Soft PE non-woven fabric applied to hygienic products and manufacturing method of soft PE non-woven fabric

A technology for hygiene products and manufacturing methods, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as increased frictional resistance, poor spinnability, and poor composite effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

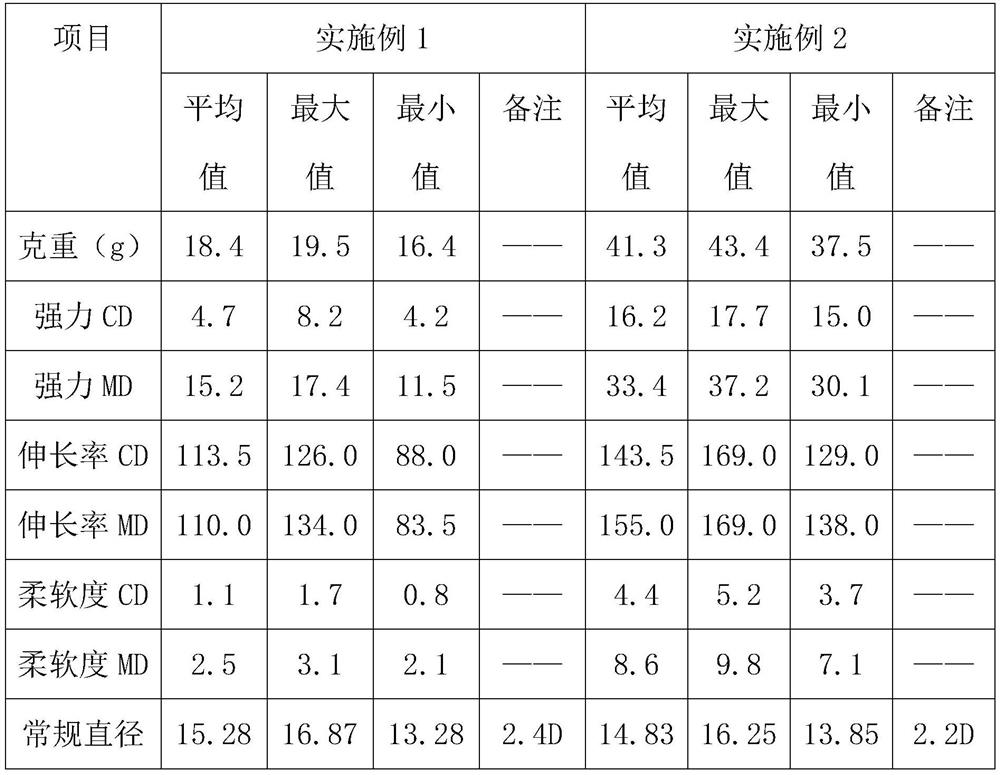

Embodiment 1

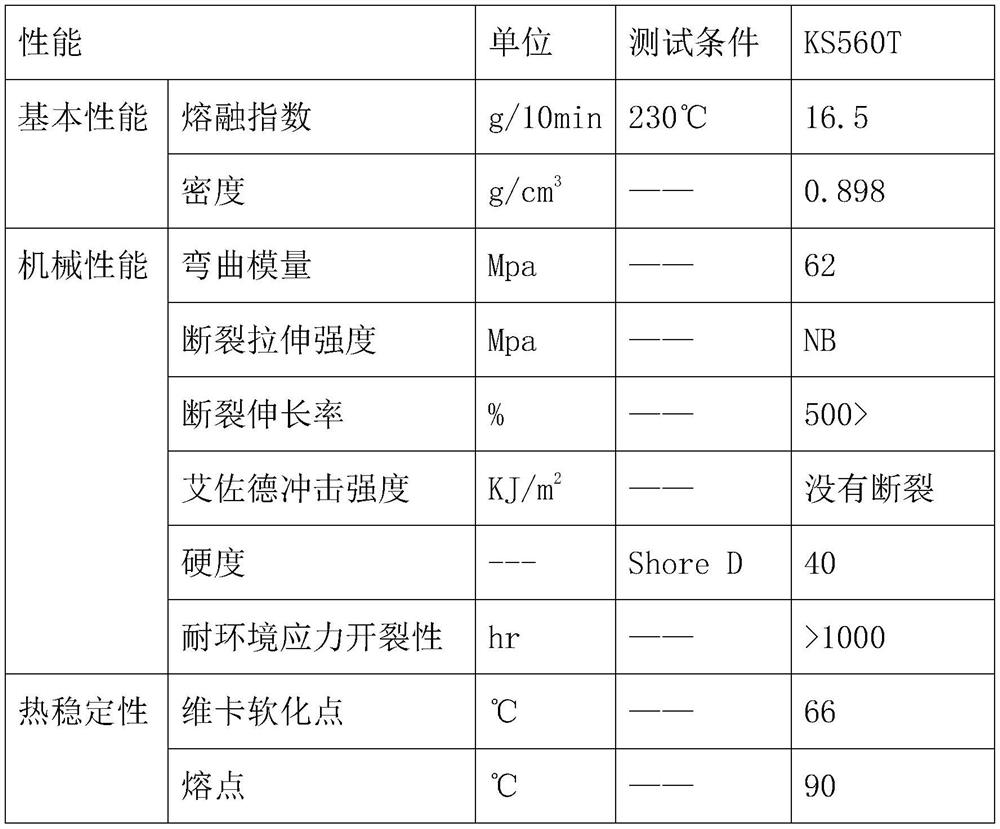

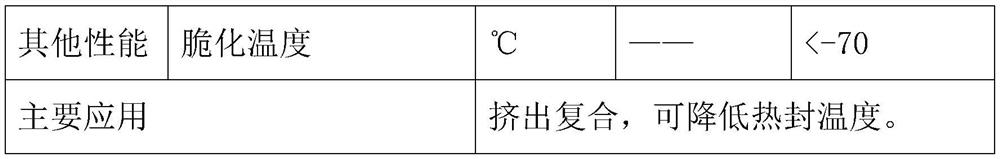

[0029] A soft PE non-woven fabric used in hygiene products, including a soft layer and a composite layer, the soft layer is made of low-melting PE raw material, the composite layer is made of PP raw material and adhesive material, the PE raw material is KS560T, the The PP raw material is H39S-2, and the binder is OMBM.

[0030] A kind of manufacturing method of the soft PE non-woven fabric that is applied to hygienic article, adopts following steps to operate:

[0031] S1. Add low-melting PE raw material KS560T into the first die head A, add conventional PP raw material H39S-2 and binder OMBM into the second die head B at a ratio of 1:1, and then mix and stir to form a slurry material;

[0032] S2. Extrude and melt the mixed and stirred slurry into the screw through the feeding system to obtain a hot melt;

[0033] S3, filtering, metering and distributing the hot melt at a certain temperature and a certain pressure;

Embodiment 2

[0049] A soft PE non-woven fabric used in hygiene products, including a soft layer and a composite layer, the soft layer is made of low-melting PE raw material, the composite layer is made of PP raw material and adhesive material, the PE raw material is KS560T, the The PP raw material is H39S-2, and the binder is OMBM.

