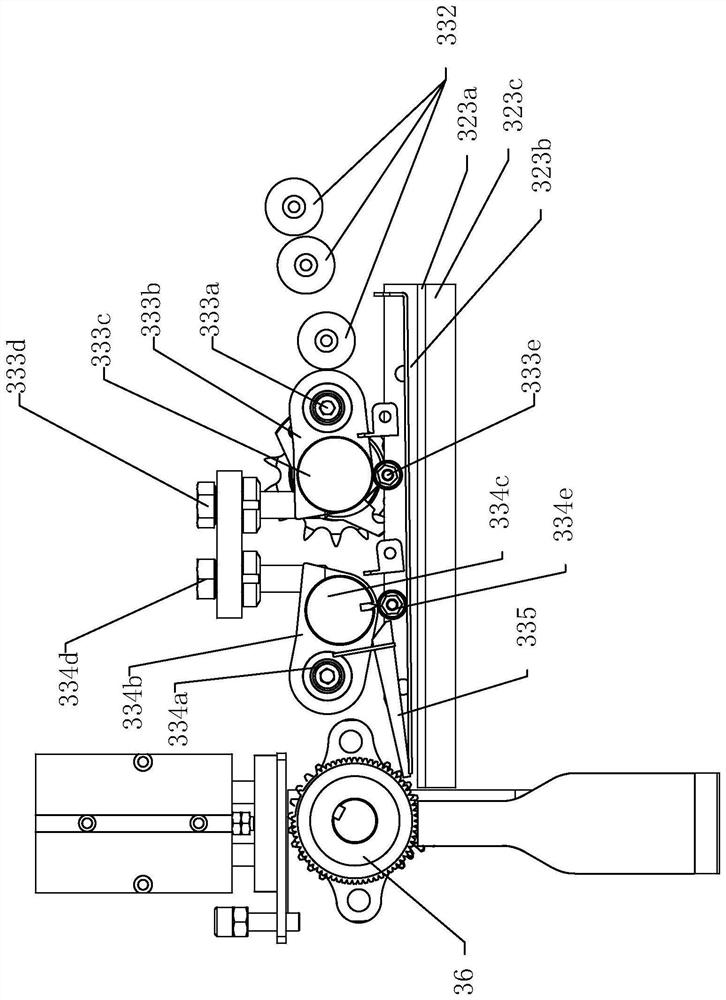

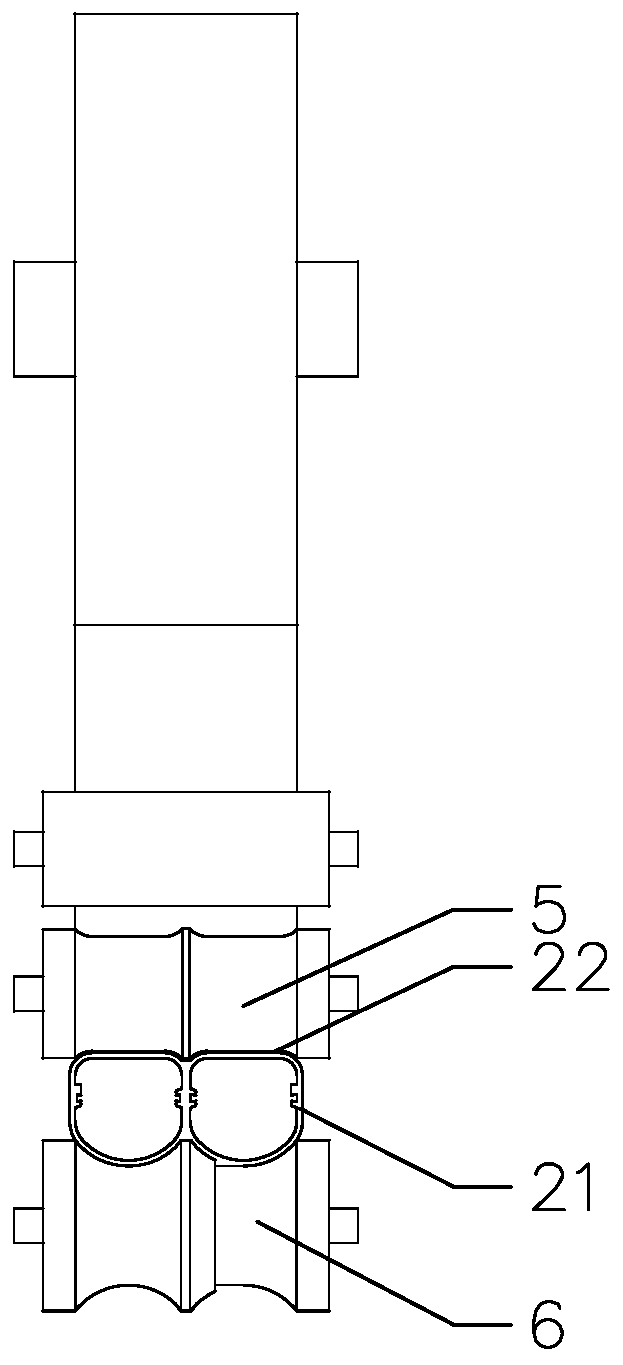

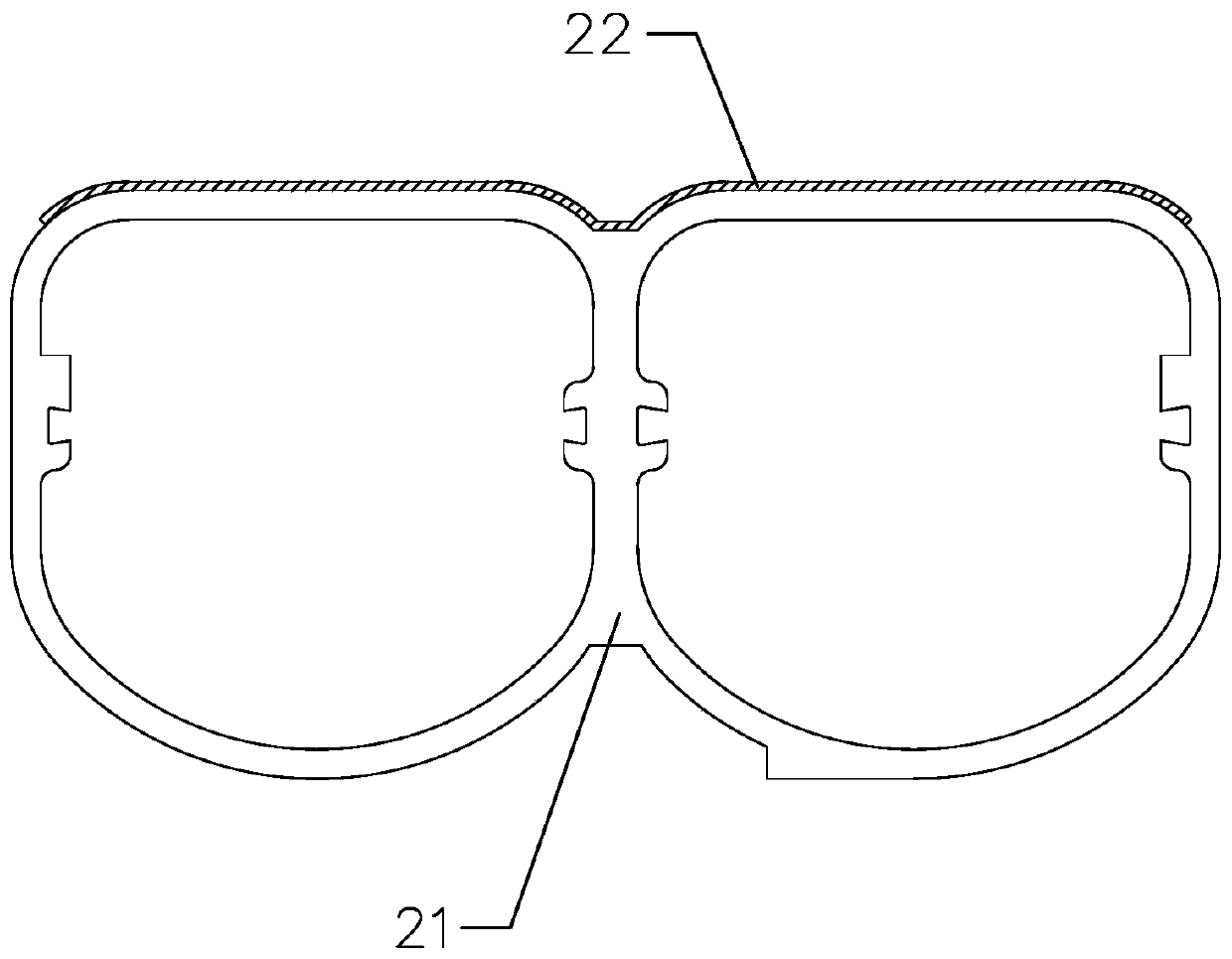

Mask forming machine

ActiveCN112223770APrecise positioningHigh conveying precisionSevering textilesHeating/cooling textile fabricsMolding machineStructural engineering

The invention relates to mask production equipment, in particular to a mask forming machine which comprises a rack, a non-woven fabric unwinding device, a forming device and an output device. The non-woven fabric unwinding device, the forming device and the output device are arranged on the rack; the forming device comprises a first guide assembly, a folding assembly, a nose bridge strip adding assembly, a composite roller assembly, a second guide assembly and a slitting assembly; the folding assembly comprises an indentation roller, a folding frame and a shaping mechanism; the nose bridge strip adding assembly comprises a nose bridge strip unwinding roller, a nose bridge strip guide roller assembly, a nose bridge strip conveying assembly, a nose bridge strip cutter assembly and a nose bridge strip guide pipe; the length of the nose bridge strip guide pipe is smaller than the length of a cut nose bridge strip; the composite roller assembly comprises a composite roller, a welding head and an ultrasonic generator; and the slitting assembly comprises an upper slitting roller and a bottom slitting roller. Non-woven fabric and the nose bridge strip can be conveyed to the forming deviceat the same time, so that the production efficiency is improved.

