Patents

Literature

53 results about "Chocolate candy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blackthorn pear products and its production

InactiveCN101073370AImprove stabilityReduce the loss of nutritional valueConfectionerySweetmeatsPEARVitamin C

The invention is concerned with a kind of Rosa roxburghii Tratt candy produce. It produces the syrup of pure Rosa roxburghii Tratt or compound Rosa roxburghii Tratt into horniness candy, horniness candy with filling, soft candy, milk lipid candy, polishing candy, glue-based candy, charging candy, chocolate candy or jelly, and so on. It increases the stability of vitamin C, vitamin P and superoxide dismutase and affords a kind of high quality candy food with double functions of nutritional health care and relaxing. The produce method relates to prepare clarified Rosa roxburghii Tratt concentrated syrup with good stability, add assistant stuff as the amount of 1 to 50 percent of whole amount into the said syrup, prepare Rosa roxburghii Tratt grain or Rosa roxburghii Tratt fast-dissolving powder and follow the routine technology to produce horniness candy, horniness candy with filling, gel candy, glue-based candy, charging candy, chocolate candy or jelly, and so on.

Owner:SHANGHAI NORMAL UNIVERSITY

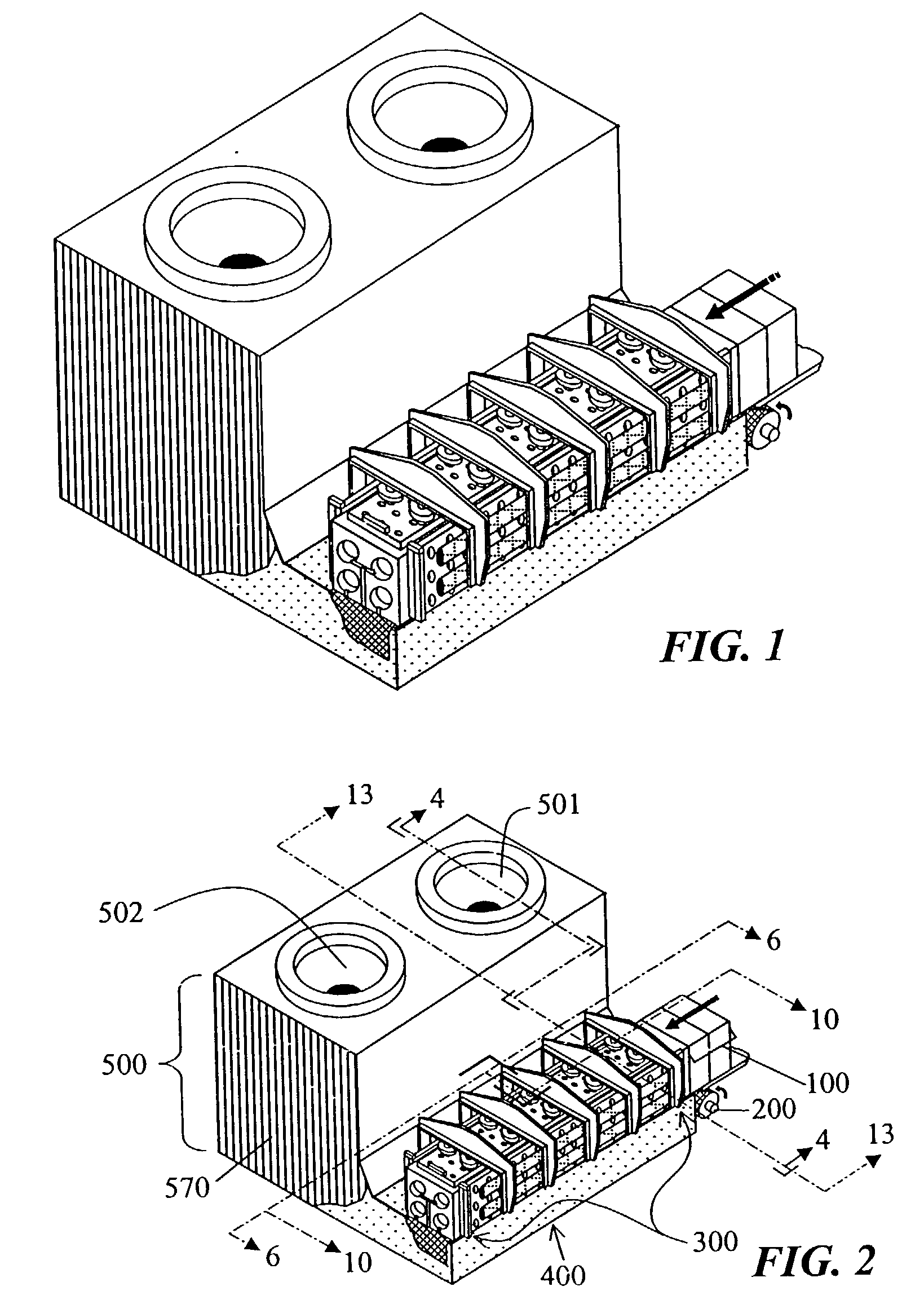

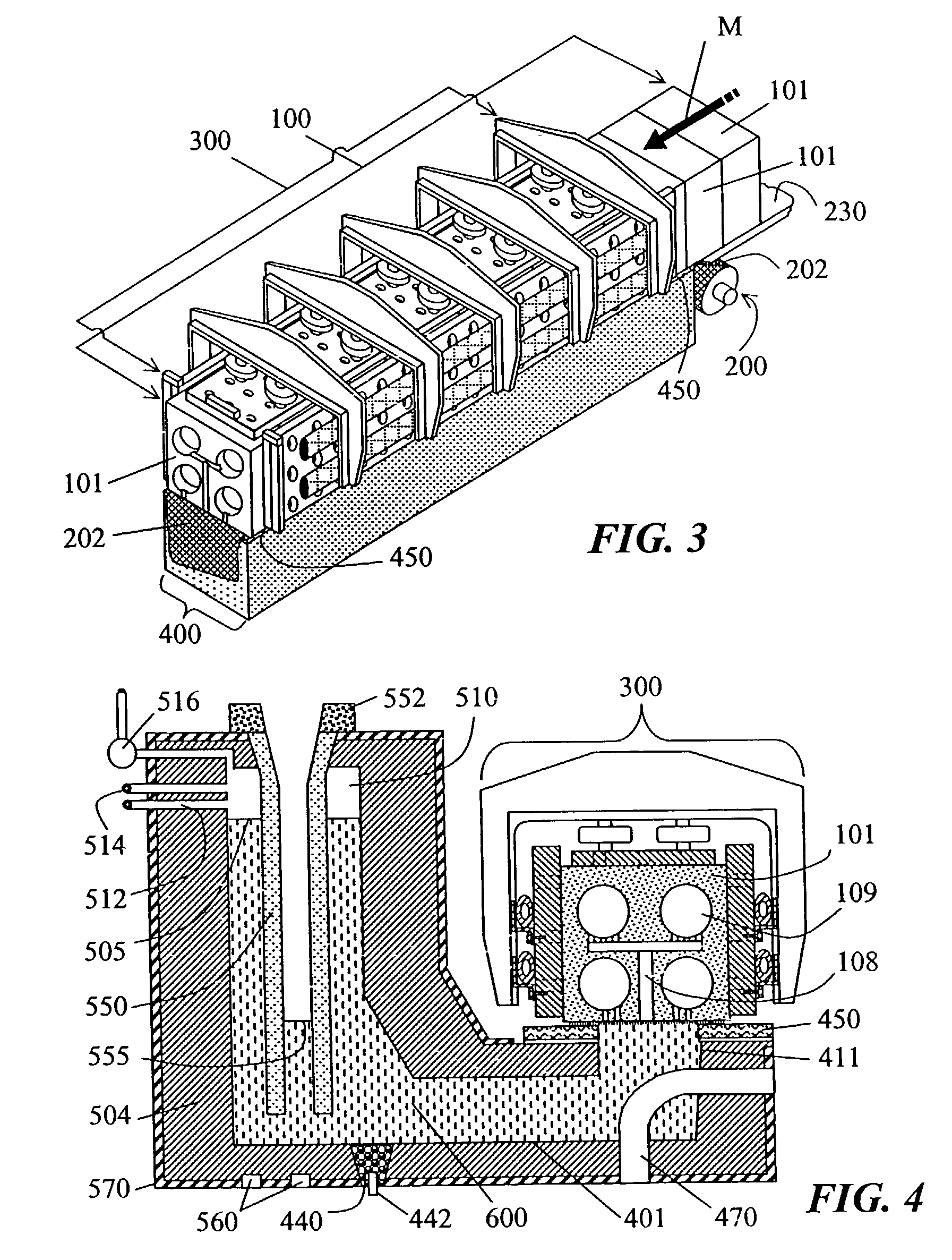

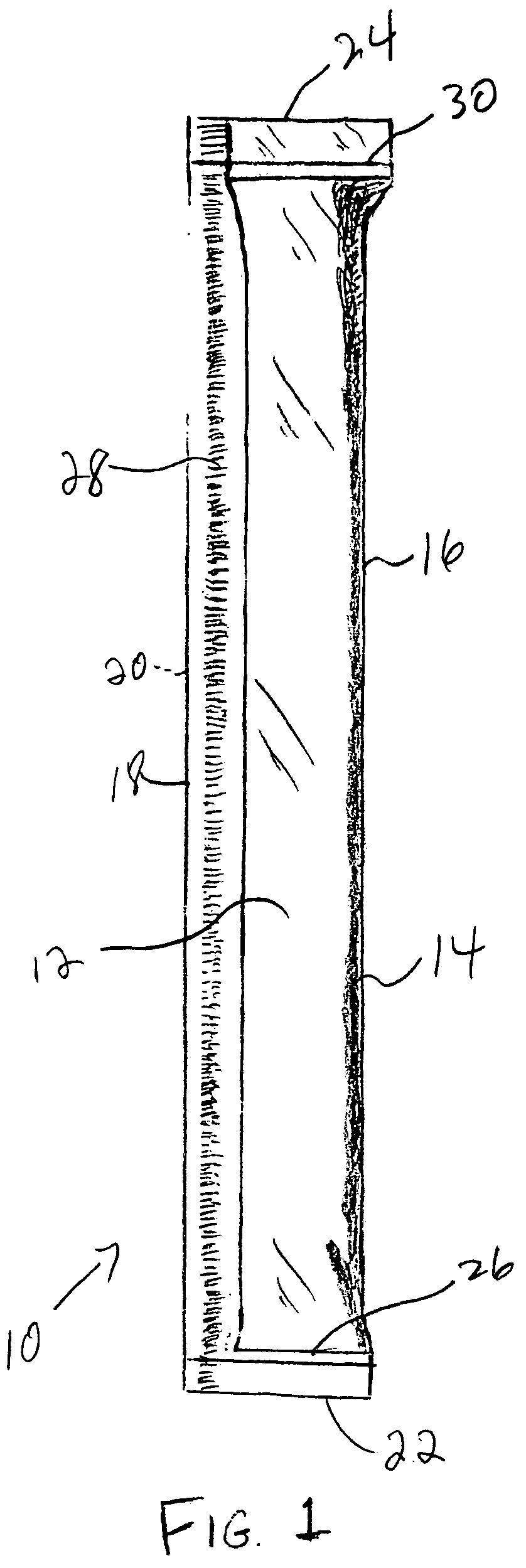

