Steel-based alloy composite piece

A technology of composite parts and base alloys, applied in the field of steel alloys, can solve problems affecting product quality, cutting difficulties, disconnection, etc., and achieve the effects of good adhesion, material saving, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

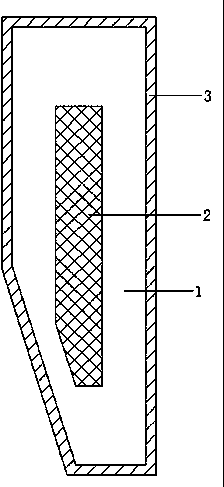

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises a steel element 1, the inside of which is provided with a closed hollow steel mold 2, and the outer surface of steel element 1 is provided with an alloy layer 3; the appearance of said hollow steel mold 2 is similar to that of steel The shapes of the elements 1 correspond to each other; the steel elements 1 are ordinary steel.

[0015] The production method of above-mentioned steel base alloy composite part is:

[0016] Water glass and quartz sand are used for pressure injection inside the production mold to make a mold that meets the specifications. The alloy layer 2 is coated on the inner surface of the mold, and the hollow steel mold 2 is placed in the cavity of the mold, and then the molten steel element 1 is placed The mixed raw material liquid is poured into the mould, the raw material liquid covers the hollow steel mold, and after cooling, a steel element 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com