A method of manufacturing a resistive sound-absorbing panel

A manufacturing method and technology for sound-absorbing panels, which are applied to the manufacturing of resistive sound-absorbing panels and the manufacturing field of sound-absorbing panels, can solve the problems of resistive sound-absorbing panels with multiple layers, difficulty in continuous automatic production, and difficulty in realizing product standardization, etc. Low production efficiency, standardized and automated flexible production, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The resistive sound-absorbing board provided by the present invention generally includes metal sheets, non-woven fabrics, and acoustic material plates. Sheets made of fine glass wool or rock wool.

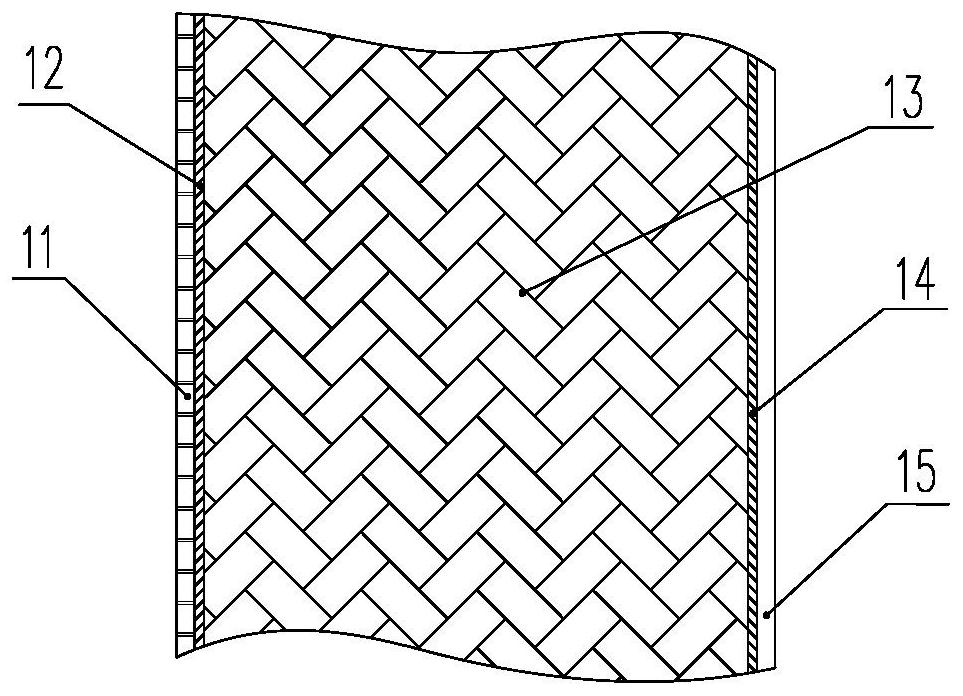

[0040] Such as figure 1 A schematic diagram of the sound-absorbing structure of a resistive sound-absorbing panel provided in an embodiment of the present invention is shown in the following figure:

[0041] A sound-absorbing structure of a resistive sound-absorbing plate provided in this embodiment sequentially includes a thin metal plate I11, an outer non-woven fabric 12, an acoustic material plate 13, an inner non-woven fabric 14, and a thin metal plate II15.

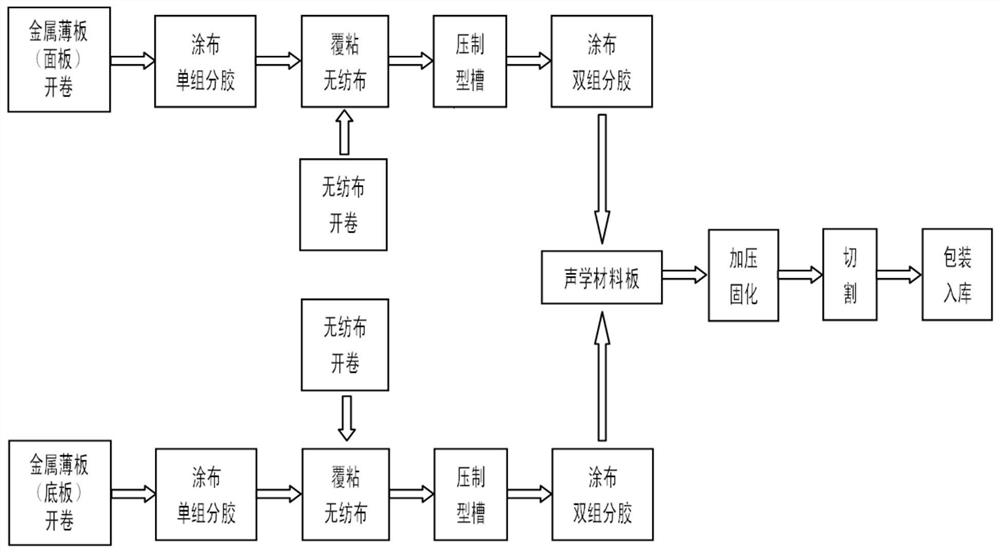

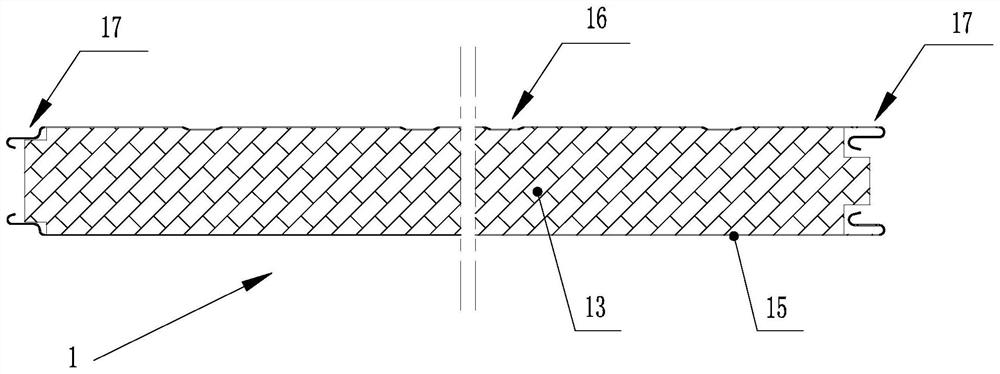

[0042] Such as figure 2 Schematic flow chart of the method for manufacturing resistive sound-absorbing panels provided by the invention, image 3 The schematic diagram of the cross-sectional structure of the resistive sound-absorbing plate provided by the present invention is as follows:

[0043] A method for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com