Owner:泉州外星人智能科技有限公司

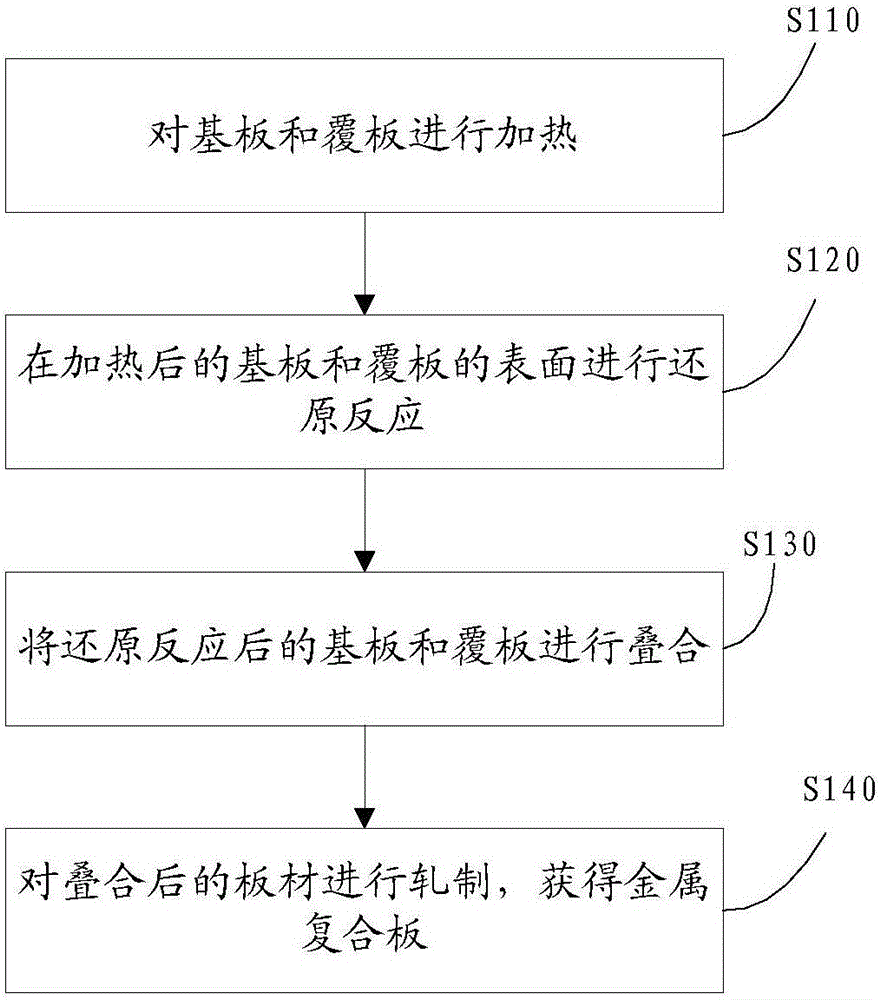

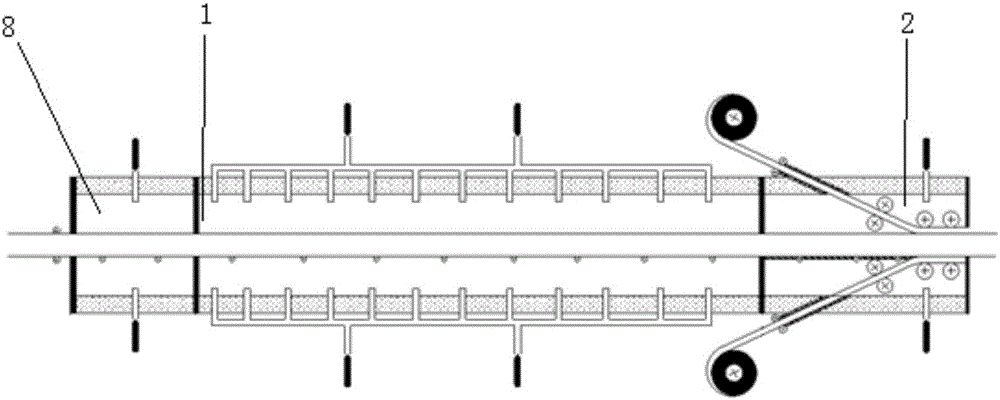

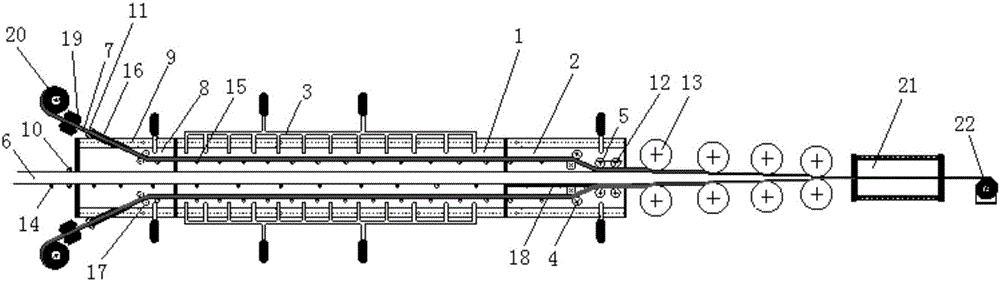

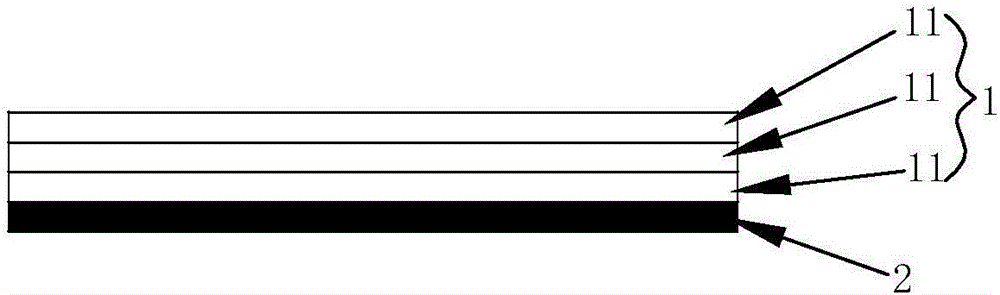

Preparation method and device for metal composite plate

ActiveCN105149351AEliminate the effects of compoundingAvoid influenceWork treatment devicesMetal rolling arrangementsInterfacial oxideComposite plate

The invention discloses a preparation method and a preparation device for a metal composite plate. The method comprises the following steps: heating a base plate and a shroud plate; performing reduction reaction on the surfaces of the base plate and the shroud plate which are heated; stacking the base plate and the shroud plate which are subjected to reduction reaction; rolling the stacked plates to obtain the metal composite plate. The surfaces of the base plate and the shroud plate which are heated are subjected to reduction reaction, so that oxides on the surfaces of the base plate and the shroud plate are removed, and the influence of the interface oxides on compounding is eliminated during compounding.

Owner:武汉钢铁有限公司

Special gluing protection film for advertising as well as preparation method and glue coating equipment of gluing protection film

PendingCN106273950ALow raw material costReduce processing costsSynthetic resin layered productsPretreated surfacesTectorial membraneEngineering

The invention provides a special gluing protection film for advertising as well as a preparation method and glue coating equipment of the special gluing protection film and relates to a sticking film for the advertising, a preparation method of the sticking film and a glue coating device of the sticking film. The special gluing protection film for the advertising is prepared from a surface film layer (1) and a glue layer (2) through gluing, wherein the surface film layer (1) comprises at least one layer of a polypropylene raw material, the glue layer (2) is located on the bottom surface of the surface film layer (1), and the surface film layer (1) is jointly glued with an advertising picture through the glue layer (2) during use. The structure is simple, the raw material cost and the processing cost of body paper can be reduced during production, and the cost can be reduced by 50% or higher; during application, the gluing protection film is convenient to stick and can be used rapidly, the work cost for removing the body paper is omitted, production of waste is reduced, the environment pollution is avoided, so that the production efficiency is greatly improved, the application cost is reduced, and the product competitiveness is improved.

Owner:夏成余 +1

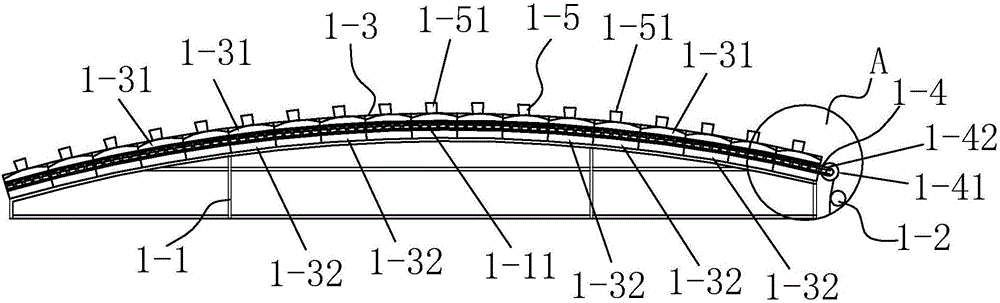

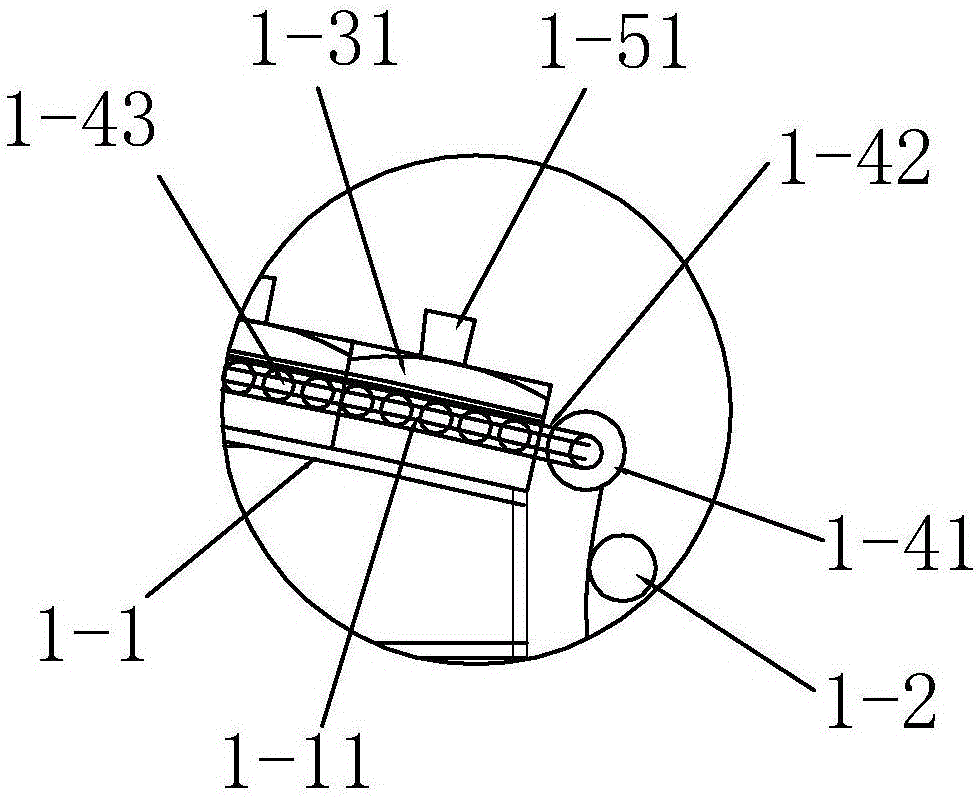

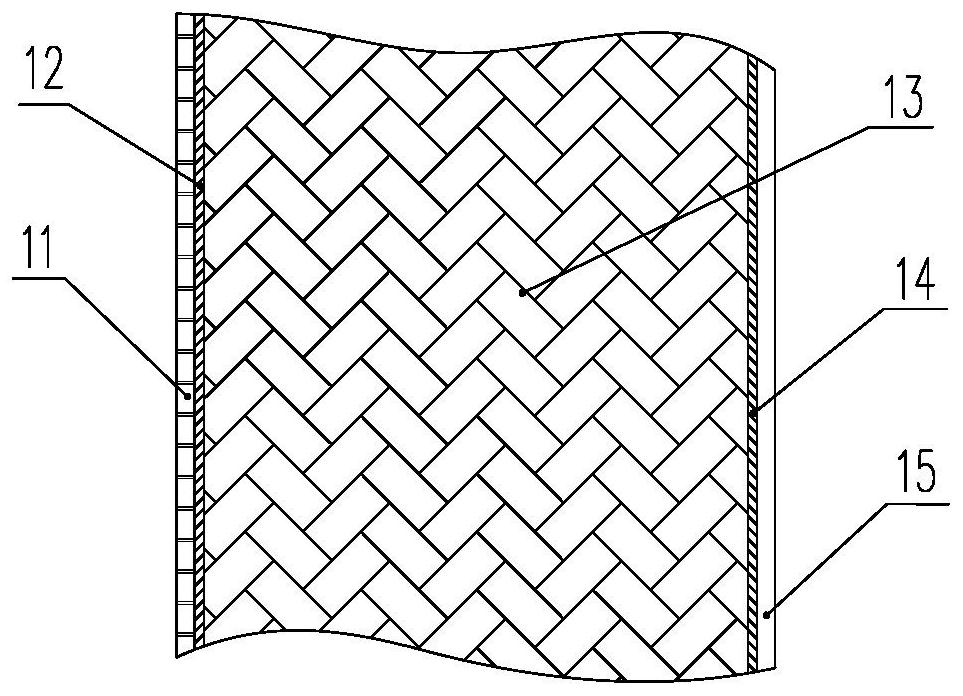

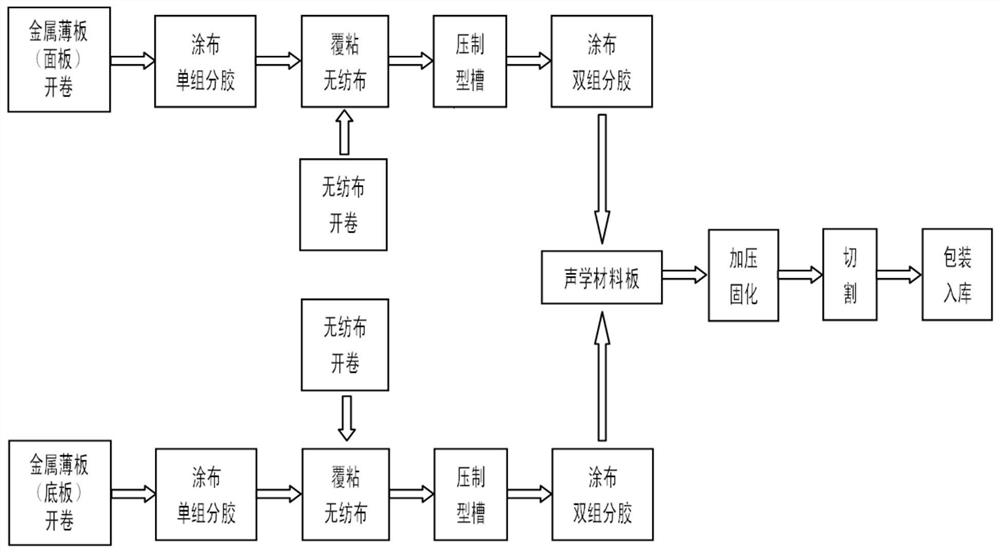

A method of manufacturing a resistive sound-absorbing panel

ActiveCN109469219BImprove the noise reduction effectHigh strengthLaminationLamination apparatusAssembly lineNonwoven fabric

