Processing method of NY/RCPP composite film for high-temperature retort pouch

A high-temperature cooking bag and processing method technology, applied in the field of composite films, can solve problems such as unfavorable purchases, aluminum-plastic composite packaging cannot be heated by microwaves, etc., and achieve the effects of excellent mechanical properties, optimized use performance, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

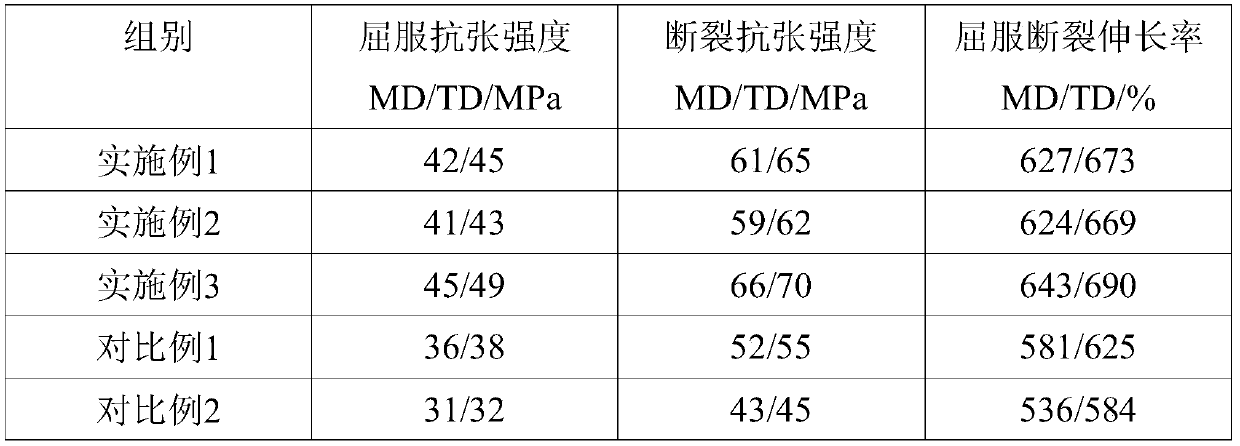

Embodiment 1

[0025] (1) Take by weighing 100g nylon 6, 8g poly(methyl vinyl ether / maleic acid) copolymer and 2g stearylamide, mix uniformly, obtain NY layer compound;

[0026] (2) Weigh 100g of cooking grade chlorinated polypropylene, 12g of ε-caprolactone / polyether / propylene oxide terpolymer and 2g of stearamide, and mix them uniformly to obtain the RCPP layer mixture;

[0027] (3) Feed the NY layer mixture and RCPP layer mixture into their respective screw extruders, melt and plasticize, the extruder I zone temperature of the NY layer mixture is 220°C, the temperature of II zone is 230°C, and the temperature of III zone Temperature 240°C, Zone IV temperature 240°C, Zone V temperature 230°C, RCPP layer compound extruder I zone temperature 130°C, II zone temperature 140°C, III zone temperature 150°C, IV zone temperature 140°C, V zone temperature The temperature is 140°C to obtain the melt of the NY layer and the melt of the RCPP layer; the melt is filtered by a filter and then pumped to th...

Embodiment 2

[0029] The difference between embodiment 2 and embodiment 1 is that the anti-blocking agent is replaced with an equal amount of zinc stearate, and all the other operations are identical.

Embodiment 3

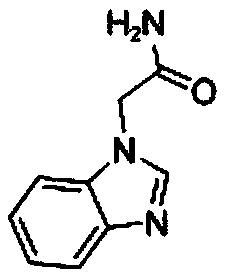

[0031] The difference between Example 3 and Example 1 is that the anti-blocking agent is replaced by an equivalent amount of 2-(1H-benzopyrazol-1-yl)acetamide, and the rest of the operations are exactly the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com