Patents

Literature

149 results about "Aerospace materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerospace materials are materials, frequently metal alloys, that have either been developed for, or have come to prominence through, their use for aerospace purposes. These uses often require exceptional performance, strength or heat resistance, even at the cost of considerable expense in their production or machining. Others are chosen for their long-term reliability in this safety-conscious field, particularly for their resistance to fatigue.

Method and apparatus for pressure adaptive morphing structure

ActiveUS20110038727A1Altered stiffnessMaximize efficiencyPropellersAircraft stabilisationMorphingDifferential pressure

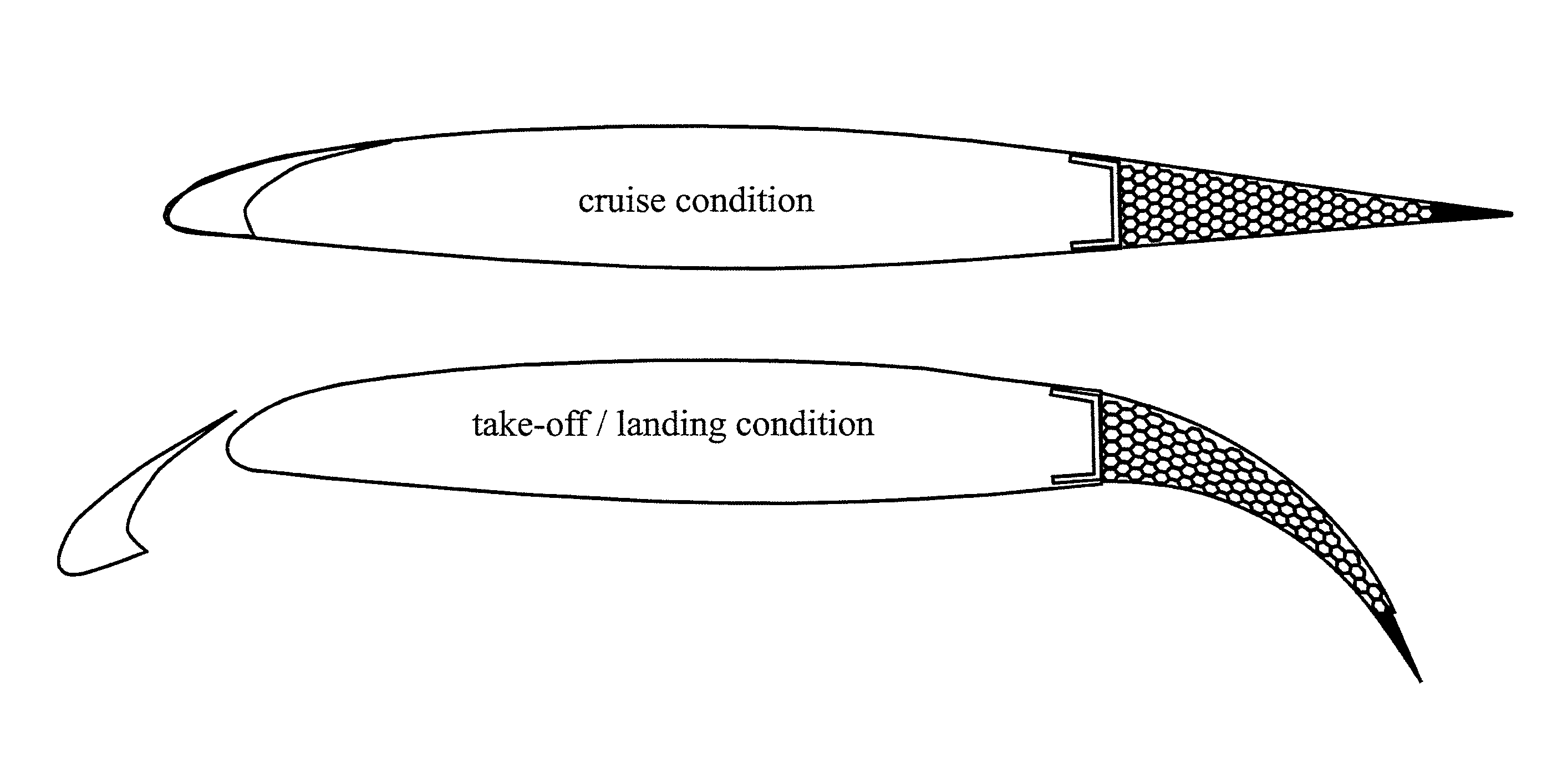

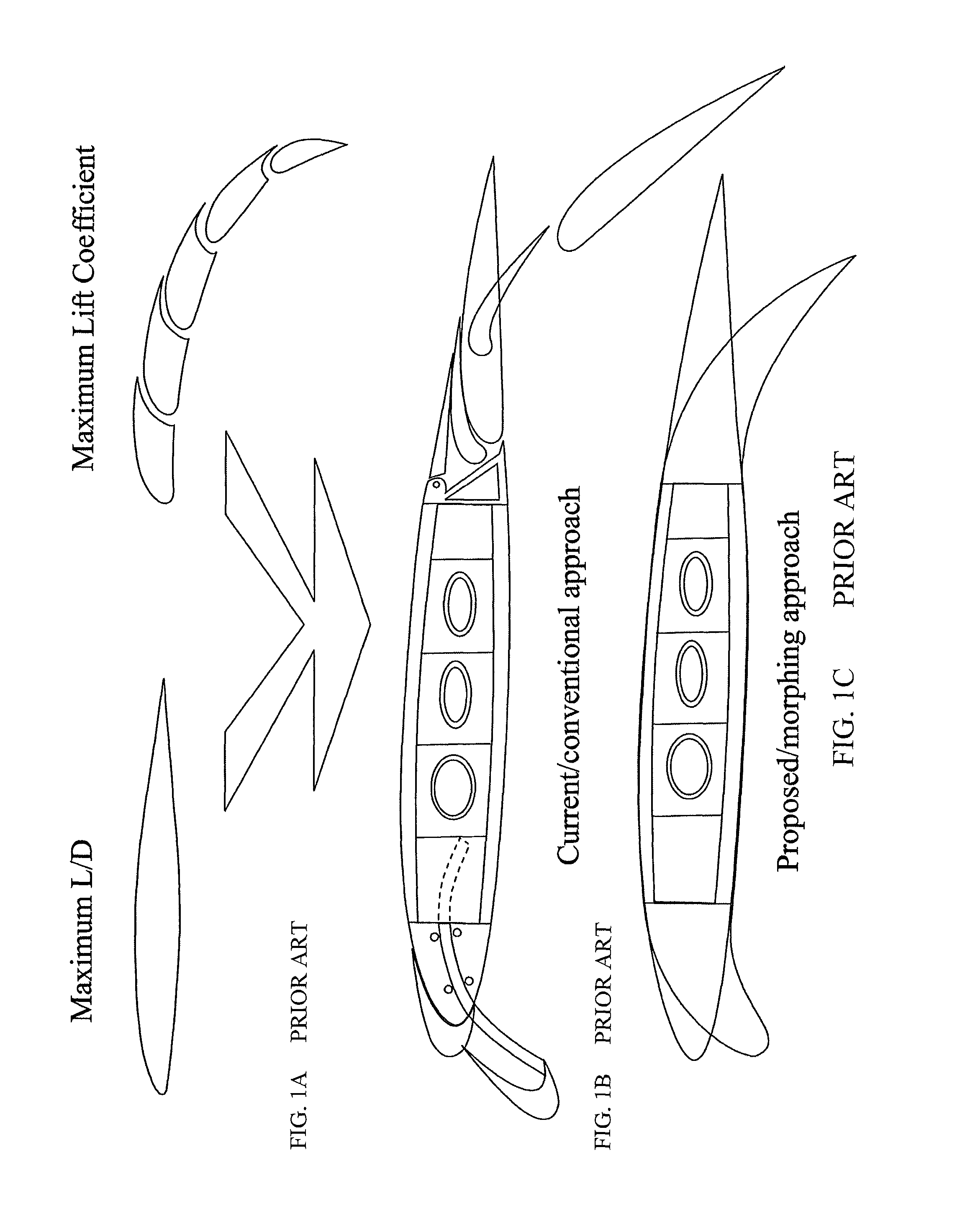

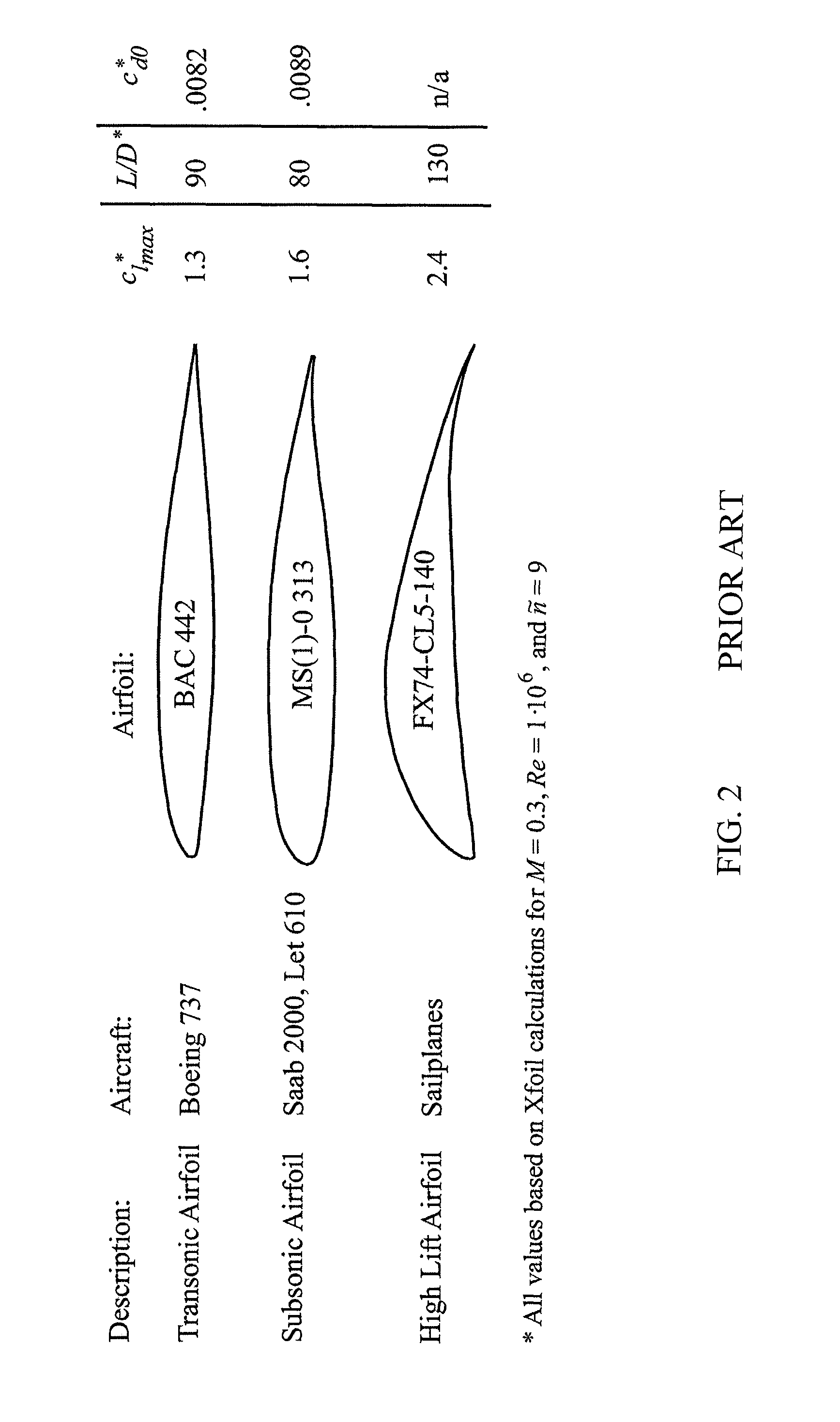

A method and apparatus for a novel adaptive aerostructure is presented that relies on certified aerospace materials and can therefore be applied in conventional passenger aircraft. This structure consists of a honeycomb material which cells extend over a significant length perpendicular to the plane of the cells. Each of the cells contains an inelastic pouch (or bladder) that forms a circular tube when the cell forms a perfect hexagon. By changing the cell differential pressure (CDP) the stiffness of the honeycomb can be altered. Using an external force or the elastic force within the honeycomb material, the honeycomb can be deformed such that the cells deviate from their perfect-hexagonal shape. It can be shown that by increasing the CDP, the structure eventually returns to a perfect hexagon. By doing so, a fully embedded pneumatic actuator is created that can perform work and substitute conventional low-bandwidth flight control actuators. It is shown that two approaches can be taken to regulate the stiffness of this embedded actuator.

Owner:UNIVERSITY OF KANSAS

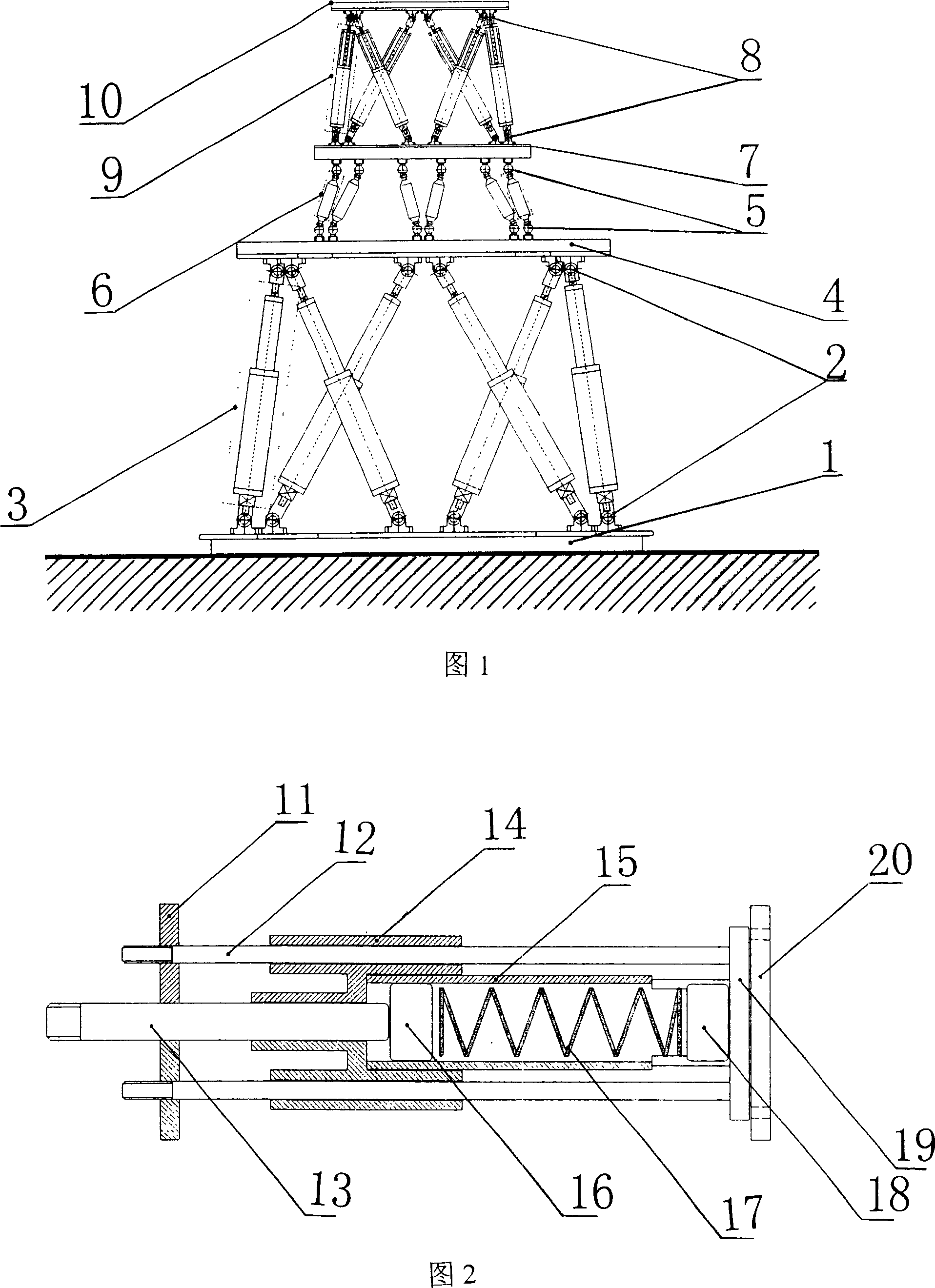

Master-slave mode two-in-parallel twelve degree of freedom generalized force adjustment loading mechanism

InactiveCN101016971AImprove linearityRealize compound vibration dampingUsing mechanical meansStands/trestlesAviationEngineering

The invention discloses a parallel twelve-freedom loading device, used in spatial loading test and fatigue test on aviation material, comprising a Stewart active parallel six-freedom loading device, a SPS six-dimension force / torque sensor and a SPS inactive parallel six-freedom adjuster, wherein the Stewart active parallel six-freedom loading device simulates the spatial motion, the active and inactive platforms of inactive parallel six-freedom adjuster follows to operate and draw or compress the bidirectional isomorphism spring device, to test wide force dynamical load, to supply high accuracy and better reliability to the six-freedom wide force dynamic synchronous loading system, to be used in spatial-ground semi-physical simulation test or the like.