The invention provides a method for manufacturing a resistive sound absorbing panel. Through an assembly line formed by connecting an unwinding machine, a gluing machine, a slotting machine, a composite molding machine, a cutting machine, a packaging machine and a conveying device in series and the procedures such as unwinding, gluing, cloth covering, slotting, re-gluing, bonding with an acousticmaterial board, pressurized curing, cutting and packaging, the resistive sound absorbing panel formed by compounding a metal sheet, a non-woven fabric and the acoustic material board is continuously produced, standard and automatic flexible production is realized, a traditional production and manufacturing mode including material cutting, welding and riveting of existing resistive sound absorbingboards is changed, and the problems of low production efficiency and unstable product quality are solved; standard and modular production of products is realized, the efficiency is high, the cost is low, the yield of the finished products is high, the quality of the products can be effectively guaranteed, and the method has a high application and popularization value.

Owner:城林科技上海有限公司

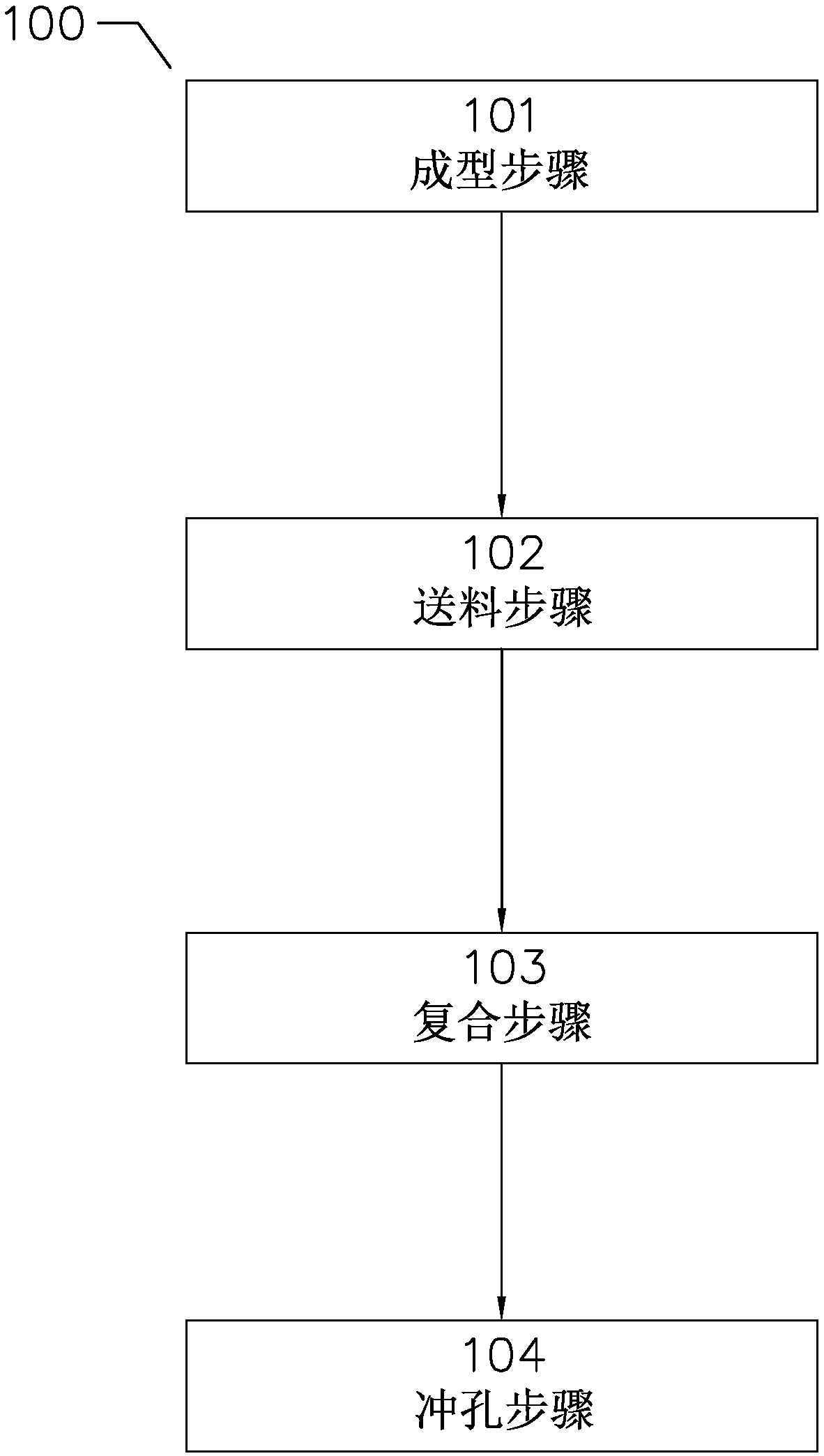

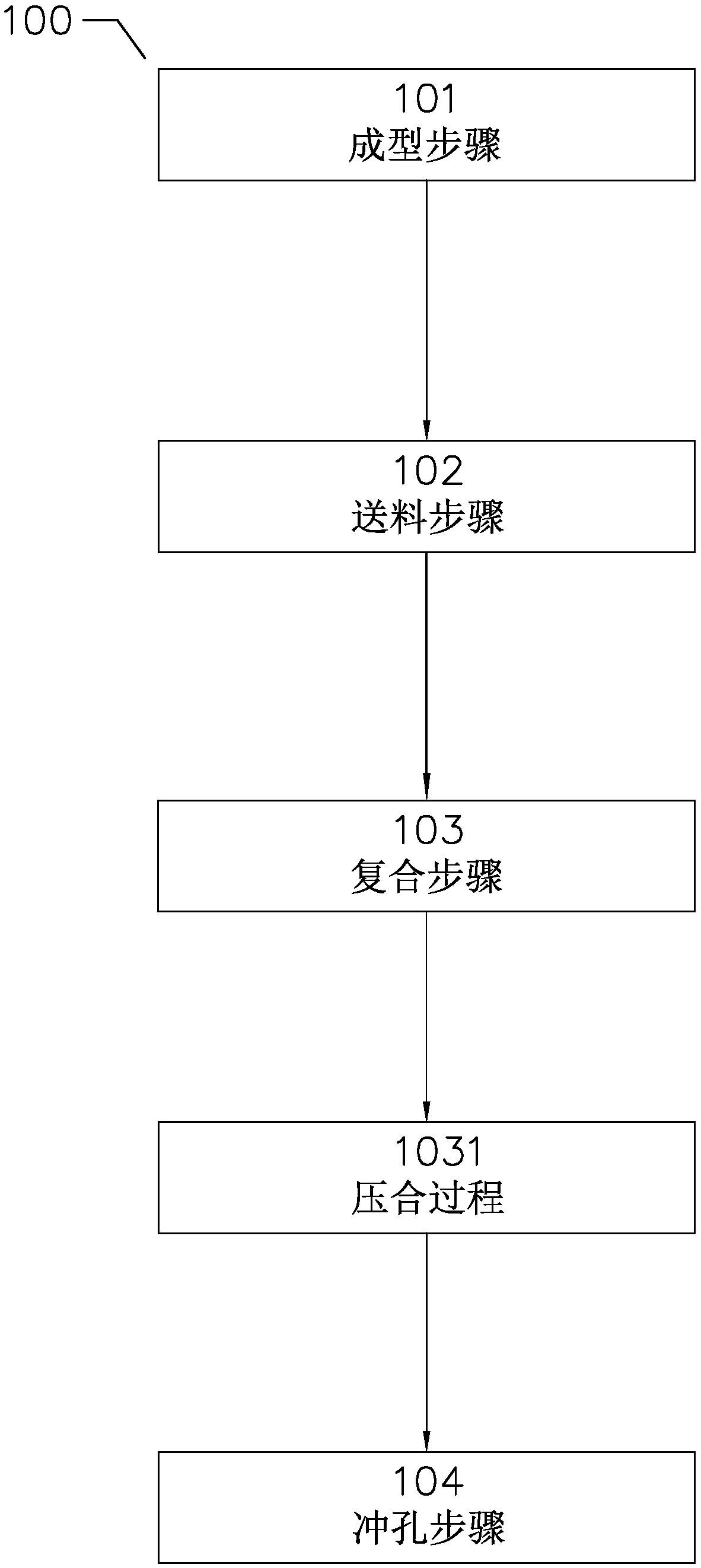

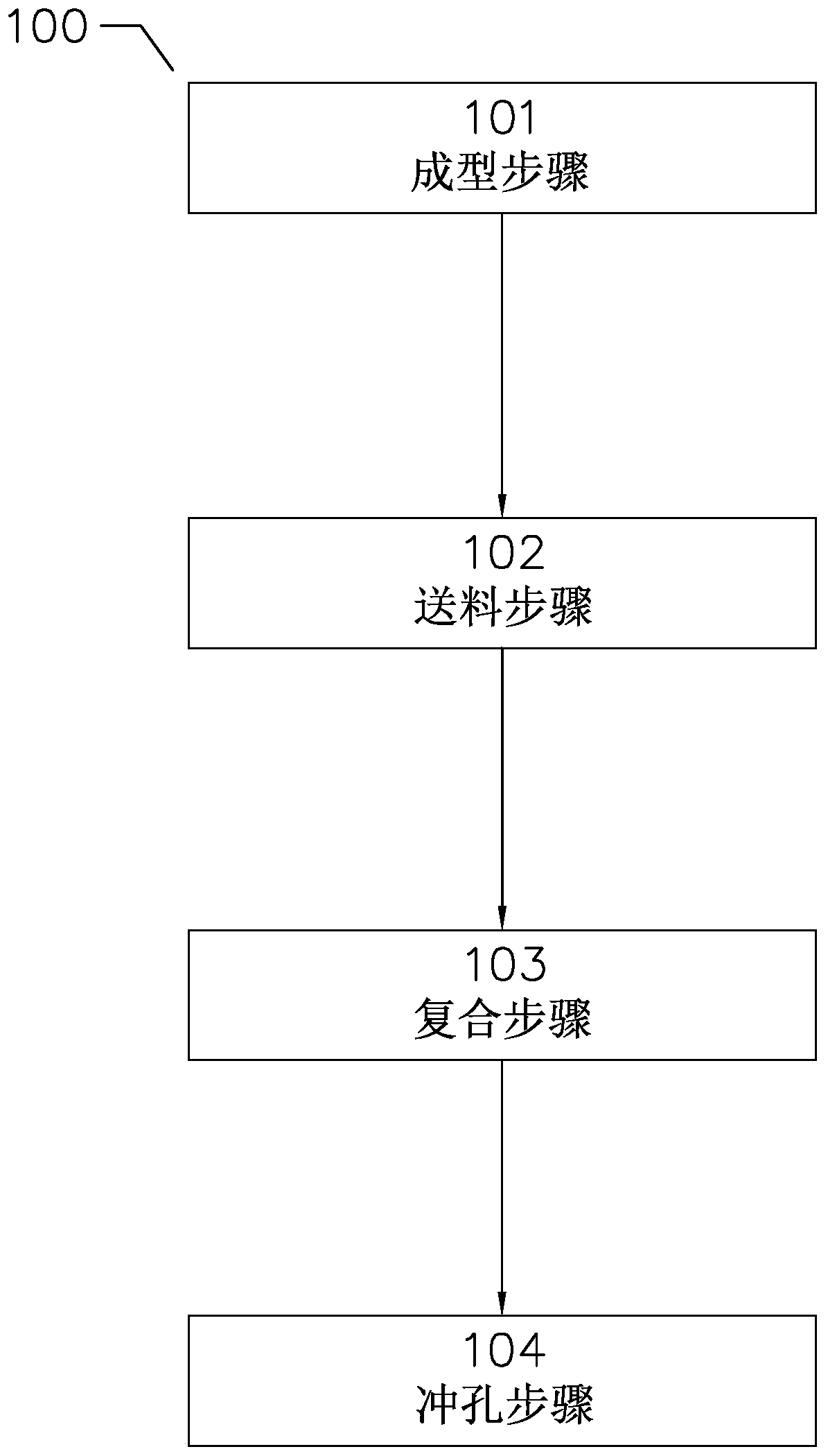

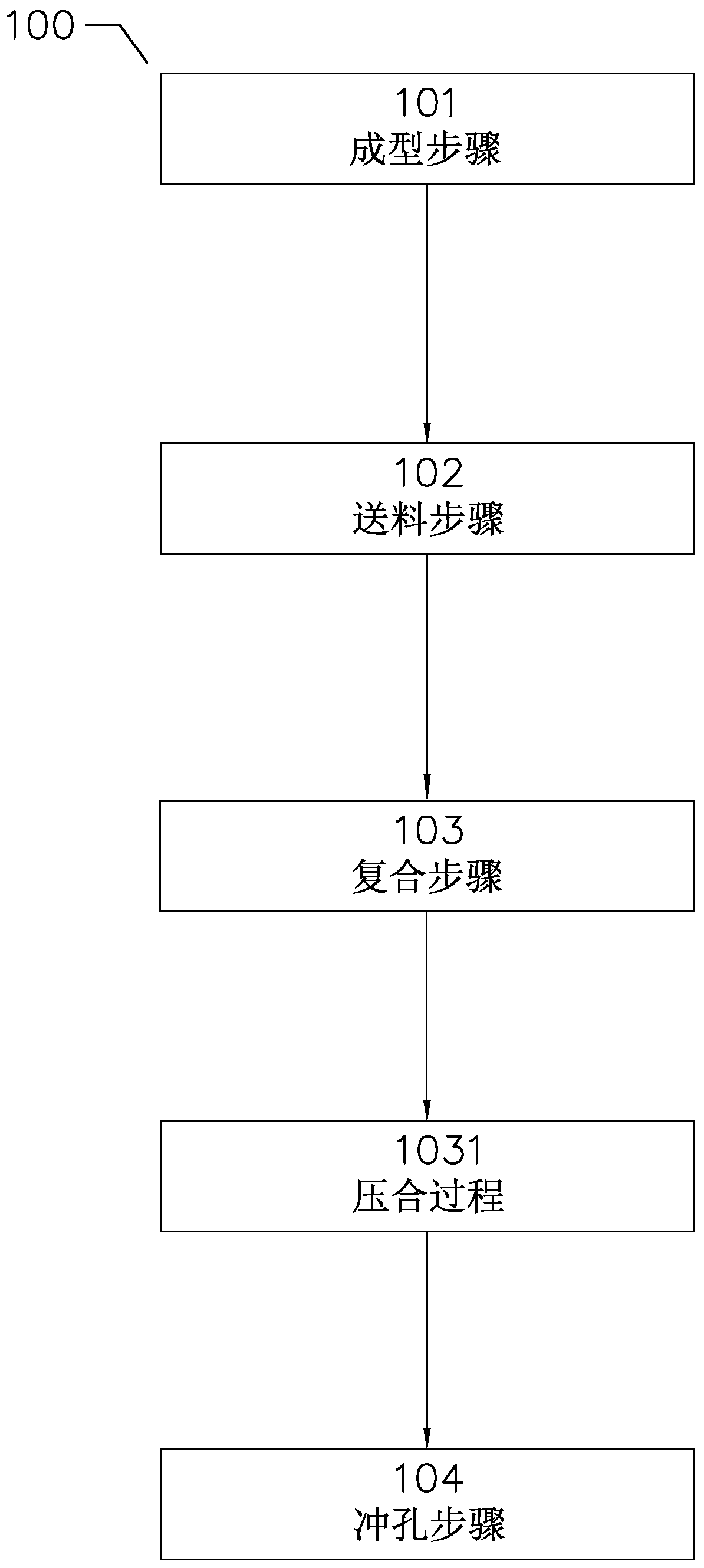

Processing method for local dual-alloy compound aluminum profile

The invention provides a processing method for a local dual-alloy compound aluminum profile. The local dual- alloy compound aluminum profile comprises a first alloy section bar and a second alloy section bar. The processing method comprises the following steps: forming: acquiring the first alloy section bar by extrusion forming; compounding: immediately covering the surface of the first alloy section bar with the second alloy section bar