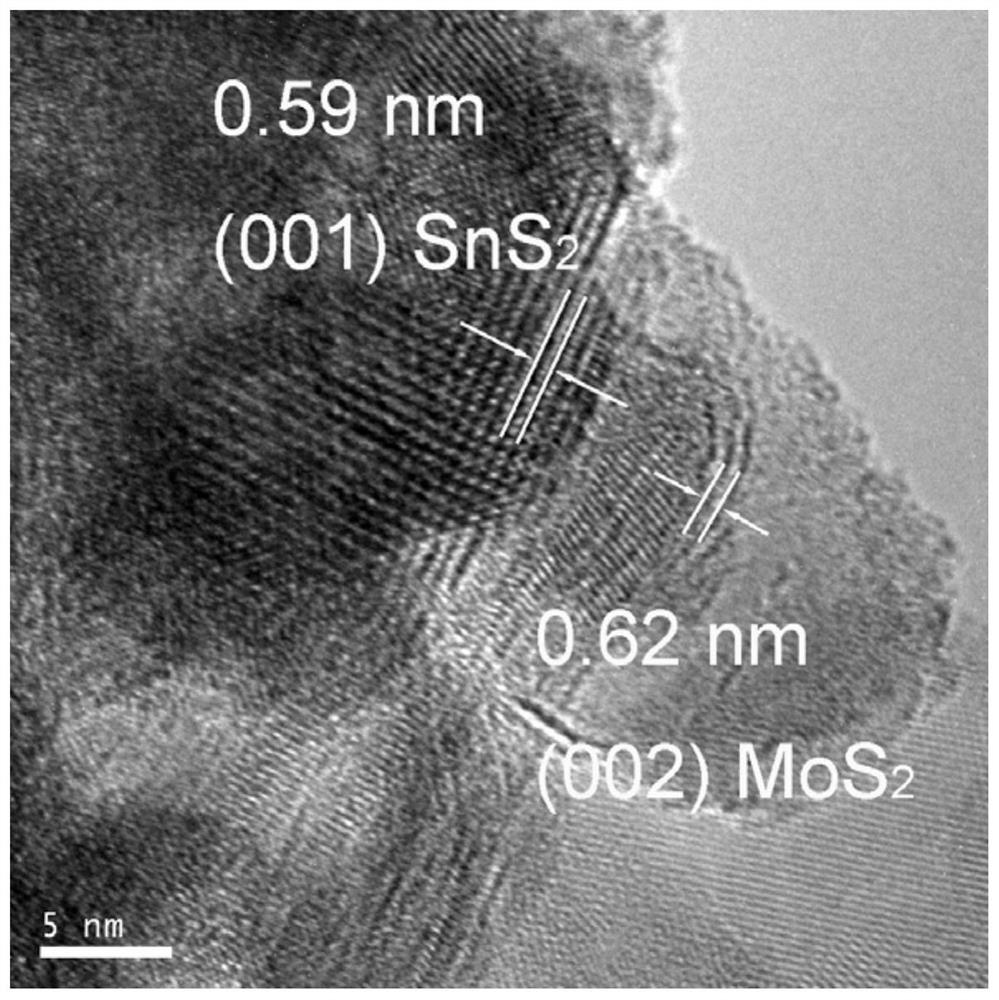

A two-dimensional surface sns 2 -mos 2 Preparation method of the complex

A composite and dimensional surface technology, applied in chemical instruments and methods, chemical/physical processes, nanotechnology for materials and surface science, etc., can solve problems such as complex difficulties and large differences, to ensure composite effects, The effect of downsizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] SnCl 4 , ethylenediamine, thiourea, and water are mixed according to the mass ratio of 1:1:2:60, placed in a hydrothermal reaction kettle for hydrothermal reaction, the hydrothermal reaction temperature is 160°C, and the constant temperature time is 8 hours; the hydrothermal reaction After the reaction, the solid-liquid mixture was subjected to solid-liquid centrifugation, the liquid product was poured out, the solid product was taken out, washed with deionized water for 3 times, and then dried at 70°C for 5 hours; the dried product was ground into powder to obtain two Dimensional nanosheet SnS 2 ; the above two-dimensional nanosheet SnS 2 , H 8 MON 2 o 4 , thioacetamide, sodium dodecylbenzenesulfonate and water are mixed according to the mass ratio of 10:1:2:1:50 to form a precursor solution, which is placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 160°C, the constant temperature time is 20 hours; the so...