Owner:ZHEJIANG UNIV

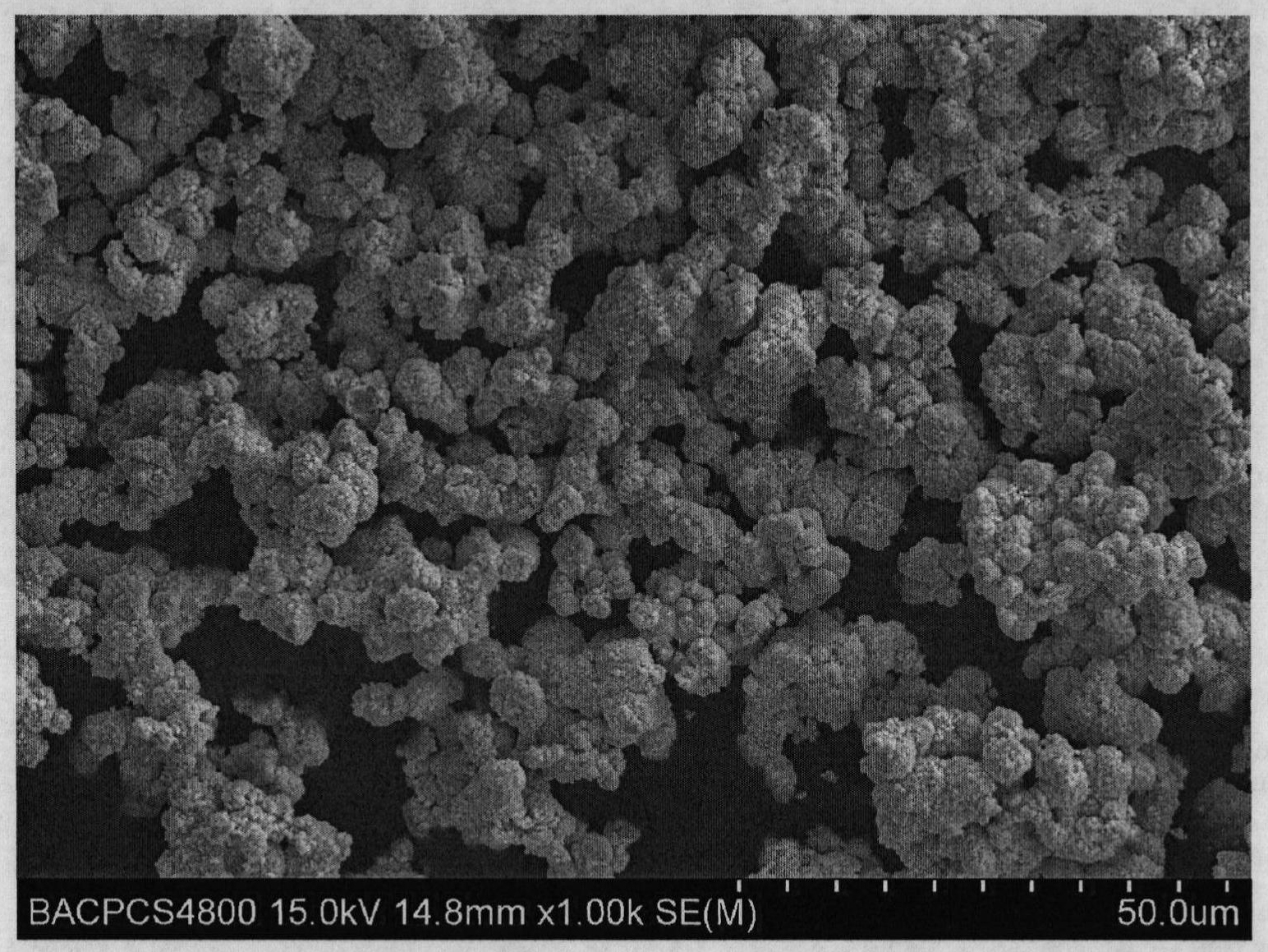

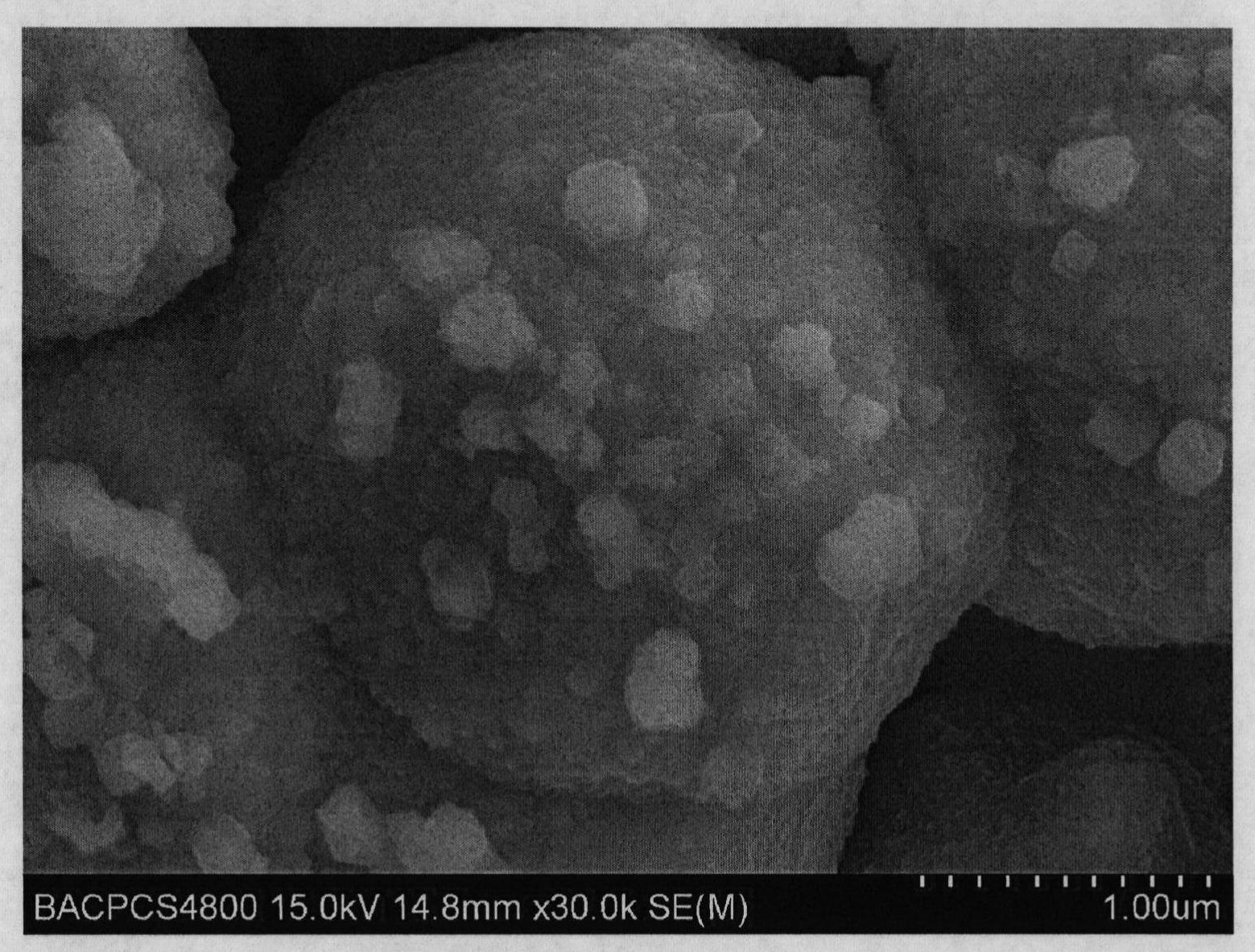

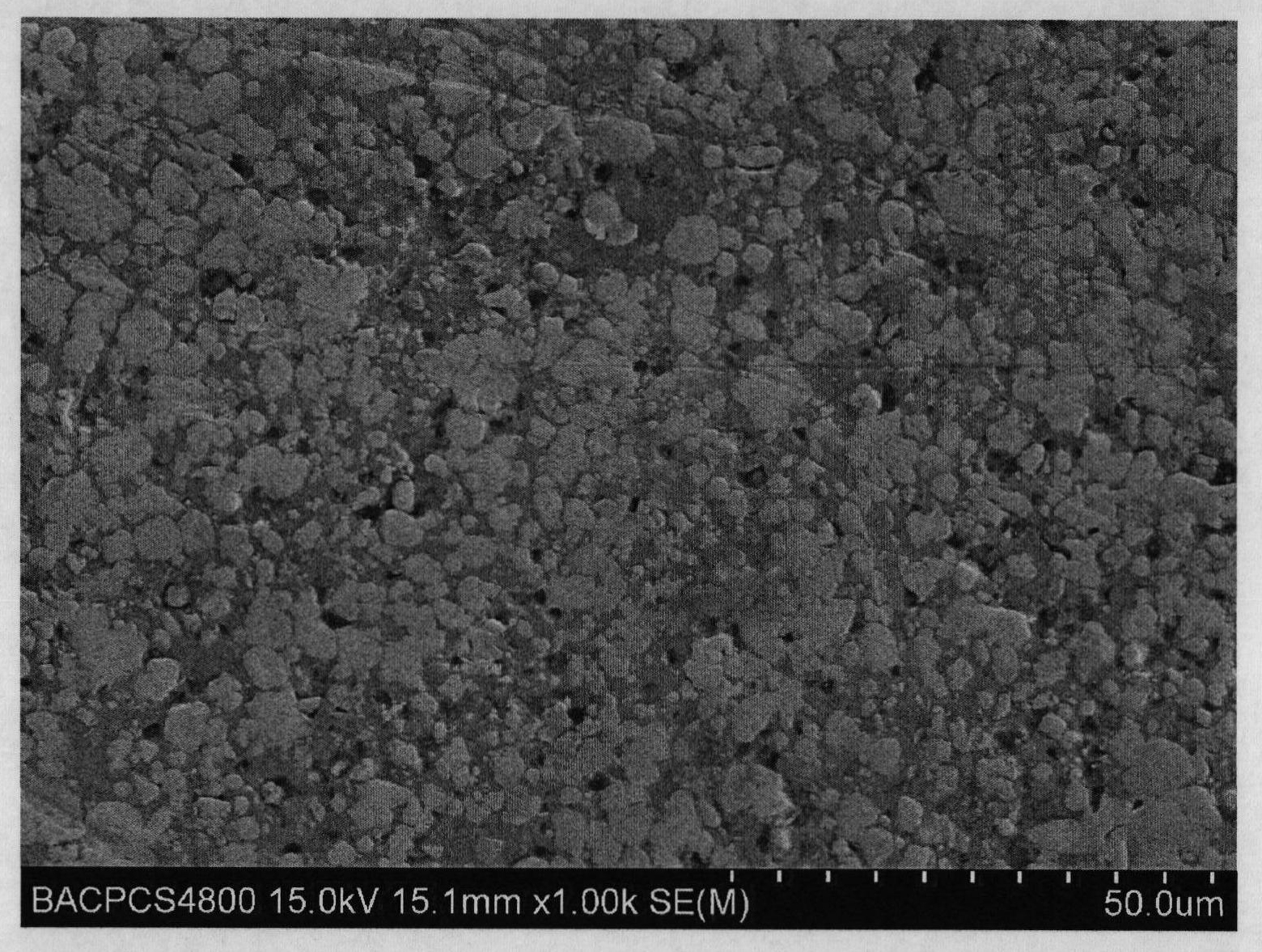

Cellulose/titanium dioxide/silica aerogel and preparation method thereof

ActiveCN103203206AGood biocompatibilityGood flexibilityColloidal chemistry detailsThermal insulationSilica gel

The invention relates to a cellulose / titanium dioxide / silica aerogel and a preparation method thereof. The method comprises the steps such as cellulose sol preparation, nano-grade titanium dioxide surface loading, silica surface coating, curing, aging, hydrophobizing, bonding forming, drying treatment, and the like. According to the invention, nano-grade cellulose is adopted as a core, and is loaded with nano-grade titanium dioxide; a silica layer is coated; and the steps such as curing, aging, hydrophobizing, bonding forming, drying treatment, and the like are carried out, such that the cellulose / titanium dioxide / silica aerogel is obtained. The aerogel has the performances such as flexibility, high strength, bacterium resistance, ultraviolet resistance, odor-removing function, warm-keeping function, thermal insulation, and sound insulation. The aerogel can be widely applied in the fields such as thermal underwear, body armor, insulation materials, pressure-resistant materials, special coatings, aerospace materials, and the like.

Owner:SHANDONG CAYON TESTING TECH

Method and apparatus for pressure adaptive morphing structure

ActiveUS8366057B2Altered stiffnessMaximize efficiencyPropellersFlexible wall reciprocating enginesMorphingDifferential pressure

Owner:UNIVERSITY OF KANSAS

Method of preparing carbon fiber by using coal to directly liquefy residue-based asphalt vinyl material

InactiveCN102733008AEfficient use ofSimple preparation routeFibre chemical featuresCarbon fibersSorbent

The method of the present invention provides a Method of preparing a spinnable mesophase and carbon fiber by using coal to directly liquefy residue-based asphalt vinyl material. According to the invention, the residue-based asphalt vinyl material which is subjected to direct coal liquefaction as a raw material, and the method comprises the following steps: grinding the asphalt vinyl material, and then placing in a high temperature tube type furnace or a high pressure reaction kettle under the inert gas protection, and preparing under the temperature of 200-500 DEG C and the pressure of 0.1-10 MPa to obtain the spinnable mesophase, performing processes of melt spinning, preoxidation and carbonization treatment on the mesophase to prepare the carbon fiber. The invention has the advantages of simple preparation method, conventional equipment, cheap raw material, good product quality and environmental protection, and is a method for high-value utilization of coal resource. The prepared carbon fiber can be used for high performance aerospace materials, adsorbents with high efficiency, separating agents, catalysts and catalyst carriers and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

Owner:HERRON DAVID J

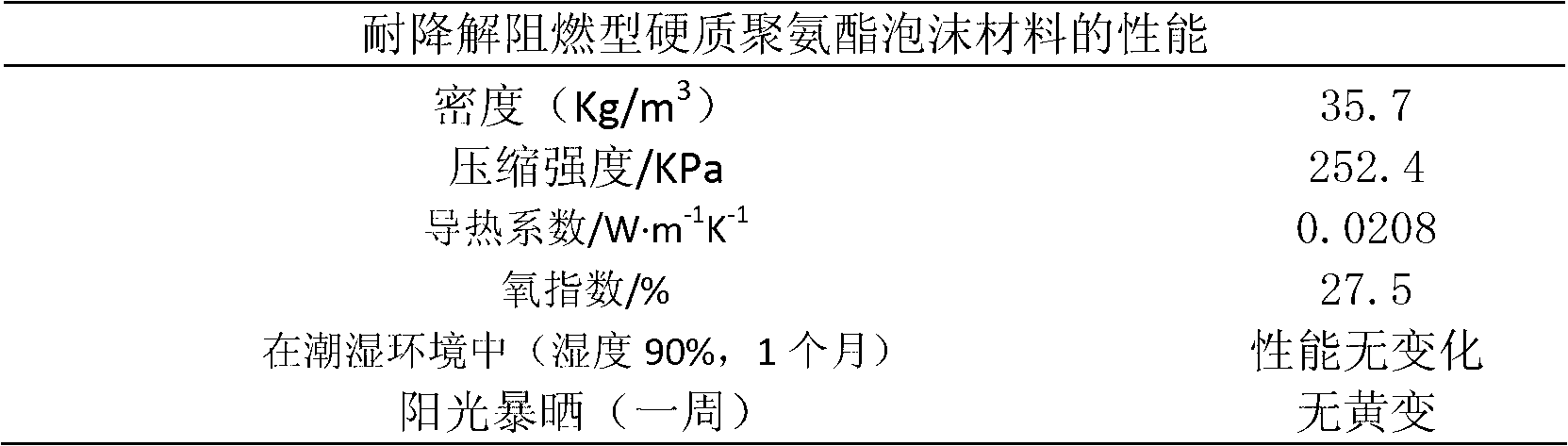

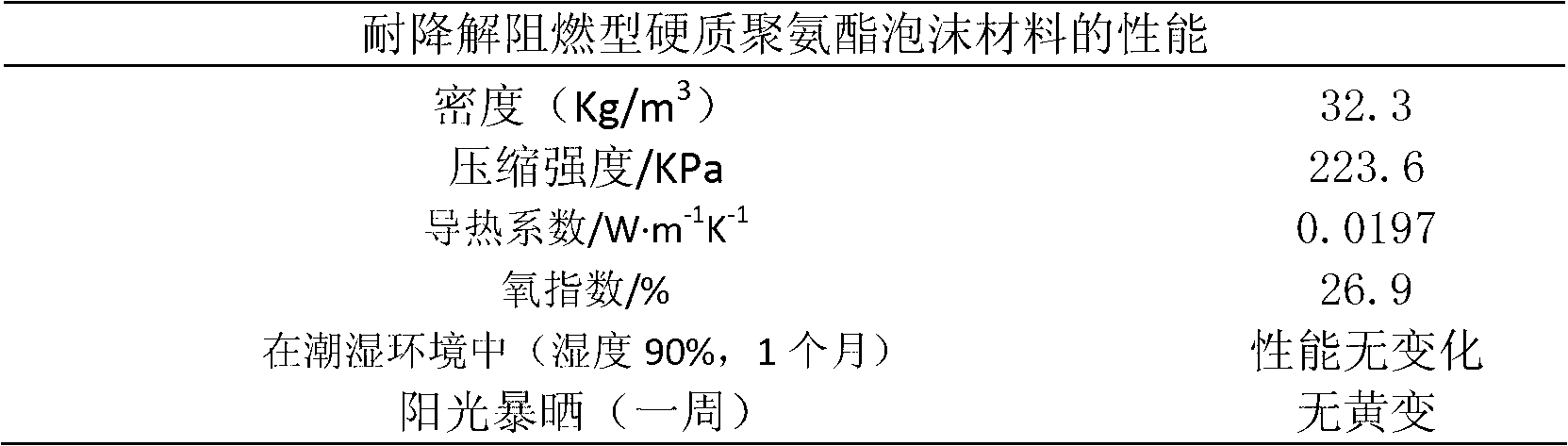

Degradation resistance fire retardation type rigid polyurethane foam material and preparation method thereof