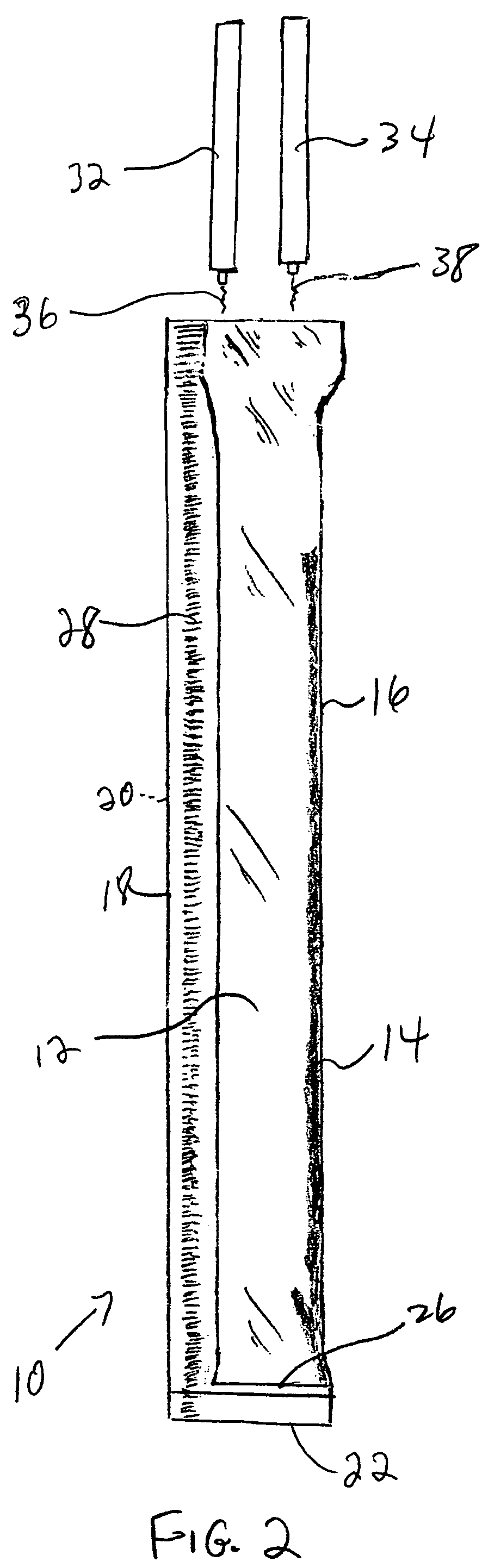

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

Owner:HERRON DAVID J

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

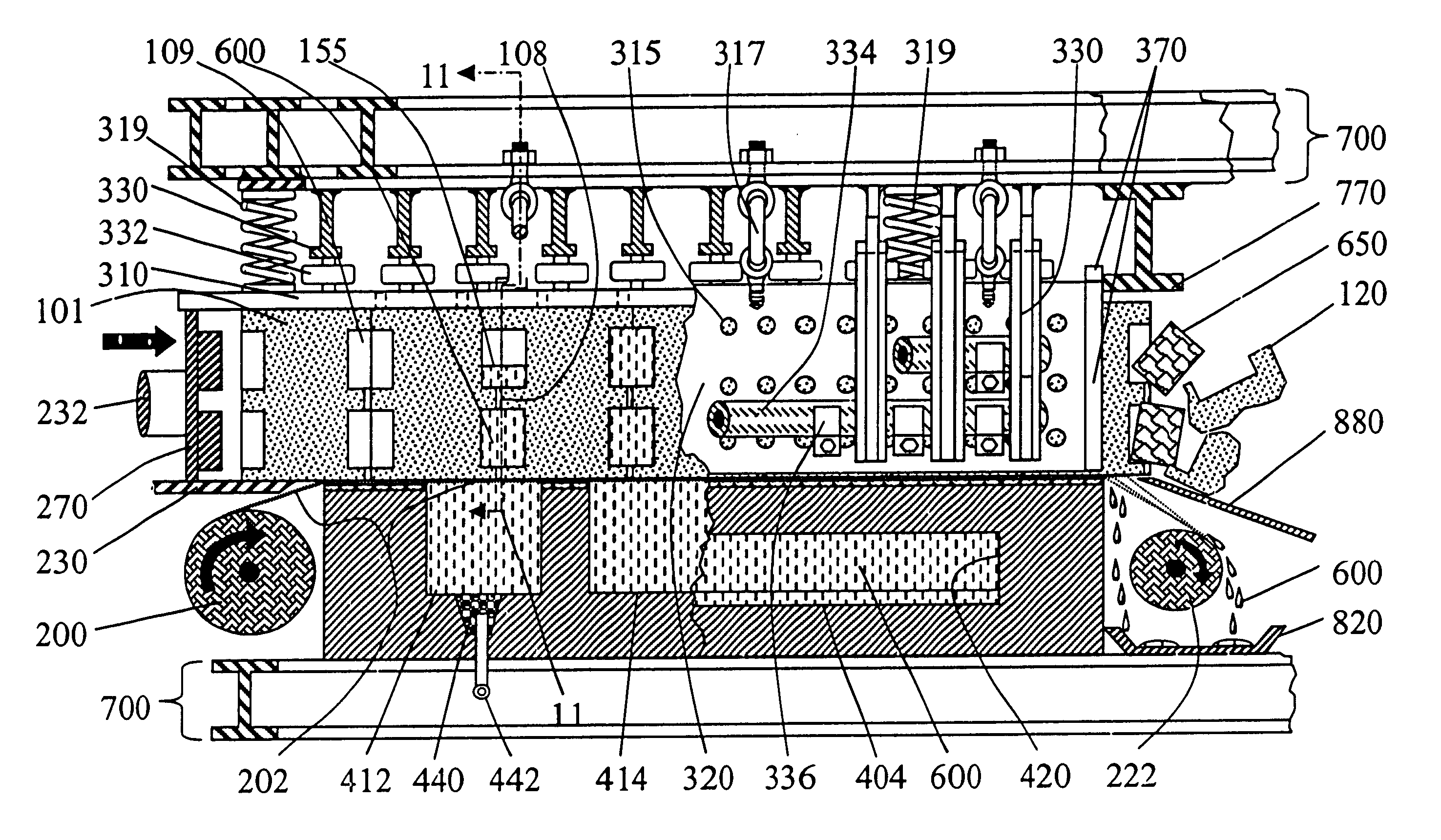

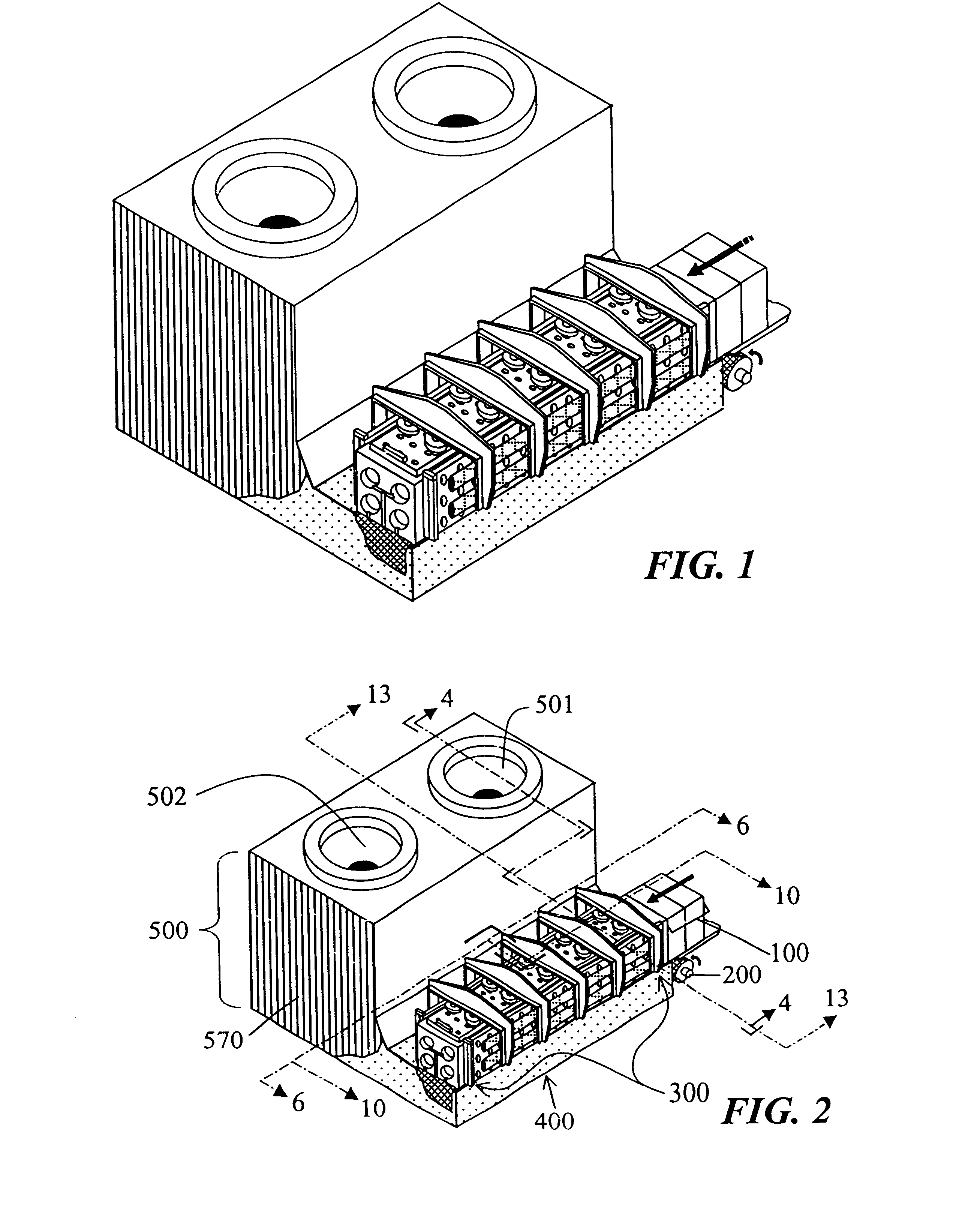

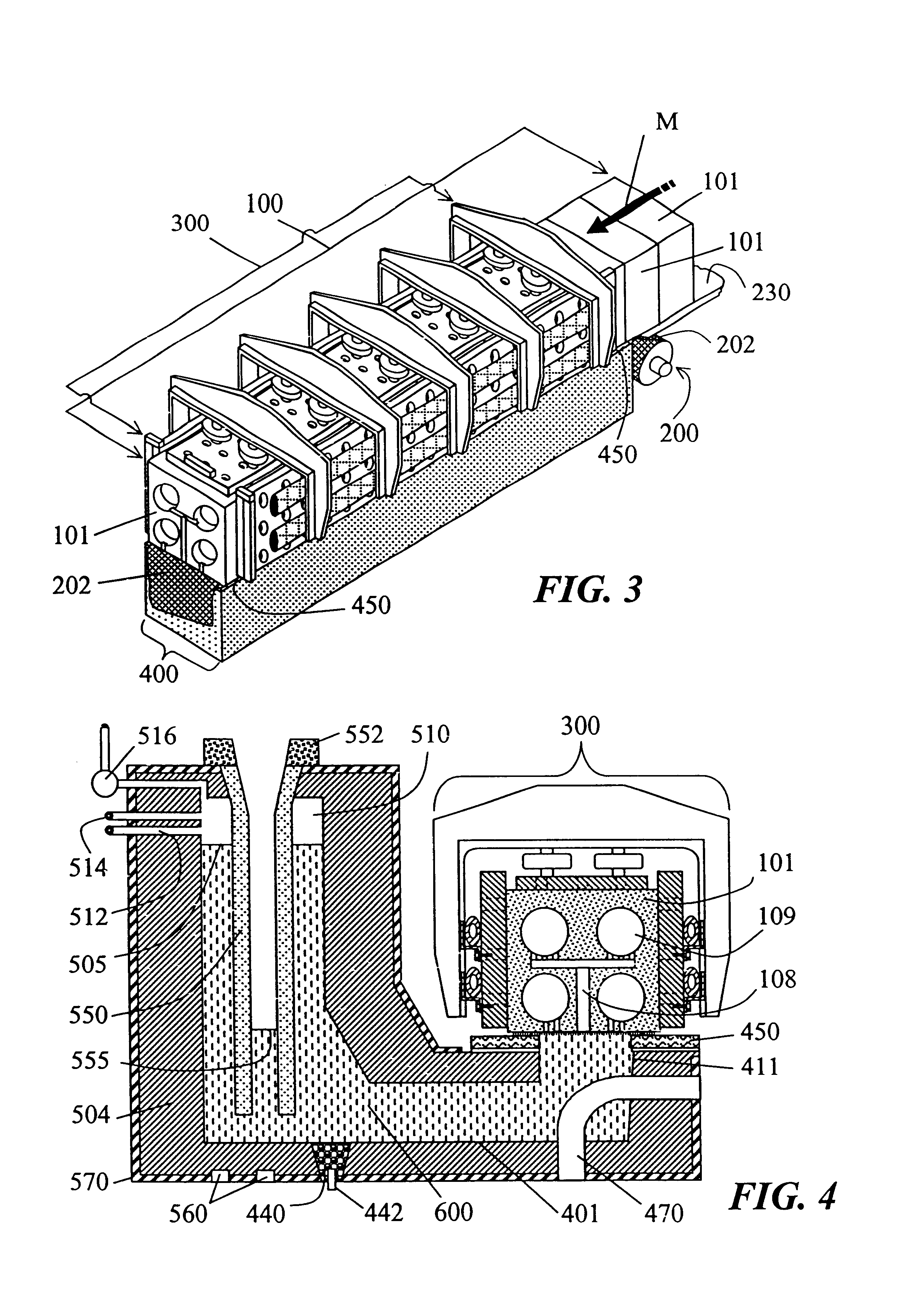

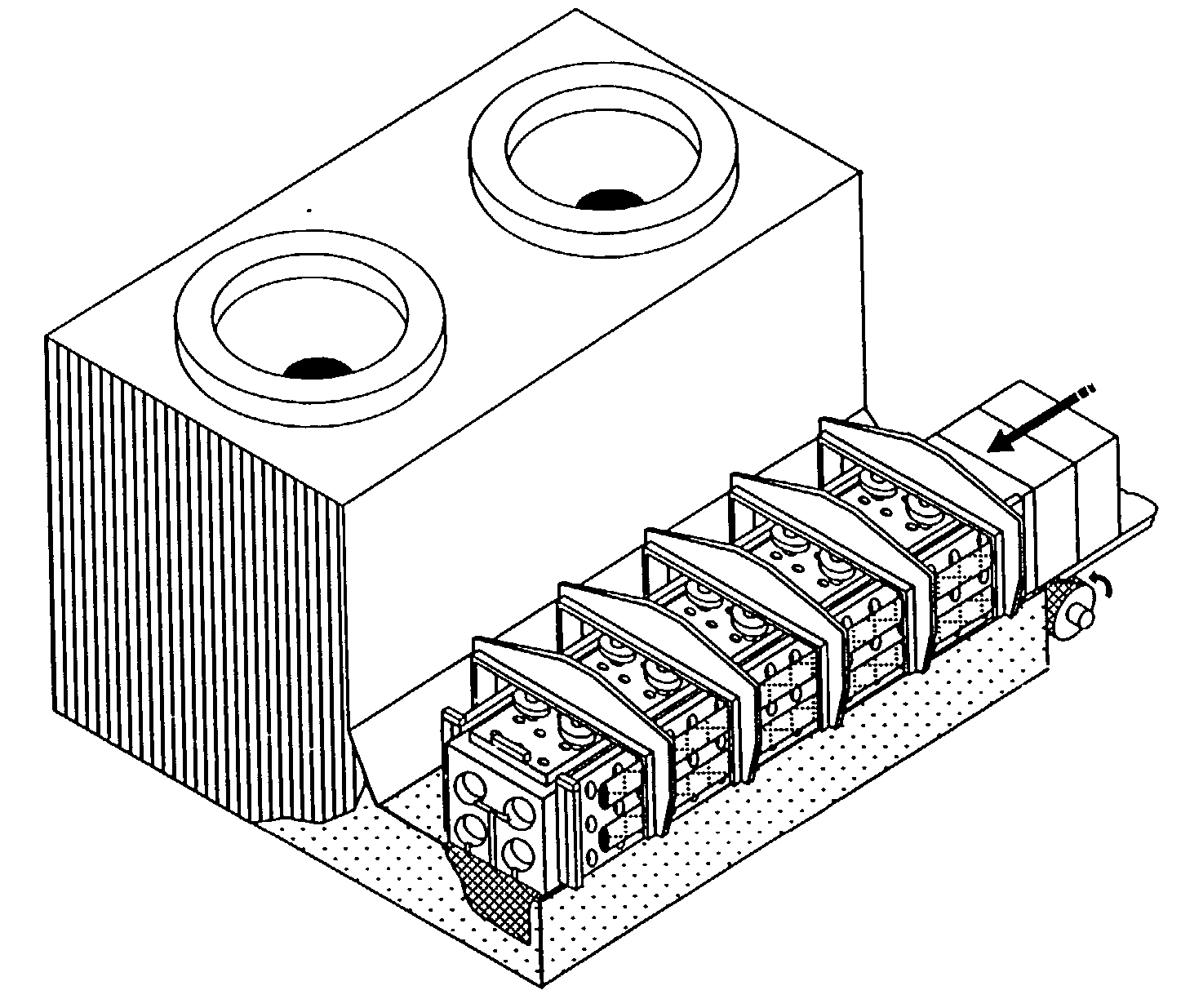

Mold filling and feeding device (400) and process including using refractory filter cloth (202) to seal a mold line (100), in continuous conveyance, to a multi-stage pressurized filling and feeding device. The mold line (100) is the line formed of vertically parted green sand molds (101). These molds can be filled with molten metal which gradually solidifies under pressure. Feeding under pressure will assist shrinkage problems in the casting process. The process includes modes of treating ductile iron with magnesium for compacted graphite. A stitch (242) of filter cloth (202) holds modifying alloy (630) to the molds (101) at high speed. A vacuum and pressure controlled column (550) provides consistent flow to thin walled castings, and pressurized feeding for heavy castings. Radiant energy losses are contained in the automatic system. The process and several special purpose machine components make a unified system for hardening liquid (600) such as plastic polymer, rubber tires, or food stuff, as in molded chocolate candy.

