Mask forming machine

A molding machine and mask technology, applied in sewing tools, other household appliances, protective clothing, etc., can solve problems such as reducing production efficiency, and achieve the effect of improving production efficiency, ensuring normal operation, and improving cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

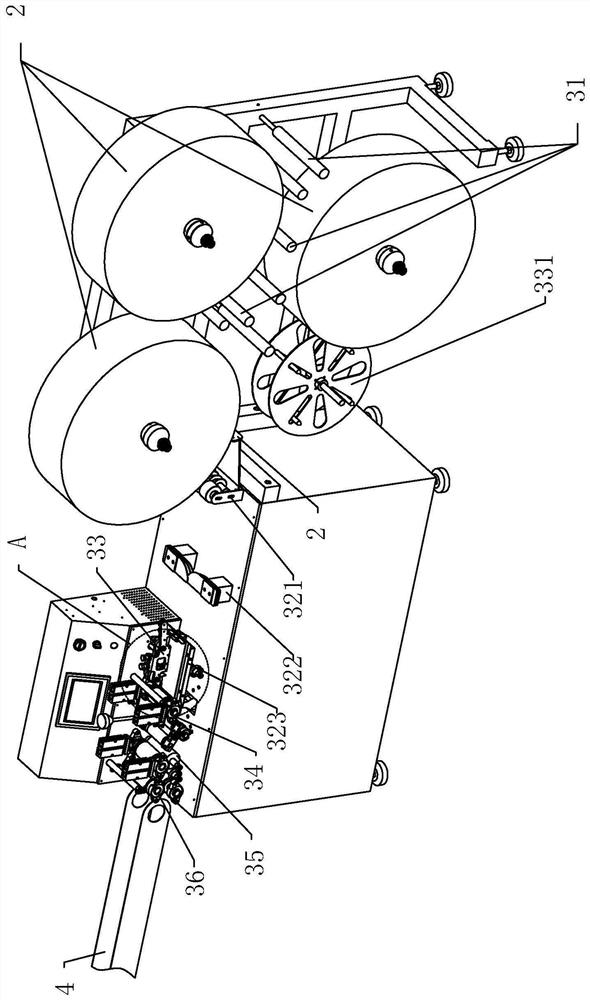

[0029] refer to Figure 1 to Figure 7 , This embodiment provides a mask forming machine, including a frame 1, a non-woven fabric unwinding device 2, a forming device and an output device 4 sequentially arranged on the frame 1 according to the processing sequence.

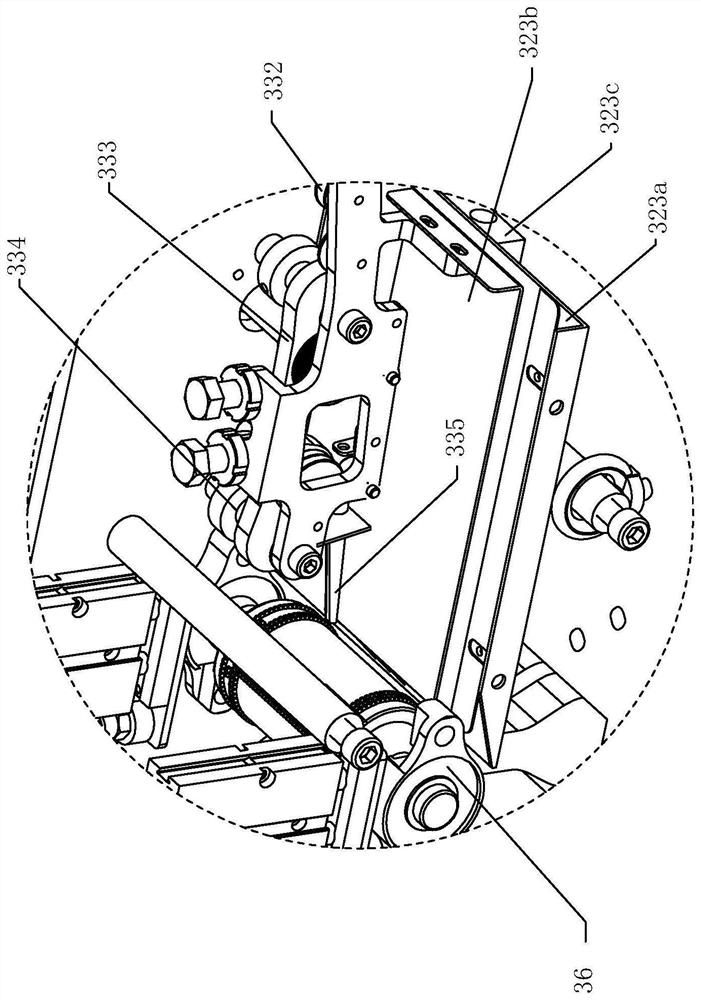

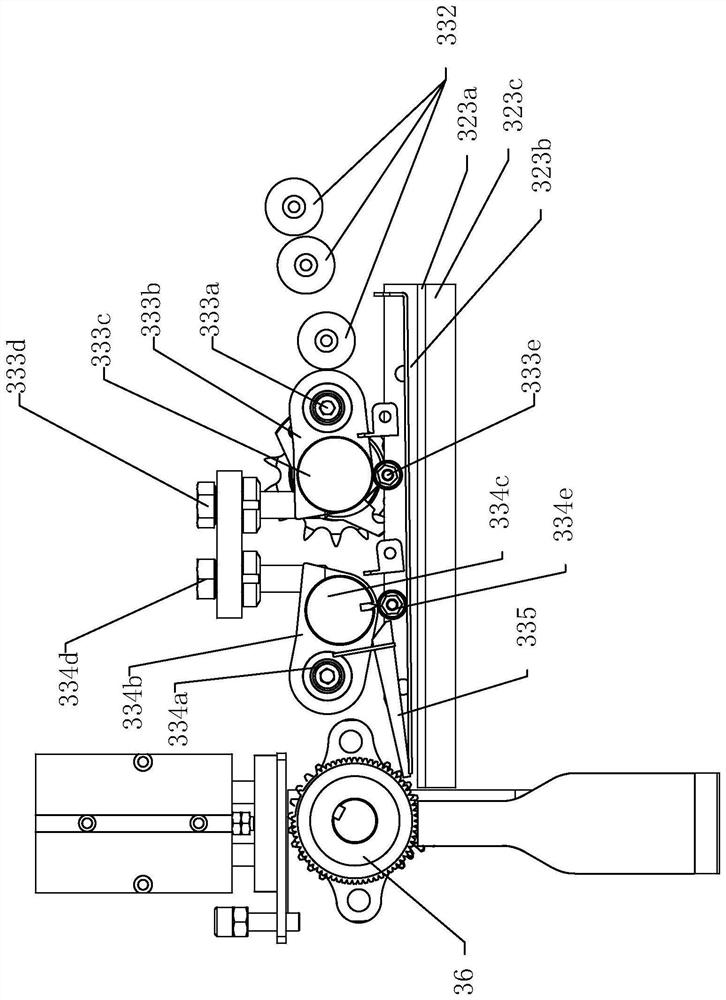

[0030] Wherein, the non-woven fabric unwinding device 2 is an existing conventional structure, and will not be repeated here. The forming device includes a first guide assembly 31, a folding assembly, a nose bridge adding assembly 33, Composite roller assembly 34, the second guide assembly 35 and slitting assembly 36, described first guide assembly 31 is combined by a plurality of guide rollers, and each described guide roller all adopts existing conventional structure, and described folding assembly includes along feeding The creasing roller 321, the folding frame 322 and the shaping mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com