High-entropy alloy with banded precipitated phase and preparation method thereof

A technology of high-entropy alloys and precipitated phases, applied in the field of high-entropy alloys, can solve the problems of poor strength and toughness matching of high-entropy alloys, achieve good room temperature tensile properties, wide composition range, and improve the effect of solid solution strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Co 33.33 Cr 33.34 Ni 33.33 Preparation and Microstructure Observation of High Entropy Alloy

[0028] Described pure cobalt, pure chromium, pure nickel and pure molybdenum all adopt commercially available common pure metals with a purity equal to 99.5%, and the chemical composition is calculated as (at.%) by atomic percentage according to the composition formula: Co: 33.33; Cr: 33.34 ; Ni: 33.33 for batching.

[0029] 1) Put pure cobalt, pure chromium, pure nickel and pure molybdenum into the rust remover and soak for 15 minutes; the rust remover is a mixture of hydrochloric acid, sulfuric acid and deionized water, and the mass percentage is 50% hydrochloric acid And sulfuric acid 3%, all the other are deionized water; The mass percentage concentration of above-mentioned hydrochloric acid is 38%, the mass percentage concentration of sulfuric acid is 75%;

[0030] 2) Ultrasonic cleaning: ultrasonically clean the pickled raw materials in absolute ethanol to ...

Embodiment 2

[0038] Example 2: (CoCrNi) 90 Mo 10 Preparation and Microstructure Observation of High Entropy Alloy

[0039] Described pure cobalt, pure chromium, pure nickel and pure molybdenum all adopt commercially available common pure metals with a purity equal to 99.5%, and the chemical composition is calculated as (at.%) by atomic percentage according to the composition formula: Co: 30; Cr: 30 ; Ni: 30; Mo: 10 for batching.

[0040] 1) Put pure cobalt, pure chromium, pure nickel and pure molybdenum into the rust remover and soak for 10-20 minutes; the rust remover is a mixture of hydrochloric acid, sulfuric acid and deionized water, and the mass percentage is hydrochloric acid 50% and sulfuric acid 3%, all the other are deionized water; the mass percentage concentration of above-mentioned hydrochloric acid is 38%, the mass percentage concentration of sulfuric acid is 75%;

[0041] 2) Ultrasonic cleaning: ultrasonically clean the pickled raw materials in absolute ethanol to remove o...

Embodiment 3

[0049] Embodiment 3: (CoCrNi) 90 Mo 10 Preparation and Microstructure Observation of High Entropy Alloy

[0050] The other steps are the same as in Example 2, except that the hot-rolled alloy plate is homogenized at 1200° C. for 1 hour, and then water-cooled to room temperature; finally, the high-entropy alloy strengthened by band-shaped precipitates according to the present invention is obtained.