The present invention discloses a degradation resistance fire retardation type rigid polyurethane foam material, which comprises a component A, a component B and a component C, wherein the component A is polyisocyanate with functionality of 2.0-3.5, the component B comprises polyether polyol or polyester polyol, a foaming agent, a cross-linking agent, a chain extender, a foam stabilizer, a catalyst, a composite stabilizer, an additive and the like, and the component C is a composite fire retardation agent. The degradation resistance fire retardation type rigid polyurethane foam material has characteristics of high strength, low combustion value, excellent fire retardation, wear resistance, hydrolysis resistance, corrosion resistance, shock resistance, good size stability, good biodegradability and the like, and can be used in vehicle materials, thermal insulation materials, structural materials, sound insulation materials, building materials, aerospace materials, packaging materials, road repair and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

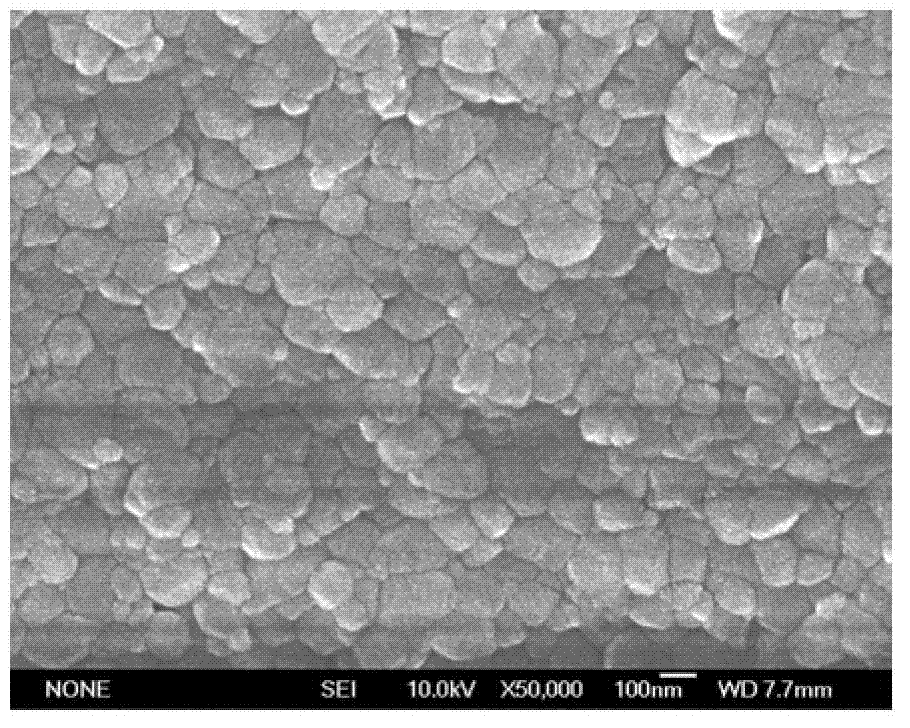

Tungsten-copper alloy with low skeleton connectivity and preparation method thereof

InactiveCN102433480AHigh catalytic activityImprove stabilityLiquid/solution decomposition chemical coatingChemical platingThermal expansion

The invention discloses a tungsten-copper alloy with low skeleton connectivity and a preparation method thereof. The tungsten-copper alloy contains 60 to 80 percent of W and 20 to 40 percent of Cu. The method comprises the following steps of: 1, selecting the particle diameter of tungsten powder; 2, pre-treating the tungsten powder, namely calculating the mass of the tungsten according to the mass percentage of the prepared tungsten-copper alloy, weighing the tungsten powder according to the particle diameter selected in the step 1, and performing surface pretreatment on the tungsten powder; 3, preparing composite powder: preparing copper-coated tungsten composite powder by adopting a chemical plating method; 4, mixing powder, namely mixing the copper-coated tungsten composite powder and copper powder in a certain ratio by using a planetary ball mill; and 5, performing final sintering, namely sintering the mixed powder obtained in the step 4 by adopting a spark plasma sintering technology, and thus obtaining the tungsten-copper alloy with low skeleton connectivity. The prepared tungsten-copper alloy has the advantages of uniform components, fine tissues, good electric conductivity and thermal conductivity, low thermal expansion coefficient and good tensile property, and is applied in the fields of electric spark machining, electronic encapsulation and aerospace material preparation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

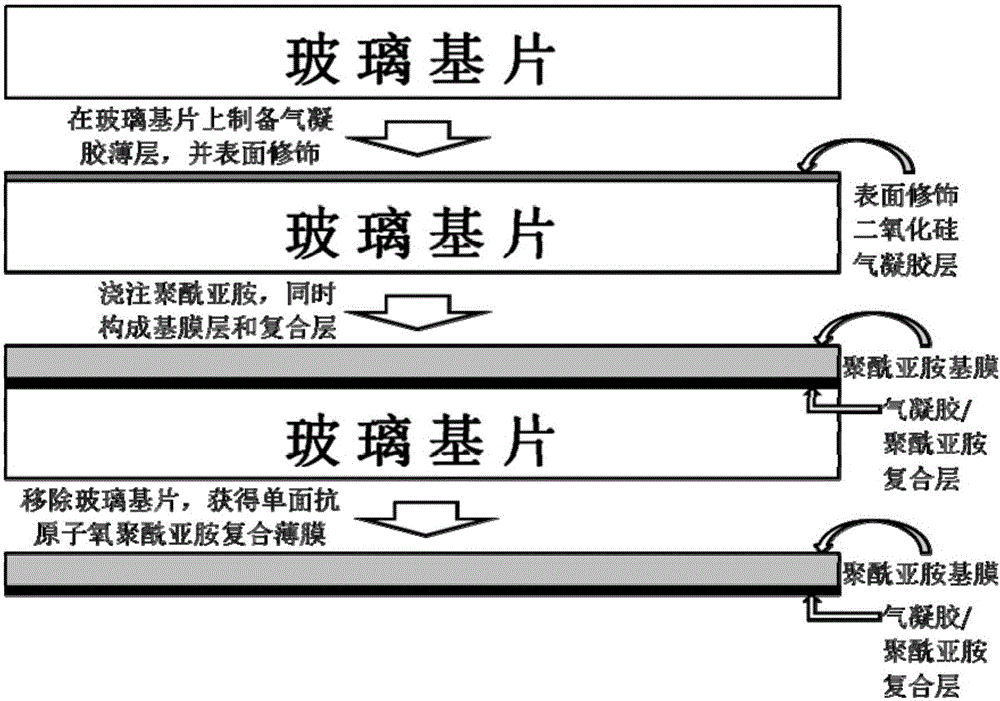

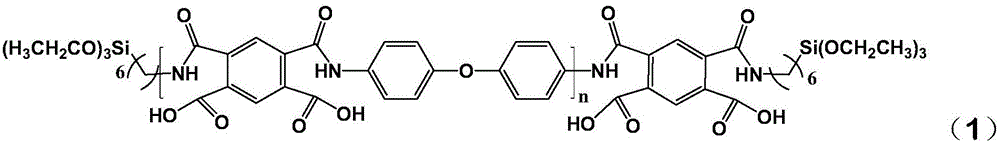

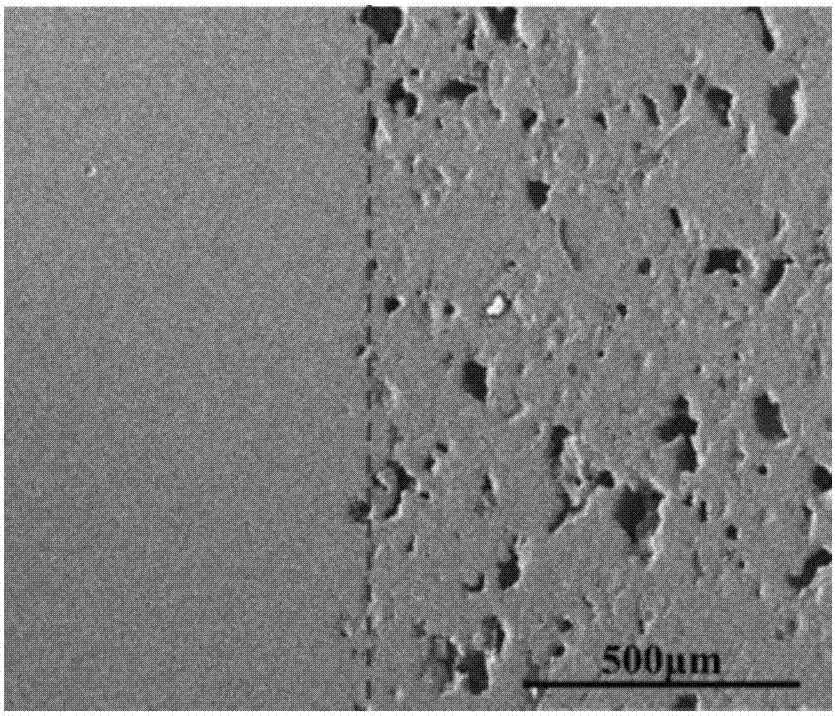

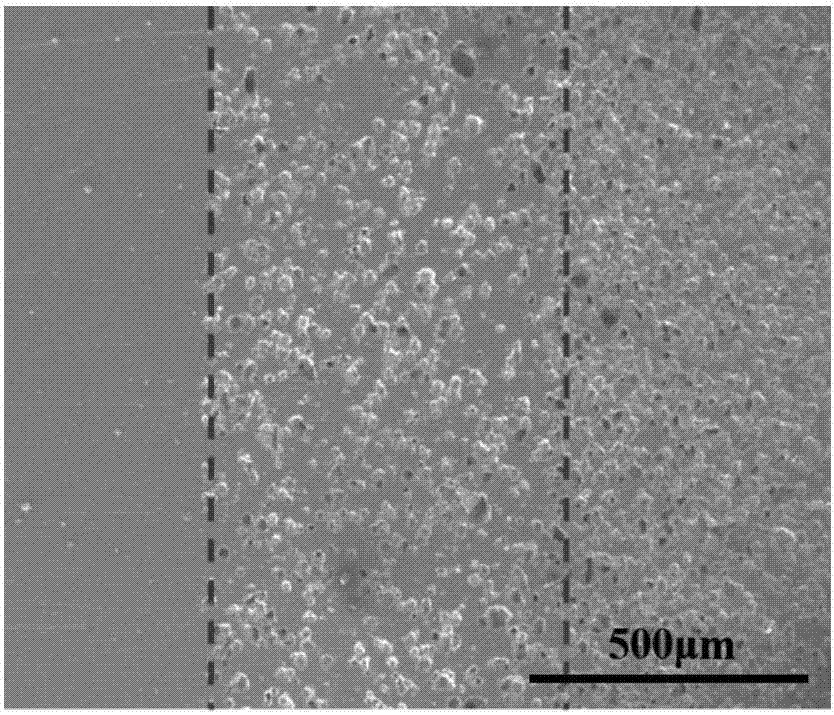

One-side atomic oxygen resistant polyimide composite film and preparation method thereof

ActiveCN105835498AImprove anti-atomic oxygen performanceImprove mechanical propertiesLamination ancillary operationsSynthetic resin layered productsHigh concentrationComposite film

The invention relates to a one-side atomic oxygen resistant polyimide composite film and a preparation method thereof. The film is mainly applied to a spacecraft in space flight. The invention specifically relates to an aerogel-containing atomic oxygen resistant polyimide film for spacecrafts and a preparation method thereof, and belongs to the technical field of aerospace material application. The composite film comprises upper and lower layers: the upper layer is a composite material layer, and the lower layer is a polyimide base film. The composite material layer contains a polyimide base film and an aerosil film obtained after surface modification. One side of the film prepared by the method is pure polyimide, and the other side is a high-concentration aerosil-containing polyimide double-layer composite film. The film thickness is 30-130 microns. The double-layer film has excellent atomic oxygen resistance and good mechanical property, can effectively resist high and low temperature impact and can meet requirement on high-performance atomic oxygen resistant films in the aerospace field.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

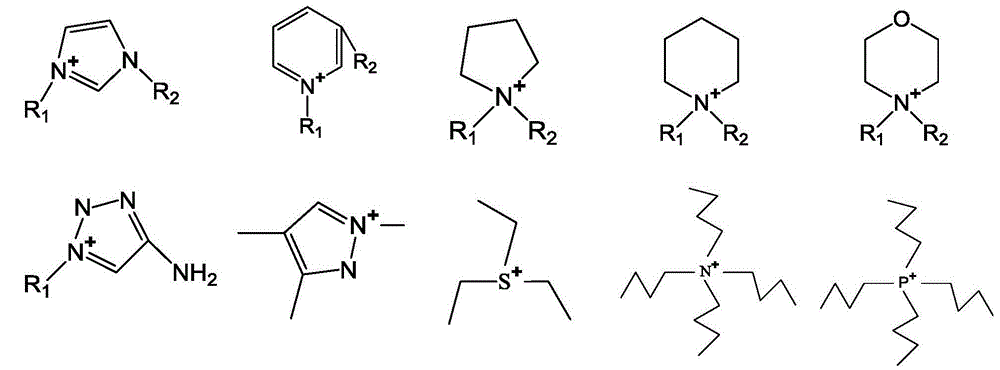

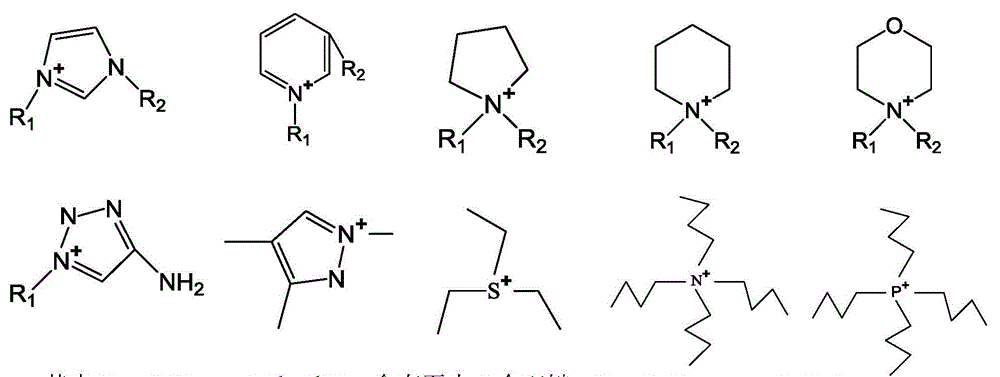

Method for preparing carbon nanometer conductive solution and conductive fibers by using ionic liquids

The invention provides a method for preparing a carbon nanometer conductive solution by using water as a solvent and ionic liquids as a dispersing agent, and a method for preparing electric heating fibers by using the carbon nanometer conductive solution. By using a water-based carbon nanometer tube or water-based graphene or nanometer superconductive carbon black dispersing solution or combining the three according to different proportions as a conductive adding material, and water-based resin as an adhering agent and one or a combination of more than two of ionic liquids of imidazolium salt, pyridinium salt, quaternary ammonium salt, quaternary phosphonium salt and the like as a dispersing gent, the conductive solution is prepared by virtue of compounding according to different proportions, and conductive fiber wires / yarns are prepared by dying and drying fiber wires / yarns through the conductive solution, and can be applied to the fields of medical apparatuses and instruments, electronic equipment, aerospace materials, far infrared heating blankets / cushions / clothes, industrial drying and the like. According to the method, the problems that the environment is polluted by a conventional organic solvent and a dispersing agent and agglomeration is easy to occur when a carbon nanometer tube, graphene, nanometer superconductive carbon black and resin are compounded are solved; the method belongs to a green, energy-saving and environment-friendly preparation technology of a carbon nanometer conductive material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