[0050] A kind of manufacturing method of the soft PE non-woven fabric that is applied to hygienic article, adopts following steps to operate:

[0051] S1. Add low-melting PE raw material KS560T into the first die head A, add conventional PP raw material H39S-2 and binder OMBM into the second die head B at a ratio of 1:1, and then mix and stir to form a slurry material;

[0052] S2. Extrude and melt the mixed and stirred slurry into the screw through the feeding system to obtain a hot melt;

[0053] S3, filtering, metering and distributing the hot melt at a certain temperature and a certain pressure;

[0054] S4. Spinning the distributed and metered hot melt...

Embodiment 3

[0071] A soft PE non-woven fabric used in hygiene products, including a soft layer and a composite layer, the soft layer is made of low-melting PE raw material, the composite layer is made of PP raw material and adhesive material, the PE raw material is KS560T, the The PP raw material is H39S-2, and the binder is OMBM.

[0072] A kind of manufacturing method of the soft PE non-woven fabric that is applied to hygienic article, adopts following steps to operate:

[0073] S1. Add the low melting point PE raw material KS560T into the first die head, add the conventional PP raw material H39S-2 and the binder OMBM into the second die head according to the ratio of 1:1, and then make it mix and stir to form a slurry;

[0074] S2. Extrude and melt the mixed and stirred slurry into the screw through the feeding system to obtain a hot melt;

[0075] S3, filtering, metering and distributing the hot melt at a certain temperature and a certain pressure;

[0076] S4. Spinning the distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com