Owner:HERRON DAVID J

Gastrodia salvia series health-care sweets product and its preparation method

The present invention discloses a kind of gastrodia salvia series health-care sweets products with the good health-care effects for curing the diseases of neurosism, anemia, sleepless, hyposia, hypomnesia, hepatitis, tumor and hypertension and its preparation method. Said series sweets products including gastrodia salvia soft maltose, creamy candy, peppermint creams, coffee condy, chocolate pattis and crataegus candy, etc.

Owner:望宏端

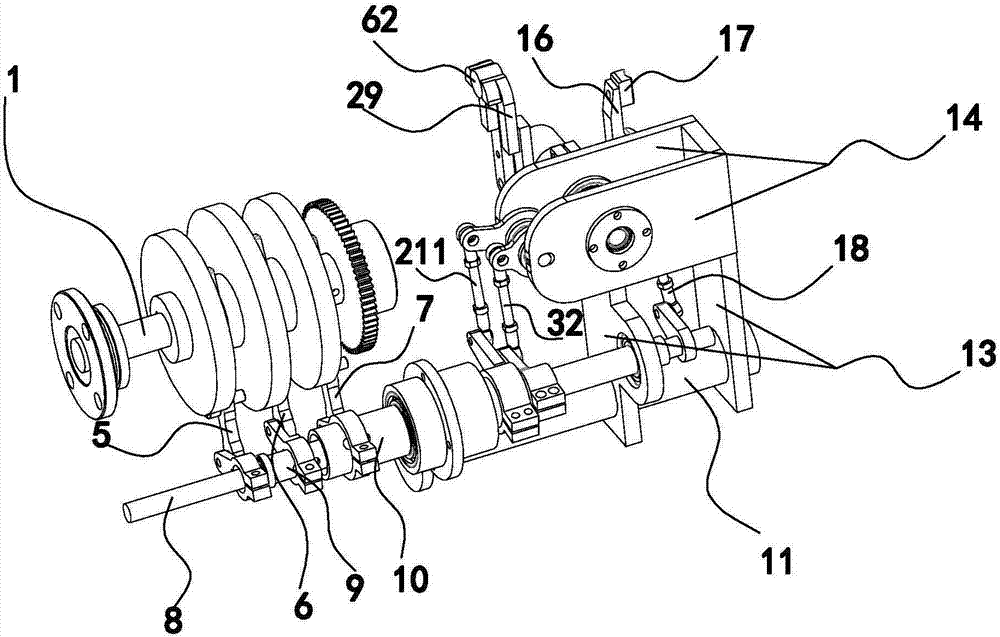

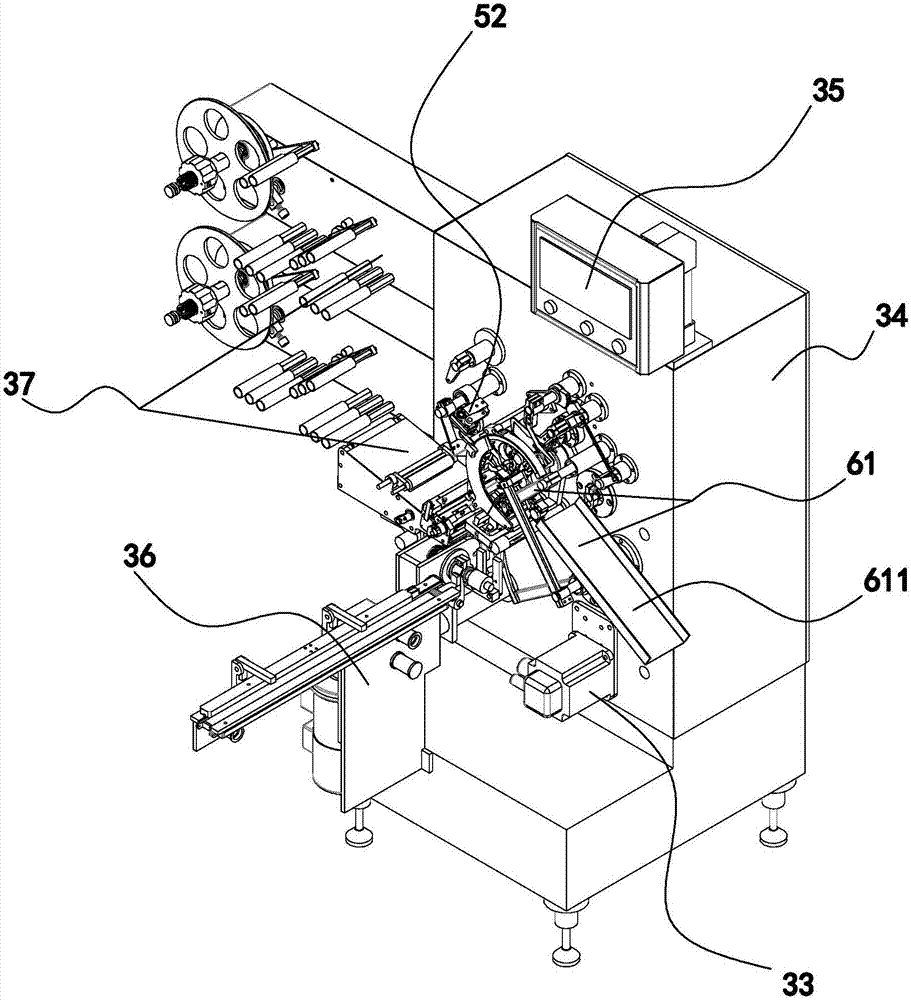

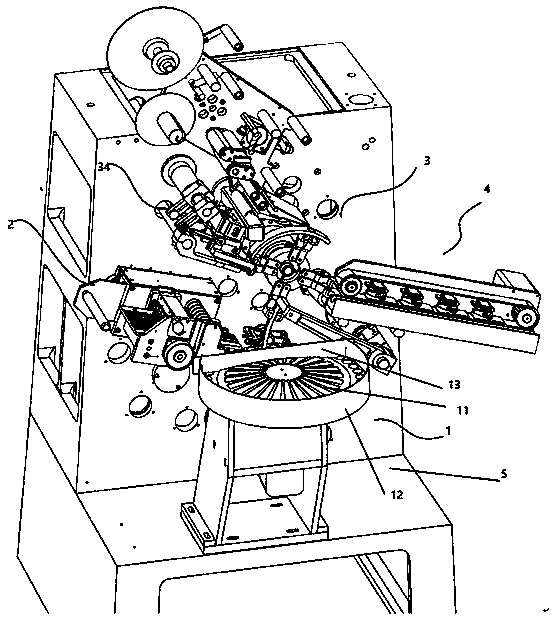

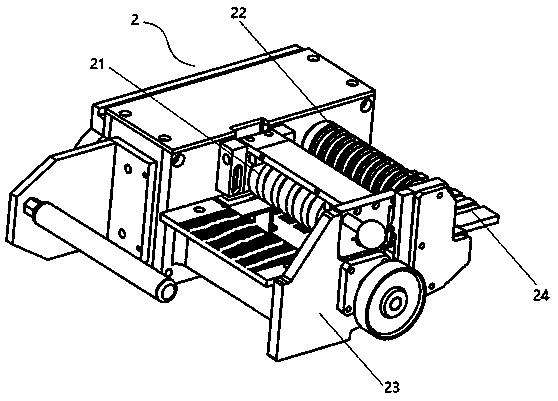

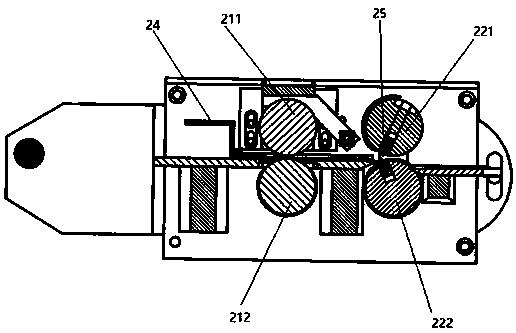

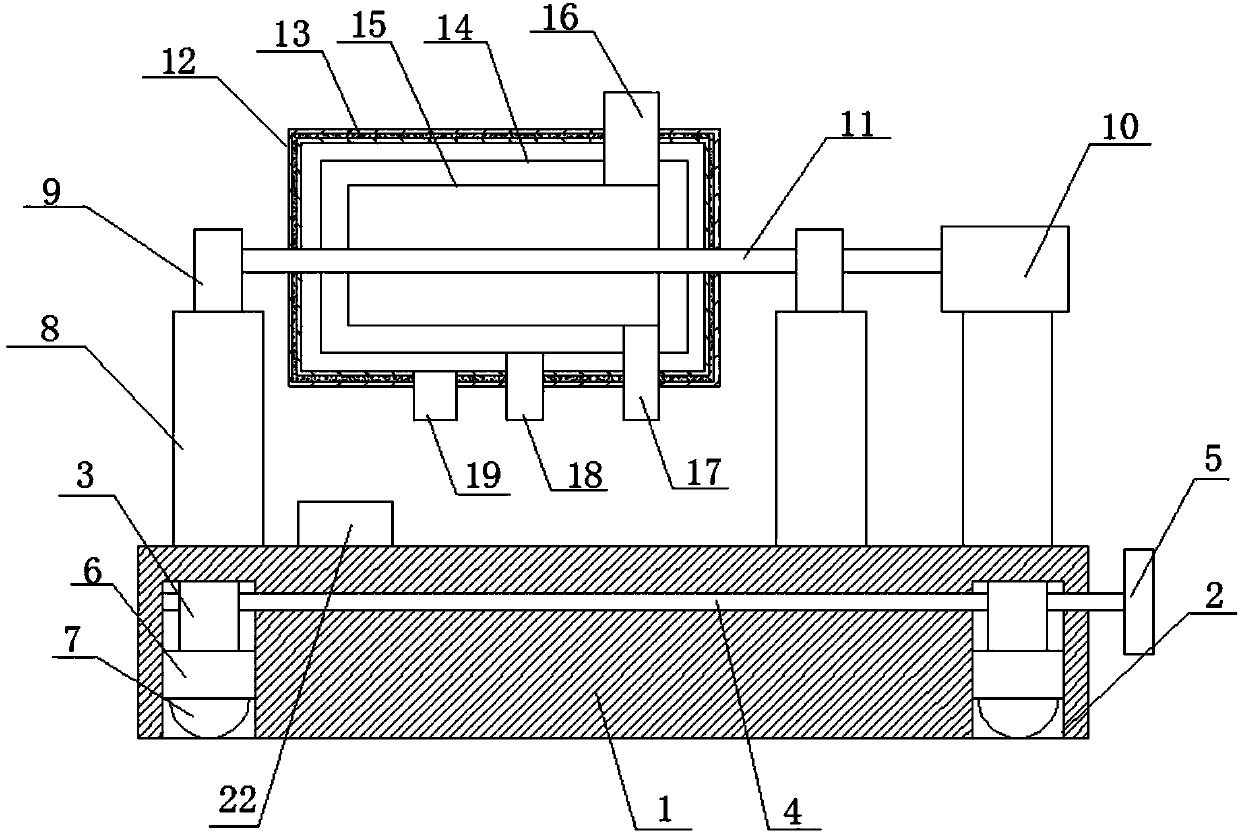

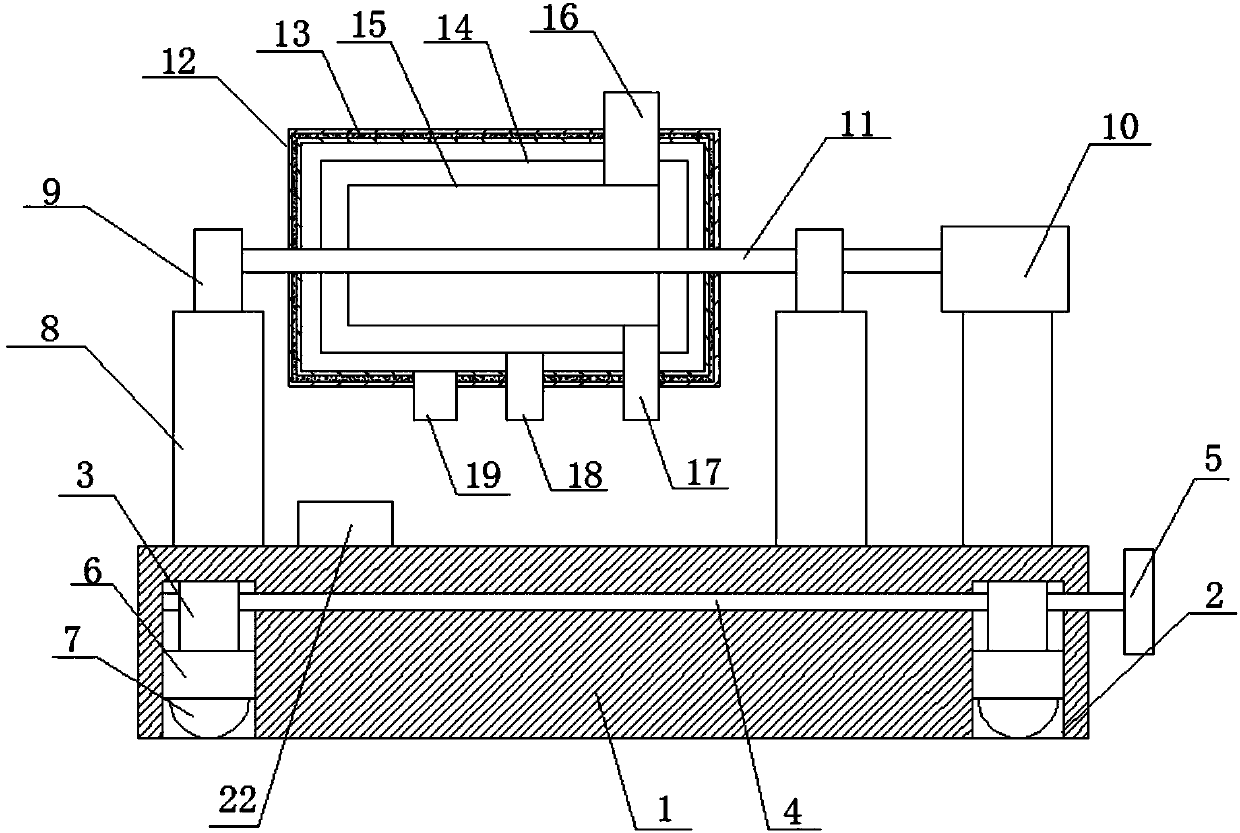

Candy taking and overturning mechanism and chocolate candy single-kink packing machine for food packing

InactiveCN107128525ASimple structureStable structureWrapping material feeding apparatusWrappingChocolate confectioneryEngineering

The invention provides a candy taking and a single-kink packing machine, belongs to the technical field of candy packing, and solves the problems of more complicated structure and low efficiency in the prior art. A chocolate candy single-kink packing machine for food packing comprises a frame, a controller, a driving motor connected with the controller, and a human-computer interaction platform. The machine further comprises a candy feeding mechanism, a candy taking and overturning mechanism, a paper feeding and cutting mechanism, a candy pressing mechanism and a candy packing mechanism; and the candy packing mechanism comprises a bottom edge packing mechanism, a side edge packing mechanism, a shrinkage twisting mechanism, a candy discharge mechanism and a clamping mechanism. The chocolate candy single-kink packing machine for food packing has the advantages of simple structure, convenience in cleaning, good transmission stability and high packing efficiency.