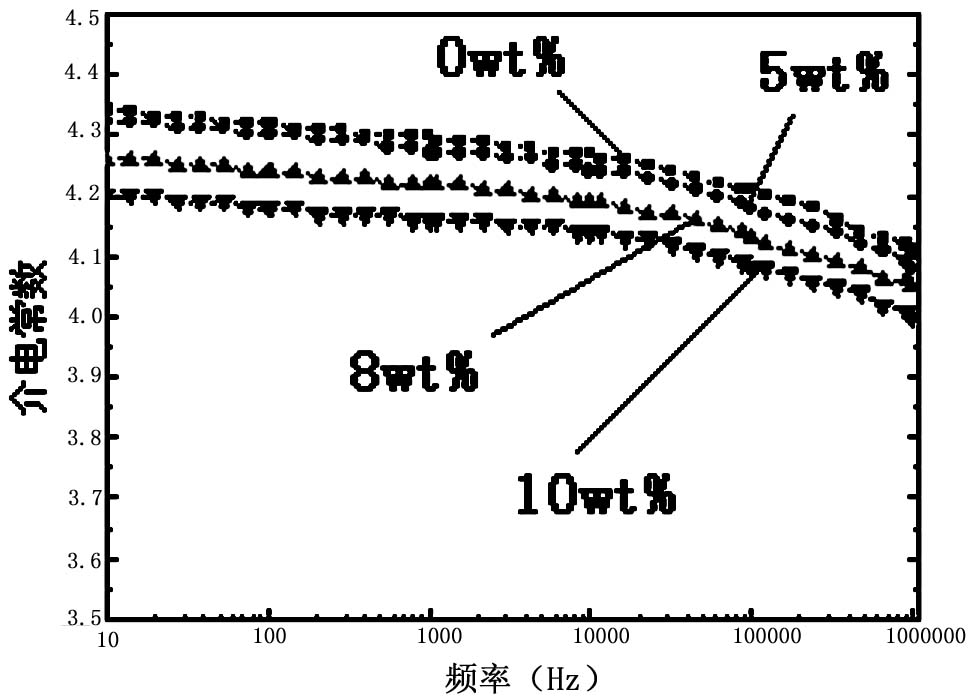

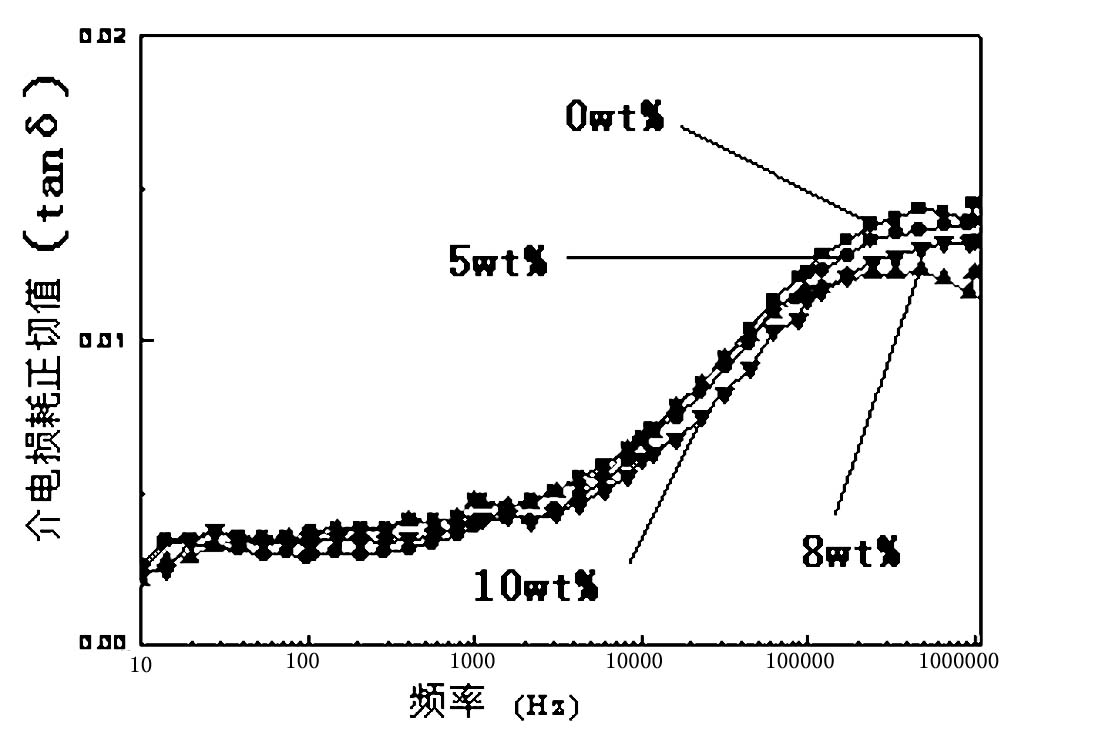

Bismaleimide resin system and preparation method thereof

The invention discloses a bismaleimide resin system and a preparation method thereof. In the method, a polyphenyl ether coated epoxy resin microcapsule is filled into allyl compound modified BMI (Bismaleimide) to obtain a novel BMI resin system. Compared with the BMI resin system in which the microcapsule is not added, the novel resin system has low dielectric constant, and glass-transition temperature is improved. The novel resin system can be used for the frontier field of national defense and civil industry, such as the production of aerospace materials, electron components and the like.

Owner:SUZHOU UNIV

Preparation method of novel tungsten-copper-zinc alloy material

InactiveCN102492884ASmall coefficient of thermal expansionImprove thermal conductivityZinc alloysElectrical discharge machining

The invention discloses a preparation method of a tungsten-copper-zinc alloy material. The preparation method comprises the specific processes of: burdening and mixing micro-scale pure tungsten powder, tungsten powder coated by pure copper on the surface as well as micro-scale copper powder and zinc powder, and carrying out cold isostatic extrusion, spark plasma sintering (SPS) and other methods to prepare the tungsten-copper-zinc alloy material with relative density more than 95%. The preparation method has the advantages that: by virtue of the preparation method, the tungsten-copper-zinc composite material with the relative density more than 95%, high hardness and higher strength can be prepared; brass has higher strength and hardness than pure copper; and through combing high strength and high density of tungsten as well as high conductivity, high thermal conductivity, higher strength and hardness and other performances of brass, the high-temperature-resistant and corrosion-resistant tungsten-copper-zinc alloy material suitable for electric spark machining, electronic packaging and aerospace materials are prepared.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

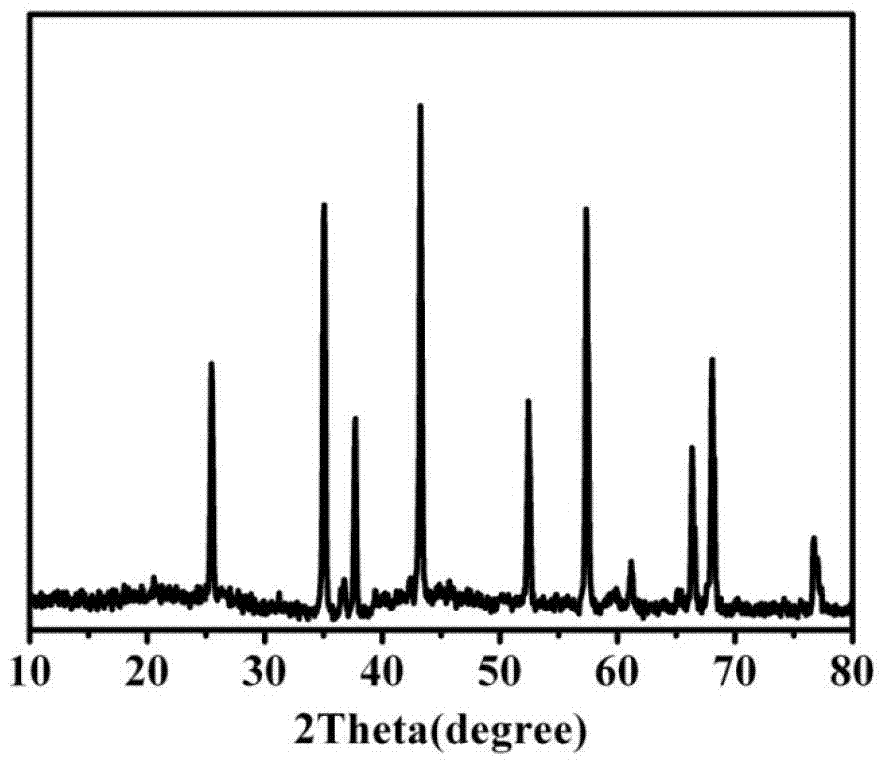

High-entropy alloy and preparation method thereof

ActiveCN108642362AImprove high temperature strengthSolve bad plasticityHigh entropy alloysRoom temperature

The invention discloses a high-entropy alloy. The high-entropy alloy comprises Cr, Fe, Co, Ni and Ta at the non-equal atomic ratio. The invention further discloses a preparation method of the high-entropy alloy. The preparation method comprises the steps of weighing Ta blocks, Co blocks, Cr blocks, Ni blocks and Fe blocks according to the stoichiometric ratio of the alloy elements; then, smeltingthe weighed raw materials in an arc-melting furnace, and obtaining the high-entropy alloy upon completion of smelting. The high-entropy alloy has excellent compression performance at high temperature,and higher plasticity at room temperature as well as excellent comprehensive mechanical properties, and meets the requirement of application to aerospace materials.

Owner:CENT SOUTH UNIV

High-strength martensite PH stainless steel material and preparation method thereof

The invention discloses a high-strength martensite PH stainless steel material, and belongs to the field of martensite stainless steel materials. The high-strength martensite PH stainless steel material is prepared from, by weight, 0.05% of C or less, 12.25%-13.25% of Cr, 7.50%-8.50% of Ni, 2.00%-2.50% of Mo, 0.90%-1.35% of Al and the balance Fe. The invention further discloses a preparation method of the stainless steel material. The components of the material are improved and simpler, a proper amount of Cr, Ni, Mo and Al is added, the novel preparation method is adopted, indoor temperature performance:tensile strength Rm is larger than or equal to 1,560 Mpa, and the yield strength Rp0.2 is larger than or equal to 1,460 Mpa; the transverse tensile elongation A is larger than or equal to 10.0%, the percentage reduction Z of area is larger than or equal to 45.0%, and the impulse test Aku is larger than or equal to 39 J; the longitudinal tensile elongation A is larger than or equal to 10.0%, the percentage reduction Z of area is larger than or equal to 35.0%, and the impulse test Aku is larger than or equal to 23 J; the performance of the martensite PH stainless steel material is obviously improved, and the needs of aerospace materials are met.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

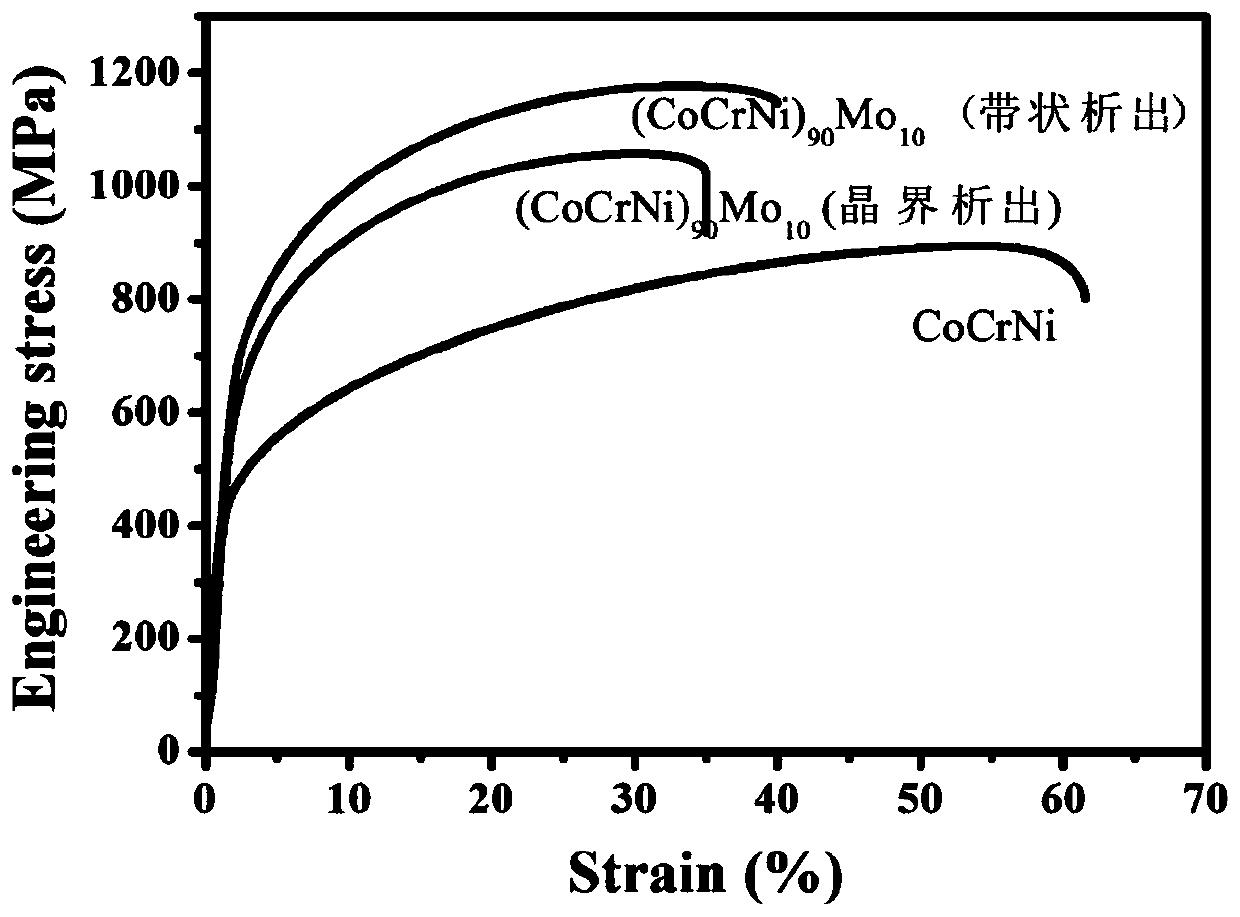

High-entropy alloy with banded precipitated phase and preparation method thereof

ActiveCN110106428AGood room temperature tensile propertiesImprove solid solution strengtheningHigh entropy alloysMo element

The invention discloses a high-entropy alloy with a banded precipitated phase. The high-entropy alloy consists of Co, Cr, Ni and Mo elements, wherein the atomic percent of Co is 25-35%, the atomic percent of Cr is 25-35%, the atomic percent of Ni is 25-35%, the atomic percent of Mo is 5-15%, and the sum of atomic percents of the components is 100%. The phase composition of the high-entropy alloy with the banded precipitated phase comprises a face-centered cubic phase and a sigma precipitated phase, wherein the sigma precipitated phase accounts for 40-60%. In the preparation method, the non-uniform precipitation of the Mo-rich phase is achieved through the combination of hot processing, solid solution processing, cold processing and annealing process, and the high-entropy alloy with the banded precipitated phase is obtained. The alloy can ensure excellent strength and toughness matching, and has application prospects in the fields of cutter materials, aerospace materials and the like.

Owner:HEBEI UNIV OF TECH

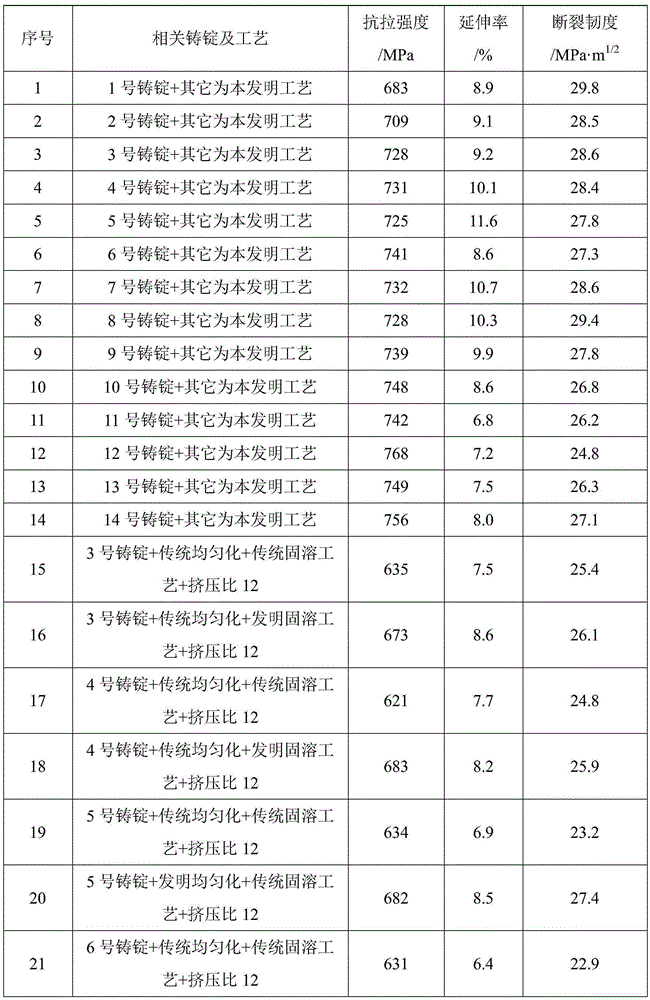

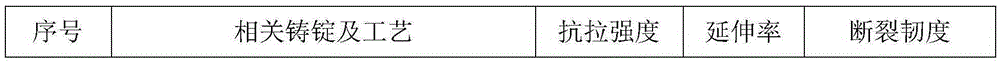

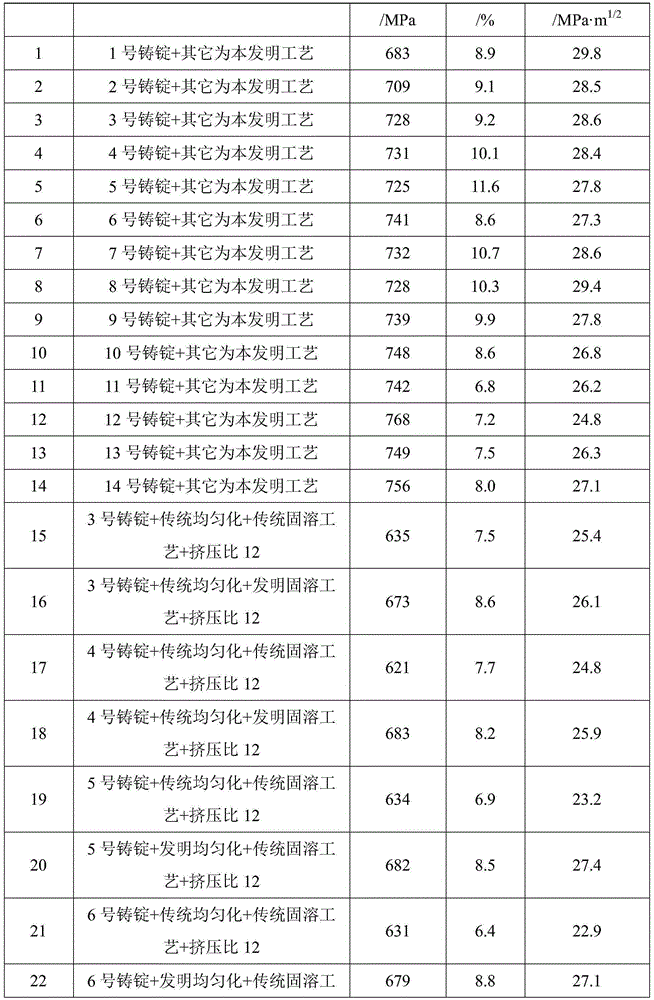

Preparing method for 700-MPa-level aluminum alloy extruded section

The invention provides a preparing method for a 700-MPa-level aluminum alloy extruded section. The 700-MPa-level aluminum alloy extruded section is prepared from, by weight percentage, 7.8% to 10.3% of Zn, 1.3% to 2.0% of Mg, 1.3% to 2.0% of Cu, 0.08% to 0.15% of Zr, smaller than or equal to 0.15% of Si, smaller than or equal to 0.15% of Fe, smaller than or equal to 0.15% of other impurities and the balance Al, wherein the weight percentage of each kind of the impurities is smaller than or equal to 0.05%. The preparing method includes the steps that the raw materials are prepared according to alloy components, fused, subjected to furnace refining and standing, and then cast into an alloy ingot with the required specification; and the alloy ingot is subjected to preferred three-stage homogenizing, then formed through a preferred extrusion technology and can be used for part machining after heat treatment. The novel aluminum alloy extruded section is even in microscopic structure and stable in performance, and the ultimate tensile strength can be higher than 700 MPa; and meanwhile elongation is higher than 8%, fracture toughness is higher than 26 MPa.m<1 / 2>, the current aerospace material selecting requirement is met, and meanwhile the aluminum alloy extruded section can be widely applied to the fields of the nuclear industry, transportation, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