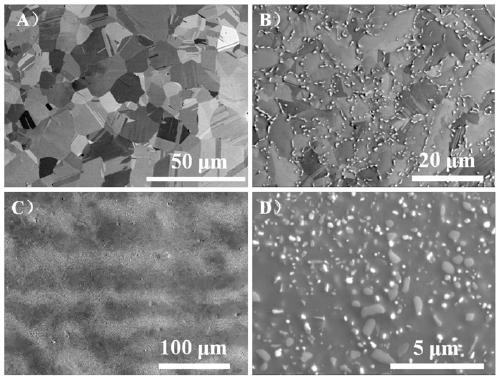

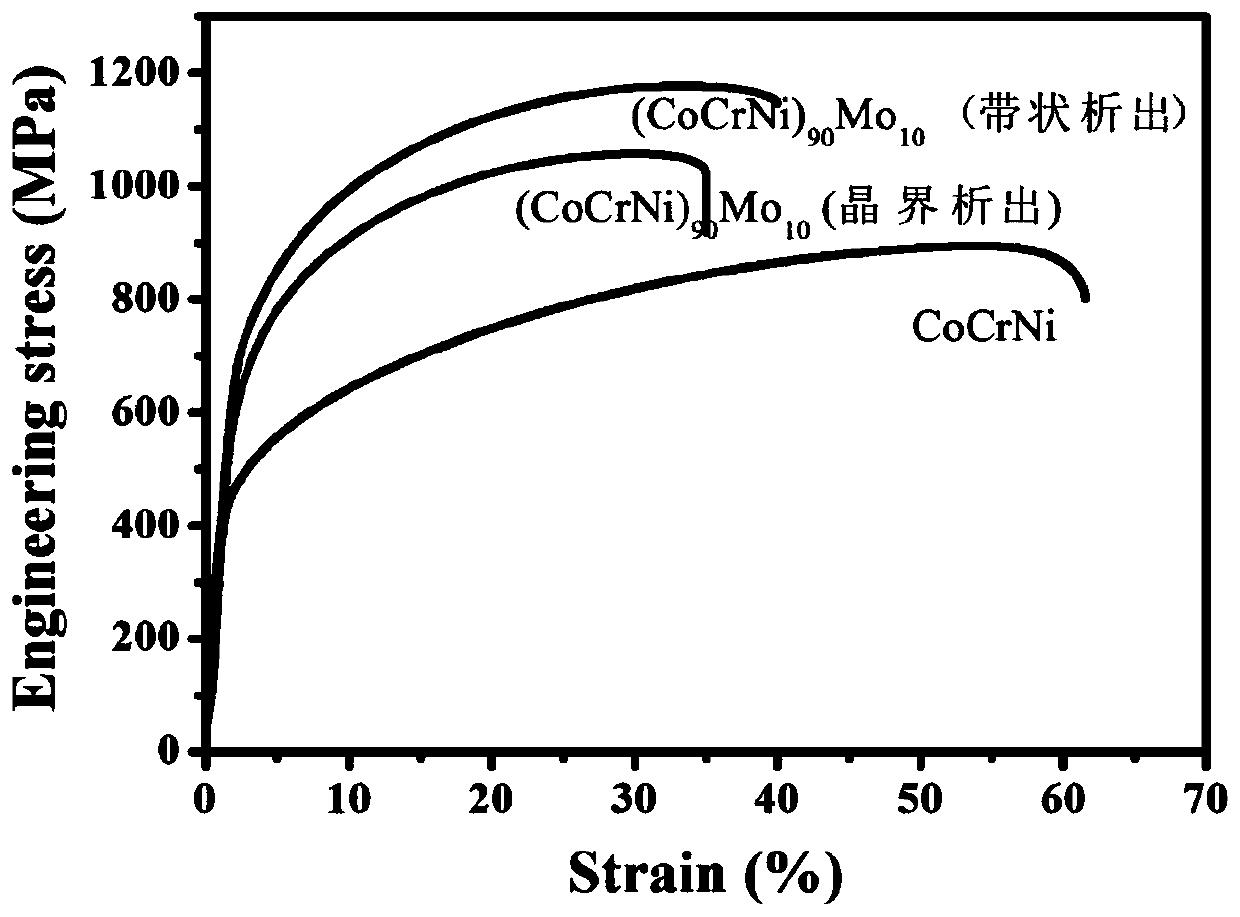

[0051] the result shows, figure 1 C (CoCrNi) 90 Mo 10 The structure of the alloy has a banded precipitated phase structure; figure 1 In D, the size of the precipitated phase is 0.1 to 2 μm. Since the experimental alloy has a band-shaped distribution of precipitation-strengthening phases, and the σ-precipitated phase accounts for 45%, its tensile mechanical properties at room temperature are very excellent. figure 2 gives Co 33.33 Cr 33.34 Ni 33.33 , (CoCrNi) 90 Mo 10 Room temperature stress-strain curves of two high-entropy alloys in the annealed state. Its tensile str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com