Owner:台州市椒江科瑞思机械科技厂

Chocolate candies fortified with natural amino acids and/or herbal nutrients for relief of insomnia, pms, and difficulty concentrating

A confection, such as chocolate, can be formulated to include naturally occurring amino acids and / or herbal extracts and / or plant extracts incorporated therein. The formulation allows a consumer to relieve health issues in a convenient, enjoyable manner. By incorporating the appropriate amino acids / herbal and plant extracts into a chocolate candy form, the confections can be formulated to provide relief of various ailments, such as insomnia, fatigue, PMS, difficulty concentrating and the like.

Owner:SMITH JR GERALD ZACHARY +1

Chocolate candies injected with probiotics and preparation method of chocolate candies

The invention discloses chocolate candies injected with probiotics and a preparation method of the chocolate candies. According to the candies, microcapsules containing bifidobacterium lactis and lactobacillus acidophilus wrap probiotic dry powder and are evenly mixed with low-sweetness massecuite, then chocolate injection is conducted, and the massecuite is prepared from freeze-dried probiotic powder, high fructose corn syrup, butter, condensed milk, fresh milk, modified starch, whole milk powder, sodium alga acid, lactic acid and salt. Chocolate injection is conducted on the prepared massecuite, and the chocolate candies injected with probiotics can be obtained. Chocolate is externally hung on the candies, the candies are of concentrated fragrance, sweet greasy, filled with the massecuite, sweet and sour and soft, the taste matching is appropriate, and to keep the probiotic activity of bacterial powder, the mixing temperature of the massecuite and the bacterial powder and the operation temperature of chocolate injection are each controlled to be within 20-50 DEG C.

Owner:GAEA GEM RICE

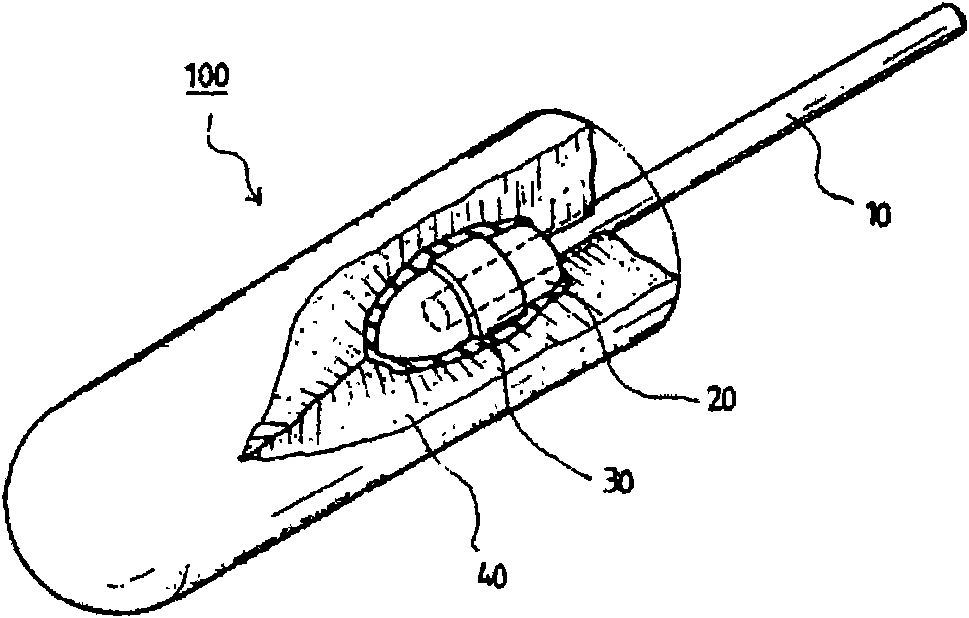

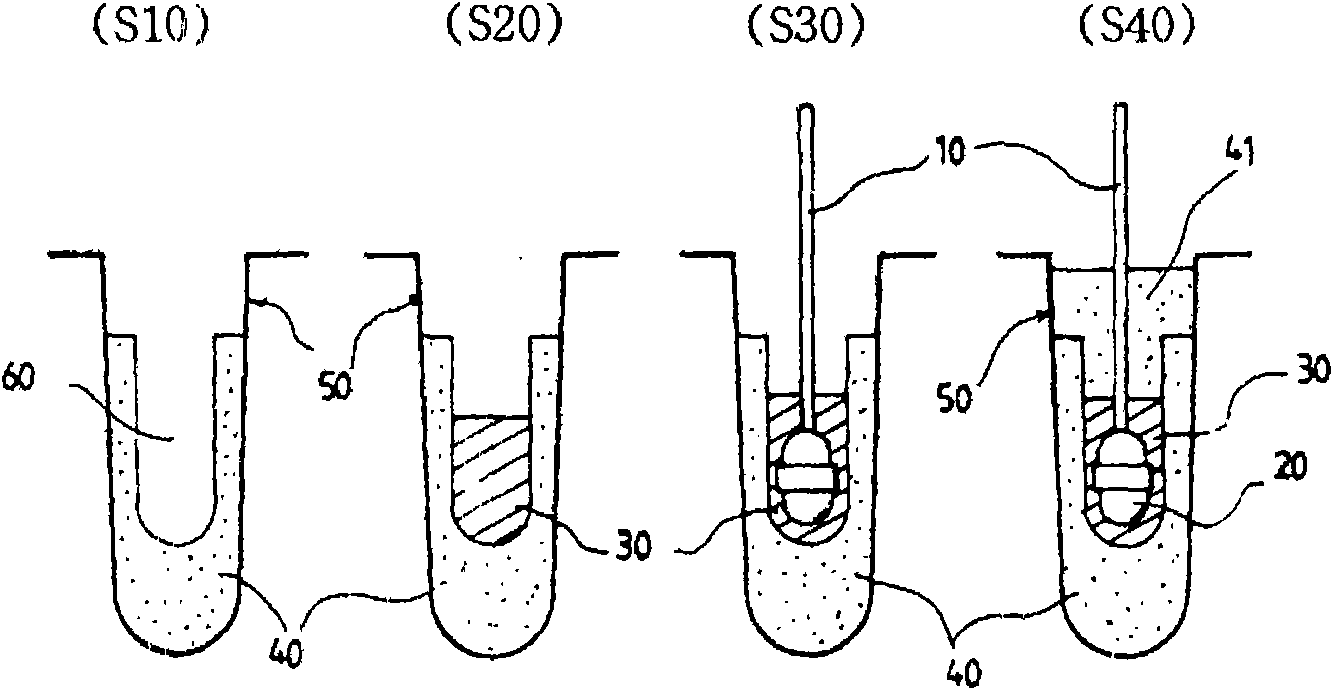

Ice cream bar containing chocolate candy and making method thereof

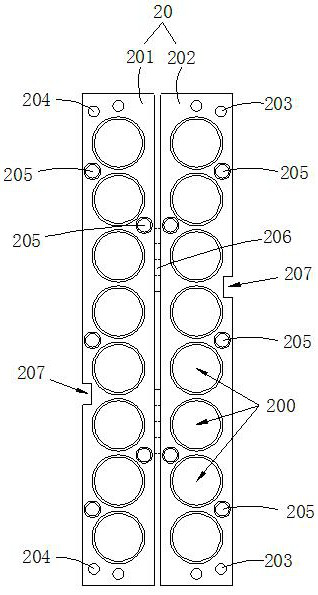

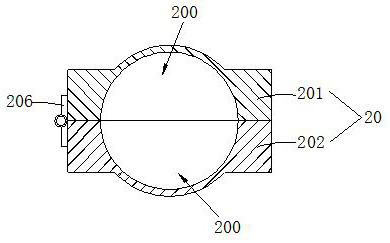

InactiveCN101617735AOvercoming problems when inserting directly into ice cream to form ice creamEasy to keepFrozen sweetsChocolate confectioneryIce cream

The invention relates to an ice cream bar containing chocolate candy and making method thereof. Candy (20) attached at one terminal of a handle (10) is inserted into and arranged in the interior of the ice cream (40), and chocolate (30) is used to cover the whole outer surface of the candy, so that the candy and the ice cream can not be directly and mutually contacted. The making method includes: a process (S10) of groove forming, the ice cream is put into a mould (50) and rapidly cooled, so that the appearance of the ice cream bar (100) is cured in accordance with the mould, the central part is absorbed and removed, so as to form the groove; a process (S20) of putting molten chocolate (30) into the groove formed by the process (S10); a process (S30) of inserting the handle (10) attached with the candy (20) into the interior of the chocolate be put in the process (S20); and a process (S40) of cooling, ice cream for terminal (41) is filled at the upper end of the handle (10) inserted into the interior of the chocolate (30) in the process (S30), the groove (60) is embedded, and then cooling is carried out.

Owner:GF CO LTD

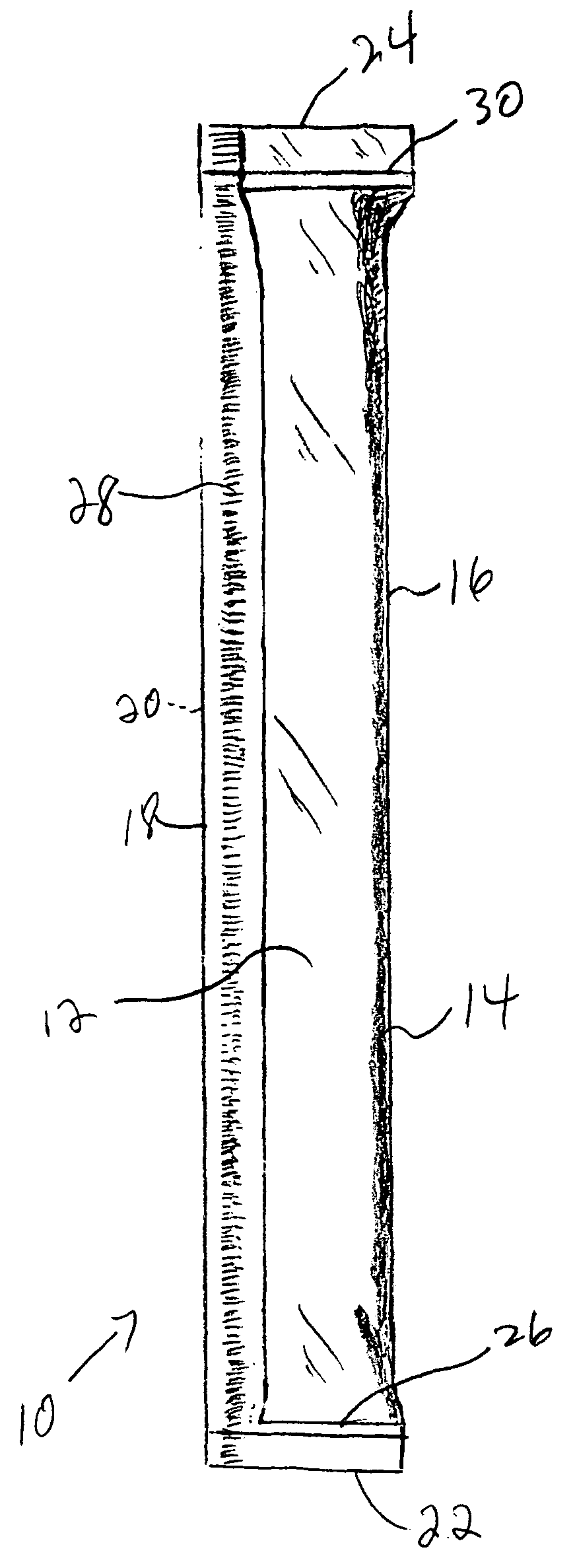

Nut butter variegate and process for preparing

InactiveUS7803417B2Convenient to enjoyFacilitate their formulationReady-for-oven doughsFood preservationEngineeringOrganoleptic

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

Chocolate candy containing iron and production

InactiveCN1613343AEnjoy delicious tasteKeep healthyMilk preparationConfectioneryCocoa PowdersSucrose

An iron-contained chocolate candy is prepared from pig's red blood cell coagulation, cane sugar, milk powder, gelatin, nipagin ethylester, vanilla powder, edible oil, cocoa and water through preparing blood-sugar cream, mixing milk powder, cocoa and vanilla powder together, mixing gelatin, edible salt, nipagin ethylester and water together, stirring while heating, adding said blood-sugar cream and can sugar, adding edible oil, adding said powder mixture, moulding and cooling.