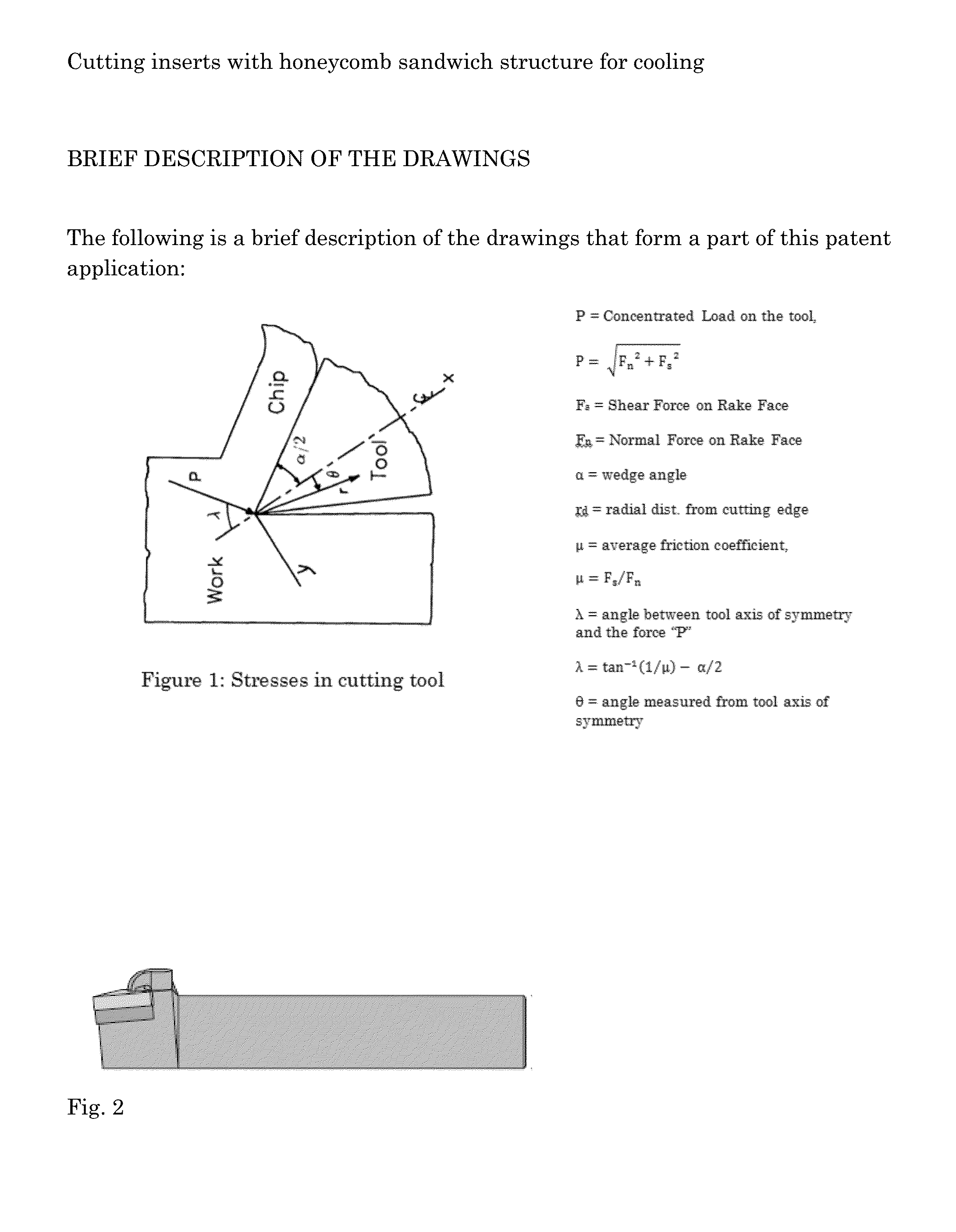

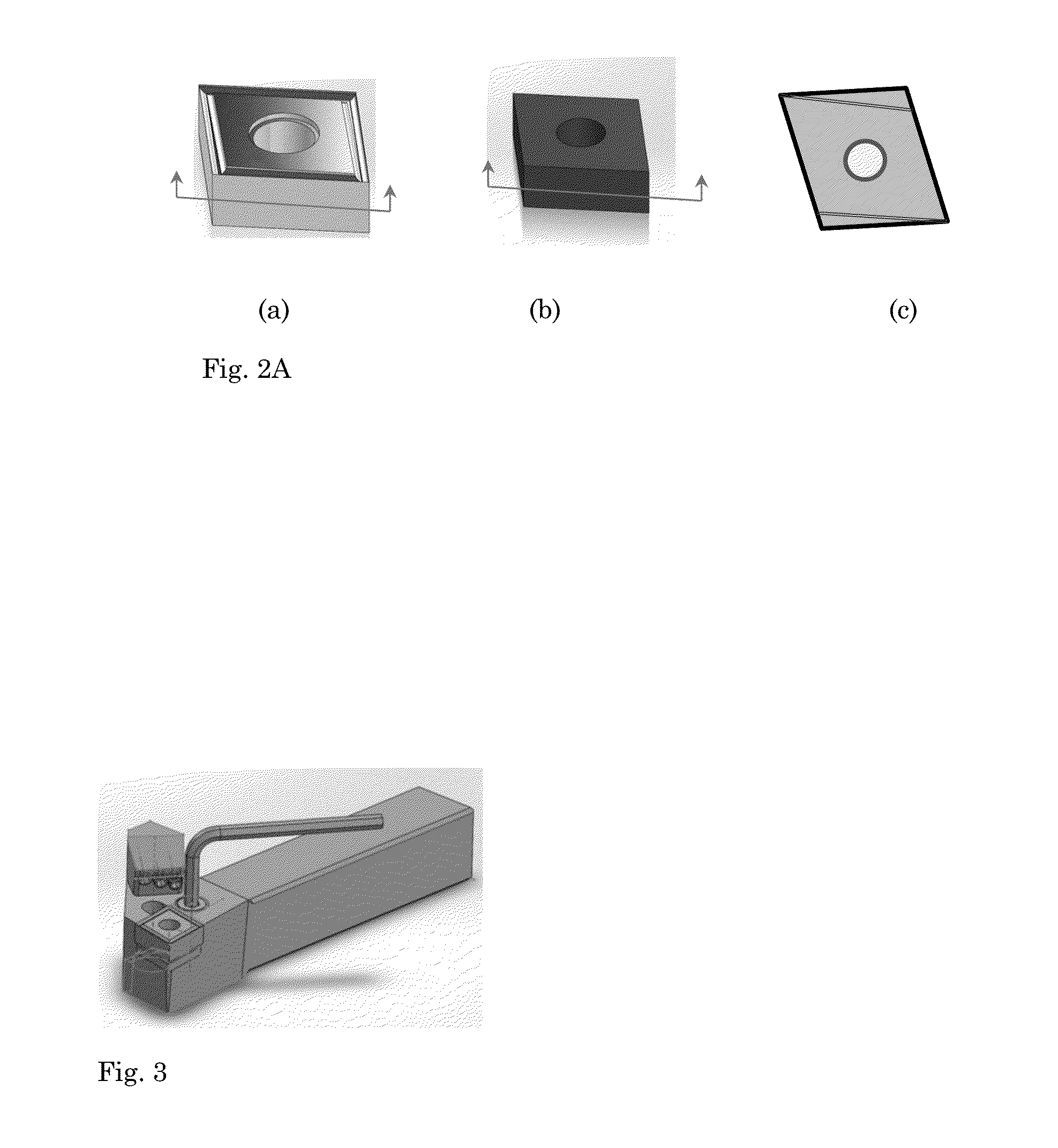

Cutting inserts with honeycomb sandwich structure for cooling

InactiveUS20160067785A1High strengthImprove cooling effectDrill bitsWorkpiecesCoolant flowHeat resistance

A new type of cutting insert is disclosed here which has sandwich structure often with honeycombs in the mid-section of the insert, to allow fluid and / or gas coolant flow through the insert from inside and reduce cutting tool temperature during work-piece cutting operation. The cutting insert includes an insert body, which includes cutting edge, nose, rake face, and flank face. The cutting insert body further contains interior coolant passageways formed by specially manufactured honeycomb structure in the insert body. The number, shape, and size of honeycomb interior passageways are carefully developed and distributed inside the insert body. Therefore, the insert provides adequate strength to withstand force and impact from cutting work-piece and also in the meantime provides effective cooling to the cutting tool. The honeycomb interior coolant passageways could be connected from the insert to the tool holder through an internal passageway in the tool holder, then to the coolant circulation system provided to the cutting tool, or directly connected to an external coolant circulation system. The cutting insert can be used in metal cutting, such as high strength aerospace materials and heat resistance materials. It can also be used in drilling tools for mine / oil / natural gas exploration.

Owner:WANG ANDREW T +1

Aluminum alloy extruded sectional material at grade of 700 MPa

The invention provides an aluminum alloy extruded sectional material at the grade of 700 MPa. The sectional material is composed of, by weight, 7.8%-10.3% of Zn, 1.3%-2.0% of Mg, 1.3%-2.0% of Cu, 0.08%-0.15% of Zr, 0-0.15% of Si, 0-0.15% of Fe, 0-0.05% of other single impurities, 0-0.15% of other impurities, and the balance Al. The alloy components are subjected to burdening. The raw materials are melted and poured to form alloy ingots with required specifications after furnace refining and standing. The alloy ingots are subjected to an optimal extrusion technique to be formed after optimized three-grade homogenization, and the alloy ingots can be used for machining parts after heat treatment. The novel aluminum alloy extruded sectional material is even in microscopic structure and stable in performance; the ultimate tensile strength can be over 700 MPa, and meanwhile the elongation rate is higher than 8% and the fracture toughness is up to 26 MPa.m<1 / 2>, so that the requirement for aerospace material selection at present is met, and the aluminum alloy extruded sectional material can be widely applied to the fields of nuclear industry, transportation, weapons and the like at the same time.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of thermal insulating material having ultralow density, ultrahigh elasticity and ultralow thermal conductivity

InactiveCN103723718ASolve the current situation that the preparation is restricted by experimental equipmentSimple processMaterial nanotechnologyGrapheneFreeze-dryingCarbon nanotube

The invention provides a preparation method of a thermal insulating material having ultralow density, ultrahigh elasticity and ultralow thermal conductivity, and relates to a preparation method of a thermal insulating material. The preparation method provided by the invention aims to solve the problems of high intensity, low elasticity and high heat conductivity coefficient of aerial and aerospace craft thermal insulating materials prepared by the existing method. The preparation method comprises the following steps of 1, preparing oxidized graphene; 2, preparing an oxidized graphene dispersion liquid; 3, preparing a carbon nano-tube dispersion liquid; 4, preparing an oxidized graphene / carbon nano-tube solution; 5, freeze drying; 6, reducing oxidized graphene-carbon nano-tube sponge; and 7, drying to obtain the oxidized graphene-carbon nano-tube sponge which is ultralow in density, ultrahigh in elasticity and ultralow in thermal conductivity, and then finishing the preparation method of the thermal insulating material ultralow in density, ultrahigh in elasticity and ultralow in thermal conductivity. The preparation method of the thermal insulating material having ultralow in density, ultrahigh in elasticity and ultralow in thermal conductivity is applied to the field of the preparation of the aerial and aerospace materials.

Owner:HARBIN INST OF TECH

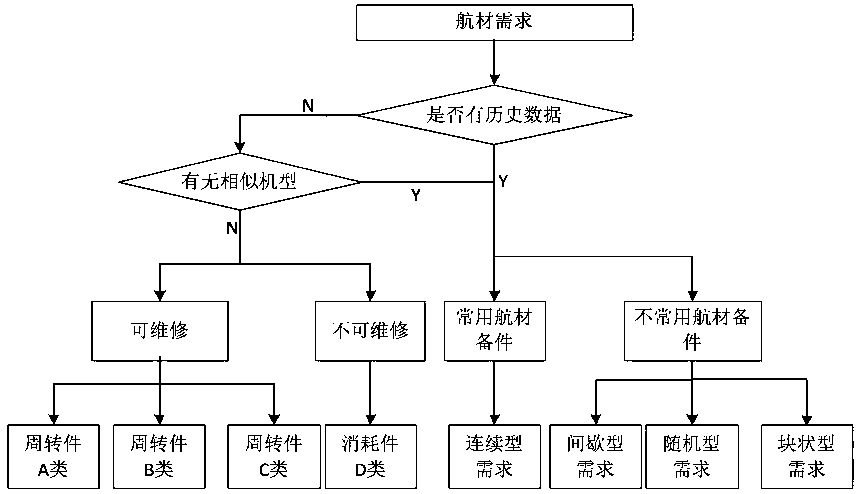

System adaptive prediction method

The invention belongs to the technical field of demand prediction, and particularly relates to a system self-adaptive prediction method. A result is predicted by utilizing a plurality of prediction models, and the method comprises the following specific steps: sorting prediction data; Predicting the data by adopting different prediction models; Comparing different prediction results; Selecting a prediction model; Wherein the prediction model comprises a moving average method, an exponential smoothing method, a reliability life calculation prediction method, an intermittent demand prediction method and a Croton prediction method. Experiments show that the optimal pricing scheme can be effectively analyzed on historical data. The method can be applied to various fields of making pricing strategies of aerospace materials, medical instrument materials and valuable instrument materials and the like.

Owner:FUDAN UNIV

Aluminum-based density gradient material and preparation method and application thereof

The invention relates to an aluminum-based density gradient material and a preparation method and application thereof. A region with density in gradient change and (or) a region with density in continuous change exist in the aluminum-based density gradient material, and the materials of all the regions in the aluminum-based density gradient material are consistent. The preparation method comprises the following steps: water-soluble pole-forming agent powder and aluminum alloy powder are proportioned according to the volume ratio of the water-soluble pole-forming agent powder to the aluminum alloy powder being X to (100-X), and then are mixed uniformly to obtain mixed powder containing different amounts of pole-forming agents; die forming is carried out on laminated spread powder, and a prefabricated blank is sintered in a vacuum environment at 575-675 DEG c to obtain a sintered body; and water soaking treatment is carried out to obtain the aluminum-based density gradient material. The aluminum-based density gradient material prepared by the method has no obvious deformation, and the density from 1.1 g / cm<3>-2.7g / cm<3> in gradient distribution is achieved through adjusting porosity; and the aluminum-based density gradient material is excellent in performance and is suitable for being used as an aerospace material.

