Preparation method of three-dimensional spherical In2S3-SnS2 compound

A technology of in2s3-sns2 and composites, which is applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of complex difficulties and large differences, and achieve the goal of ensuring the composite effect and reducing the size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix 10g of indium nitrate, 20gl-isoleucine, 10g of sodium borohydride and 600g of water in a mass ratio of 1:2:1:60, and place them in a hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 160°C , the constant temperature time is 8 hours; the solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, washed 3 times with deionized water, and then dried at 70°C for 5 hours; After drying, the product was ground into powder to obtain a three-dimensional spherical In 2 S 3 ; 100g three-dimensional spherical In 2 S 3 , 10gSnCl 4 , 20g of thiourea, 10g of ethylenediamine and 500g of water are mixed according to the mass ratio of 10:1:2:1:50 to form a precursor solution, and placed in a hydrothermal reaction kettle for hydrothermal reaction. The time is 20 hours; the solid-liquid mixture after the hydrothermal reaction ...

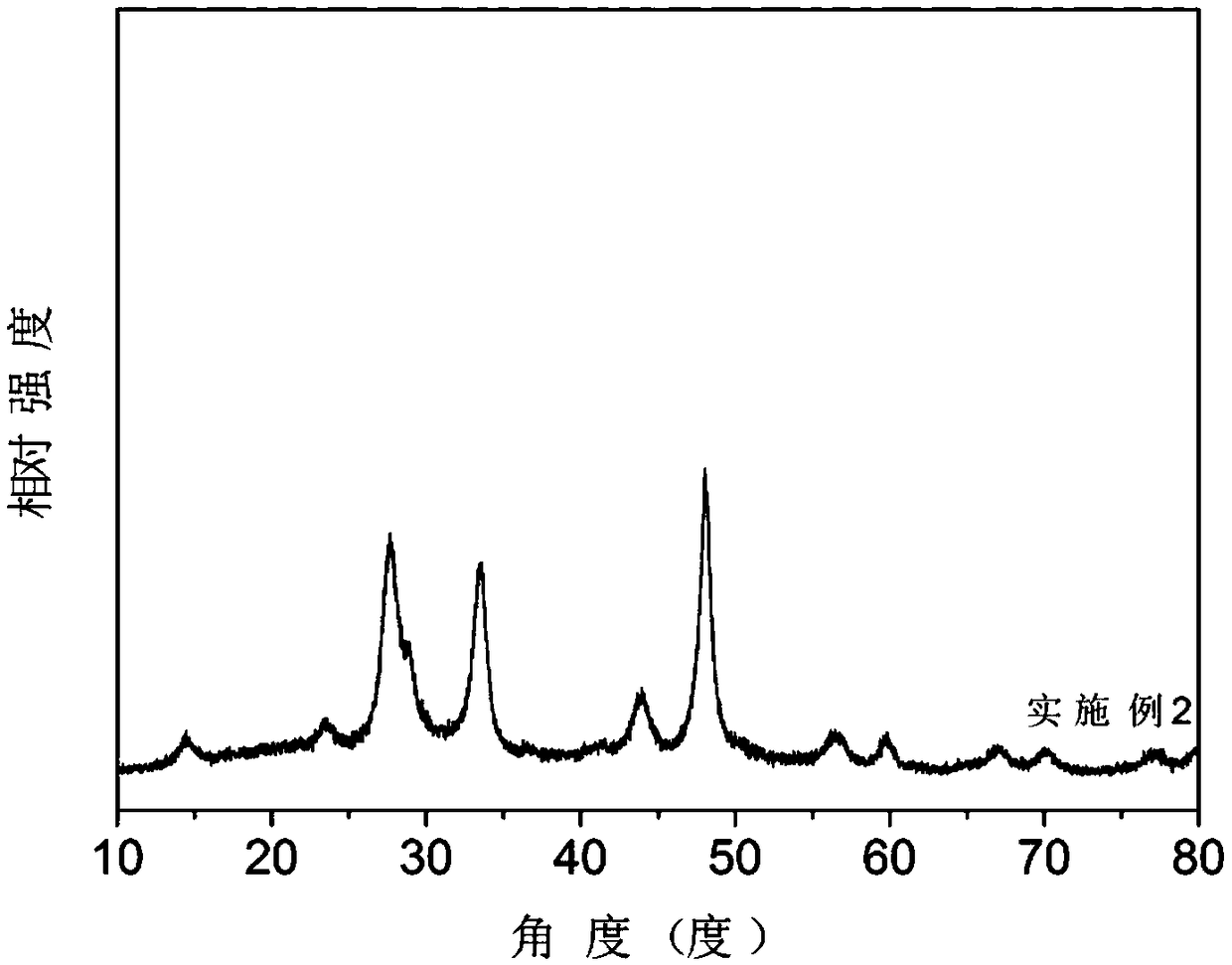

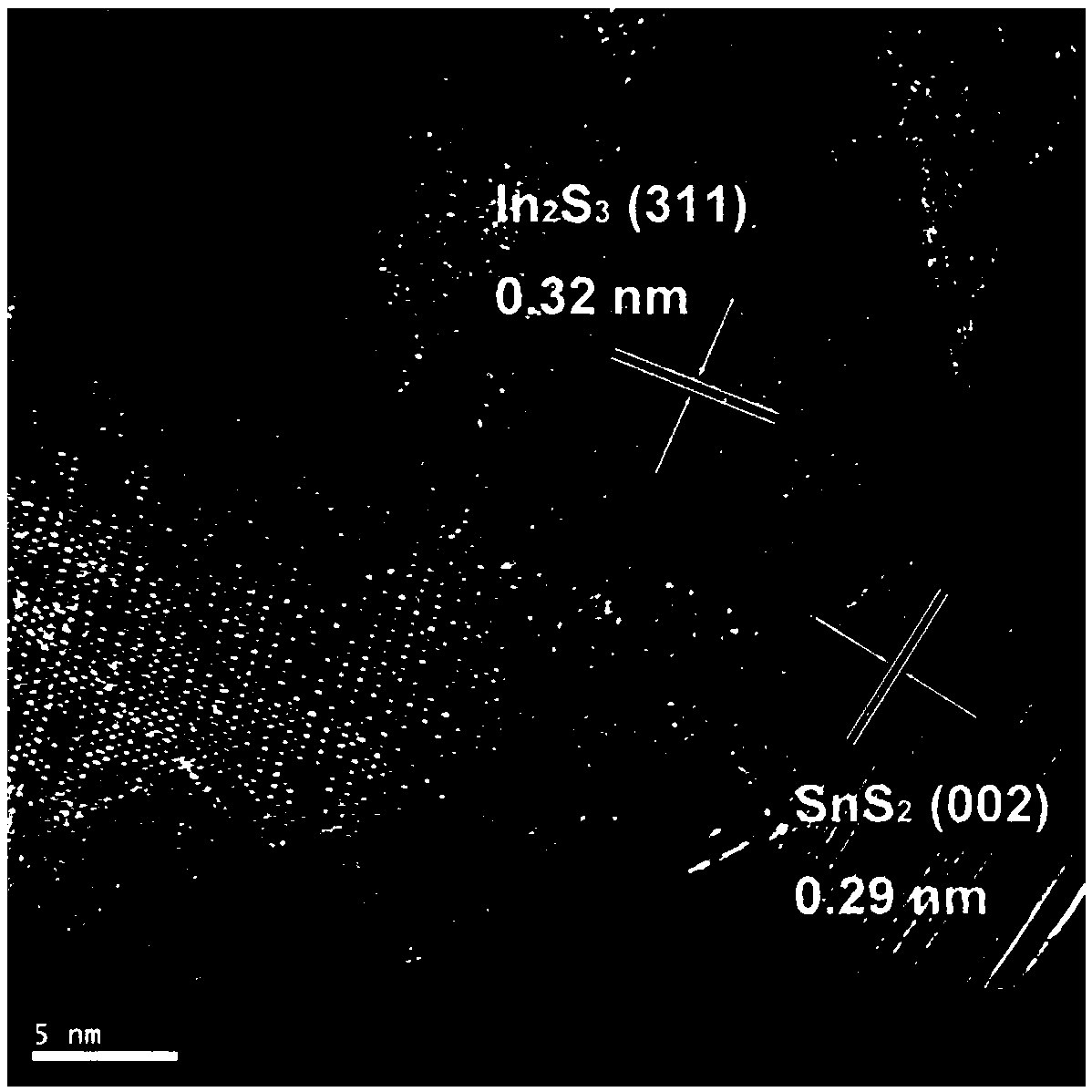

Embodiment 2

[0021] Mix 10g of indium nitrate, 30gl-isoleucine, 10g of sodium borohydride and 600g of water in a mass ratio of 1:3:1:60, and place them in a hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 180°C , the constant temperature time is 10 hours; the solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, washed with deionized water for 3 times, and then dried at 80°C for 6 hours; After drying, the product was ground into powder to obtain a three-dimensional spherical In 2 S 3 ; 100g three-dimensional spherical In 2 S 3 , 20gSnCl 4 , 30g of thiourea, 20g of ethylenediamine and 500g of water are mixed according to the mass ratio of 10:2:3:2:50 to form a precursor solution, and placed in a hydrothermal reaction kettle for hydrothermal reaction. The time is 24 hours; the solid-liquid mixture after the hydrothermal reac...

Embodiment 3

[0024] Mix 10g of indium nitrate, 40gl-isoleucine, 20g of sodium borohydride and 600g of water in a mass ratio of 1:4:2:60, and place them in a hydrothermal reaction kettle for hydrothermal reaction. The temperature of the hydrothermal reaction is 200°C , the constant temperature time is 12 hours; the solid-liquid mixture after the hydrothermal reaction is subjected to solid-liquid centrifugation, the liquid product is poured out, the solid product is taken out, washed with deionized water for 3 times, and then dried at 80°C for 8 hours; After drying, the product was ground into powder to obtain a three-dimensional spherical In 2 S 3 ; 100g three-dimensional spherical In 2 S 3 , 30gSnCl 4 , 40g of thiourea, 30g of ethylenediamine and 500g of water are mixed according to the mass ratio of 10:3:4:3:50 to form a precursor solution, and placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 200°C, constant temperature The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com