Owner:薛洪爱

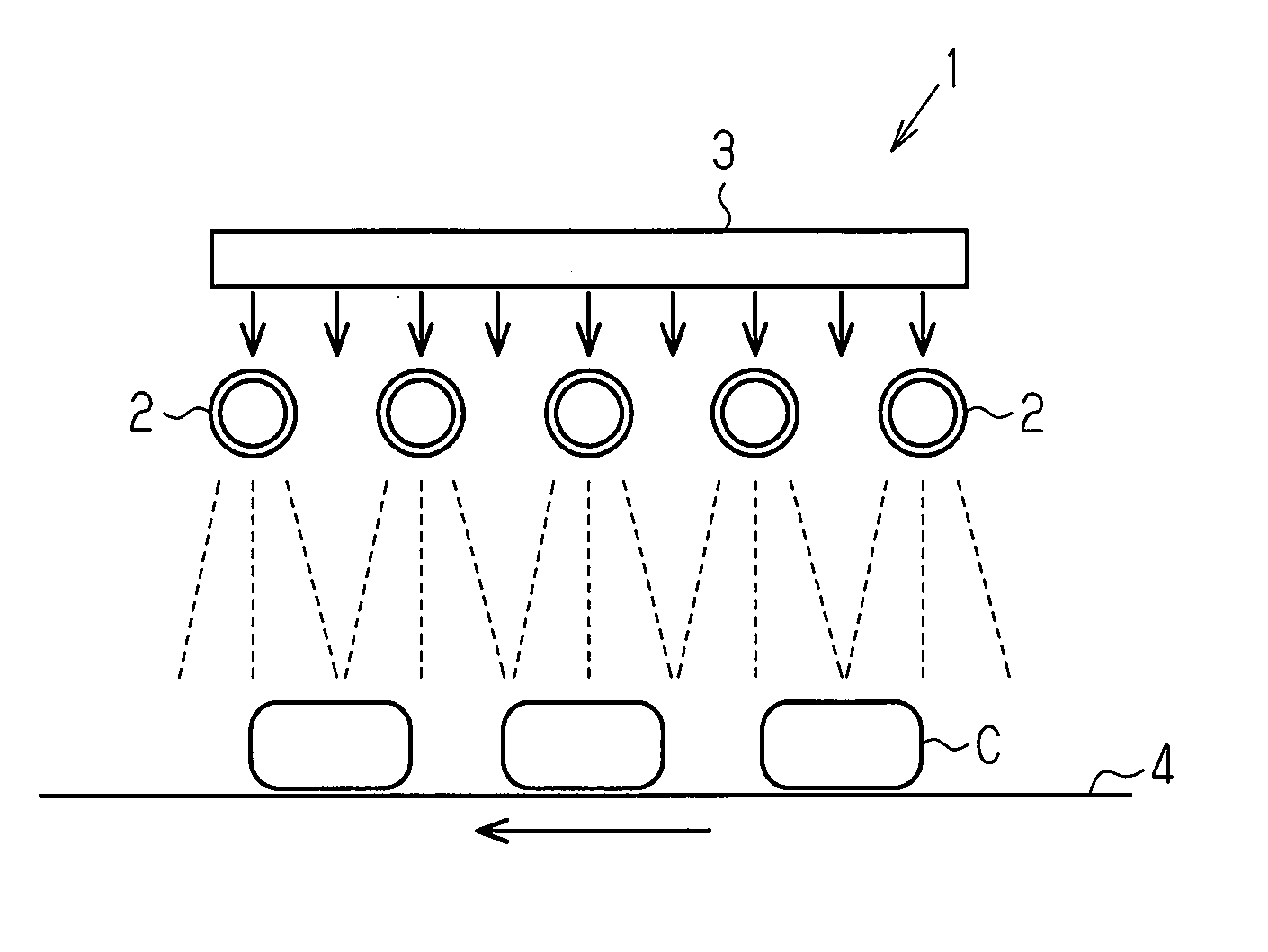

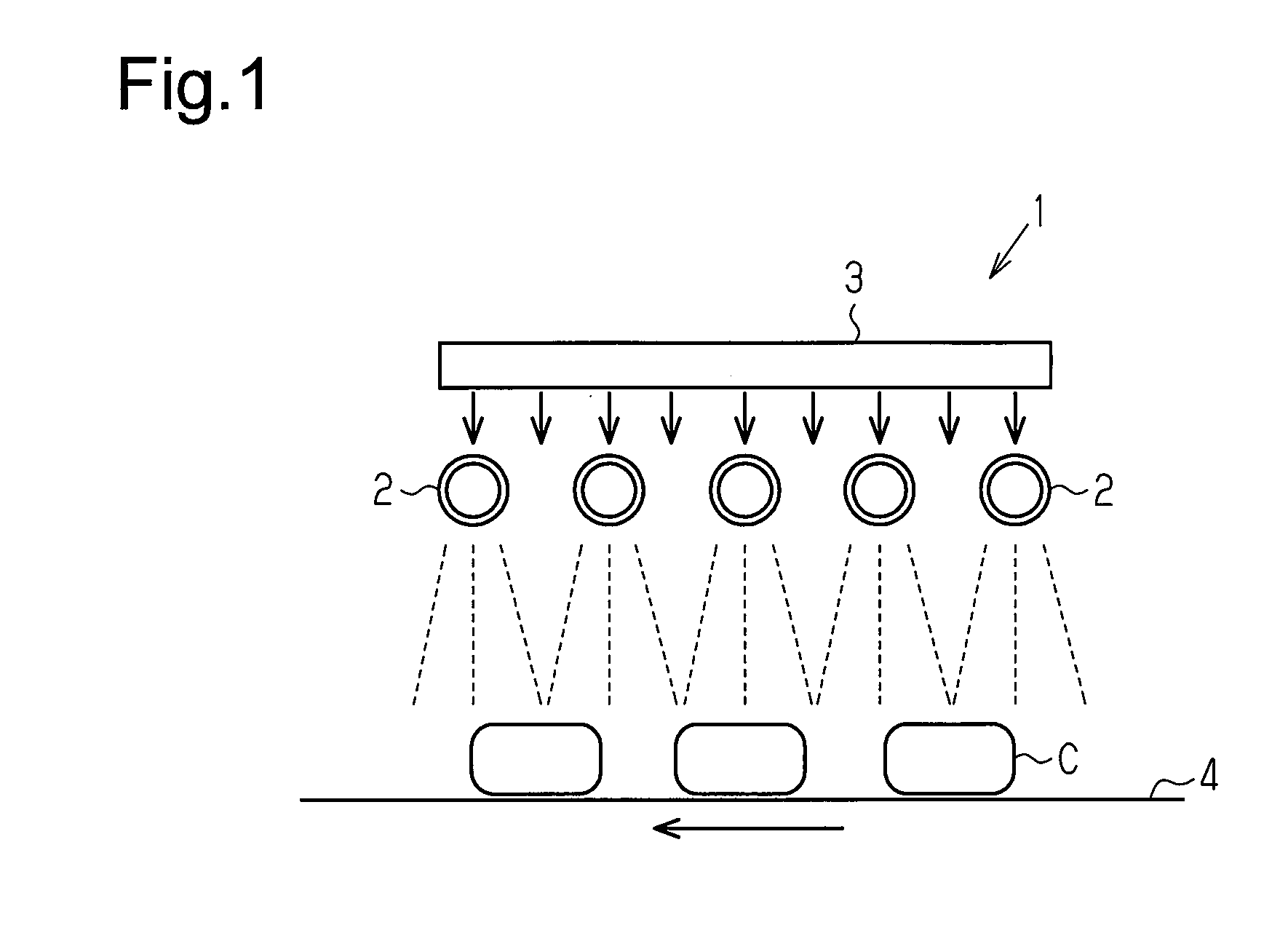

Baked chocolate confectionery

ActiveUS20150289535A1Easily broughtCrispy textureMilk preservationConfectioneryChocolate confectionerySurface structure

A technique for imparting a mild soft texture inherent to chocolate, particularly a melt-like texture, to the inside of a baked chocolate confectionery obtained by baking a surface of a chocolate molded article. In the present invention, the inside of a baked chocolate confectionery obtained by baking a surface of a chocolate molded article comprising a chocolate dough, a surface structure of the baked chocolate confectionery not adhering to the fingers at 40° C., includes a soft portion in which the maximum particle size of solids as measured by a micrometer is 40 μm or less.

Owner:MORINAGA & COMPANY

Reduced Milk Fat Non-standardized Milk Chocolate (Milk Fat Free/Low Milk fat) and Standardized Reduced Milk Fat Milk Chocolate with Improved Health Characteristics

InactiveUS20100278978A1Good for healthImprove antioxidant capacityFood ingredient as antioxidantConfectioneryButterfatMilk Chocolate

A reduced milk fat, reduced sugar, improved health characteristic, higher antioxidant content, improved taste, texture, melt, and creaminess non-standardized milk chocolate that can have a milk fat content of 0% to 8% and is blended with a standardized chocolate, an edible oil blend, 100% Cocoa Powder, Confectionery Sugar, Cocoa Seed Butter Crystals, and synergistic antioxidant flavor blend including; Virgin Coconut Oil, Vanilla Powder, Blackberry, and Acai Berry. A standardized milk chocolate product with 3.69% or higher milk fat that has improved health characteristics , higher antioxidant content, improved taste, texture, melt, and creaminess from a synergistic antioxidant flavor blend including; Virgin Coconut Oil, Vanilla Powder, Blackberry, and Acai Berry. The ingredients are in specific amounts and ratios such that they can be easily incorporated into the compositions without adversely affecting the stability or feel, and actually improve taste, texture, melt, and creaminess as well as improve health characteristics of the compositions. The compositions can be manufactured and sold in any format that current chocolate confectionery products are sold in including; squares, tablet bars, molded shapes, as coatings or as enrobing material, or as ingredients in foods that have chocolate or chocolate compositions in them, etc. Additionally the process for preparing such compositions is provided.

