Cup-shaped noise reduction and sound absorption member

A noise reduction and sound absorption technology, which is applied in the direction of noise absorption devices and buildings, can solve the problems of not causing sound barriers, and achieve the effects of enhancing sound absorption capacity, achieving impedance matching, and efficient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

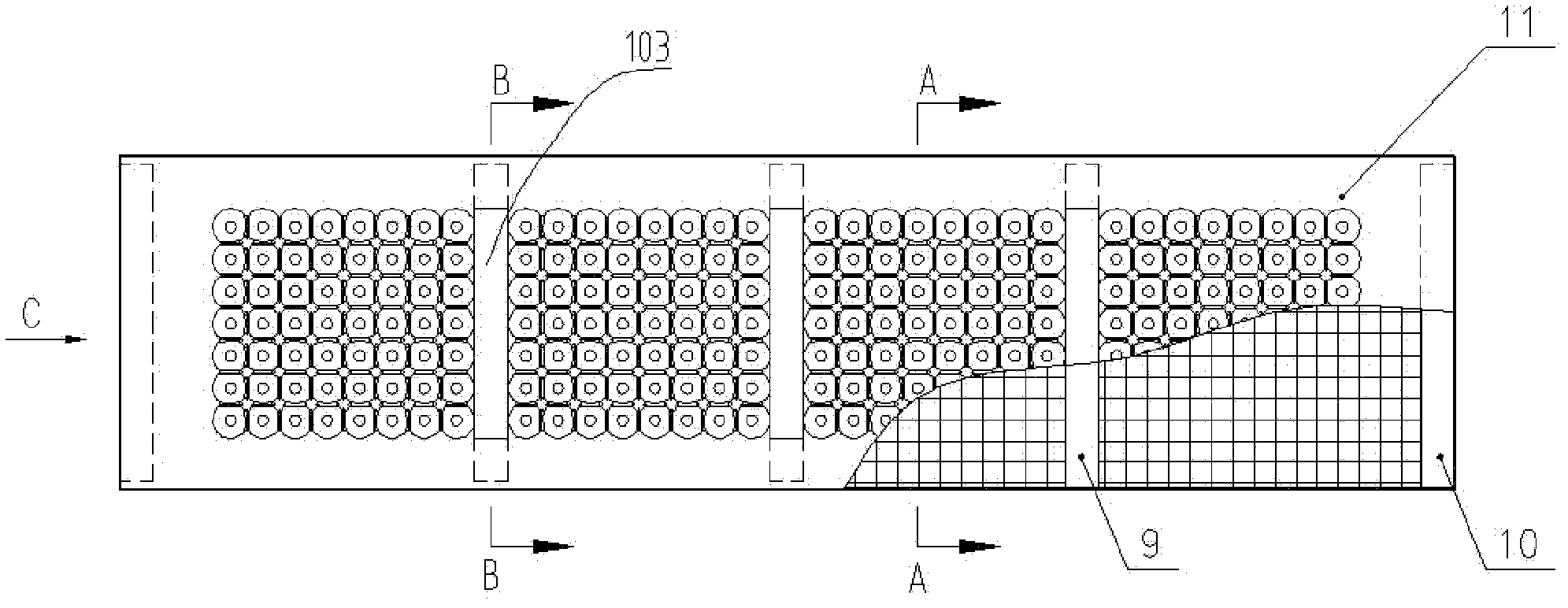

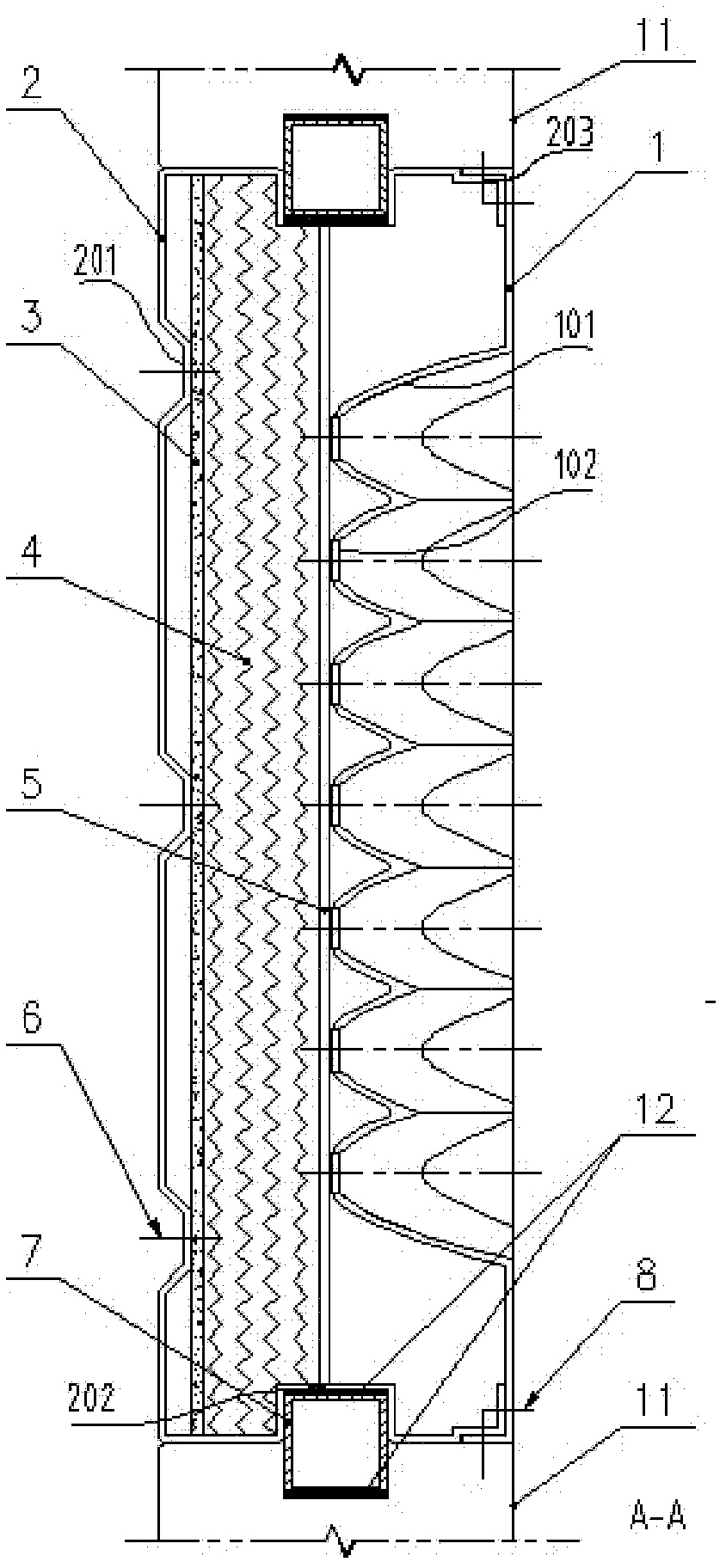

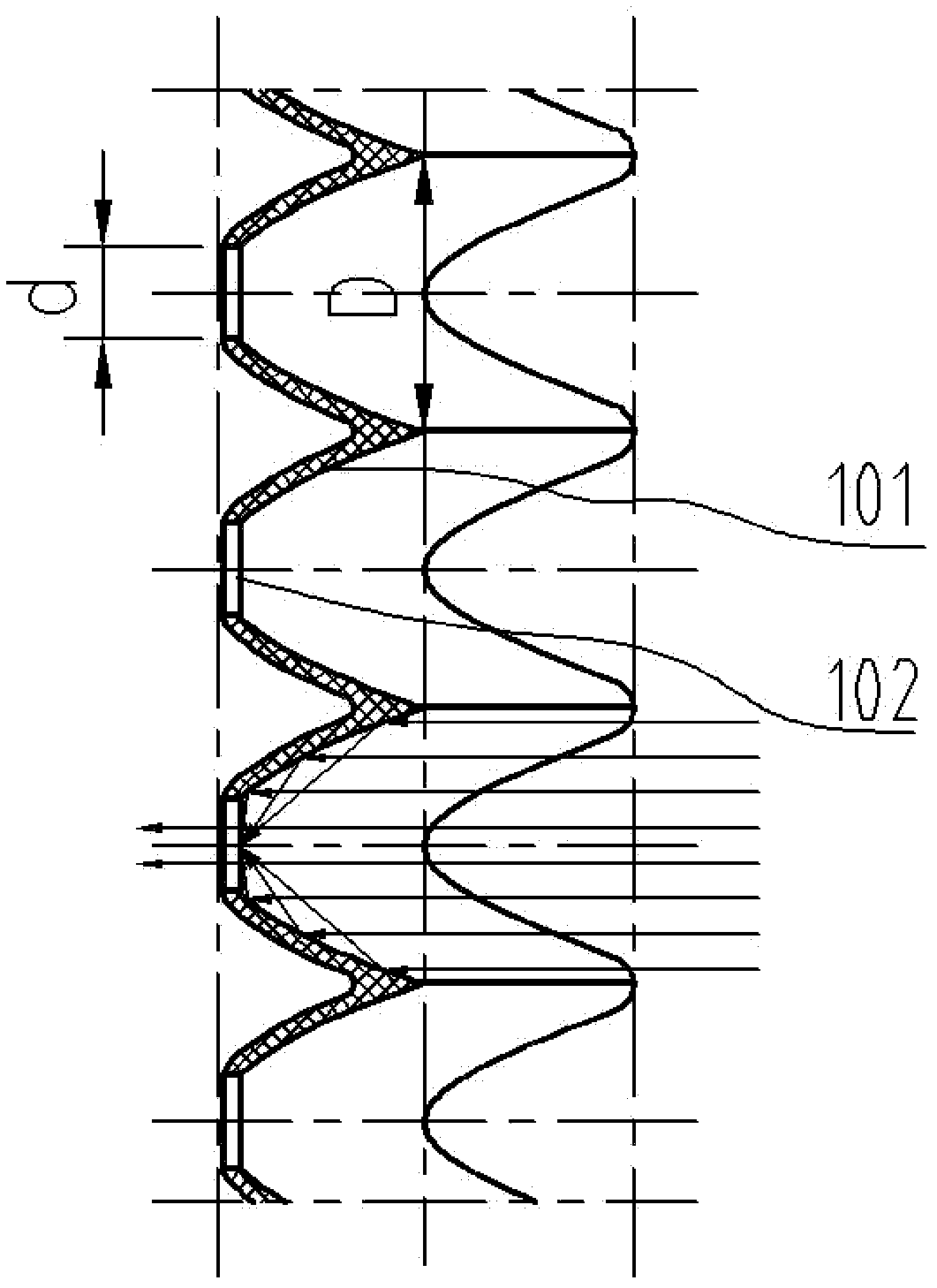

[0034] Such as figure 1 , figure 2 As shown, the cup-shaped noise-reducing and sound-absorbing member of the present invention is composed of several cup-shaped noise-reducing and sound-absorbing member units 11, and each cup-shaped noise-reducing and sound-absorbing member unit 11 includes a panel 1, a backboard 2, a sound insulation