Method for preparing graphene by using green reducing agent

A technology of graphene and reducing agent, applied in the field of graphene, can solve the problems of sodium borohydride being flammable and explosive, the high price of HI acid, restricting industrial production, etc., and achieve the effect of convenient industrial production, low cost and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

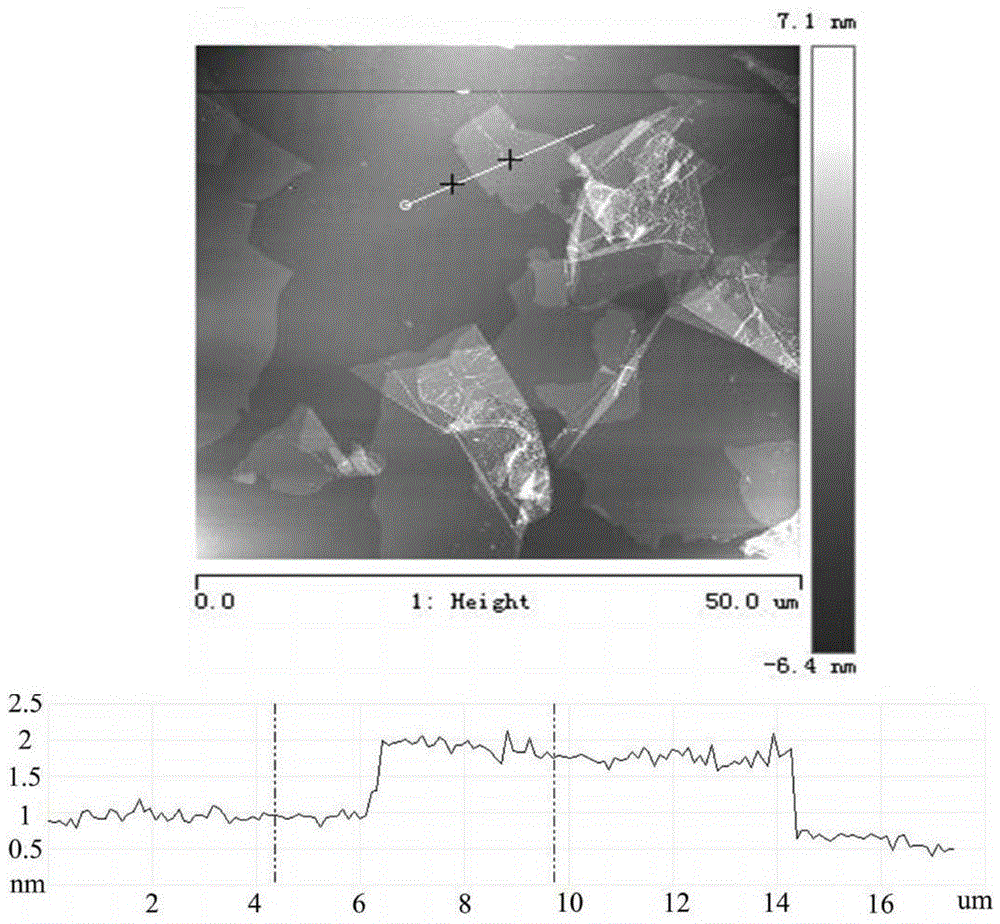

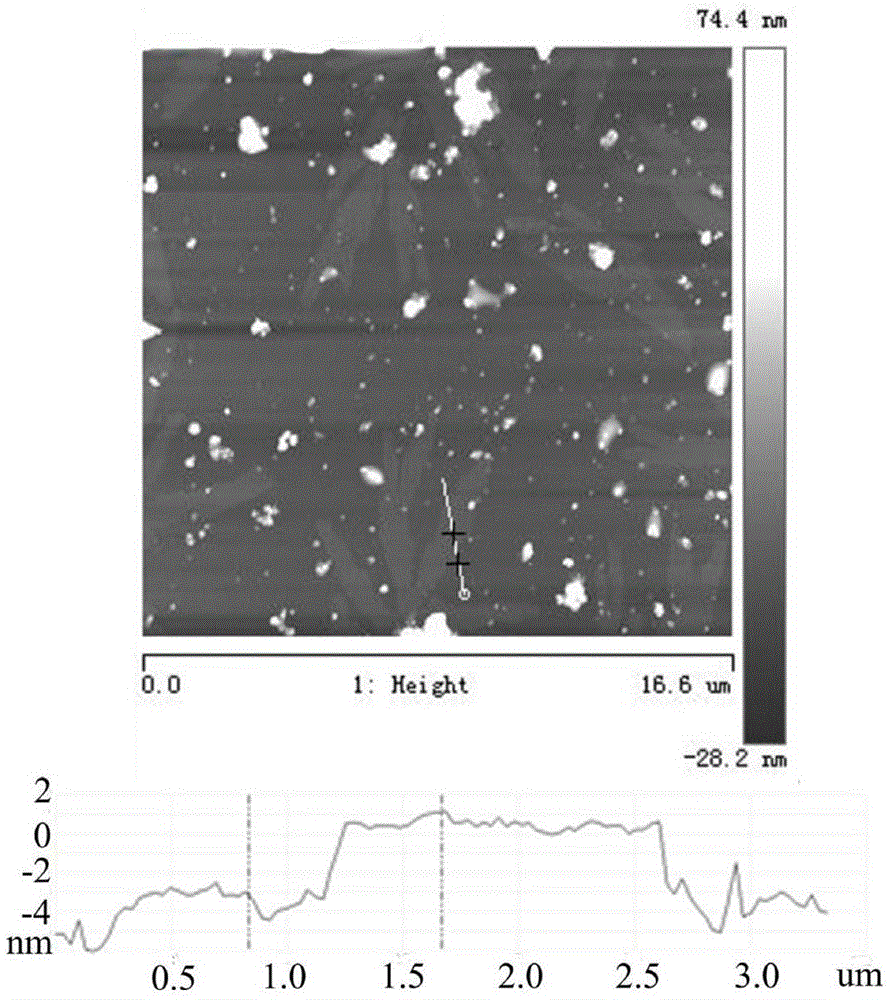

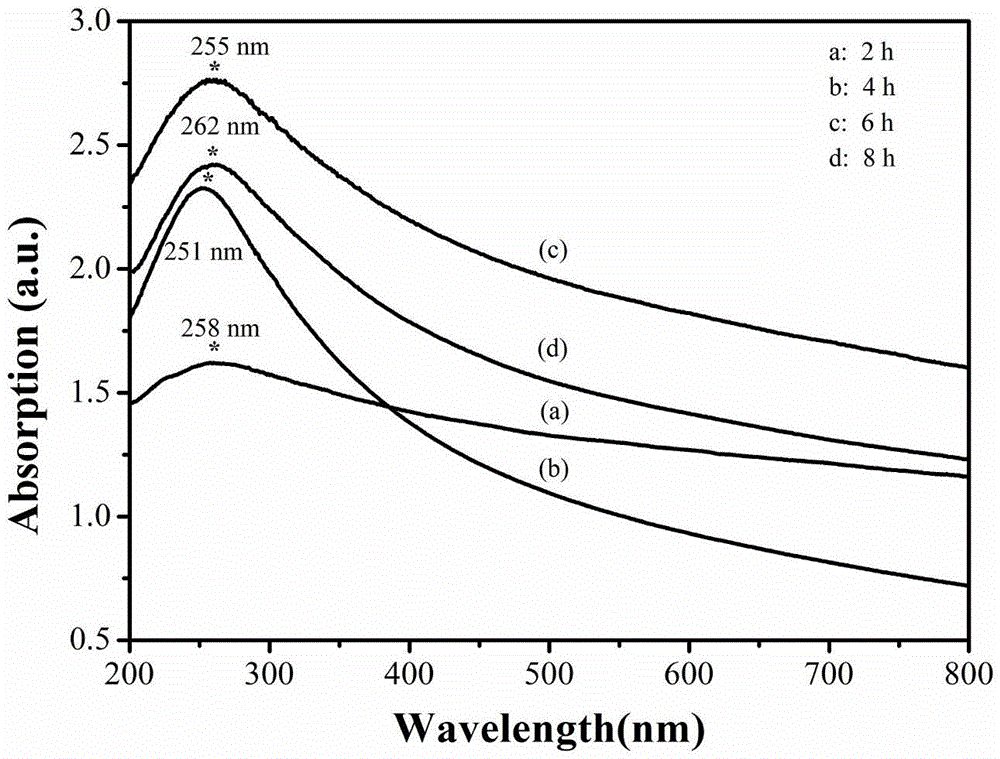

Image

Examples

Embodiment 1

[0031] (1) Preparation of graphene oxide; the reaction temperature is 0-5°C, add 1g of graphite powder, 0.5g of sodium nitrate and 3g of potassium permanganate in sequence to 23mL of concentrated sulfuric acid, stir the mixed solution magnetically for 0-60min; heat up to 35 ℃, continue to stir for 30min, slowly add 110mL deionized water; heat to 90℃, keep stirring for 30min, then add 18mL hydrogen peroxide, filter while hot; and wash with 5% HCl solution and deionized water until no sulfate is detected in the filtrate Finally, the filter cake is dried;

[0032] (2) Prepare a graphene oxide solution with a volume of 100mL and a mass fraction of 0.2%, and add NH dropwise under magnetic stirring conditions 3 ·H 2 O adjusts the pH value to about 10;

[0033] (3) Weigh 0.02g of L-tyrosine, add it to a 100mL volumetric flask, and prepare an L-tyrosine solution with a concentration of 0.2mg / mL;