Owner:ERVIN GARY

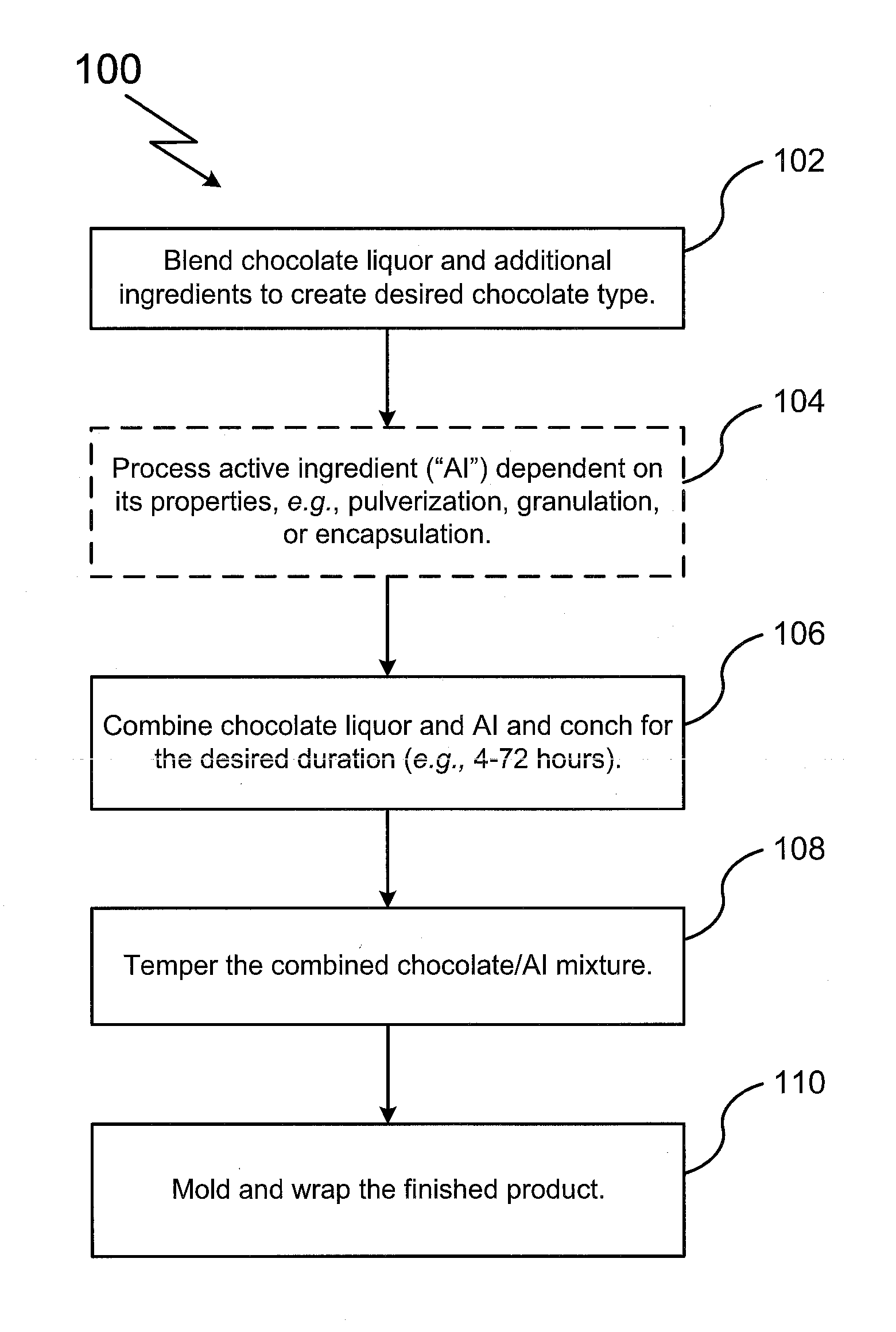

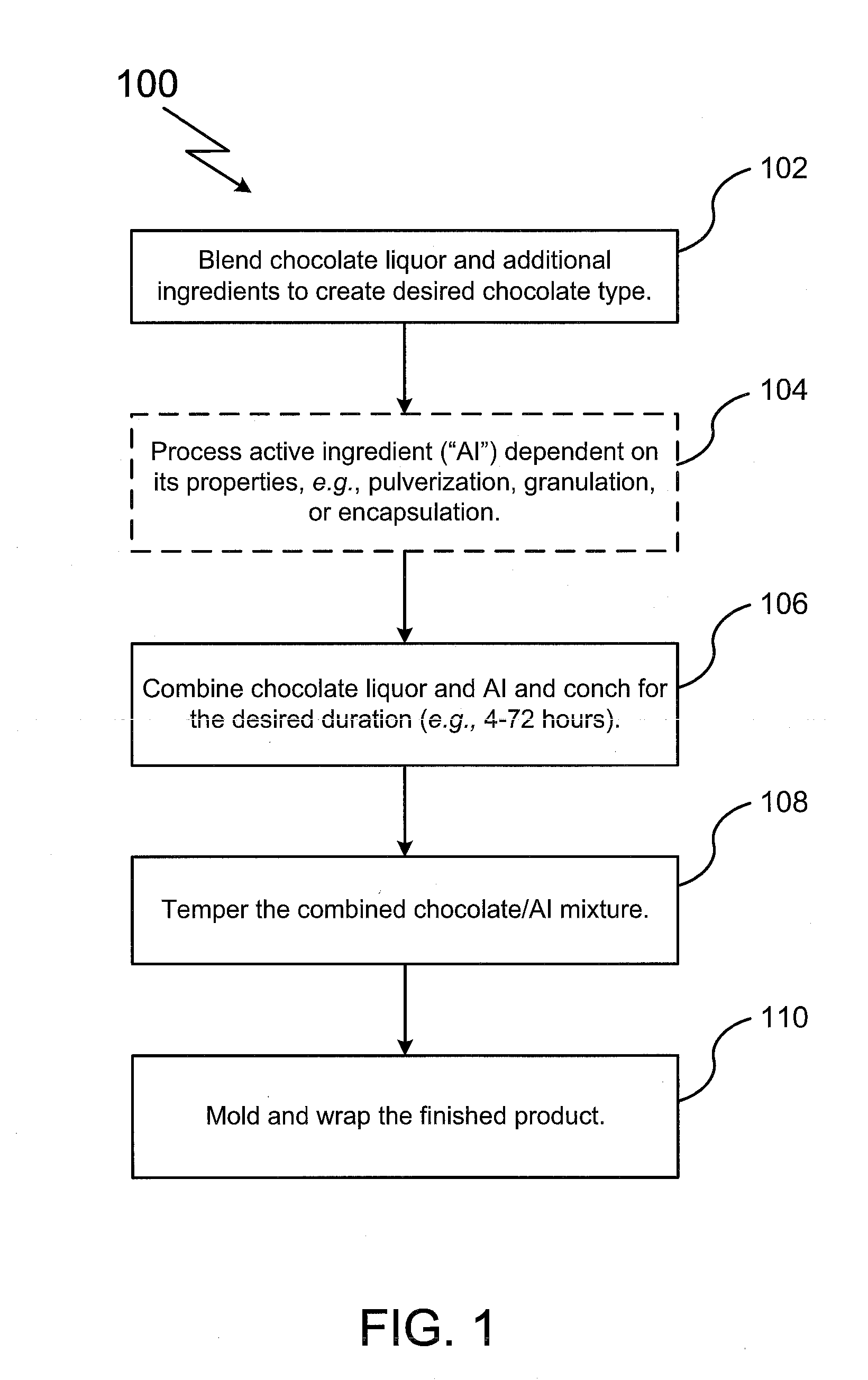

Chocolate delivery system for live microorganisms

A chewable composition for the oral delivery of live microorganisms is provided. The chewable composition includes a delivery vehicle and an active ingredient incorporated therein. The delivery vehicle may include a chocolate candy. The active ingredient may include a predetermined amount of at least one probiotic. The delivery vehicle may also include a predetermined amount of at least one prebiotic. The delivery vehicle may also include any combination of nutraceuticals, vitamins, minerals, antioxidants, soluble and insoluble fiber, herbs, plants, probiotics, prebiotics, antioxidants, amino acids, fatty acids, digestive enzymes, dietary supplements, or any other health promoting ingredient.

Owner:HERO NUTRITIONALS

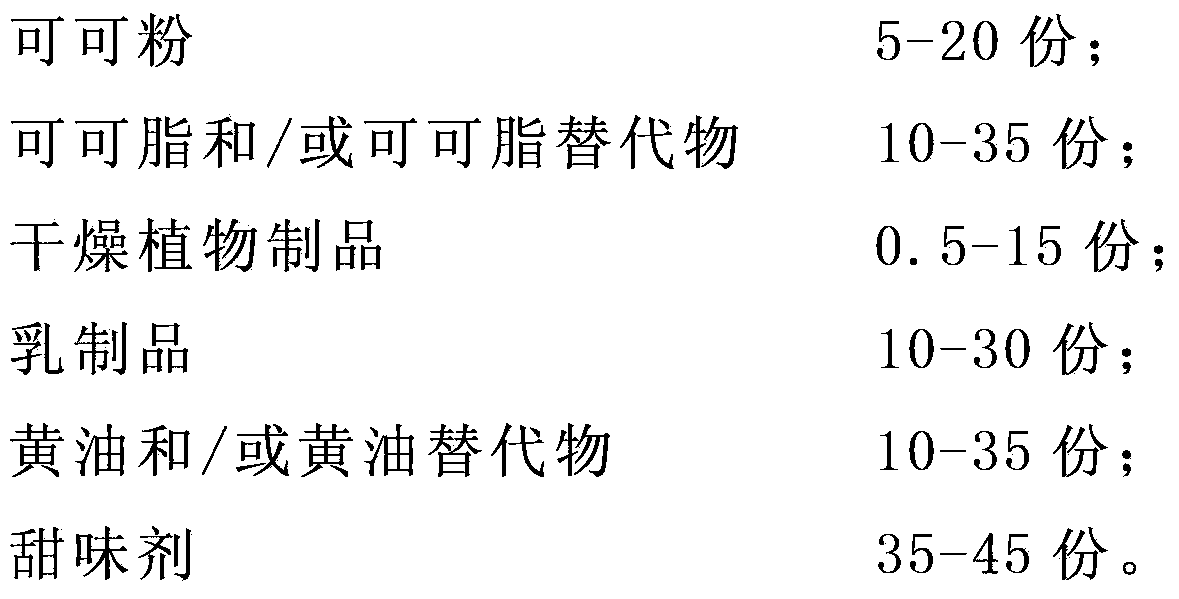

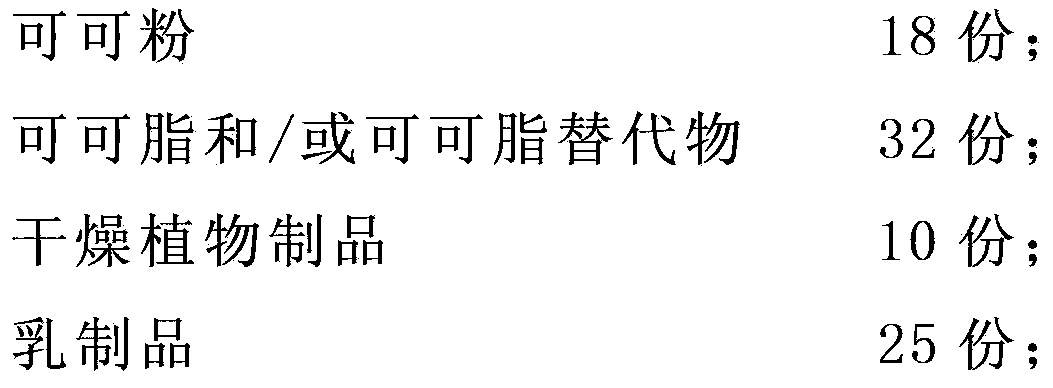

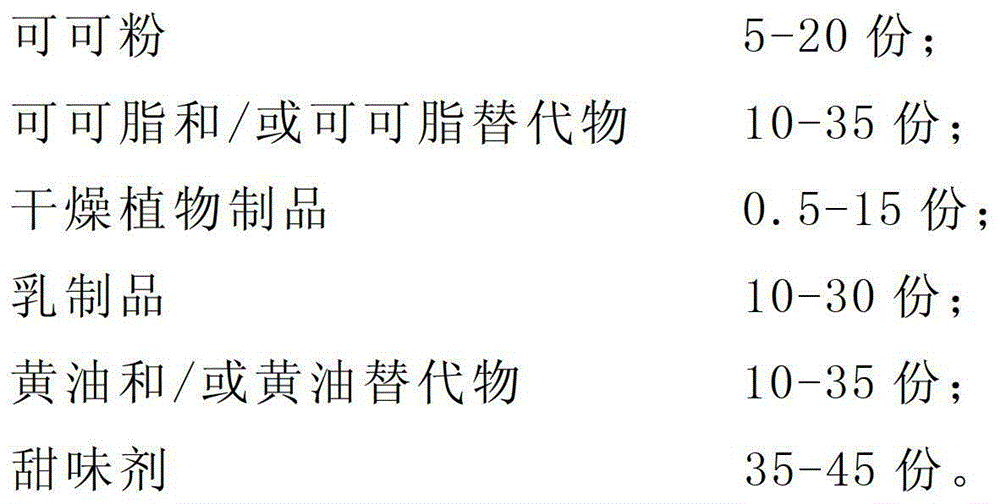

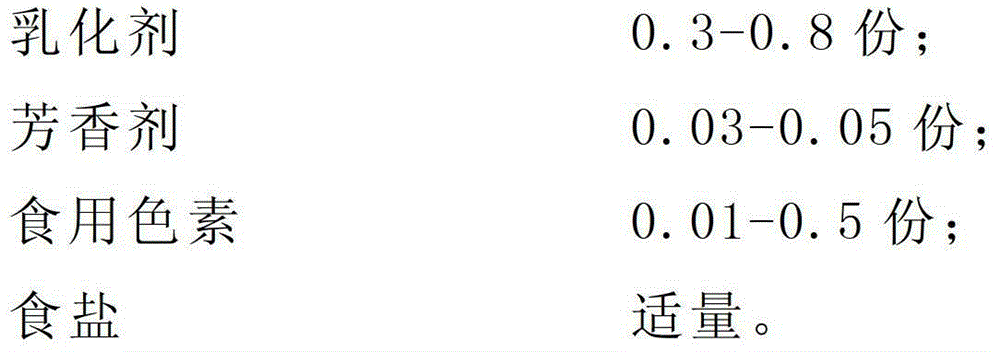

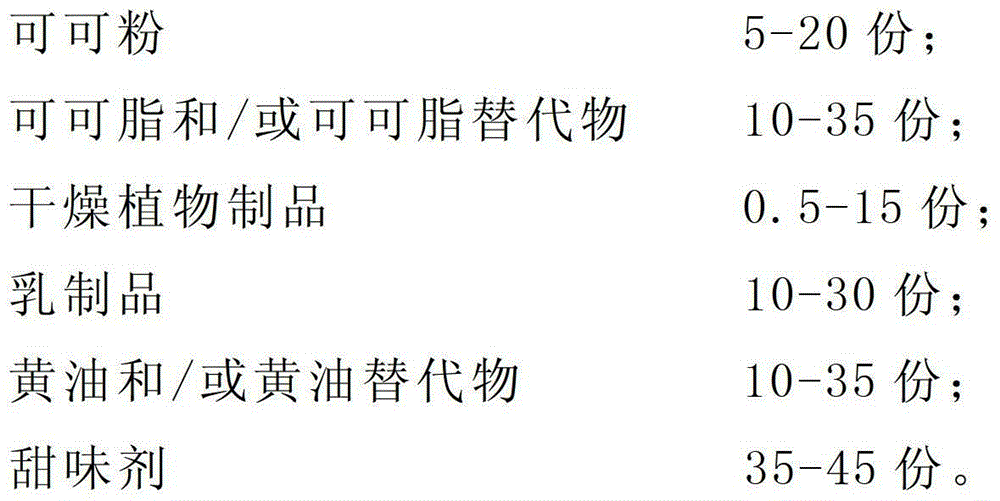

Chocolate frosting and preparation method thereof

ActiveCN103444967AImprove caking coagulation performanceQuality improvementConfectionerySweetmeatsCocoa PowdersButter cocoa

The invention provides chocolate frosting and a preparation method thereof, belonging to the technical field of foods and solving the technical problems in the prior art that the chocolate frosting is poor in formability and single in taste, and the like. The chocolate frosting comprises the following components in parts by mass: 5-20 parts of cocoa powder, 10-35 parts of cocoa butter and / or a cocoa butter substitute, 0.5-15 parts of a dry plant product, 10-30 parts of a dairy product, 10-35 parts of butter and / or a butter substitute, and 35-45 parts of a sweetener. The chocolate frosting provided by the invention has the advantages of good formability, fresh and cool taste, rich flavor and the like.

Owner:NINGBO MOKAI TRADE

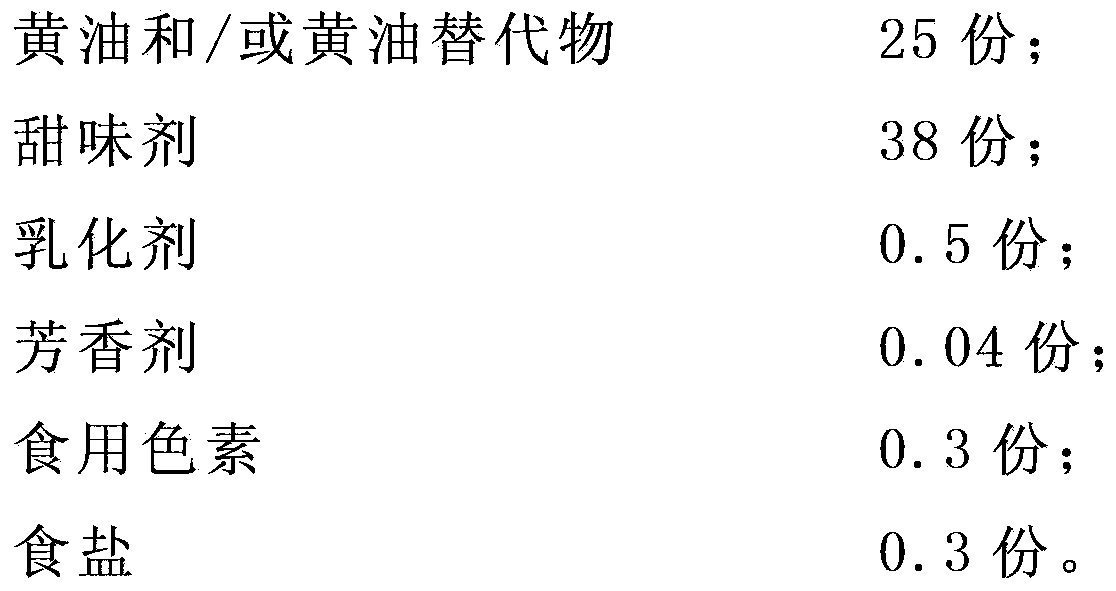

Chocolate sugar coat milk curd and production method thereof

The invention provides a chocolate sugar coat milk curd and a production method thereof, and belongs to the technical field of food. The technical problem that the milk curd taste is single in the prior art is solved. The production method comprises the following steps: step A, individually preparing chocolate sugar coat raw materials and milk curd raw materials; step B, making the milk curd raw materials into milk curd blocks, heating and melting the chocolate sugar coat raw materials, covering the milk curd blocks with a layer of chocolate sugar coat, carrying out a surface treatment on the chocolate sugar coat by hot air, and cooling so as to obtain the chocolate sugar coat milk curd. The chocolate sugar coat milk curd produced by the provided method has the advantages of rich tastes, long shelf life, and low fat content.

Owner:NINGBO MOKAI TRADE

Blackthorn pear products and its production

The invention is concerned with a kind of Rosa roxburghii Tratt candy produce. It produces the syrup of pure Rosa roxburghii Tratt or compound Rosa roxburghii Tratt into horniness candy, horniness candy with filling, soft candy, milk lipid candy, polishing candy, glue-based candy, charging candy, chocolate candy or jelly, and so on. It increases the stability of vitamin C, vitamin P and superoxide dismutase and affords a kind of high quality candy food with double functions of nutritional health care and relaxing. The produce method relates to prepare clarified Rosa roxburghii Tratt concentrated syrup with good stability, add assistant stuff as the amount of 1 to 50 percent of whole amount into the said syrup, prepare Rosa roxburghii Tratt grain or Rosa roxburghii Tratt fast-dissolving powder and follow the routine technology to produce horniness candy, horniness candy with filling, gel candy, glue-based candy, charging candy, chocolate candy or jelly, and so on.