board 3. Sound-absorbing cotton 4, gauze 5, support frame 9 and end plate 10; wherein the panel 1 is placed facing the railway track, and is composed of several rectangular arrays and trapezoidal transverse ribs 103, each rectangular array is composed of several paraboloid shaped acoustic bars. The reflective cups 101 of the structure are evenly distributed, and the two groups of arrays are connected by vertically arranged transverse ribs 103. A diffraction hole 102 with the same radius as the focal plane of the parabolic surface is opened at the bottom of each reflective cup 101; the cross section of the back plate 2 is The opening is rectangu...

Embodiment 2

[0042] The structure and installation method of this embodiment are the same as those of the first embodiment, the difference lies in that the specifications and dimensions of the cup-shaped noise-reducing and sound-absorbing component unit 11 and the column 13 are different from those of the first embodiment. The size of the cup-shaped noise-reducing and sound-absorbing component unit 11 of this embodiment is 3940*500*140mm, and the spacing of the columns 13 is 4000mm; the parabolic equation of the busbar of the reflecting cup 101 is y 2 =15x, the parameters of each element are the radius r=7.5mm of the focal plane circle, the aperture=15mm of the diffraction hole 102, the diameter of the tangent circle is 50mm, the center of the circle is 47.1mm apart from the position distance of the apex, and the radius R of the largest circle is 1 =27mm; the rectangular connecting groove 202 at the upper and lower ends of the backboard 2 is 80mm wide and 23mm deep, and the specification of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com