when the first alloy section bar is extruded, thereby bonding the second alloy section bar on the surface of the first alloy section bar under the residual processing temperature of the first alloy section bar, namely, compounding the first alloy section bar with the second alloy section bar. The residual processing temperature of the first alloy section bar is utilized to bond the second alloy section bar to the surface of the first alloy section bar, no independent fixing structure is required, no repeated intermediate annealing is required, and theproblem of uneven thickness of the processed compound aluminum profile caused by the differences in hardness, non-deformability, and the like, of two alloys can be avoided, so that the processing method has the advantages of few and simple processes and high processing efficiency.

Owner:浙江海亮新材料有限公司 +1

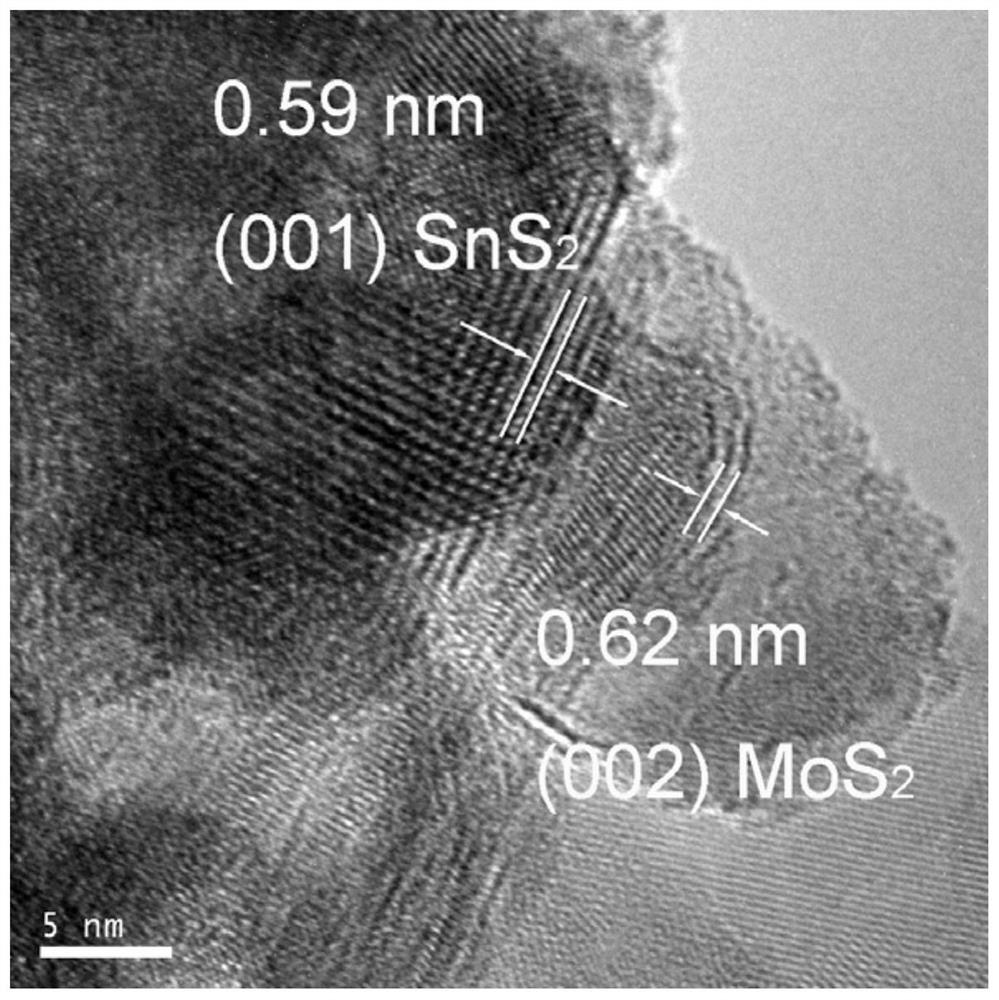

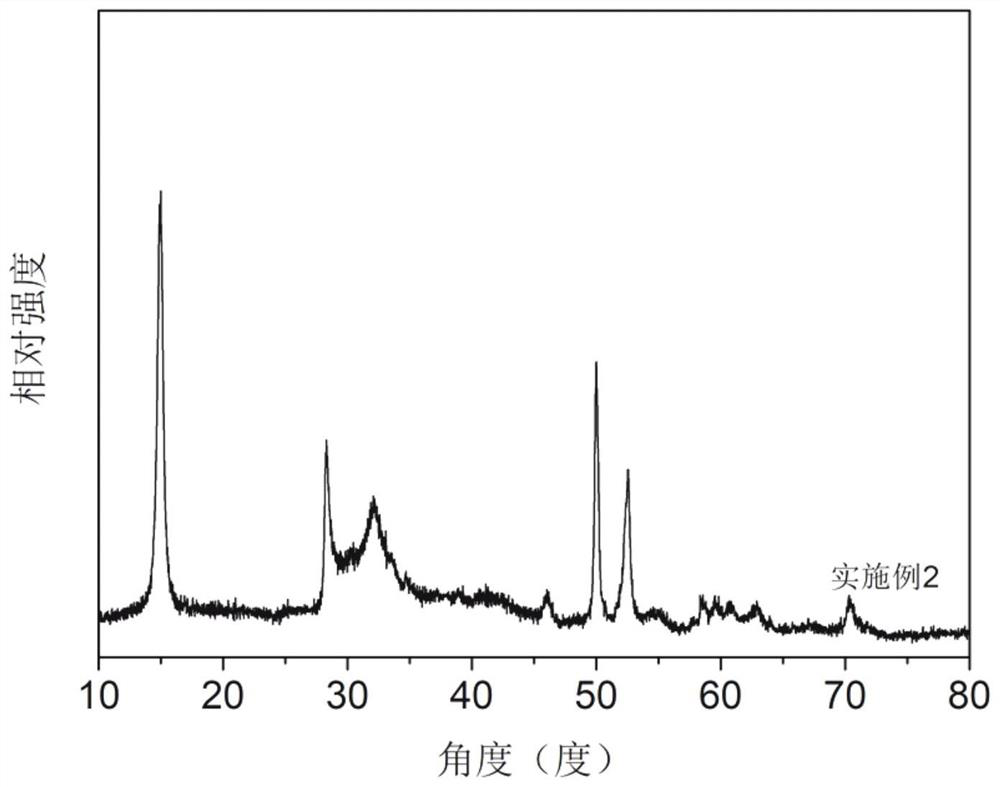

A two-dimensional surface sns 2 -mos 2 Preparation method of the complex

ActiveCN109174130BWon't breakSmall sizeMaterial nanotechnologyPhysical/chemical process catalystsThioureaThio-

The invention relates to a two-dimensional surface SnS 2 ‑MoS 2 Method for the preparation of the complex. The method of the present invention will SnCl 4 , ethylenediamine, thiourea, and water are mixed to form a precursor solution, and placed in a hydrothermal reaction kettle for hydrothermal reaction to obtain a two-dimensional nanosheet SnS 2 ; the two-dimensional nanosheet SnS 2 , H 8 MON 2 O 4 , thioacetamide, sodium dodecylbenzenesulfonate and water are mixed into a precursor solution, placed in a hydrothermal reactor for secondary hydrothermal reaction to obtain a two-dimensional surface SnS 2 ‑MoS 2 Complex. The method of the invention has the advantages of simple process, easy control and high production efficiency.