Owner:SHANGHAI NORMAL UNIVERSITY

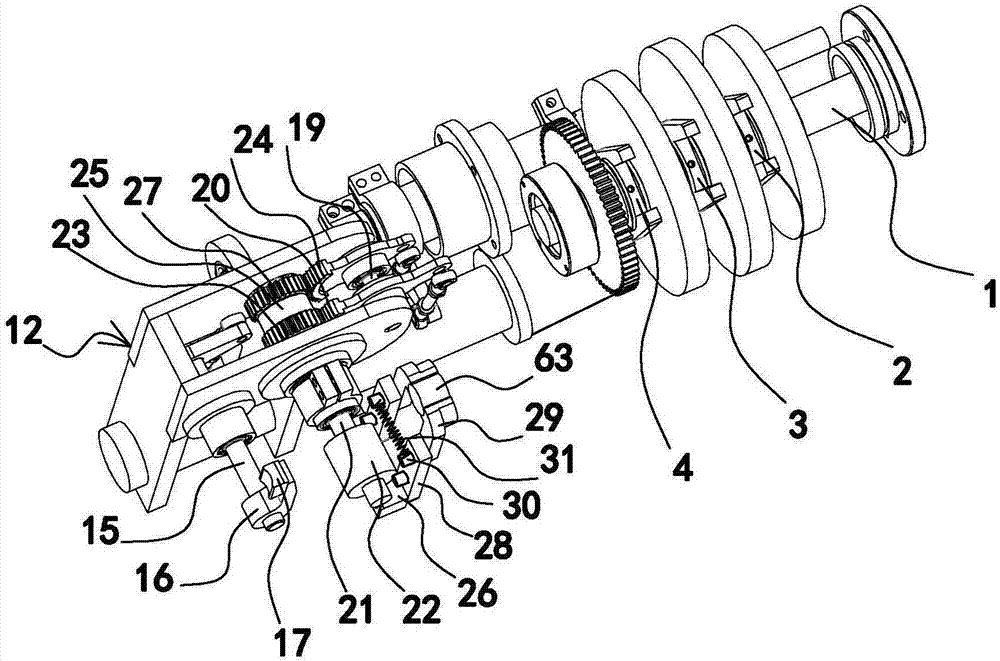

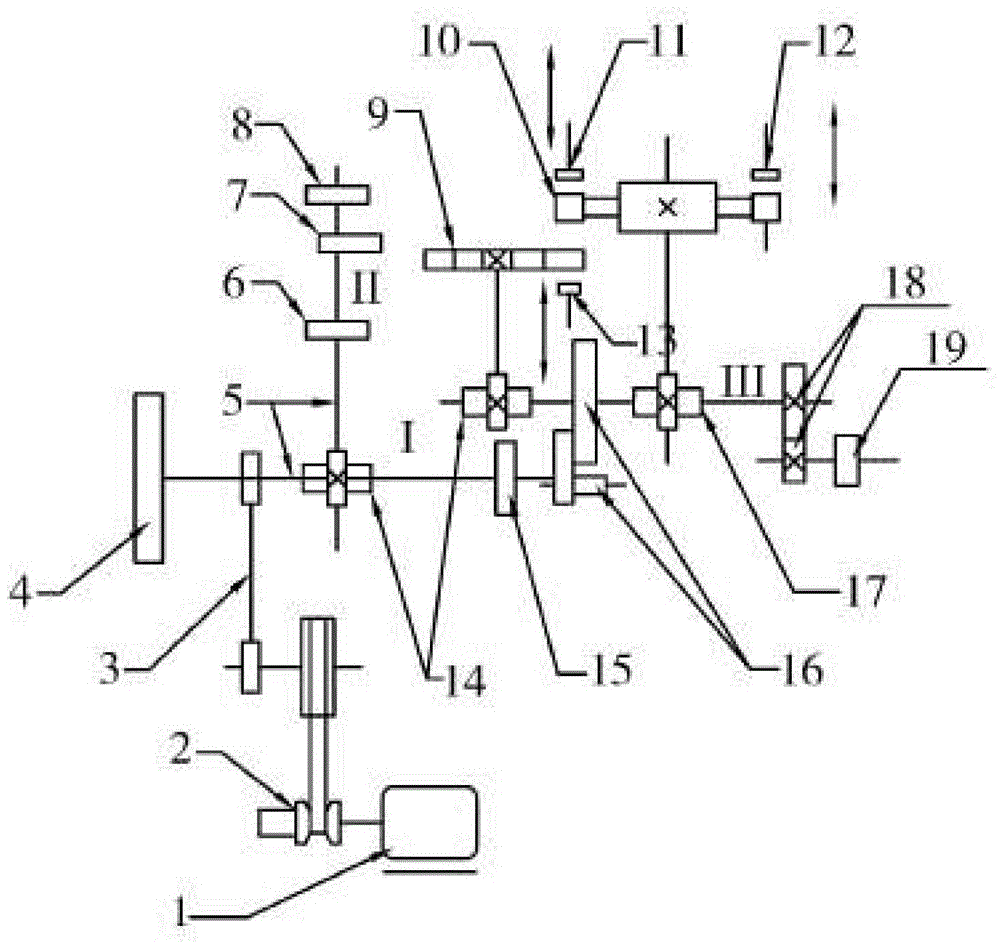

Chocolate candy packaging machine

The invention discloses a chocolate candy packaging machine which comprises an electromotor, a belt-type stepless speed regulator, a chain wheel transmission mechanism, a first handwheel, a second handwheel, a distribution shaft, a left spiral gear pair, a candy ejecting rod, a candy ejecting rod cam, a paper cutter cam, a paper supply component, a grooved wheel mechanism, a candy feeding component, a candy gripping mechanical arm and a candy pulling rod, wherein the electromotor is transmitted through the belt-type stepless speed regulator and the chain wheel transmission mechanism, the first handwheel is connected with one end of a transverse shaft of the distribution shaft, the distribution shaft is connected with the candy ejecting rod cam, the paper cutter cam and the paper supply component through the left spiral gear pair, the candy feeding component and the candy gripping mechanical arm are arranged at the upper end of the left spiral gear pair, the other end of the transverse shaft of the distribution shaft is in transmission connection with the candy feeding component and the candy gripping mechanical arm through the grooved wheel mechanism, and the candy pulling rod is arranged on the upper portion of the candy gripping mechanical arm. The chocolate candy packaging machine is simple in structure, high in working efficiency, stable in working state and suitable for packaging most kinds of chocolate candy.

Owner:TIANJIN JINGUPING FOOD

Rolling type chocolate candy skin kneading packaging machine

PendingCN111559529AAutomate the packaging processReduce manual labor intensityWrapping material feeding apparatusWrappingChocolate candyPackaging machine

The invention relates to a rolling type chocolate candy skin kneading packaging machine, wherein the machine comprises a candy arranging tray, a paper conveying module, a packaging module, a kneadingmodule and a machine frame; and a step surface for placing the candy arranging tray is arranged on the machine frame. A chocolate ball-shaped candy is arranged through the candy arranging tray and then enters a falling candy through hole, and rotates to an area to be packaged driven by a turntable, a packaging paper is cut by the paper conveying module and covers the chocolate candy, then under the cooperation of a candy ejector rod and a candy feeding rod, the chocolate candy and the candy paper are delivered to a clamping jaw, the clamping jaw rotates to a folding station for folding and packaging by a folding unit, after the folding and packaging are completed, the candy is transported to an output station through the rotation of the clamping jaw and enters the kneading module for kneading; thus, the automatic packaging of the candy paper of a hemispherical candy is realized, the manpower labour intensity is reduced correspondingly, and the work efficiency is improved.

Owner:NANTONG WEALTH MASCH TECH CO LTD

Xinhui dried orange peel chocolate candy and manufacturing method thereof

The invention relates to a Xinhui dried orange peel chocolate candy and a manufacturing method thereof. The chocolate candy is prepared from the following raw materials in parts by weight: 2 to 15 parts of Xinhui dried orange peel, 10 to 20 parts of cocoa liquor, 15 to 20 parts of cocoa butter, 3 to 12 parts of white granulated sugar, 5 to 15 parts of red bean powder, 5 to 15 parts of purple potato powder, and 3 to 30 parts of pawpaw concentrate powder. The manufacturing method comprises the following steps: (1) preparing raw materials; (2) heating cocoa liquor and cocoa butter to melt cocoa liquor and cocoa butter, and refining cocoa liquor and cocoa butter; (3) adding ingredients into cocoa slurry until the ingredients can be kneaded into balls by hand; (4) moulding the mixture by a moulding machine; (5) drying and packaging. The chocolate candy has a special fragrance of Xinhui dried orange peel and also has a healthcare function. Moreover, the chocolate comprises red bean powder, purple potato powder, and pawpaw concentrate powder, thus is rich in natural nutrients, and has a crispy and palatable taste and a unique flavor.

Owner:周卫斌

Health betelnut

InactiveCN1435110AEnhance disease prevention and resistance functionEliminate side effectsConfectioneryUnknown materialsMedicineLycium barbarum fruit

A health areca food series including sweets, chocolate, chewing gum, etc is characterized by that besides the areca component, it contains the additives prepared from ganoderma, cordyceps, aloe, wolfberry fruit, astragalus root, bamboo, etc.

Owner:吴跃飞

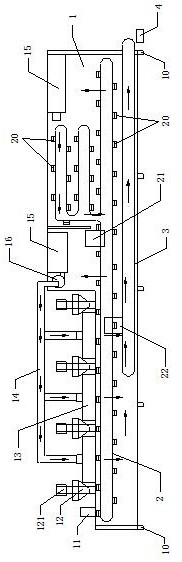

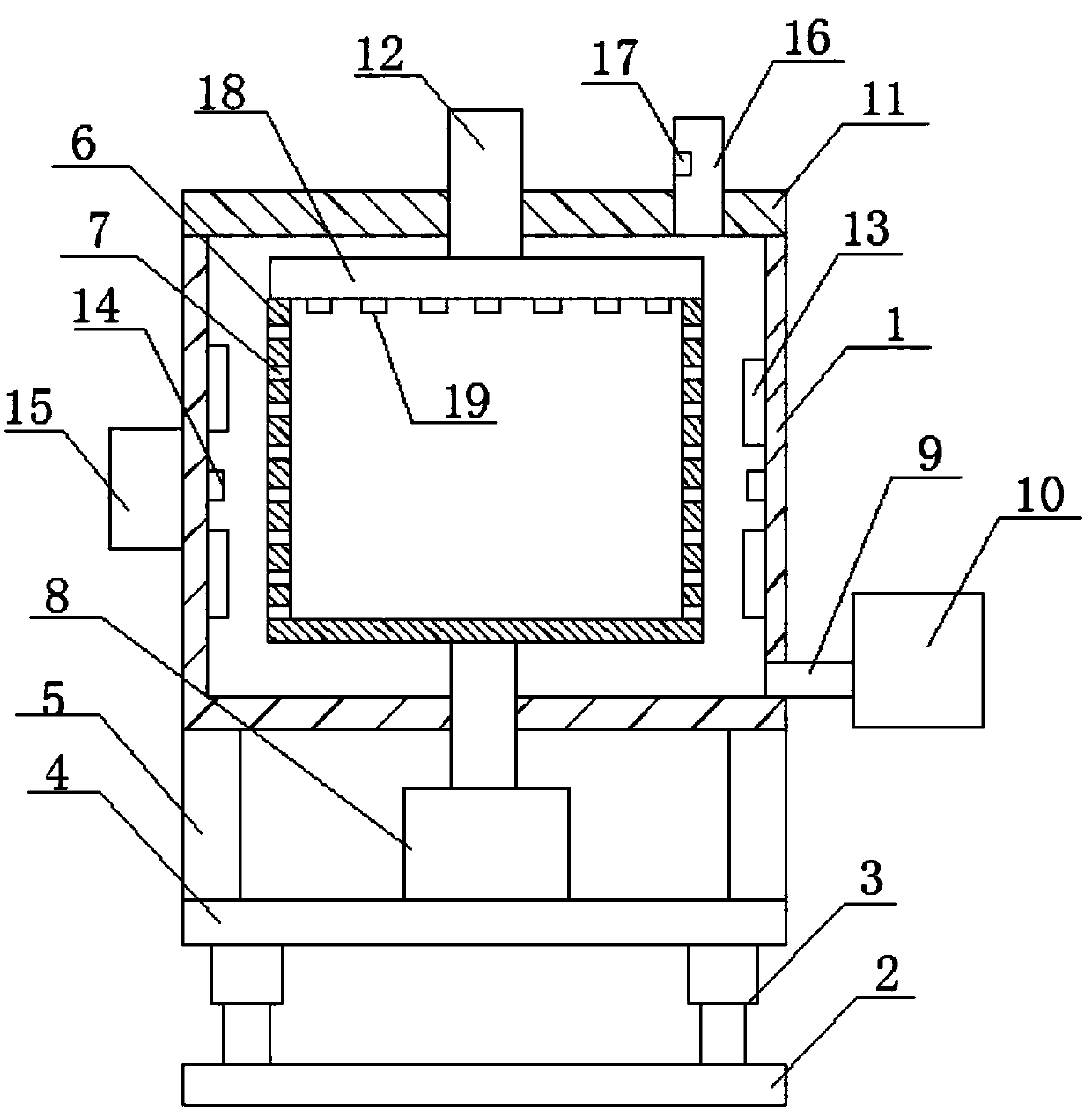

3D (three-dimensional) candy and chocolate candy production line

PendingCN113142362ASufficient cooldownImprove cooling effectConfectionerySweetmeatsChocolate confectioneryCooling effect

The invention relates to a 3D (three-dimensional) candy and chocolate candy production line. The 3D (three-dimensional) candy and chocolate candy production line comprises a cabinet body, wherein a chain, a conveying belt, a mold closing device, a mold opening device and a plurality of air conditioners are mounted in the cabinet body, a plurality of molds are arranged on the chain, an oil spraying device and a plurality of pouring devices are mounted at the front end of the cabinet body, and a plurality of ventilation hoods are mounted at the upper end of the cabinet body. The upper mold and the lower mold of each mold are provided with mutual corresponding grooves, the upper mold and the lower mold are closed by the mold closing device after candies or chocolate materials are injected into the grooves, the materials in the grooves in two sides are naturally bonded together and fused into a whole, and then a complete 3D candy shape is formed. The right end of the chain is set in S-shaped multiple-time folding back, the space of the cabinet body is fully utilized, the space of a working place occupied by the cabinet body is reduced, besides, the mold cooling time is enough, the cooling effect is good, the whole production line achieves automatic production, and the production efficiency is high.