[0034] (4) Add the prepared L-tyrosine solution into the mixed solution in step (2), ...

Embodiment 2

[0036] (1) with embodiment 1;

[0037] (2) Prepare a graphene oxide solution with a volume of 100mL and a mass fraction of 0.1%, and add NH dropwise under magnetic stirring conditions 3 ·H 2 O adjusts the pH value to about 10;

[0038] (3) Weigh 0.01g of L-tyrosine, add it into a 100mL volumetric flask, and prepare an L-tyrosine solution with a concentration of 0.1mg / mL;

[0039] (4) Add the prepared L-tyrosine solution into the mixed solution in step (2), and stir magnetically for 8 hours under the condition of a water bath at 95°C. Centrifuge, wash several times with water, and dry.

Embodiment 3

[0041] (1) with embodiment 1;

[0042] (2) Prepare a graphene oxide solution with a volume of 100mL and a mass fraction of 0.05%, and add NH dropwise under magnetic stirring conditions 3 ·H 2 O adjusts the pH value to about 10;

[0043] (3) Weigh 0.01g of L-tyrosine, add it into a 100mL volumetric flask, and prepare an L-tyrosine solution with a concentration of 0.1mg / mL;

[0044] (4) Add the prepared L-tyrosine solution into the mixed solution in step (2), and stir magnetically for 8 hours under the condition of a water bath at 95°C. Centrifuge, wash several times with water, and dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com