Owner:HANGZHOU DIANZI UNIV

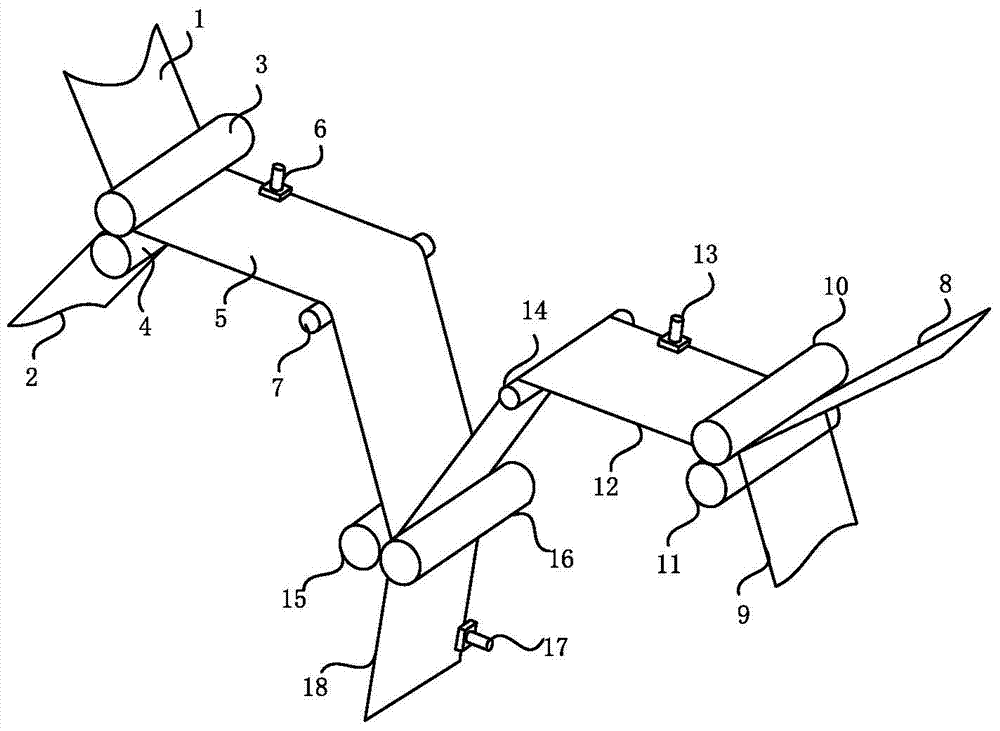

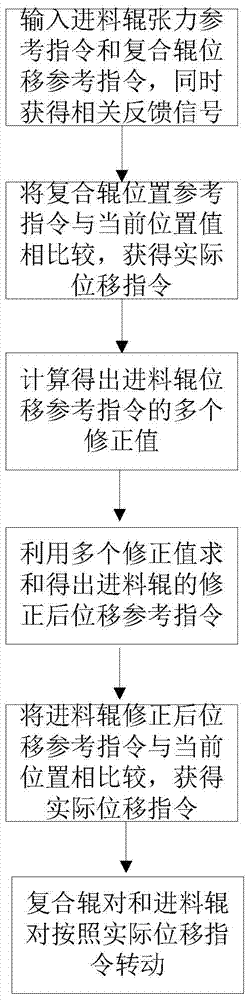

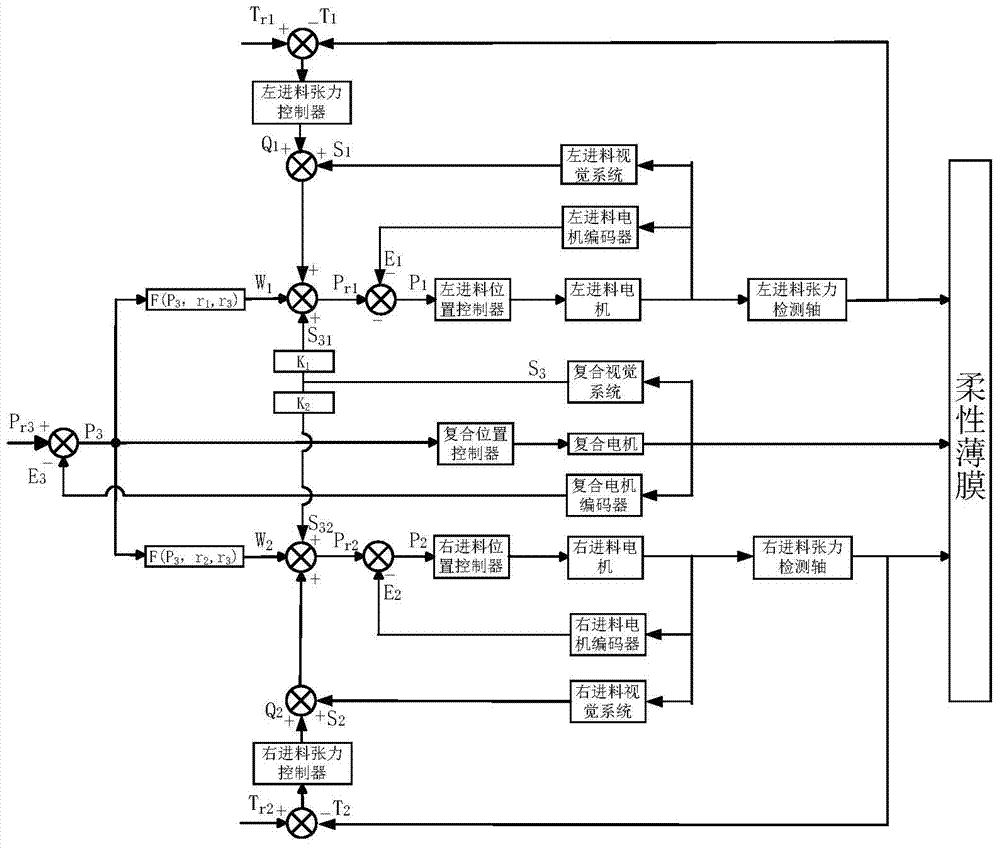

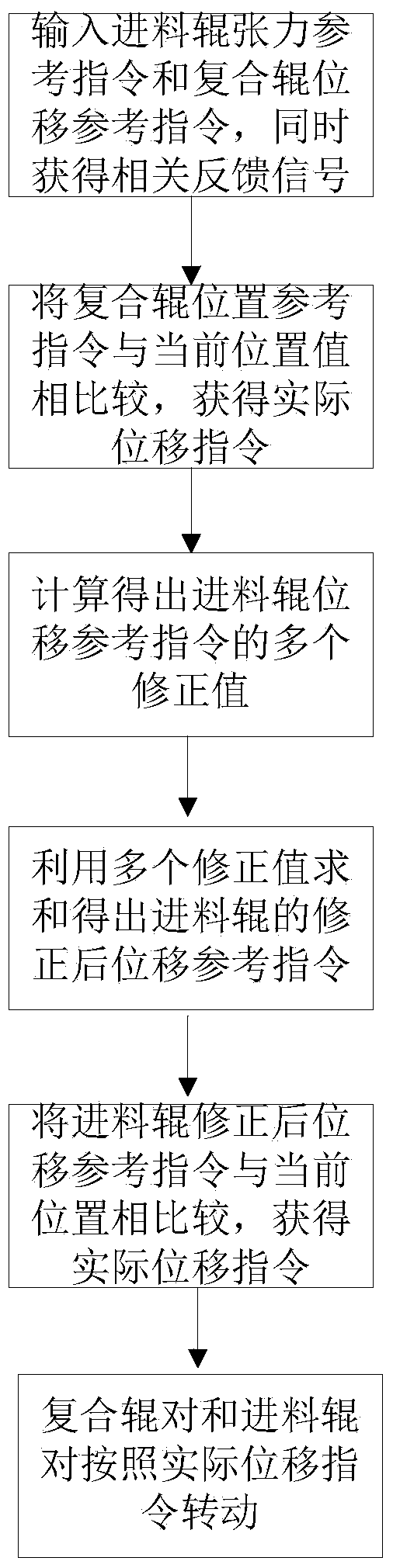

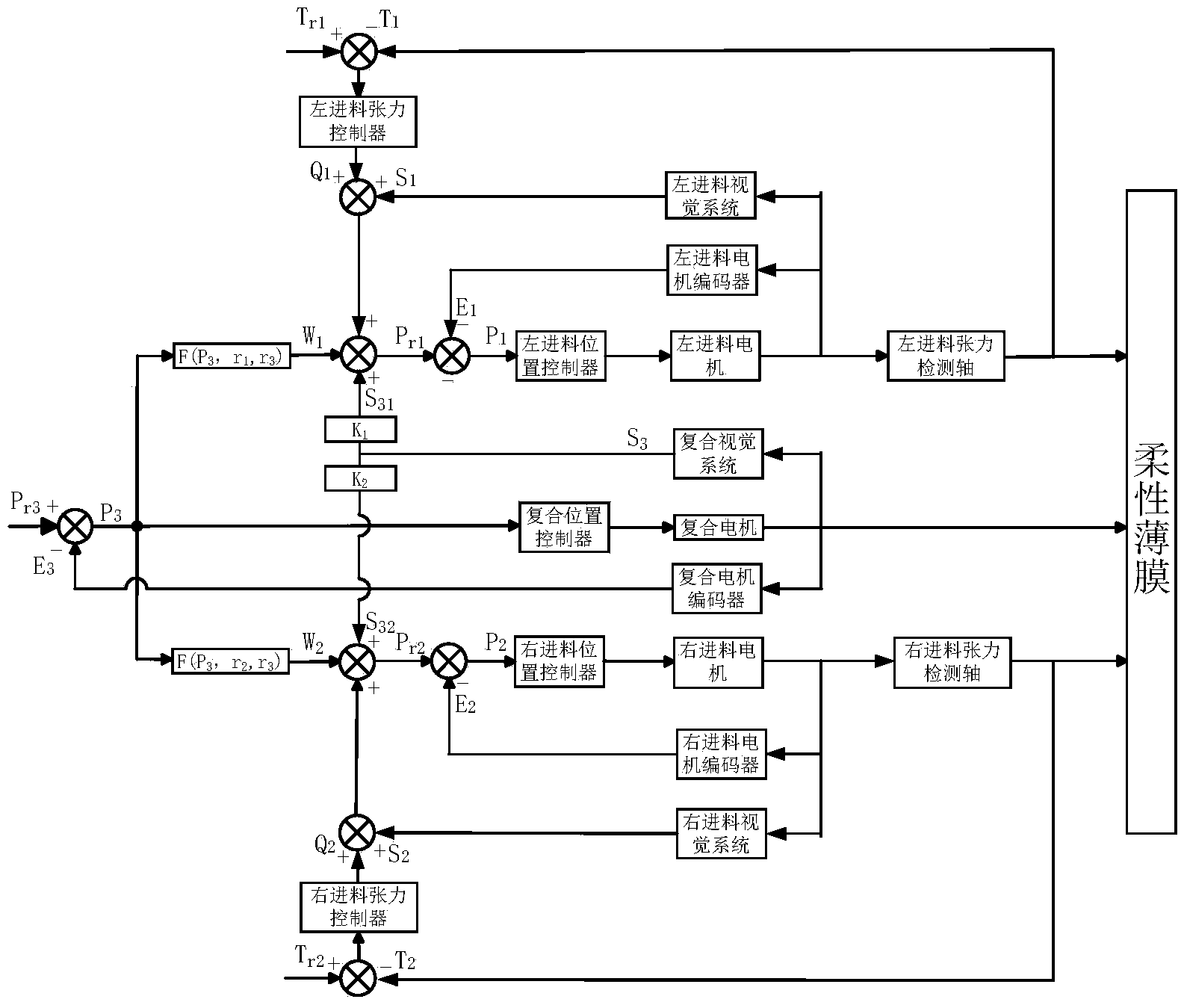

A control method suitable for multilayer film compounding

ActiveCN103612467BHigh feed accuracyImprove alignment accuracyControlling laminationLaminationClosed loopMovement control

The invention discloses a control method suitable for combination of a plurality of layers of films. The control method comprises the following steps of inputting a tension reference instruction of a feeding roll and a displacement reference instruction of a composite roll and obtaining feedback signals including the current positions, the position deviations and the tension states of the feeding roll and the composite roll; comparing the displacement reference instruction of the composite roll with the current position value of the composite roll so as to take the result as an actual displacement instruction and realize displacement closed-loop control; based on the actual displacement instruction of the composite roll, calculating to obtain a displacement reference instruction of the feeding roll before correction; correcting the displacement reference instruction before correction by multiple modes so as to obtain a corresponding actual displacement instruction and realize displacement closed control; and respectively rotating the roll pair according to the actual displacement instruction so as to realize synchronous movement control process of combination of the plurality of layers of films. By the control method, the positioning effect of the combination of the plurality of layers of films can be obviously improved; simultaneously, the control method disclosed by the invention has the characteristics of high feeding accuracy, stable tension control, high automation degree and convenience in operation and the like.