Owner:泉州壕源机械有限公司

Weight-losing chocolate candy

InactiveCN105851433AAbundant raw materialsStrong fragranceCocoaNatural extract food ingredientsSugar intakeWeight gaining

The invention discloses weight-losing chocolate candies. The weight-losing chocolate candies are prepared from the following raw materials: cocoa masses, isomalto-oligosaccharide, garcinia pedunculata, skimmed milk powder, chili pepper leaves, lotus leaves, ophiopogon japonicus, erigeron canadensis, table salt, kefir, Centrum powder and lysozyme. The weight-losing chocolate candies provided by the invention are rich in raw materials, crispy in the outsides and soft in the insides, appropriate in sour-sweet tastes, mellow in aromas, balanced in nutrition and easy to absorb; and the weight-losing chocolate candies are capable of enhancing immunity, protecting the cardiac and cerebral vessels, promoting gastrointestinal functions, resisting oxidation, eliminating toxicant, beautifying as well as losing weight and slimming without bounce back. The functional oligosaccharide is utilized to replace white granulated sugar, so that the chocolate candies are mild in sweetness, sugar absorption is inhibited, and sugar intake is reduced; thus, the chocolate candies are capable of inhibiting weight gains. The traditional Chinese medicines are wide in sources and easy to obtain, and the wastes are made profitable; thus, the chocolate candies are enriched in natural fat-reducing ingredients so that weight loss can be fundamentally realized. The weight-losing chocolate candies are packaged by vegetable papers and stone papers, so that the packaged weight-losing chocolate candies are low in costs, safe, non-toxic as well as capable of protecting the environment and saving costs. Moreover, the lysozyme added therein has natural anti-bacterial effects, and increases protein contents; and the lysozyme is free of any additives, so that the weight-losing chocolate candies are safe and healthy for eating.

Owner:YINGSHANG HAOYUAN FOOD

Production method of black rice chocolate candies

InactiveCN103783233AImprove protectionGood colorConfectionerySweetmeatsButter cocoaAdditive ingredient

The invention discloses a production method of black rice chocolate candies. The technical characteristics are as follows: the raw materials comprise black rice, cocoa butter, cocoa butter substitute, non-dairy creamer, maltodextrin and salt; the production method comprises the following steps that black rice is subjected to cleaning, airing by spreading, drying and grinding, which are strictly controlled; saccharified and ground milled rice flour is mixed with enzymolyzed and concentrated black rice skin flour to form the black rice flour, the mixture is mixed with the non-dairy creamer, the salt, the cocoa butter substitute, the maltodextrin and the cocoa butter, the mixture is ground finely to prepare chocolate base material, and the chocolate base material is mixed with the black rice flour to prepare the black rice chocolate. The black rice chocolate candies keep the basic flavor of the chocolate and also have the black rice flavor; and the candies have the black rice baking fragrance, have chocolate mouthfeel and also have the active substances and the nutritional ingredients of the black rice.

Owner:周亚刚

Roxburgh rose chocolate candy

InactiveCN105146014ARetain nutritional valueGood chewingConfectionerySweetmeatsGlucose-Fructose SyrupNutritive values

The invention discloses roxburgh rose chocolate candy. The roxburgh rose chocolate candy comprises 500-800 parts of roxburgh rose, 1000-1300 parts of dark chocolate, 65-85 parts of gel, 2-4 parts of sucrose ester, 50-80 parts of butter, 100-280 parts of white granulated sugar, 200-380 parts of glucose syrup and 80-180 parts of honey. The high-quality roxburgh rose is adopted as a raw material, nutritive value of the roxburgh rose is maintained, the made roxburgh rose chocolate candy is good in chewing, the external roxburgh rose part is good in elasticity, and the internal chocolate stuffing and moderate in softness and hardness; the roxburgh rose chocolate candy retains unique sweet and sour taste and full aroma of the roxburgh rose and unique taste of chocolate, and is capable of meeting requirements of most people for taste.

Owner:王佳英

Polygonatum sibiricum coffee beverage and preparation method thereof

PendingCN113016918ARich tasteEasy to prepareGreen coffee treatmentRoasted coffee treatmentBiotechnologyWarm water

The invention discloses a polygonatum sibiricum coffee beverage and a preparation method thereof. The beverage comprises 10-15 parts of coffee powder, 4-5 parts of chocolate syrup, 0.1-0.15 part of a compound emulsifier, 0.1-0.2 part of lemon juice, 0.5-0.6 part of skimmed creamer, 1-2 parts of secret polygonatum sibiricum powder and the balance of water, and the secretly-prepared polygonatum sibiricum powder is prepared through a nine-steaming and nine-drying process and has the granularity of 80-100 meshes. The preparation method comprises the following steps: preparing secret rhizoma polygonati powder, namely steaming and drying fresh rhizoma polygonati tubers of four years old for nine times, and grinding into the secret rhizoma polygonati powder with the granularity of 80-100 meshes; and brewing coffee, adding the secretly-prepared rhizoma polygonati powder, the coffee powder, the chocolate syrup, the compound emulsifier, the lemon juice and the skimmed creamer into a beverage cup, adding a proper amount of warm water, and rapidly stirring until the materials are uniformly mixed. The rhizoma polygonati coffee beverage is simple in preparation method and rich in taste, the nutrition and health care value of coffee is increased through the added secret rhizoma polygonati powder, and the rhizoma polygonati coffee beverage has the effects of tonifying qi, nourishing yin, tonifying the spleen, moistening the lung and tonifying the kidney.

Owner:HANGZHOU YUNXI ENVIRONMENTAL PROTECTION TECH

Appetite-improvement candy and preparation method thereof

The invention discloses a candy food, especially discloses a mint-chocolate candy and belongs to the field of food processing. The mint-chocolate candy comprises, by mass, 45-55% of sugar, 15-25% of cocoa powder, 10-20% of cocoa butter, 5-10% of a mint concentrate, 3-5% of a wild chrysanthemum flower concentrate and 2.5-5% of deionized water. Through combination of chocolate, mint and wild chrysanthemum flower, the mint-chocolate candy has a perfect taste and a newfangled mouthfeel, has the original mellow taste of chocolate, and satisfies people taste demands. Through use of mint and wild chrysanthemum flower, the product has a refreshing taste, is rich in nutrients and has effects of resisting bacteria and viruses, clearing heat, diminishing inflammation, resisting oxidation, improving immunity, promoting digestion and improving appetite.

Owner:苏均远

Food processing method

InactiveCN108323748ASolve the real problemImprove quality of lifeFood scienceFood additiveFreeze-drying

The invention provides a chocolate-Auricularia auricula processing method, which comprises: selecting materials, removing impurities, carrying out shear finishing, rapidly cleaning the food, drying and puffing the Auricularia auricula through hot drying, vacuum microwave drying, low-temperature freeze drying and other methods, shaping the dried or puffed Auricularia auricula, flavoring the shapedAuricularia auricula with melted chocolate candy, shaping again, and packaging. According to the present invention, the processing method is simple, any food additives are not used, the whole processing process can be completed through the ordinary physical processing method, and the processing method cannot affect the nutrients of Auricularia auricula, and can retain the original flavor and the original dietary therapy health features of Auricularia auricula; and by infusing the aroma and the sweetness of chocolate candy into Auricularia auricula, the obtained food has characteristics of mellow taste, crispy and delicious taste after the entrance, rich nutrition and convenient eating, and can bring good experience to people.

Owner:姜华

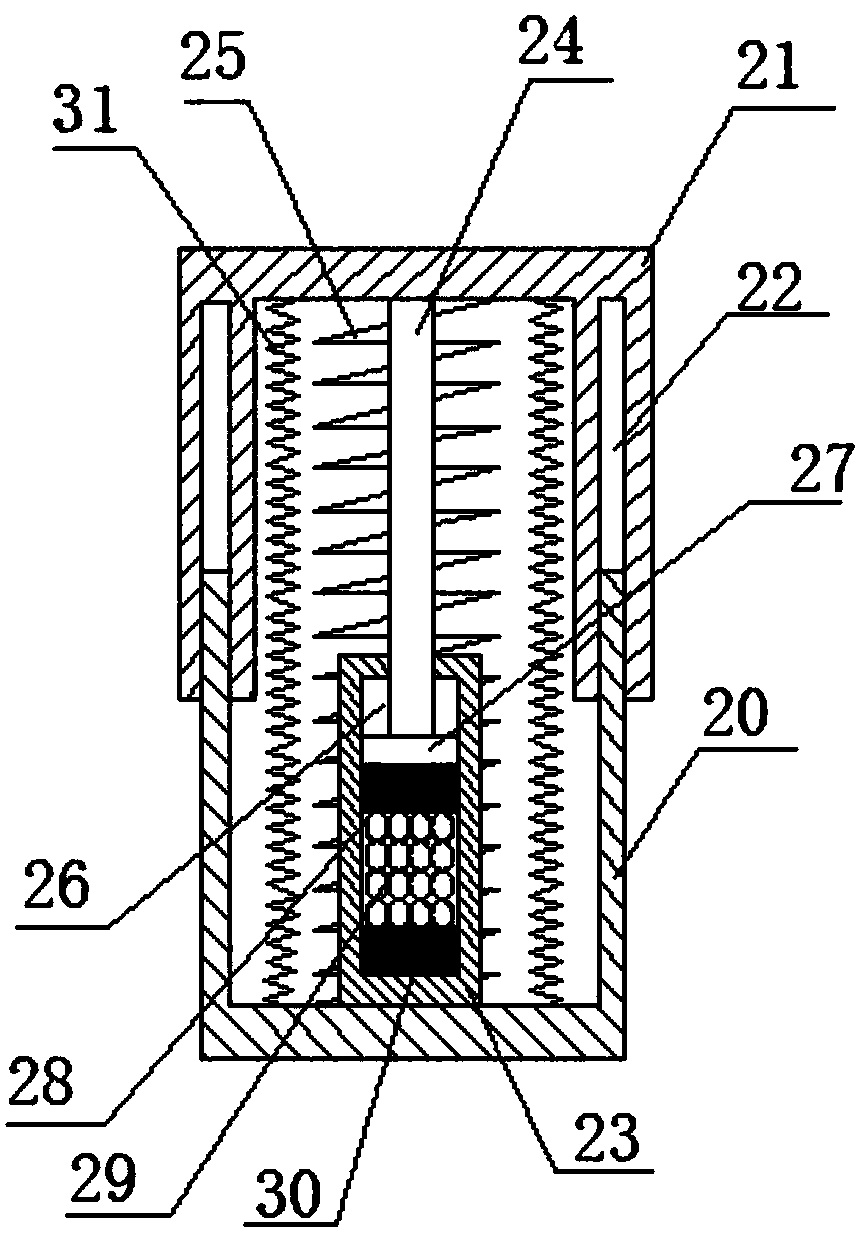

Multi-stage screening machine for chocolate candy processing

The invention discloses a multi-stage screening machine for chocolate candy processing. The multi-stage screening machine comprises a base; grooves are formed in the lower side of the base in a bilateral symmetry mode. An eccentric wheel is arranged in each groove; a driving shaft penetrating through the two eccentric wheels is arranged in the base; sliding seats matching the eccentric wheels arearranged in the grooves; universal wheels are arranged on the lower side of the sliding seats. A plurality of supporting columns are arranged on the upper side of the base. A second motor is arrangedat the upper end of the rightmost supporting column, bearings are arranged at the upper ends of the other supporting columns, the output end of the second motor is connected with a rotating shaft, therotating shaft sequentially penetrates through the bearings of the supporting columns, a screening barrel is arranged on the rotating shaft, a sound insulation layer is arranged on the barrel wall ofthe screening barrel, and a first screening net and a second screening net are arranged in the screening barrel from inside to outside. The multi-stage screening machine is simple in structure, convenient to use, capable of achieving multi-stage screening, low in noise, long in service life and convenient to move.

Owner:TIANJIN FUXIA FOOD CO LTD

Raw material cleaning device for chocolate candy processing

The invention discloses a raw material cleaning device for chocolate candy processing. The raw material cleaning device comprises a shell and a base. A groove is formed in the upper side of the base,a damping pad is arranged in the groove in an embedded mode, a groove is further formed in the upper side of the damping pad, a supporting plate is arranged in the groove of the damping pad, an innercylinder is arranged in the shell, a plurality of water splashing holes are formed in the periphery of the inner cylinder, a motor is arranged in the middle of the upper side of the supporting plate,and an output shaft of the motor extends into the shell and is connected with the lower end of the inner cylinder, and a drain pipe is arranged on the right side of the shell. A water storage tank isconnected to the right end of the drain pipe, an end cover is arranged at the upper end of the shell, a water inlet pipe is arranged in the middle of the end cover, a water spray device is connected to the lower end of the water inlet pipe, a plurality of water spray heads are arranged at the lower side of the water spray device, a plurality of heating devices and a temperature sensor are arrangedon the inner side of the shell, a control device is arranged on the left side of the shell, an exhaust port is formed in the end cover, and a humidity sensor is arranged on the exhaust port. The rawmaterial cleaning device is simple in structure, convenient to use and good in temperature uniformity, integrates cleaning and drying, and is high in efficiency.

Owner:TIANJIN FUXIA FOOD CO LTD

Roxburgh rose fruit chocolate candy

InactiveCN107981001ARetain nutritional valueGood chewingFood ingredient as antioxidantCocoaNutritive valuesFruit juice

The present invention relates to a roxburgh rose fruit chocolate candy. The candy is characterized by comprising the following components in parts by weight: 500-800 parts of roxburgh rose fruit juice, 1000-1300 parts of dark chocolate, 65-85 parts of a gel, 2-4 parts of sucrose ester, 50-80 parts of butter, 100-280 parts of sucrose, 200-300 parts of winter jujubes, 80-180 parts of honey, 50-100 parts of peppermint and 1-5 parts of an antioxidant. According to the roxburgh rose fruit chocolate candy, high-quality roxburgh rose fruits and the roxburgh rose fruit juice are adopted as raw materials, so that the nutritive value of the roxburgh rose fruits is reserved; and the prepared roxburgh rose fruit chocolate candy is good in chewing feeling, the outer roxburgh rose fruit portion is goodin elasticity, and inner chocolate stuffing is neither too hard nor too soft. The roxburgh rose fruit chocolate candy of the invention simultaneously reserves the unique sour-sweet taste and strong fragrance of the roxburgh rose fruits and the unique taste of the chocolate, and can meet taste requirements of the majority of people.

Owner:龙里县泽洋生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com