A kind of ultrafine nano-silicon/carbon composite material and its preparation method and application

A carbon composite material, ultra-fine nanotechnology, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve the problems of uneven dispersion and easy agglomeration of nano-silicon-based particles and carbon-based materials, and improve cycle stability , avoid agglomeration, and ensure the effect of compound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

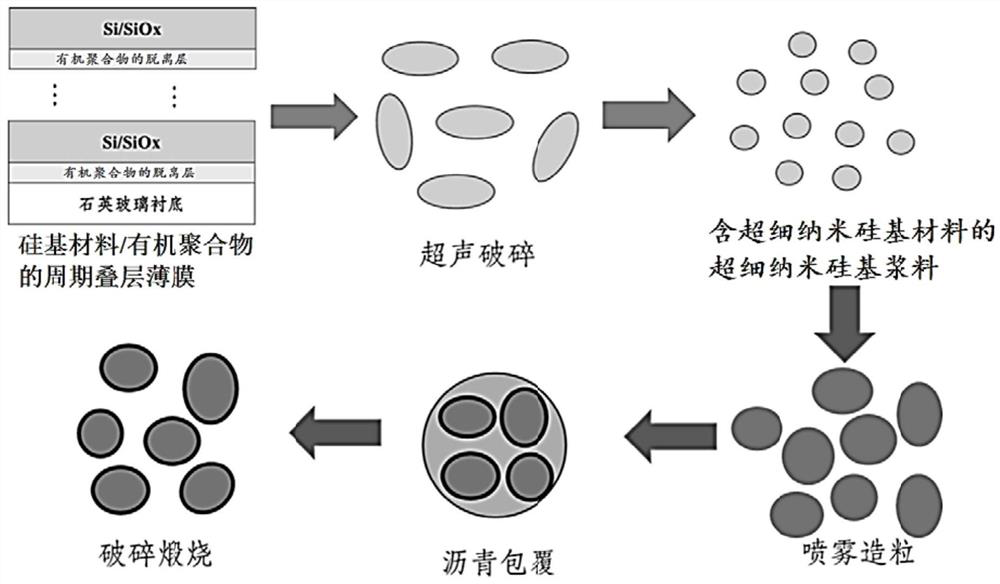

[0030] Preferably, wherein the preparation method of ultrafine nano-silicon-based slurry comprises the following steps:

[0031] Step S1, using electron beam evaporation technology to prepare a periodic laminated film of nano-Si or SiOx / organic polymer, and finally reach a certain thickness;

[0032] Step S2, put the silicon-based material / organic polymer periodic laminated film with the substrate into alcohol, and use 1-2kW ultrasonic treatment for 10-20 minutes to perform ultrasonic crushing, so that the silicon-based material / organic polymer periodic laminated film The film is peeled off from the substrate and dispersed in alcohol to obtain the primary slurry of silicon-based materials;

[0033]Step S3, adding a certain amount of alcohol to the silicon-based material slurry after ultrasonication, adjusting the grinding slurry with a solid content of 5% to 8%, performing wet grinding for 1 to 2 hours, and grinding to a certain particle size, that is Obtain silicon-based slu...

Embodiment 1

[0041] Step S1, using electron beam evaporation technology to prepare a periodic laminated film of Si / organic polymer, wherein the silicon evaporation source uses intrinsic silicon particles with a purity of 3N or more, and the release layer of the organic polymer uses polyvinyl alcohol as the evaporation material, nanometer The thickness of Si is 30nm, the thickness of the organic release layer is 20nm, and a laminated coating material with a thickness of up to 40 μm is formed by alternate coating.

[0042] Step S2, put the coating material with the substrate into alcohol, and perform ultrasonic crushing, the ultrasonic power is 1kW, and the time is 10min;

[0043] Step S3, adding alcohol to the ultrasonicated slurry, adjusting the solid content to 5%, performing wet grinding for 1 hour, and grinding until the D50 of the ultrafine nano-silicon-based material contained therein is 40nm, to obtain an ultra-fine nano-silicon-based slurry ;

[0044] Step S4, adding 30% of high-te...

Embodiment 2

[0048] Step S1, using electron beam evaporation technology to prepare a periodic laminated film of SiOx / organic polymer release layer, wherein the evaporation material is SiO, the release layer of the organic polymer uses polyvinyl alcohol as the evaporation material, the thickness of nano-SiOx is 60nm, organic The thickness of the release layer is 20nm, and a laminated coating material with a thickness of up to 100 μm is formed by alternate coating.

[0049] Step S2, put the coating material with the substrate into alcohol, and perform ultrasonic crushing, the ultrasonic power is 1kW, and the time is 10min;

[0050] Step S3, adding alcohol to the ultrasonicated slurry, adjusting the solid content to 5%, and performing wet grinding until the D50 of the ultrafine nano-silicon-based material contained therein is 70nm to obtain an ultra-fine nano-silicon-based slurry;

[0051] Step S4, adding 30% high-temperature petroleum pitch and 17% PVP to the ultrafine nano-silicon-based slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com