Owner:武汉国创科光电装备有限公司

A processing method of partial double-alloy composite aluminum profile

The invention provides a processing method for a local dual-alloy compound aluminum profile. The local dual- alloy compound aluminum profile comprises a first alloy section bar and a second alloy section bar. The processing method comprises the following steps: forming: acquiring the first alloy section bar by extrusion forming; compounding: immediately covering the surface of the first alloy section bar with the second alloy section bar when the first alloy section bar is extruded, thereby bonding the second alloy section bar on the surface of the first alloy section bar under the residual processing temperature of the first alloy section bar, namely, compounding the first alloy section bar with the second alloy section bar. The residual processing temperature of the first alloy section bar is utilized to bond the second alloy section bar to the surface of the first alloy section bar, no independent fixing structure is required, no repeated intermediate annealing is required, and theproblem of uneven thickness of the processed compound aluminum profile caused by the differences in hardness, non-deformability, and the like, of two alloys can be avoided, so that the processing method has the advantages of few and simple processes and high processing efficiency.

Owner:浙江海亮新材料有限公司 +1

A kind of ultrafine nano-silicon/carbon composite material and its preparation method and application

ActiveCN112234178BGuaranteed composite effectReduce usage bloat defectsNegative electrodesLi-accumulatorsCarbon compositesElectrical battery

The invention discloses an ultrafine nano-silicon / carbon composite material, a preparation method and application thereof, and belongs to the technical field of lithium battery negative electrode material preparation. The present invention adopts the method of staged roasting to prepare ultrafine nanometer silicon / carbon composite material based on ultrafine nanometer silicon-based slurry, high-temperature petroleum pitch and polyvinylpyrrolidone, and the material has excellent electrical properties. Beam evaporation combined with crushing process to prepare ultrafine nano-silicon-based slurry. The present invention solves the problem of nano-silicon-based materials such as nano-Si and nano-SiOx having too large a particle size, difficulty in controlling oxidation, and uneven dispersion during the preparation process of ultra-fine nano-silicon / carbon composite materials. The silicon / carbon composite material has low expansion and high cycle stability, so it can be used as a silicon-based composite negative electrode material for batteries.

Owner:SHAANXI COAL & CHEM TECH INST

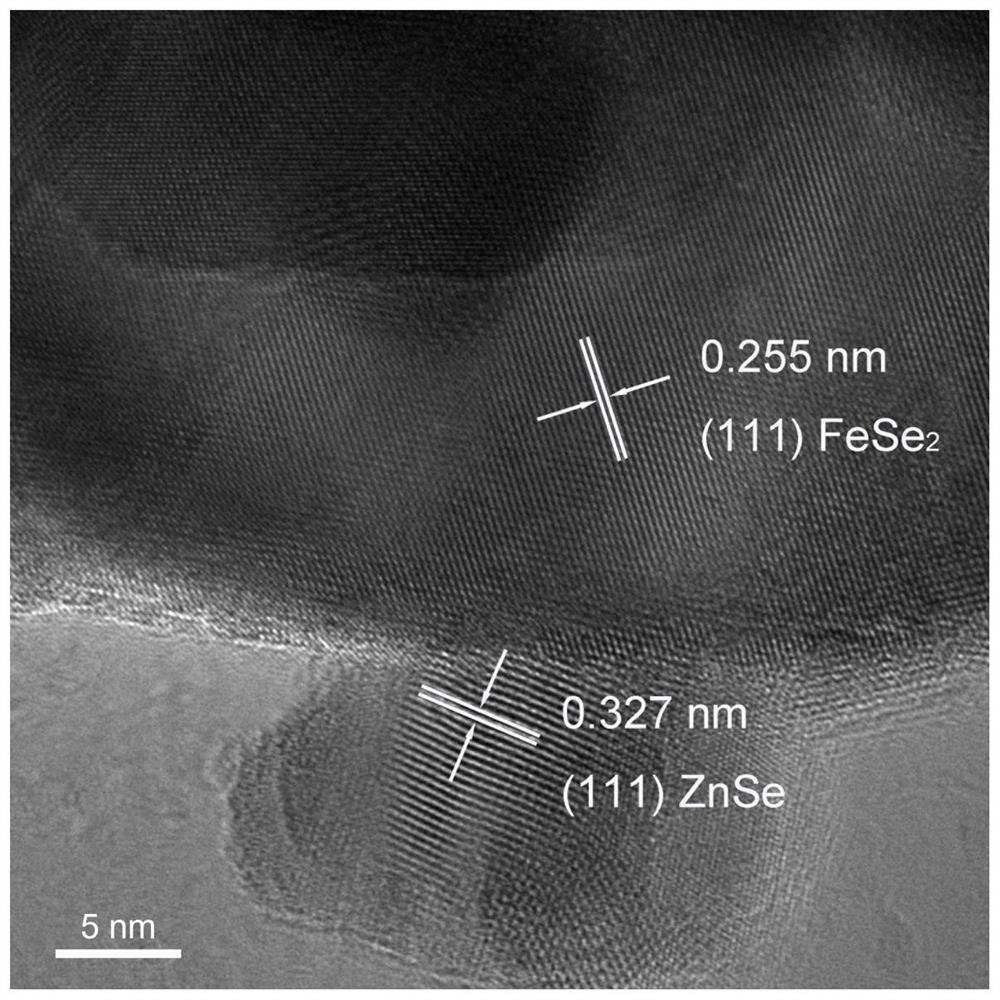

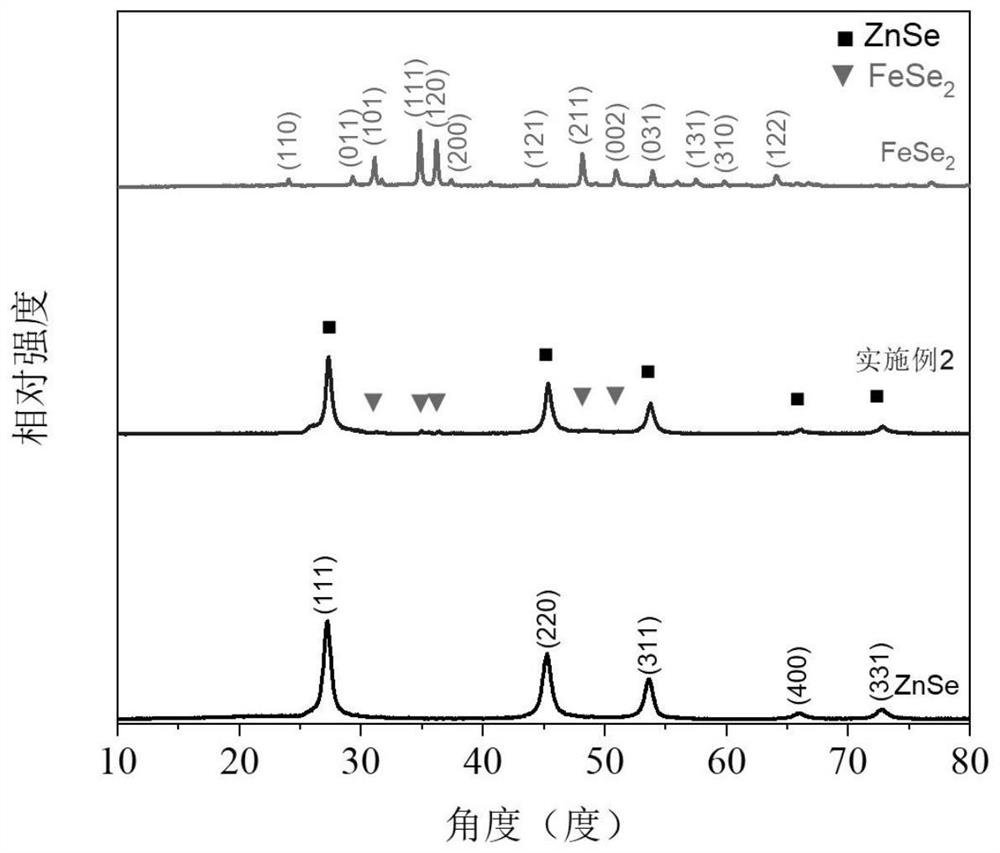

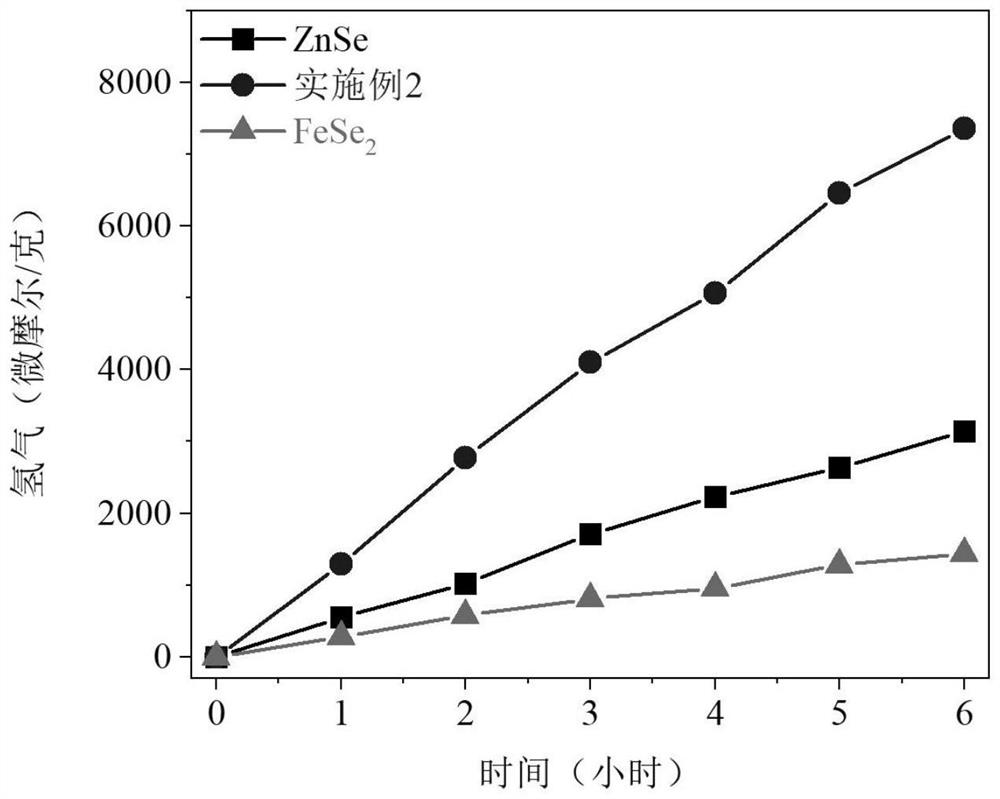

Zero-dimensional ZnSe-one-dimensional FeSe2 heterojunction catalyst as well as preparation method and application thereof

PendingCN114247453ASmall sizeGuaranteed not to break downHydrogenPhysical/chemical process catalystsPtru catalystAmmonium bromide

The invention relates to a zero-dimensional ZnSe-one-dimensional FeSe2 heterojunction catalyst as well as a preparation method and application of the zero-dimensional ZnSe-one-dimensional FeSe2 heterojunction catalyst. The method comprises the following steps: mixing Zn (CH3COO) 2.2 H2O, SeO2, sodium hexadecyl benzene sulfonate, hydrazine hydrate and water to form a precursor solution, and putting the precursor solution into a hydrothermal reaction kettle for hydrothermal reaction to obtain zero-dimensional nano granular ZnSe; zero-dimensional nano granular ZnSe, FeCl3, Na2SeO3, cetyltrimethylammonium bromide, hydrazine hydrate and water are mixed into a precursor solution, and the precursor solution is placed in a hydrothermal reaction kettle to be subjected to secondary hydrothermal reaction. The catalytic hydrogen production rate and the photocurrent density of the zero-dimensional ZnSe-one-dimensional FeSe2 heterojunction catalyst prepared by the preparation scheme are 2.4 times and 3 times of those of a single ZnSe product respectively, and the performance of the heterojunction photocatalyst is obviously enhanced. The method is simple in process, easy to control and high in production efficiency.