Owner:CENT SOUTH UNIV

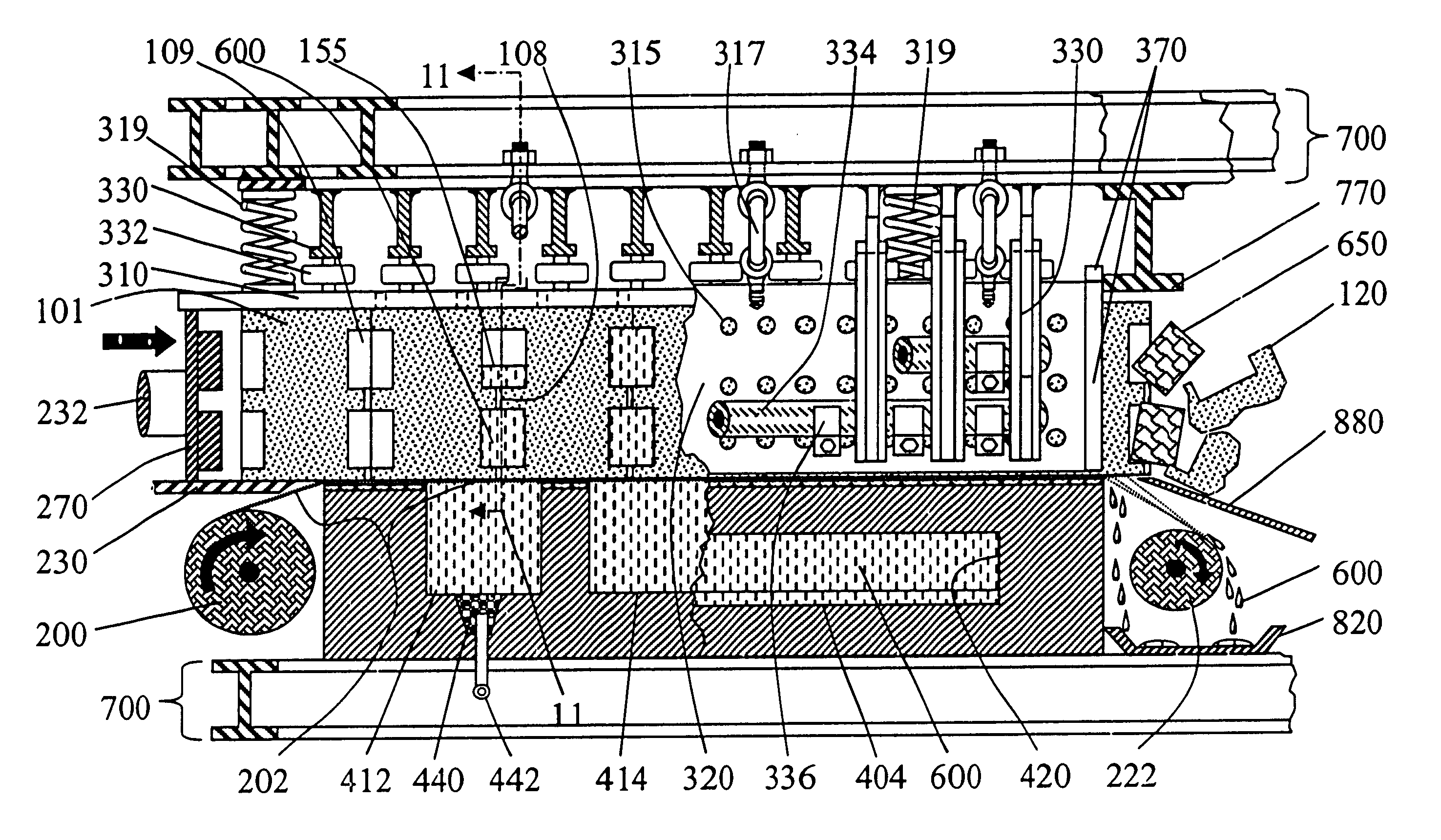

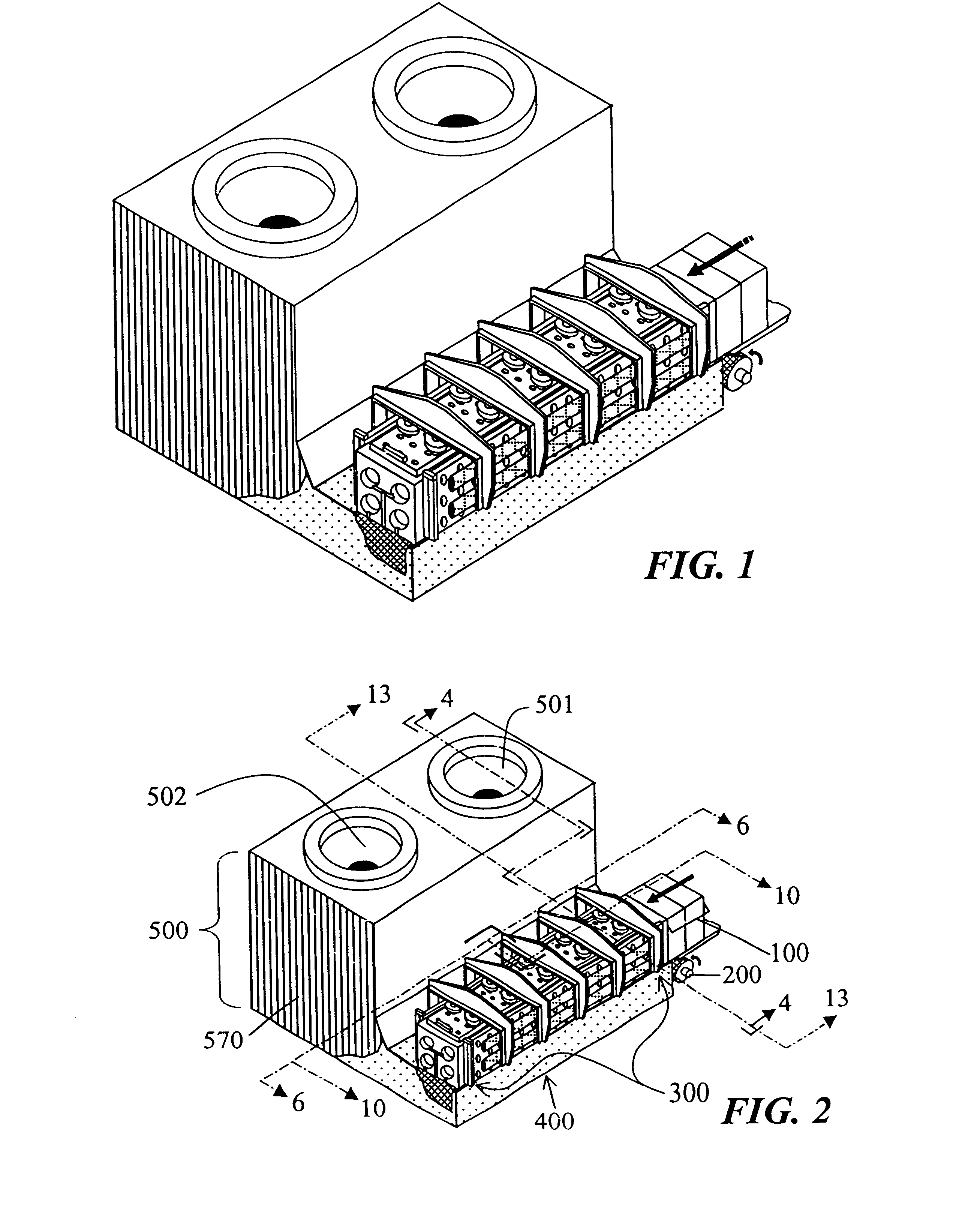

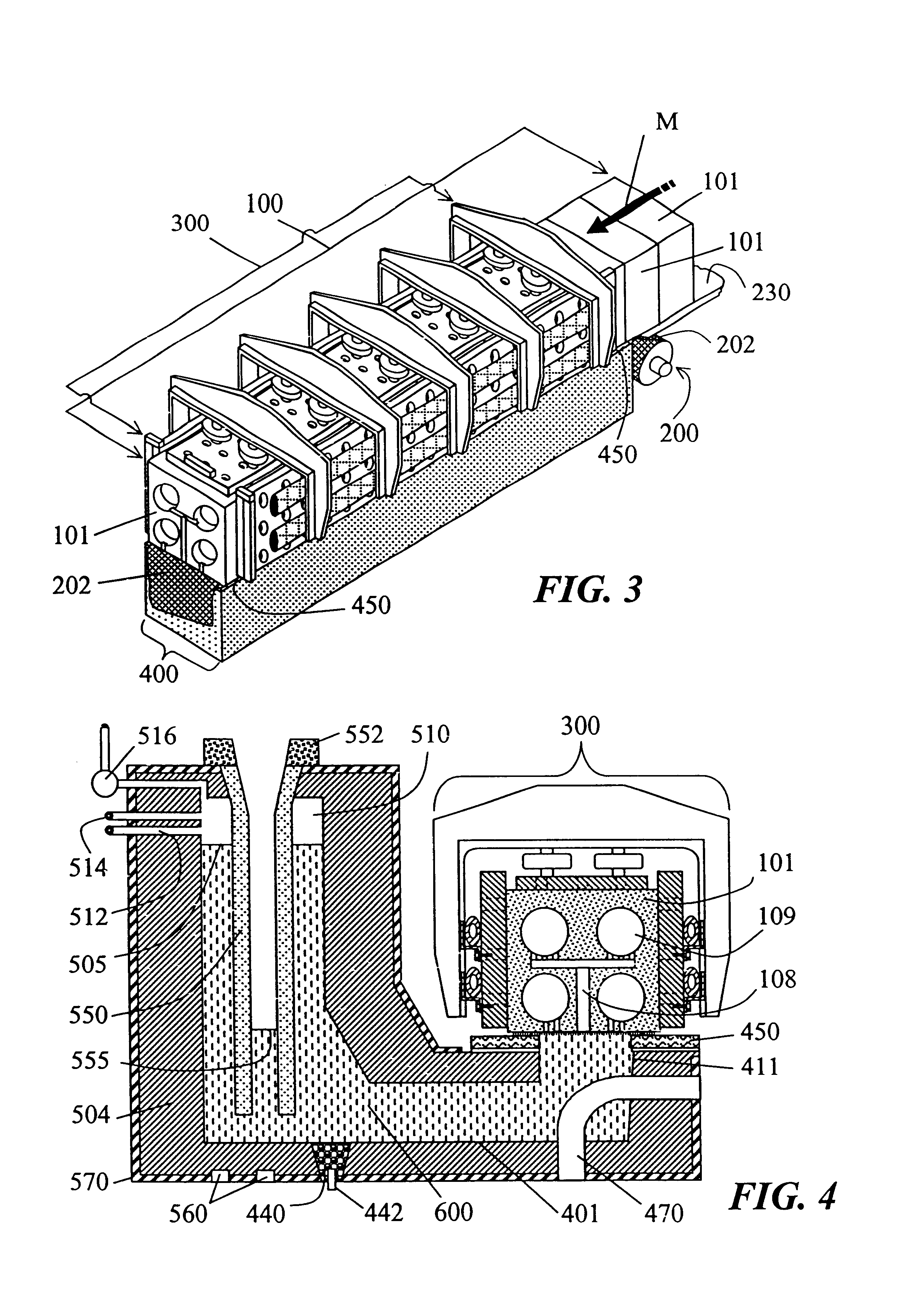

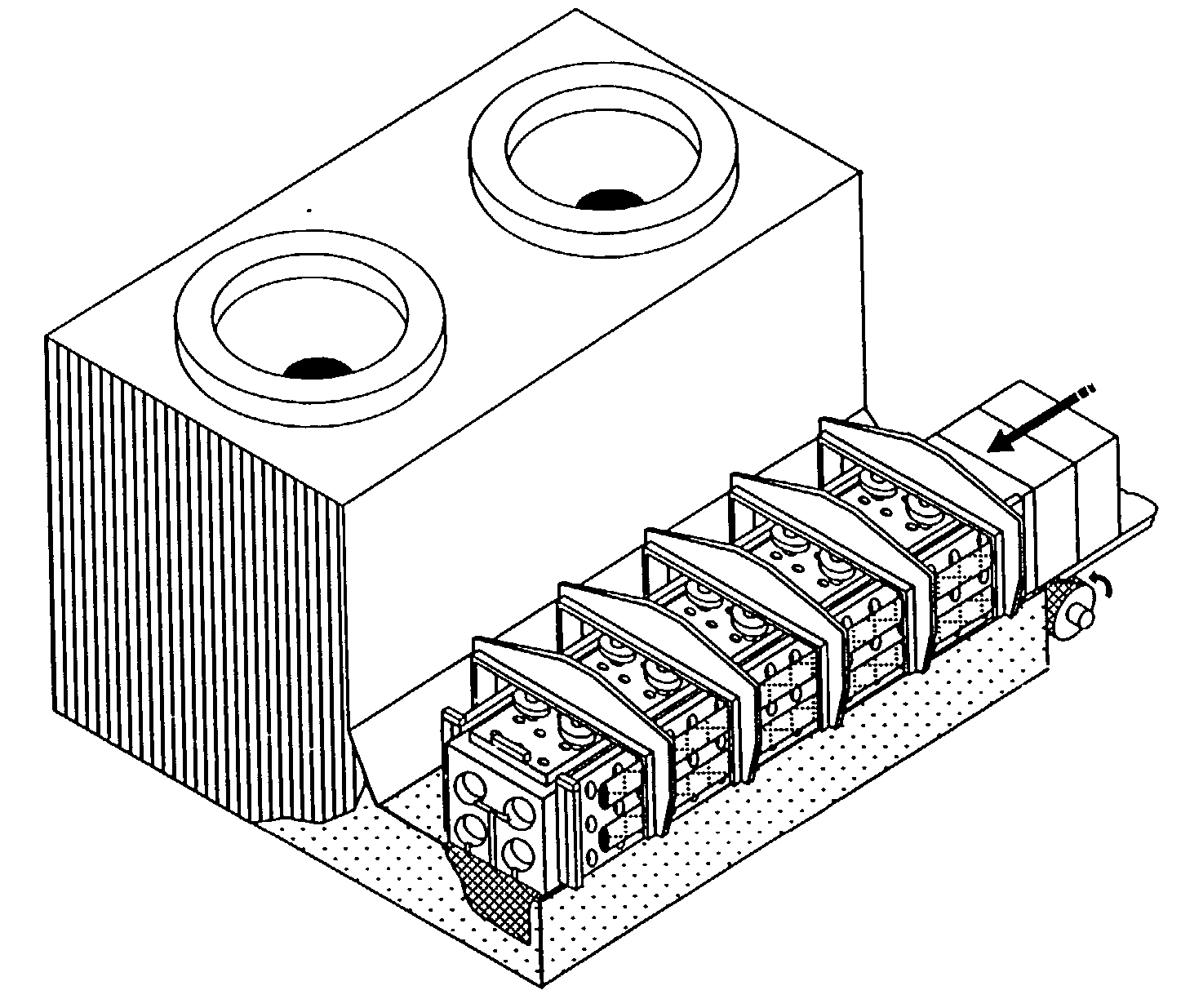

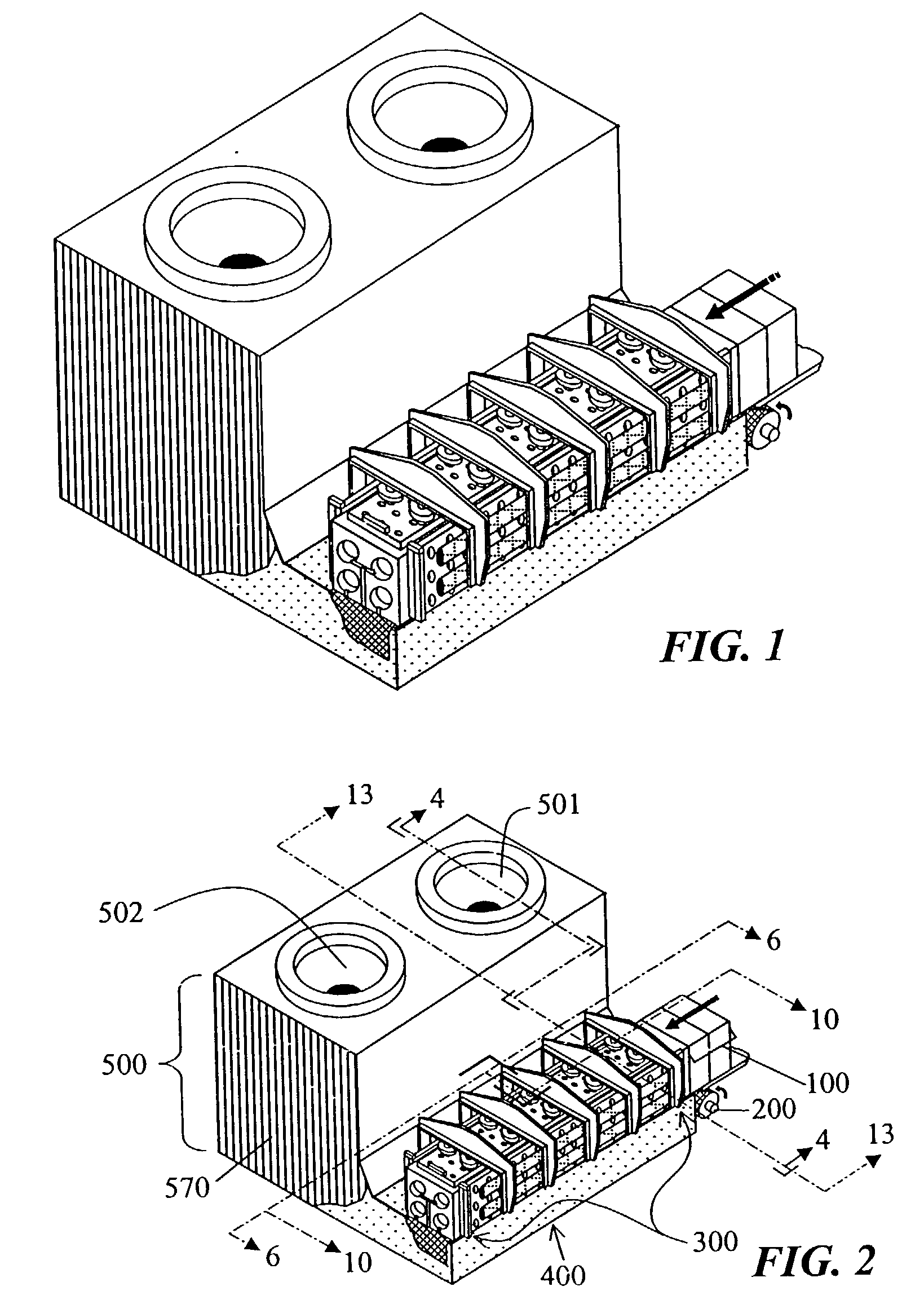

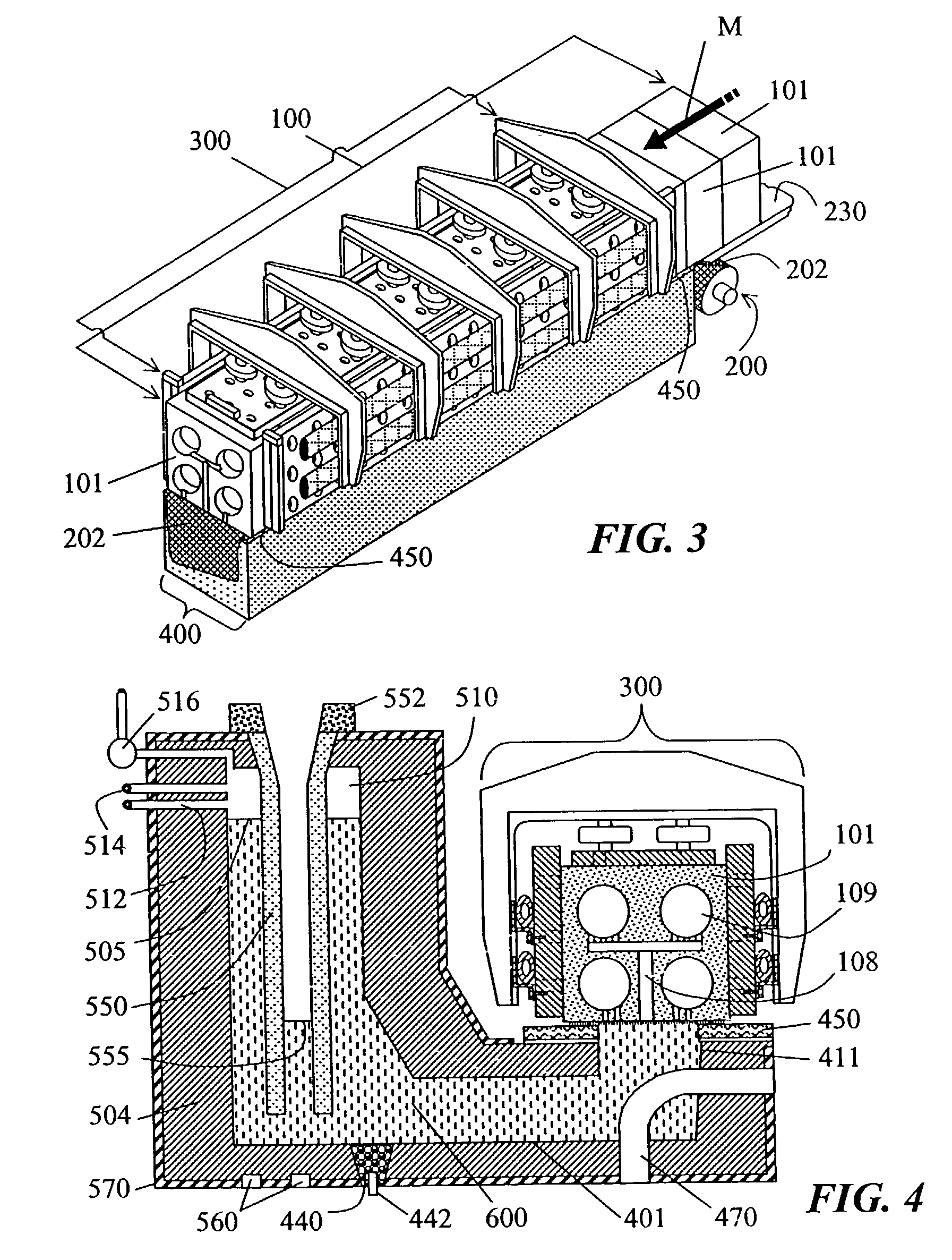

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

Mold filling and feeding device (400) and process including using refractory filter cloth (202) to seal a mold line (100), in continuous conveyance, to a multi-stage pressurized filling and feeding device. The mold line (100) is the line formed of vertically parted green sand molds (101). These molds can be filled with molten metal which gradually solidifies under pressure. Feeding under pressure will assist shrinkage problems in the casting process. The process includes modes of treating ductile iron with magnesium for compacted graphite. A stitch (242) of filter cloth (202) holds modifying alloy (630) to the molds (101) at high speed. A vacuum and pressure controlled column (550) provides consistent flow to thin walled castings, and pressurized feeding for heavy castings. Radiant energy losses are contained in the automatic system. The process and several special purpose machine components make a unified system for hardening liquid (600) such as plastic polymer, rubber tires, or food stuff, as in molded chocolate candy.

Owner:HERRON DAVID J

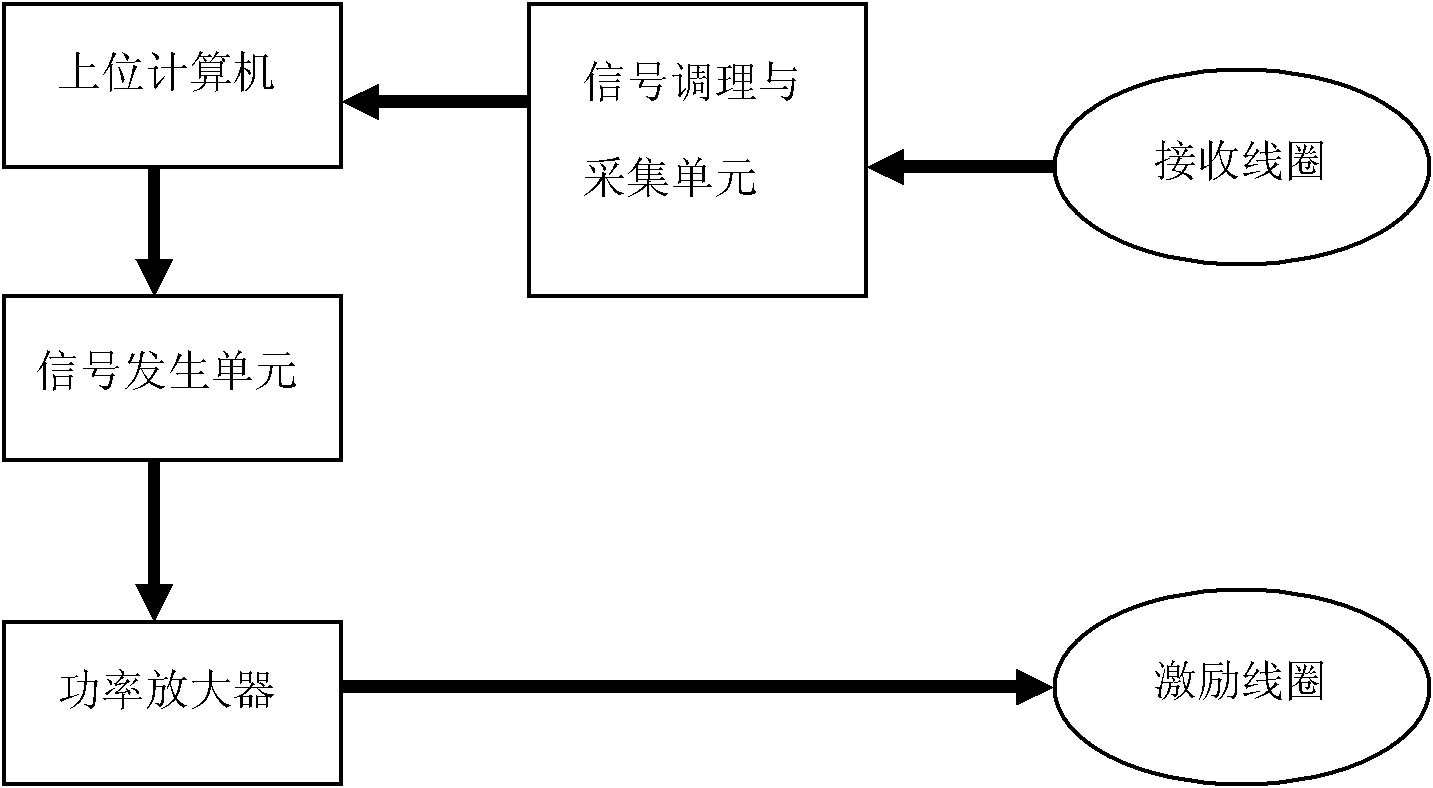

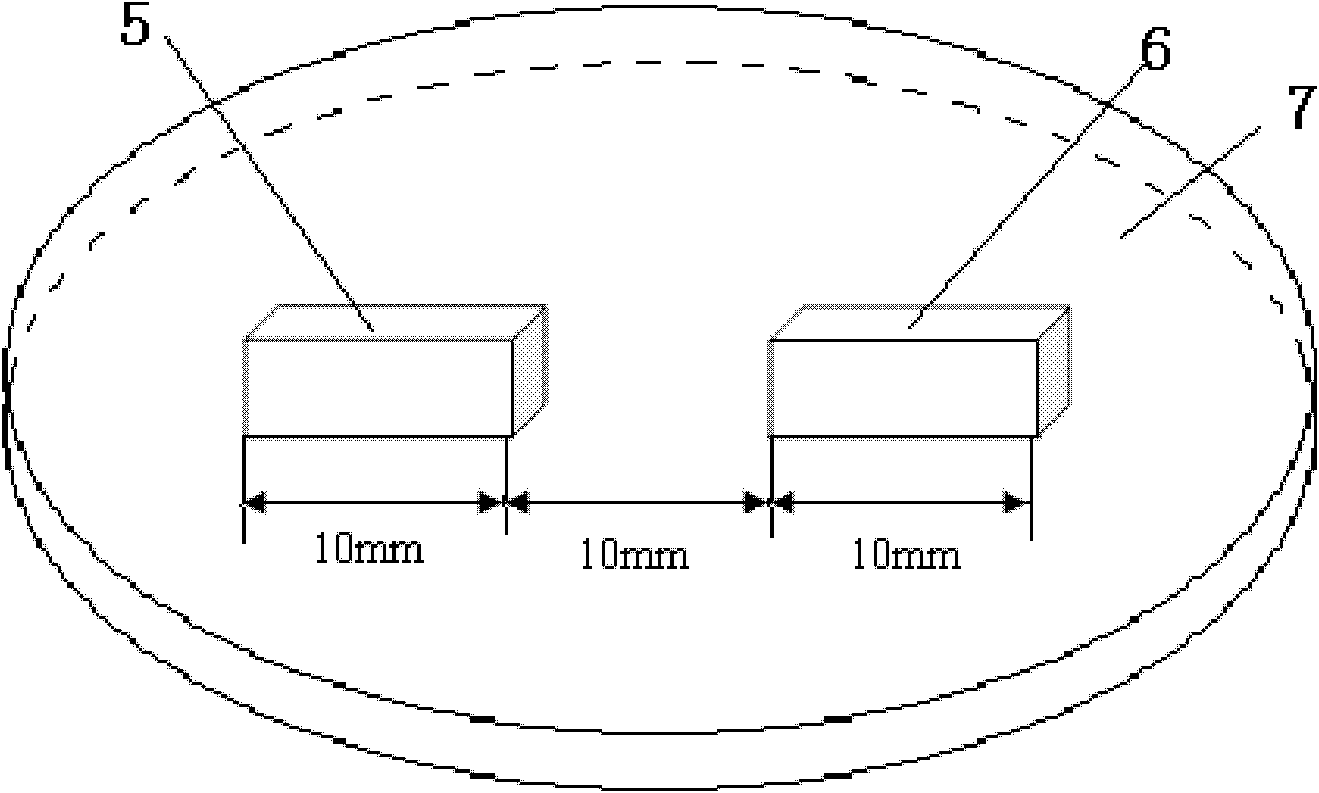

Device and method for measuring carbon fiber reinforced plastic based on electromagnetic sensing

The invention relates to the technical field of non-destructive testing of carbon fiber reinforced plastic (CFRP), in particular to a device for measuring carbon fiber reinforced plastic based on electromagnetic sensing, which comprises an exciting coil, a receiving coil, a signal conditioning and acquisition unit, a power amplifier and a host computer. The exciting coil and the receiving coil formed by winding a wire around a flat magnetic core are both arranged on a carbon fiber reinforced plastic