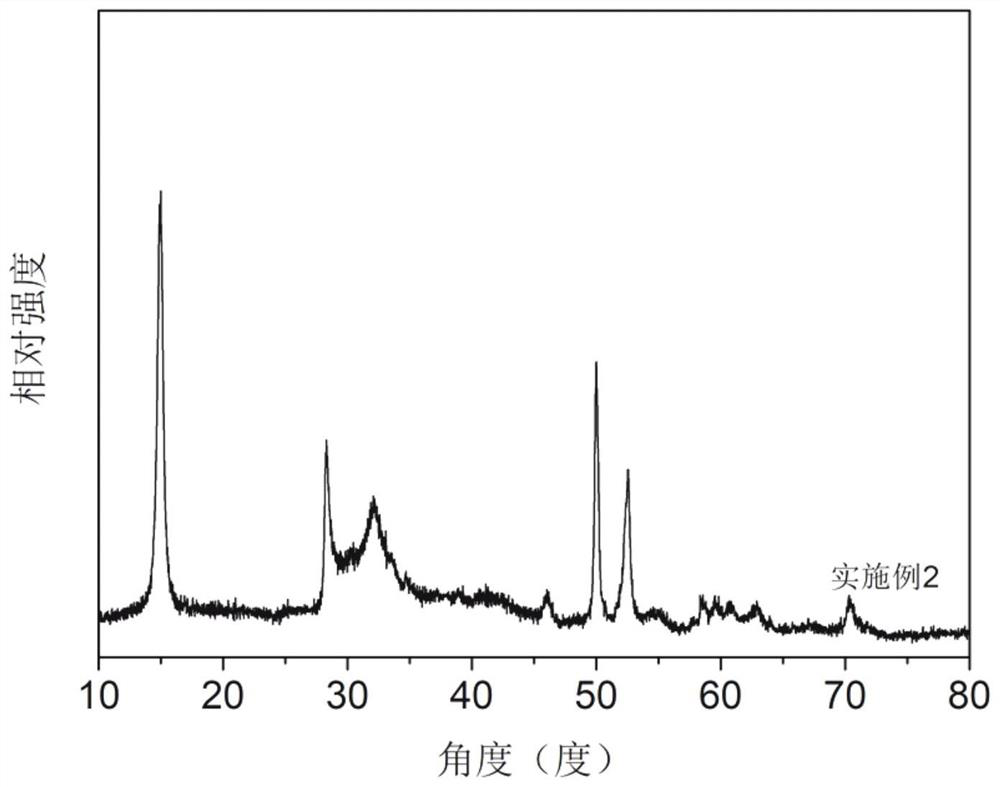

Embodiment 2

[0020] SnCl 4 , ethylenediamine, thiourea, and water are mixed according to the mass ratio of 1:2:4:60, placed in a hydrothermal reaction kettle for hydrothermal reaction, the hydrothermal reaction temperature is 200 ° C, and the constant temperature time is 12 hours; the hydrothermal reaction The solid-liquid mixture after the reaction was subjected to solid-liquid centrifugation, the liquid product was poured out, the solid product was taken out, washed with deionized water for 3 times, and then dried at 80°C for 8 hours; the dried product was ground into powder to obtain two Dimensional nanosheet SnS 2 ; the above two-dimensional nanosheet SnS 2 , H 8 MON 2 o 4 , thioacetamide, sodium dodecylbenzenesulfonate and water are mixed according to the mass ratio of 10:2:4:4:50 to form a precursor solution, which is placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 200°C, the constant temperature time is 30 hours; the ...

Embodiment 3

[0023] SnCl 4 , ethylenediamine, thiourea, and water are mixed according to the mass ratio of 1:1:3:60, placed in a hydrothermal reaction kettle for hydrothermal reaction, the hydrothermal reaction temperature is 180 ° C, and the constant temperature time is 10 hours; the hydrothermal reaction The solid-liquid mixture after the reaction was subjected to solid-liquid centrifugation, the liquid product was poured out, the solid product was taken out, washed with deionized water for 3 times, and then dried at 80°C for 6 hours; the dried product was ground into powder to obtain two Dimensional nanosheet SnS 2 ; the above two-dimensional nanosheet SnS 2 , H 8 MON 2 o 4, thioacetamide, sodium dodecylbenzenesulfonate and water are mixed according to the mass ratio of 10:2:3:3:50 to form a precursor solution, which is placed in a hydrothermal reaction kettle for hydrothermal reaction. The hydrothermal reaction temperature is 180°C, the constant temperature time is 24 hours; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com