Owner:HANGZHOU DIANZI UNIV

a zns-sns 2 Preparation method of the complex

The present invention relates to a kind of ZnS-SnS 2 Method for the preparation of the complex. The inventive method will ZnCl 2 , oleic acid amide, thiourea, and water are mixed to form a precursor liquid, and placed in a hydrothermal reaction kettle for hydrothermal reaction to obtain nano-ZnS; nano-ZnS, SnCl 2 , thioacetamide, hydrazine hydrate and water are mixed to form a precursor solution, which is placed in a hydrothermal reactor for secondary hydrothermal reaction to obtain ZnS‑SnS 2 Complex. The method of the invention has the advantages of simple process, easy control and high production efficiency.

Owner:HANGZHOU DIANZI UNIV

Steel-based alloy composite piece

InactiveCN104309199AGuaranteed composite effectReduce manufacturing costMetal layered productsAlloy composite

The invention belongs to the technical field of alloy for steel, and particularly discloses a steel-based alloy composite piece. The steel-based alloy composite piece comprises a steel element, and is characterized in that a closed hollow steel mould is arranged inside the steel element, and an alloy layer is arranged on the outer surface of the steel element. The steel-based alloy composite piece is structure in structure, convenient to use, reasonable in design, and flexible in application, the adhering effect of the alloy layer is good, phenomena of foaming or separation is unlikely to occur, the production cost is low, and the steel-based alloy composite piece is suitable for wide popularization and application.

Owner:JINAN XINJIE MACHINERY MFG

A rolling composite process of aluminum-clad steel pipe material

ActiveCN103599932BGuaranteed composite effectImprove bindingMetal rolling arrangementsAlloyCarbon steel

The invention provides a rolling compositing process of aluminum-clad steel pipe material. According to the process, aluminum alloy material and carbon steel material are composited well; production cost is low, and composting is effective. According to the technical scheme, the process is characterized in that the carbon steel material and the aluminum alloy material are prepared respectively, the carbon steel material and the aluminum alloy material are stacked and fed into a rolling mill to be rolled, and the aluminum-clad steel pipe material is obtained. Rolling deformation is controlled ranging from 60% to 70% during cold rolling.

Owner:YINBANG CLAD MATERIAL

Control method suitable for combination of plurality of layers of films

ActiveCN103612467AHigh feed accuracyImprove alignment accuracyControlling laminationLaminationClosed loopMultiple modes

The invention discloses a control method suitable for combination of a plurality of layers of films. The control method comprises the following steps of inputting a tension reference instruction of a feeding roll and a displacement reference instruction of a composite roll and obtaining feedback signals including the current positions, the position deviations and the tension states of the feeding roll and the composite roll; comparing the displacement reference instruction of the composite roll with the current position value of the composite roll so as to take the result as an actual displacement instruction and realize displacement closed-loop control; based on the actual displacement instruction of the composite roll, calculating to obtain a displacement reference instruction of the feeding roll before correction; correcting the displacement reference instruction before correction by multiple modes so as to obtain a corresponding actual displacement instruction and realize displacement closed control; and respectively rotating the roll pair according to the actual displacement instruction so as to realize synchronous movement control process of combination of the plurality of layers of films. By the control method, the positioning effect of the combination of the plurality of layers of films can be obviously improved; simultaneously, the control method disclosed by the invention has the characteristics of high feeding accuracy, stable tension control, high automation degree and convenience in operation and the like.

Owner:武汉国创科光电装备有限公司

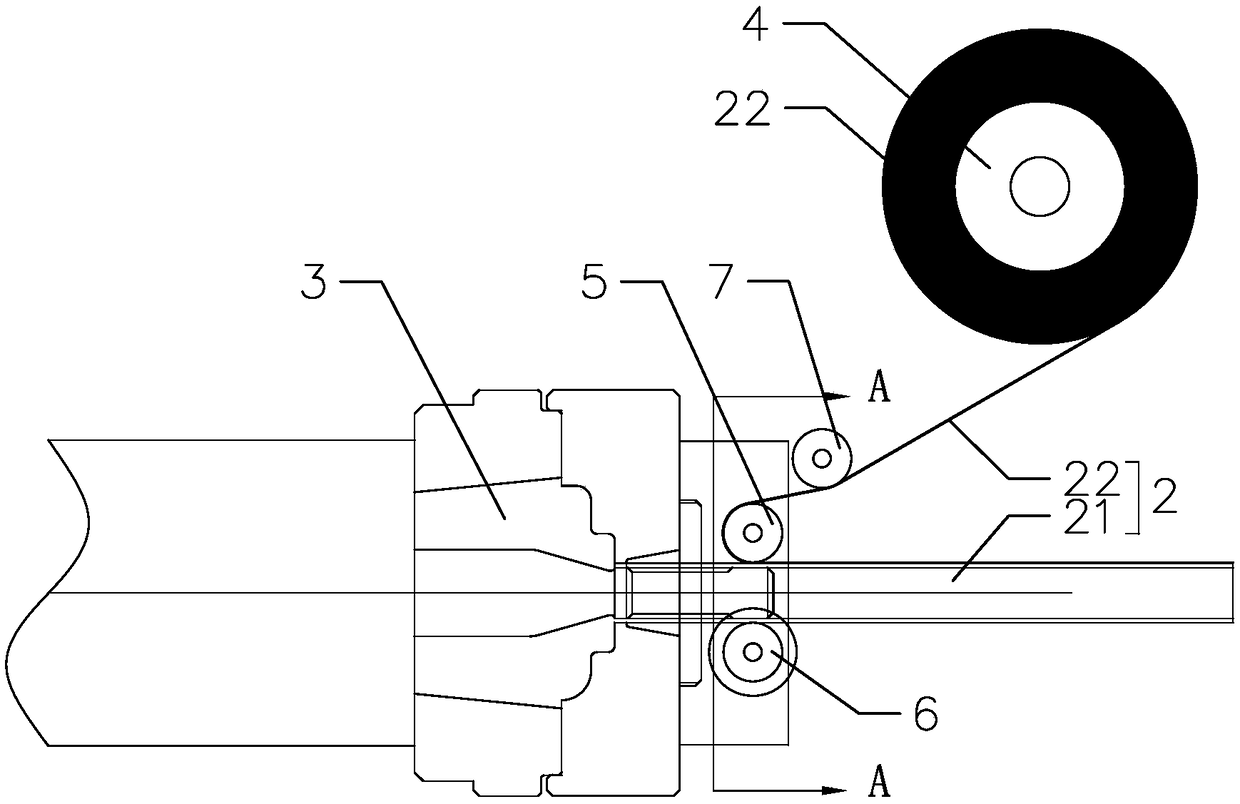

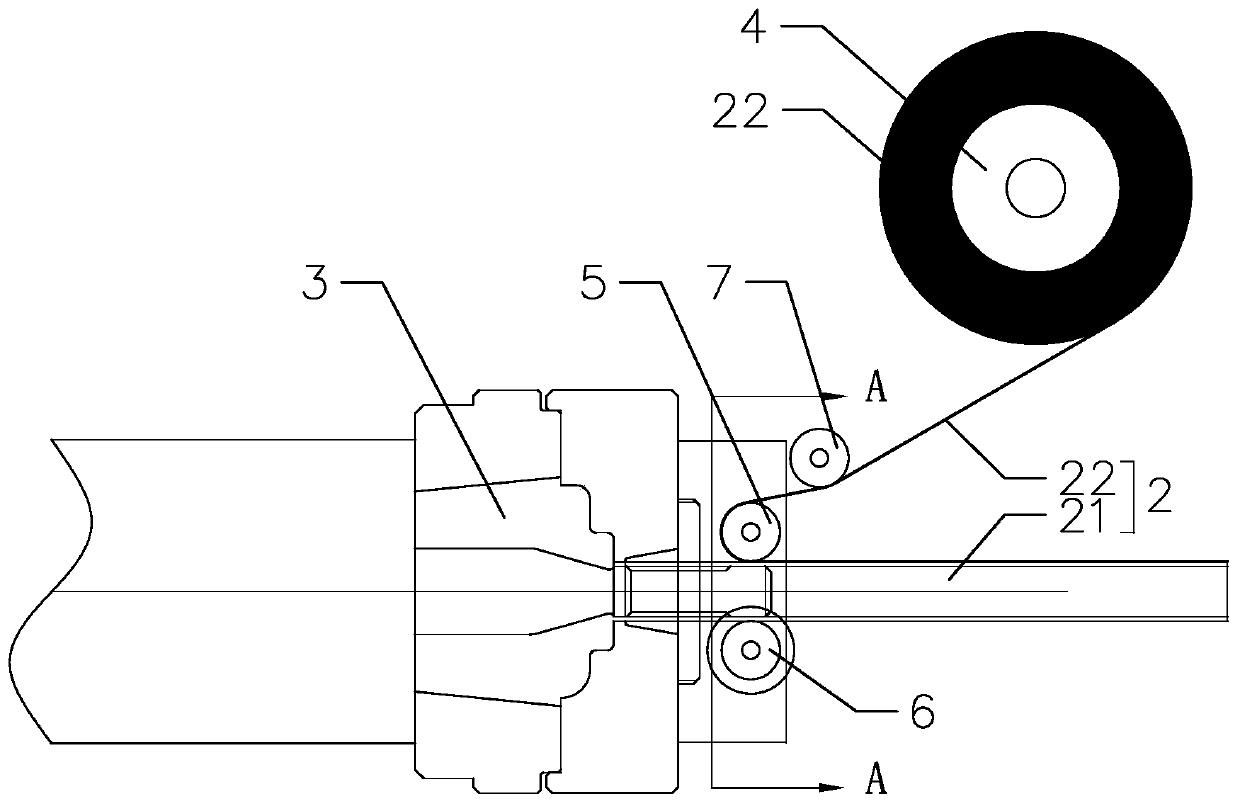

A processing equipment for partial double alloy composite aluminum profiles

The invention provides a processing device for a local dual-alloy compound aluminum profile. The processing device comprises an extruding machine and a conveying device, wherein the extruding machineis used for processing a first alloy section bar; a mould for forming the first alloy section bar is arranged in the extruding machine; the conveying device is used for conveying a second alloy section bar; the conveying device comprises a coiling plate used for winding the second alloy section bar; the coiling plate is moveably and rotatably arranged; when the first alloy section bar is continuously extruded, the second alloy section bar is continuously conveyed to and compounded on the surface of the first alloy section bar; the second alloy section bar is conveyed by the coiling plate to anextruding outlet of the first alloy section bar; the second alloy section bar is adhered to the surface of the first alloy section bar under the effect of gravity and is bonded to the surface of thefirst alloy section bar under the residual processing temperature of the first alloy section bar, so as to finish the compounding of two alloys. Such a processing manner has the advantages of few andsimple processes, high processing efficiency, low defective percentage, less raw material consumption and low processing cost.