board and are rotated with angles increasing, and an excitation signal is exerted on the exciting coil at each angle so as to collect a sensing signal on the receiving coil; and the host computer is used for processing signals according to the collected signal, so as to find out a carbon fiber extension direction for the carbon fiber reinforced plastic. The invention simultaneously provides a measuring method adopted by the device. Moreover, the invention can rapidly test the carbon fiber reinforced plastic CFRP in a non-contact way under the condition of being non-contact, and has great significance in the testing of aerospace materials.

Owner:TIANJIN UNIV

Benzocyclobutene functional groups-contained benzoxazine monomer and synthetic method and use thereof

InactiveCN102391202AImprove flame retardant performanceImprove heat resistanceOrganic chemistryPolymer sciencePtru catalyst

The invention belongs to the technical field of macromolecular materials and particularly relates to a benzocyclobutene functional groups-contained benzoxazine monomer and a synthetic method and a use thereof. According to the synthetic method, amino-contained benzocyclobutene, phenolic compounds and formaldehydes (or paraformaldehydes) are adopted as raw materials, and the target monomer is obtained through synthesizing by adopting a solvent method or a solvent-free method. The benzoxazine monomer has lower viscosity at a certain temperature and can be cured through a method of heating or catalyzing by a catalyst. The obtained resin after curing has excellent thermal stability, mechanical properties, and extremely-low hygroscopicity, and thus, the resin can be used as an electronic packaging material, a high-temperature resisting and flame-retarding material, a high-performance composite material, an aerospace material and the like.

Owner:FUDAN UNIV

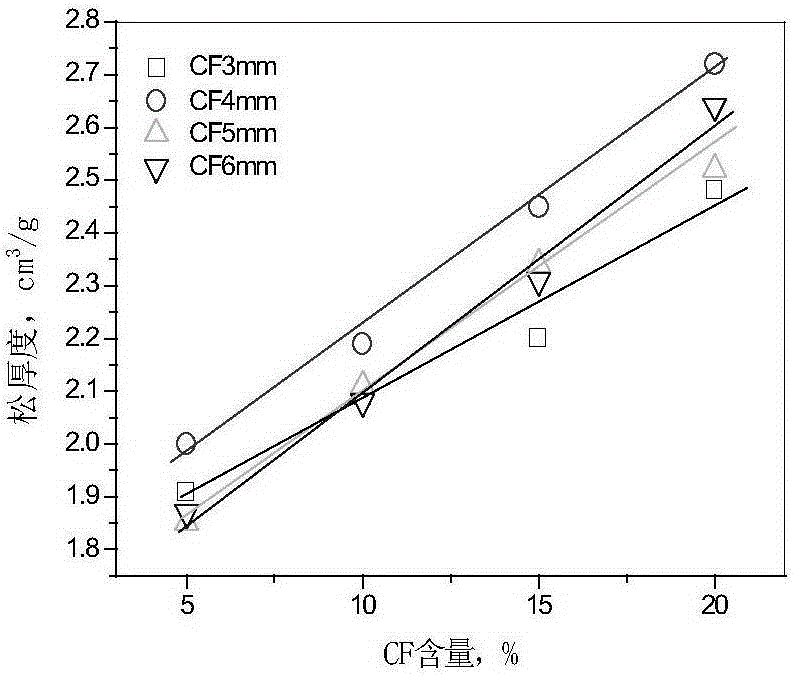

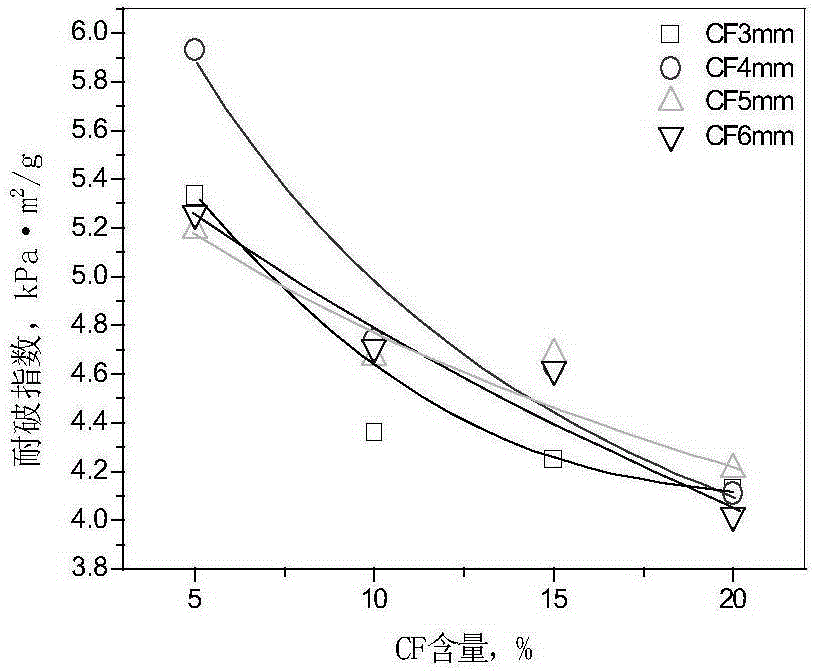

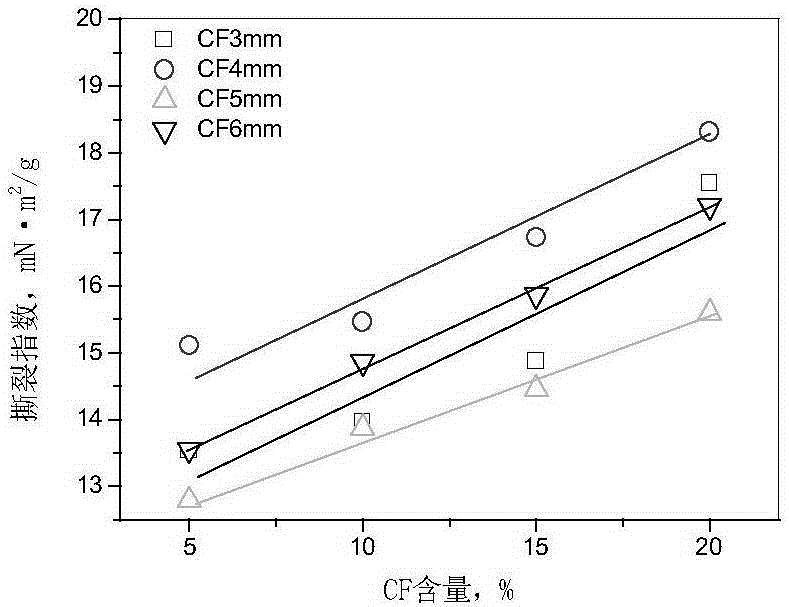

Preparation method and evenness measurement method for carbon fiber synthetic paper

