Nanometer modified capsule material for high-altitude aerostat and preparation method thereof

A nano-modification and nano-material technology, which is applied in the field of aerospace materials, can solve the problems of further improvement of comprehensive performance, achieve excellent sunlight reflection performance, easy operation and control, and small absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

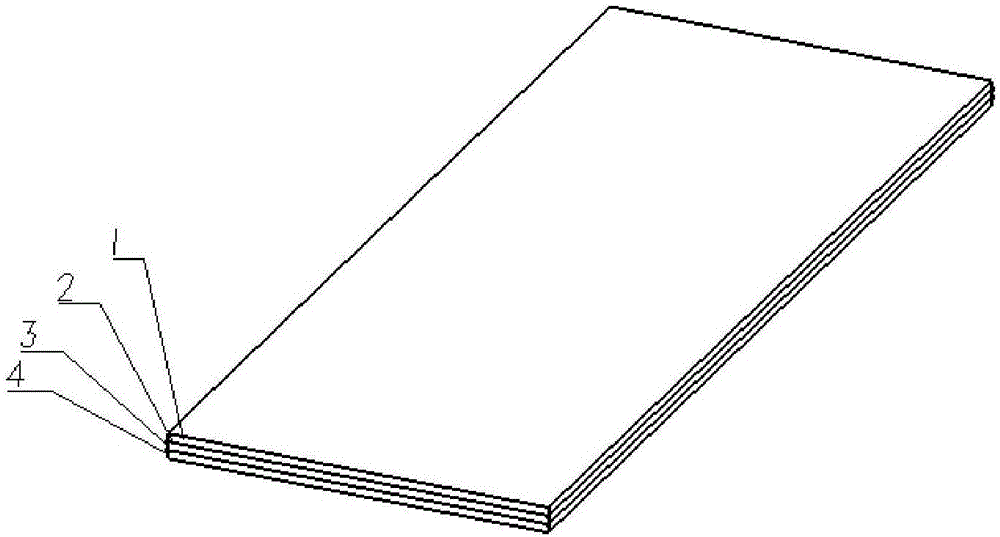

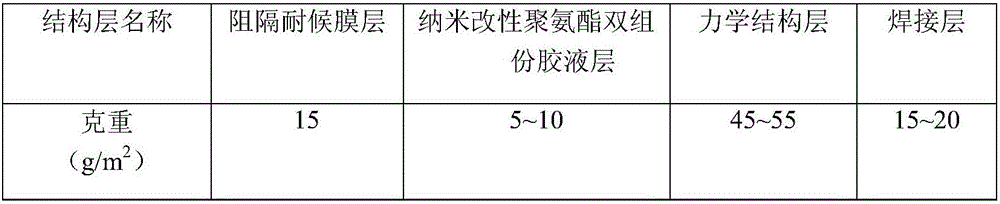

[0023] Such as figure 1 As shown, the capsule material of the present invention includes a barrier weather-resistant film layer 1, a nano-modified glue layer 2, a mechanical structure layer 3 and a nano-modified welding glue layer 4, and the mechanical structure layer 3 is a PBO high-strength fiber plain weave cloth , one side of the mechanical structure layer 3 is connected to the barrier weather-resistant film layer 1 through the nano-modified glue layer 2, the other side of the mechanical structure layer 3 is connected to the nano-modified welding glue layer 4, and the nano-modified welding glue layer 4 is the polyurethane hot-melt adhesive that adds nanometer material.

[0024] The barrier and weather-resistant film layer 1 is a surface-treated single-layer double-sided aluminized TPU film with a thickness of 10-20 μm.

[0025] The nano-modified glue layer 2 is polyurethane glue added with nanomaterials, and the added amount of nanomaterials is 0.5%-1%.

[0026] The numb...

Embodiment 2

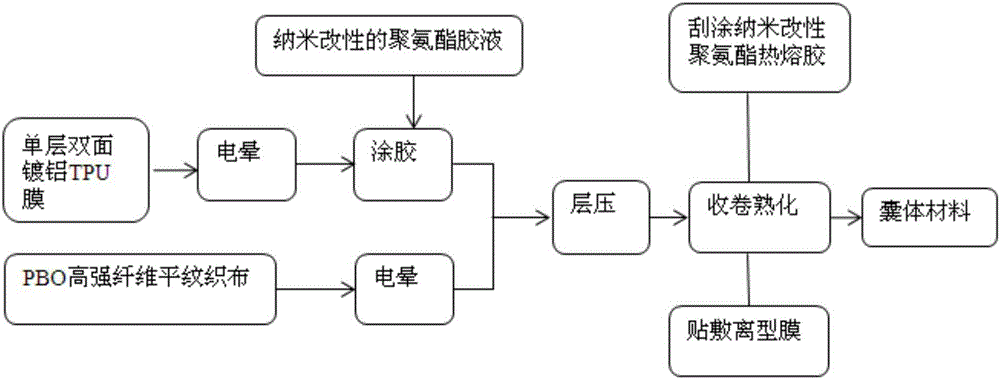

[0030] Such as figure 2 Shown, the preparation method of capsule material of the present invention comprises the following steps:

[0031] Step 1: Glue and compound the single-layer double-sided aluminum-coated TPU film through the laminating machine. After corona, uniformly coat nano-modified polyurethane glue, and corona-treated PBO high-strength fiber plain weave cloth Bonding, after compounding, winding, aging at 80°C to 100°C for one day to obtain a fully matured composite cloth;

[0032] Step 2: Scrape-coat the surface of the composite cloth obtained in Step 1 with polyurethane hot-melt adhesive added with nanomaterials, dry in a long drying tunnel, attach a release film, and roll and mature to obtain the capsule material.

[0033] In this embodiment, TPU double-sided aluminized film is used for compounding with PBO high-strength fiber plain weave cloth, and a nano-modified polyurethane two-component adhesive is used to improve the rubbing resistance of the capsule mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com