Owner:浙江海亮新材料有限公司 +1

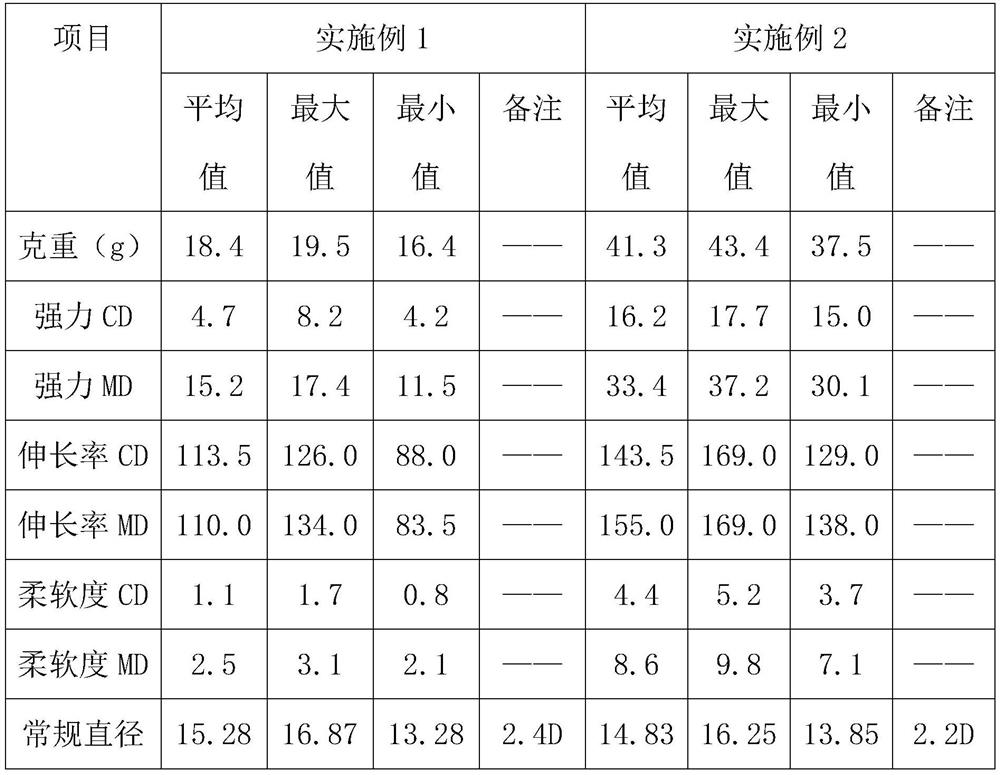

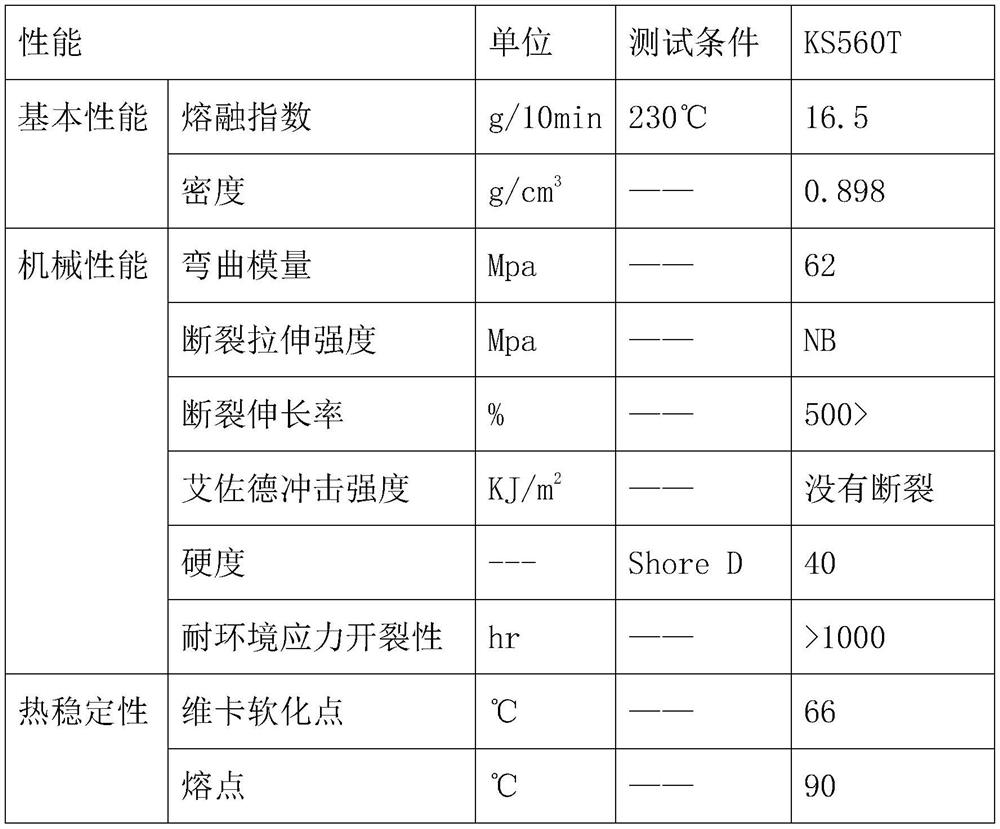

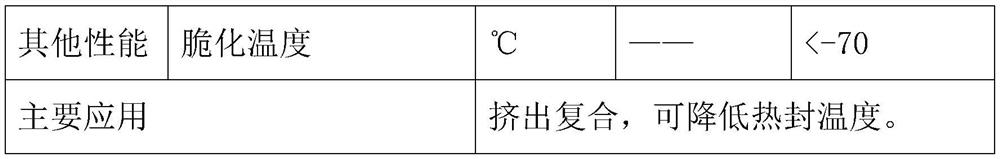

Soft PE non-woven fabric applied to hygienic products and manufacturing method of soft PE non-woven fabric

The invention discloses a soft PE non-woven fabric applied to hygienic products and a manufacturing method of the soft PE non-woven fabric, and belongs to the field of PE non-woven fabrics. The soft PE non-woven fabric applied to the hygienic products comprises a soft layer and a composite layer, the soft layer is made of a low-melting-point PE raw material, the composite layer is made of a PP rawmaterial and a binding material, KS560T is selected as the PE raw material, H39S-2 is selected as the PP raw material, and OMBM is selected as the binding material; and a double-layer structure is adopted, the soft layer is made of a PE raw material with low melt indexes, the soft effect is extremely good, the composite layer is made of the PP raw material and the binding material in a mixed manner, the composite effect of the composite layer, the PE layer and a paper diaper can be guaranteed, more stability is achieved, meanwhile, the good soft effect can be kept, the dual-layer composite technology is adopted, the PE layer and a PP spunbond layer are composited, the soft effect of the PE can be kept, and the composite application to the waistline and other positions of the paper diaperis not influenced.

Owner:山东恒鹏卫生用品有限公司

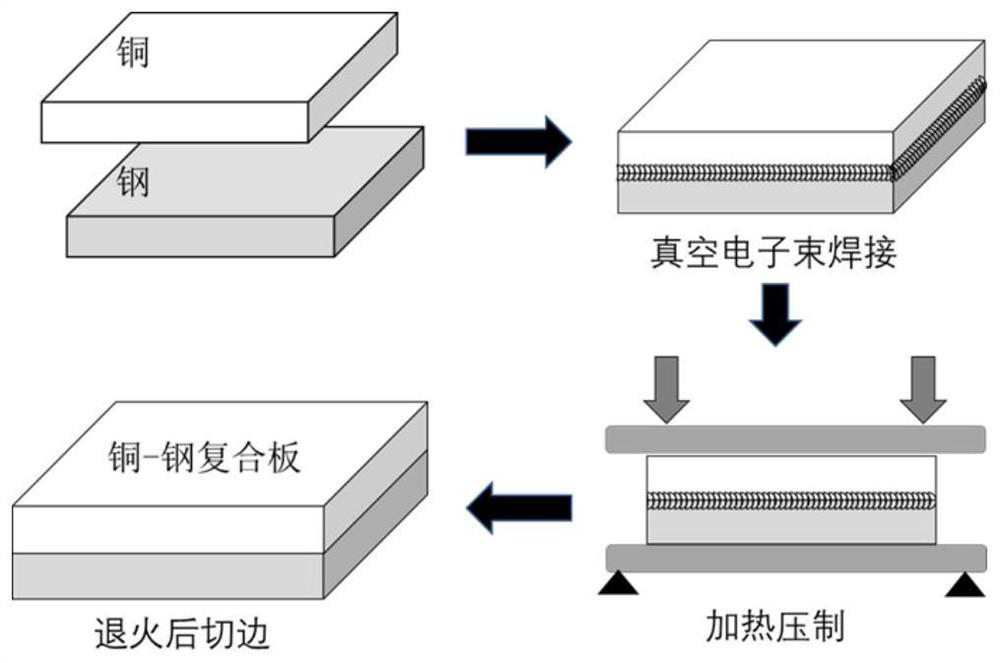

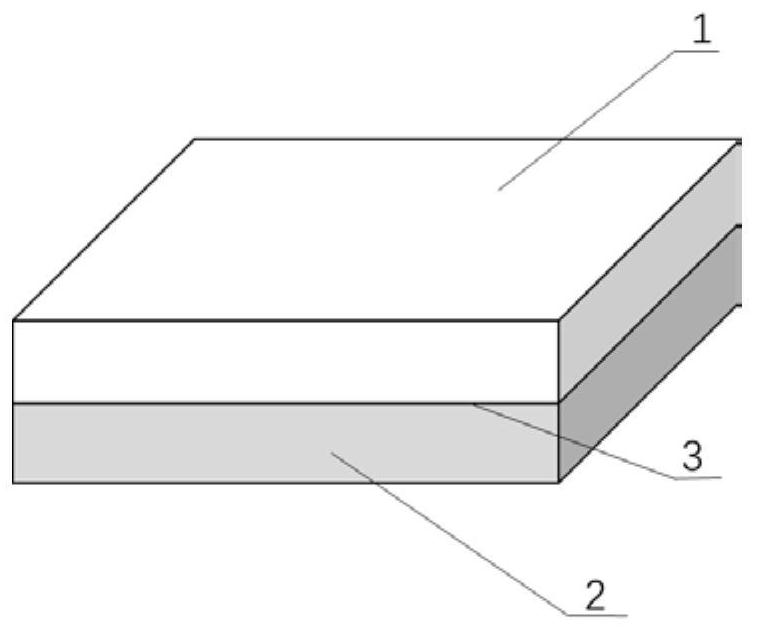

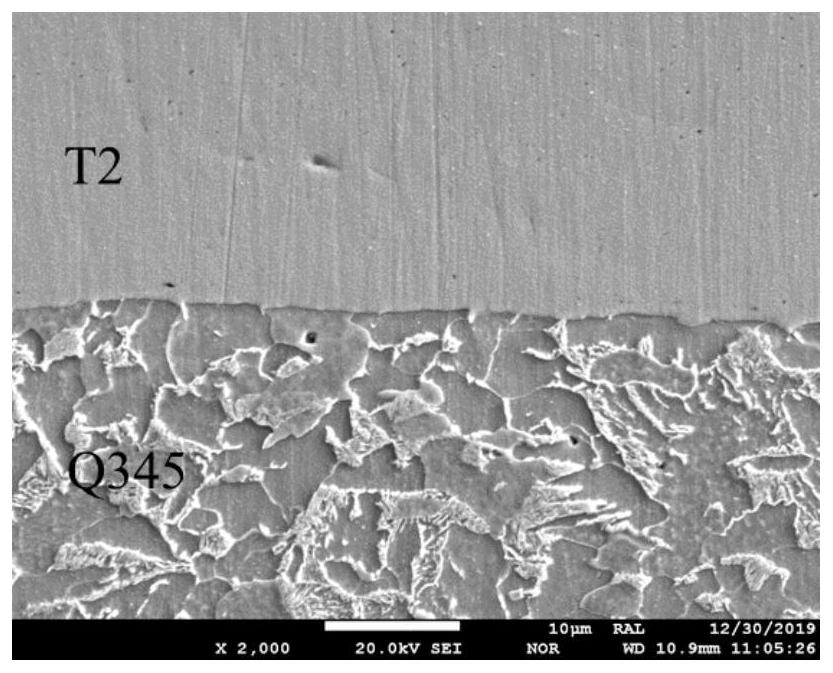

A kind of preparation method of thick-gauge copper-steel composite board

ActiveCN112077429BHigh strengthHigh bonding strengthElectron beam welding apparatusSurface oxidationComposite slab

A method for preparing a thick-gauge copper-steel composite plate, which belongs to the field of composite plate preparation; the preparation method comprises the following steps: Step 1: surface-treat copper plates and steel plates to remove surface scale; step 2: treat the copper plates and steel plates After forming the billet, put it into a vacuum electron beam welding machine to evacuate, and then carry out electron beam welding and packaging; step 3: heat and diffuse the obtained vacuum welded and packaged copper-steel composite slab; step 4: heat the composite panel Pressing is applied to the blank to make the copper-steel interface completely compound, and the copper-steel clad plate of the present invention is obtained. The purpose of the present invention is to effectively realize the preparation of thick-gauge copper-steel composite plates, save costs, and various mechanical properties can effectively meet the application requirements in the metallurgical field. The thick-gauge copper-steel clad board prepared by the invention has an interfacial bonding rate of up to 100% and high bonding strength.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com