Quick rubber mixing and coating gun

A kind of glue mixing and gluing gun, fast technology, applied in the field of gluing guns, can solve the problems of inconvenient cleaning, waste of glue drying, endless use, etc., to achieve the effects of convenient operation, rapid glue mixing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

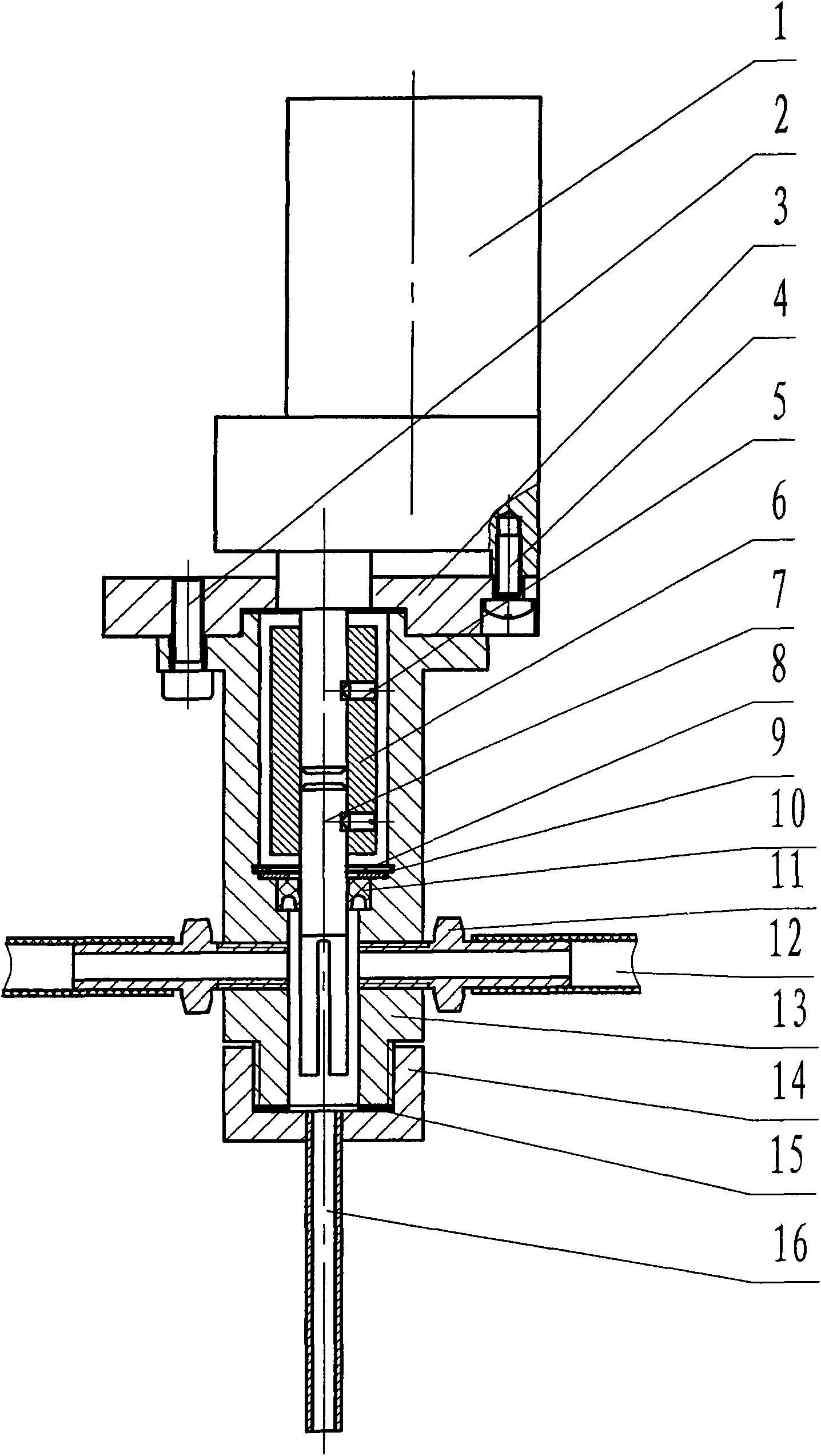

[0015] refer to figure 1 , a fast glue mixing glue gun, comprising: a motor 1 and a connection plate 3, the motor 1 is arranged on one side of the connection plate 3, and the other side of the connection plate 3 is connected with a glue mixing chamber 13, in the glue mixing chamber There are two or more glue inlets on the side of 13. There are joints 11 on the glue inlets and rubber hoses 12 are connected. The rubber hose 16 can be fixed on the nut 14 by means of riveting or welding. The output shaft of the motor 1 is connected with a shaft blade 7, which is located in the rubber mixing chamber 13, and a seal is installed on the shaft blade 7 and the rubber mixing chamber 13. Ring 10, and seal ring 10 with washer 9 and back-up ring 8. In this embodiment: the connecting plate 3 is connected with the moving parts of the glue applicator. When working, the glue supply system transports two or more kinds of glue into the small glue mixing chamber 13, and the shaft blade 7 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com