InactiveCN105274896AAchieving dual synergiesImprove performanceMaterial analysis by optical meansPaper/cardboardFiberMeasurement cost

The invention discloses a preparation method for carbon fiber synthetic paper. The preparation method comprises the steps of mixing carbon fibers with plant fibers for conducting pulping, manufacturing paper with pulp and forming the paper, conducting secondary squeezing and conducting drying under the condition of constant temperature and humidity. The carbon fiber synthetic paper prepared through the preparation method has good electrical conductivity, thermal conductivity, mechanical properties and the like and can be widely applied to electromagnetic wave shielding materials, heat-emitting materials, aerospace materials and the like. Meanwhile, the invention provides an evenness measurement method for the carbon fiber synthetic paper, measurement efficiency for measuring evenness of the paper is effectively improved, measurement cost for measuring evenness of the paper is effectively lowered, the application scope is wide, and reproducibility is good.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Metal honeycomb material used in aerospace and aircraft separation layer, and preparation method thereof

InactiveCN103612433ASolve the strength problemTroubleshooting the presence of brazing materialMetal layered productsNon-electric welding apparatusHoneycombAerospace materials

The present invention discloses a metal honeycomb material used in an aerospace and aircraft separation layer, and a preparation method thereof. The metal honeycomb material comprises an upper panel, a lower panel and a metal honeycomb interlayer. The preparation method comprises: material prefabrication, explosion welding, stress annealing, stretch forming and other steps. According to the present invention, the internal of the prepared metal honeycomb does not contain brazing fluxes and other impurities, the bond strength is high, and the material is a novel aerospace material.

Owner:魏玲

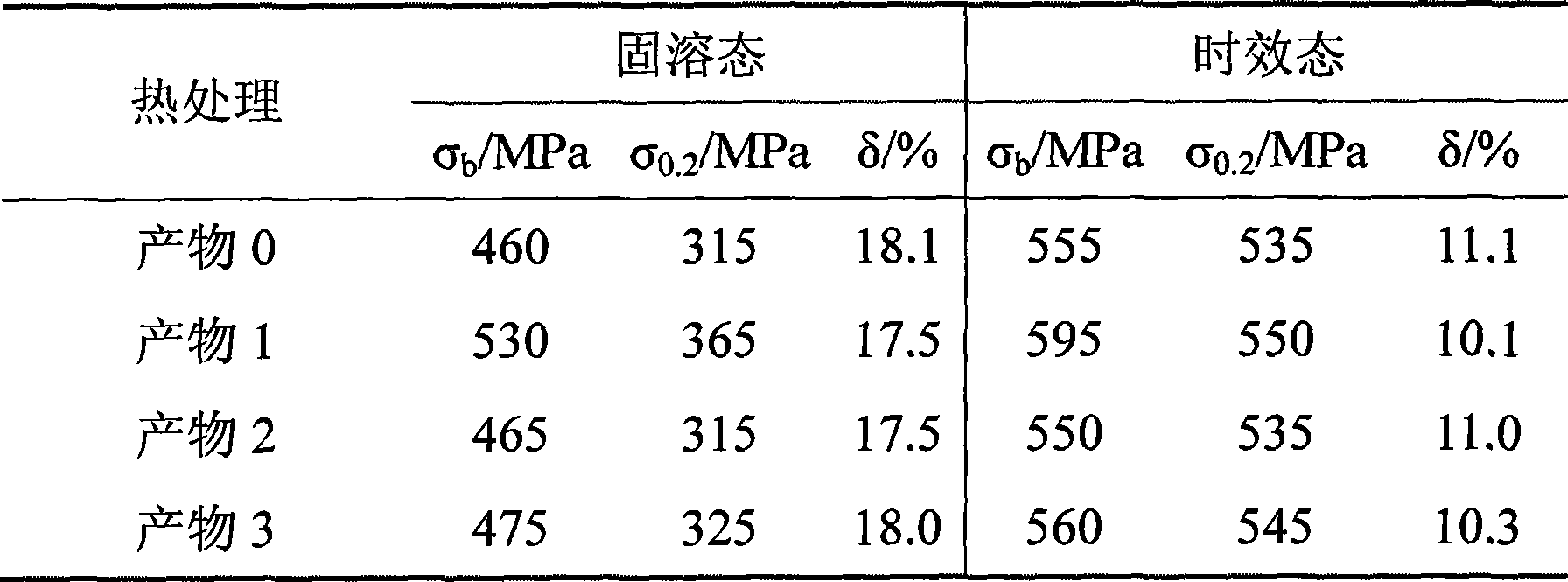

Thermal treatment method for Al-Zn-Mg-Sc-Zr alloy

A heat treatment method of Al-Zn-Mg-Sc-Zr alloy comprises such five steps as hot rolling, first solution, cold rolling, second solution and aging. During the first solution, a second-phase is dissolved in a base to obtain supersaturated solution, thus effectively improving the alloying effects of Sc and Zr and at the same time softening the alloy to provide fully softened organism for later cold rolling with comparatively large deformation; the later cold rolling can smash the undissolved coarse phase, thus is beneficial for the coarse phase to be dissolved in the matrix during the second solution, improves the supersaturation level of the base, lowers the probability of the occurrence of cracks during the alloy deformation, and at the same time lays a foundation for aging to precipitate more strengthening phases. Compared with the conventional heat treatable alloy, when the cold rolling deflection of the alloy treated by the method of the invention is 50.0%, the tensile strength and yield strength of the alloy in solution state are respectively improved by 70MPa and 50MPa and the tensile strength and yield strength of the alloy in aging state are respectively improved by 40MPa and 35MPa. The method of the invention is simple in technique and convenient in operation, is applicable to industrial application and provides a new processing method for the improvement of the property of aerospace materials.

Owner:CENT SOUTH UNIV

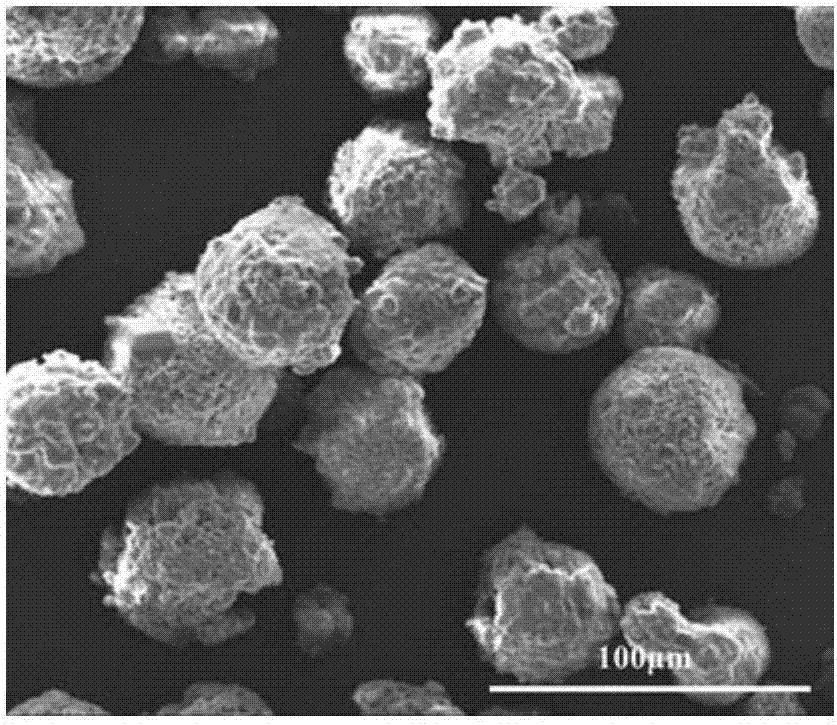

Preparation method of aluminum hydroxide gel and microlite alpha-Al2O3 aggregate

ActiveCN102807243ASmall grainReduce grain sizeAmmonium nitratesAluminium oxide/hydroxide preparationAluminium hydroxideDevice material

The invention relates to an aluminum hydroxide gel. The preparation method includes performing reaction of aluminum nitrate hydrate and ammonia water to obtain aluminum hydroxide, adding additive to suspension after ball-milling to obtain aluminum hydroxide gel, and drying to obtain aluminum hydroxide dried gel; and grinding and calcining the aluminum hydroxide dried gel to prepare microlite alpha-Al2O3 aggregate. The preparation method is suitable for large-scale production of the microlite alpha-Al2O3 aggregate, conditions of process are easy to control, grain size of primary grain of the prepared microlite alpha-Al2O3 aggregate is 50-400nm, particle size of secondary aggregate particle of the prepared microlite alpha-Al2O3 aggregate is 75-600um, the prepared microlite alpha-Al2O3 aggregate is compact in structure, density is 3.90-3.98g / cm<3>, and hardness is 19-24GPa. The prepared microlite alpha-Al2O3 aggregate can be used for abrasive, high-temperature-resistant material, electronic device material, high-frequency insulation material, aerospace material, information material and the like.

Owner:SHANDONG UNIV

Heat treatment process for improving low temperature plasticity of selective laser melting forming GH4169 alloy

InactiveCN109321854AMeeting urgent needsIncrease temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingAlloy

The invention belongs to the technical field of heat treatment of additive manufacturing advanced aerospace materials, and particularly relates to a heat treatment process for improving low temperature plasticity of a selective laser melting forming GH4169 alloy. The heat treatment process is used for significantly improving low temperature plasticity. The heat treatment process comprises the steps that 1, homogenization heat treatment is carried out on the selective laser melting forming GH4169 alloy; 2, solid solution heat treatment is carried out on the selective laser melting forming GH4169 alloy obtained after homogenization heat treatment; and 3, aging heat treatment is carried out on the selective laser melting forming GH4169 alloy obtained after homogenization and solid solution. According to the heat treatment process, the high temperature homogenization process is additionally arranged before conventional solid solution, system optimization is carried out on the heat preservation temperature and the holding time parameter of all processes, the ultra-low temperature plasticity of the selective laser melting forming GH4169 alloy is greatly improved, is greatly improved from10.5% to more than 20%, and is far higher than the design index requirements, it is ensured that the comprehensive mechanical properties of the products meet the design specification requirements, and the urgent need of the model to the materials is met.

Owner:CAPITAL AEROSPACE MACHINERY +1

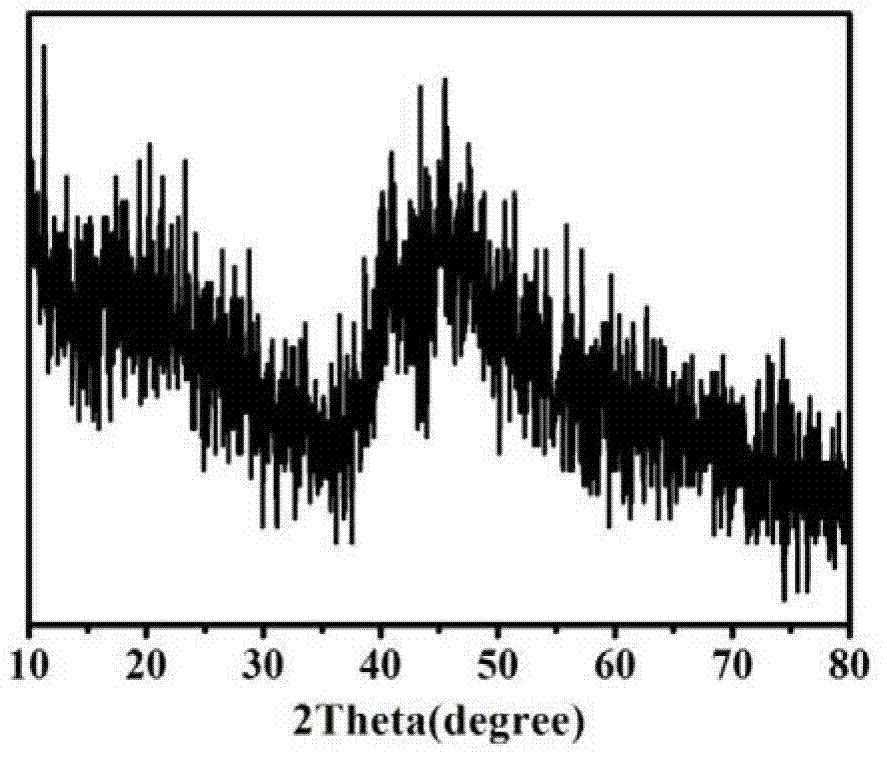

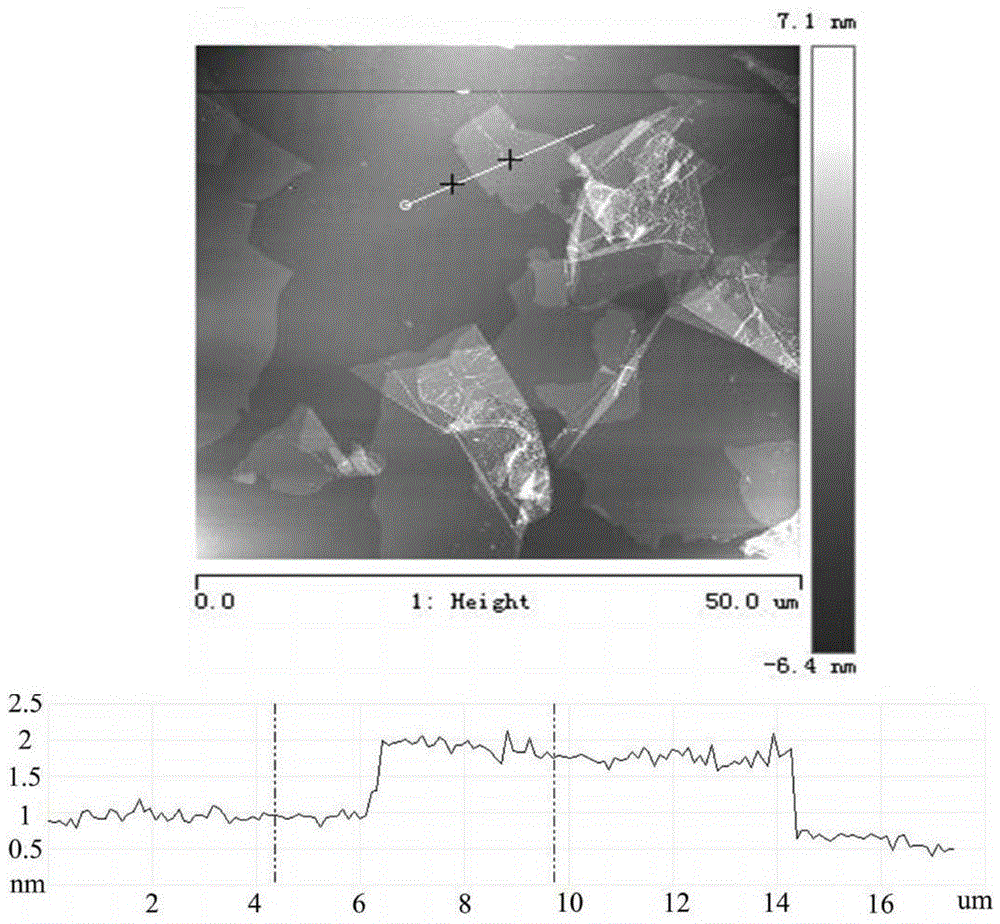

Method for preparing graphene by using green reducing agent

The invention discloses a method for preparing graphene by using a green reducing agent, and relates to the technical field of graphene. The method comprises the steps: firstly, preparing graphite oxide by using a Hurmers method, and then stripping by ultrasonic waves to form a graphene oxide solution; then under an alkaline condition, reducing graphene oxide by using L-tyrosine as a reducing agent to obtain reduced graphene; and finally, washing with water, centrifuging and carrying out freeze vacuum drying to obtain a graphene powder. The green environmental-protection reducing agent is used for preparation of graphene. Compared with a traditional reducing agent, the used reducing agent has the advantages of low cost, no toxicity, and green and environmental protection; the prepared graphene has the advantages of larger specific surface area, high-temperature resistance, corrosion resistance, high strength, and good electrical conductivity, can be applied in the fields of smart clothing, lithium ion batteries, super capacitors, anti-corrosion coatings, military aerospace materials and the like.

Owner:宁国市龙晟柔性储能材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com