Patents

Literature

114results about How to "Crispy texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of crisp vegetable slice food and making method thereof

InactiveCN1698467AImprove leisure featuresHigh retention rateFood preservationFood preparationSugarRaw material

The invention provides a formula of crisp vegetable slice food and making method which comprises finishing and cleaning the vegetable raw material, blanching, cooling and airing, passing through heated-air drying (not required), appending flavoring and color substances, then boiling and flavoring according to formulation, loading into dishes, pre-forming and carrying out vacuum microwave drying. The formula comprises vegetable 60-65%, flavoring and coloring substances 10-12%, white sugar 7-8%, water 6-8%, starch 4-5%, glucose 3-4%, trehalose 3-4%, gourmet powder 0.08-0.1%, sweetener 0.02-0.1%.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD

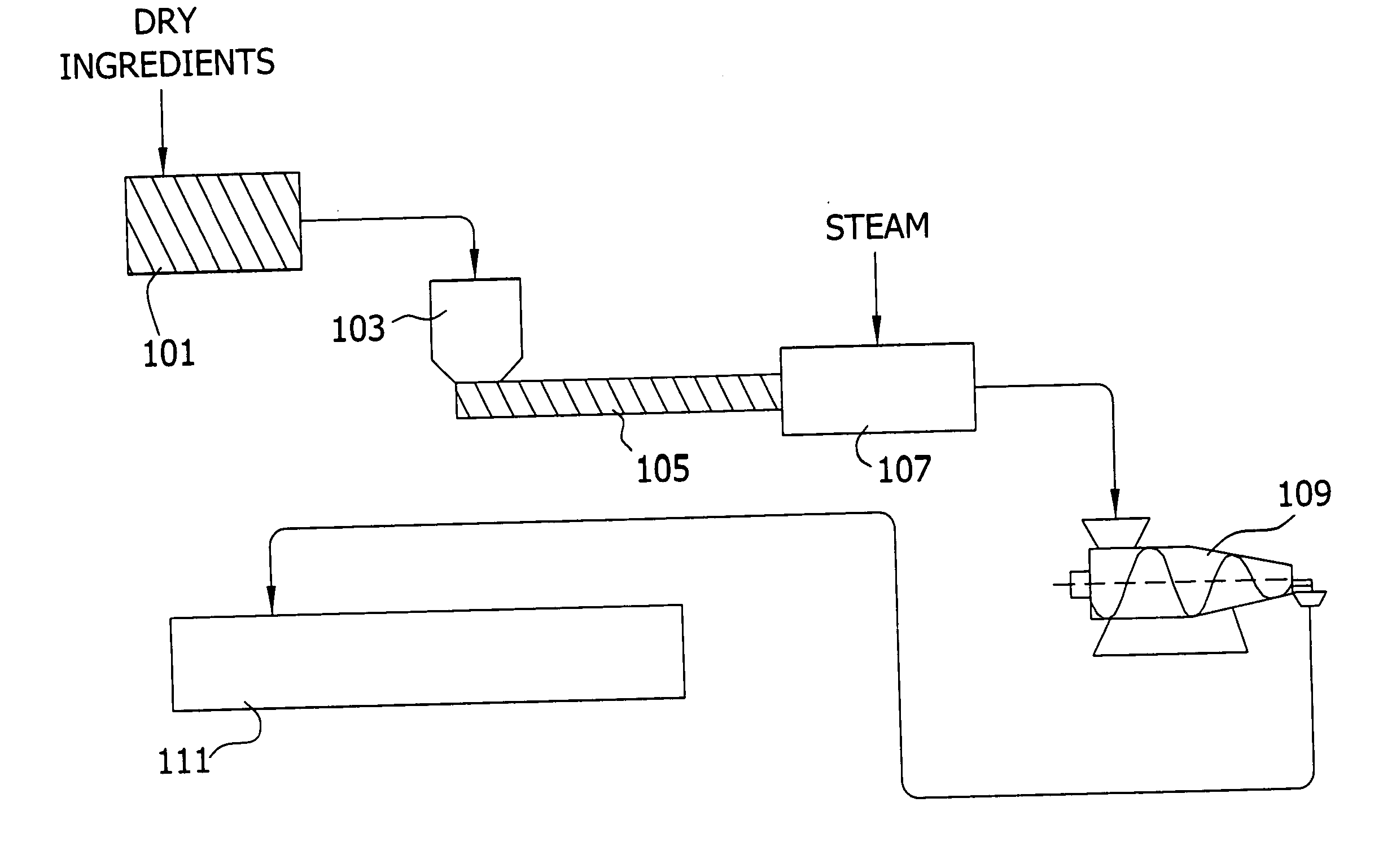

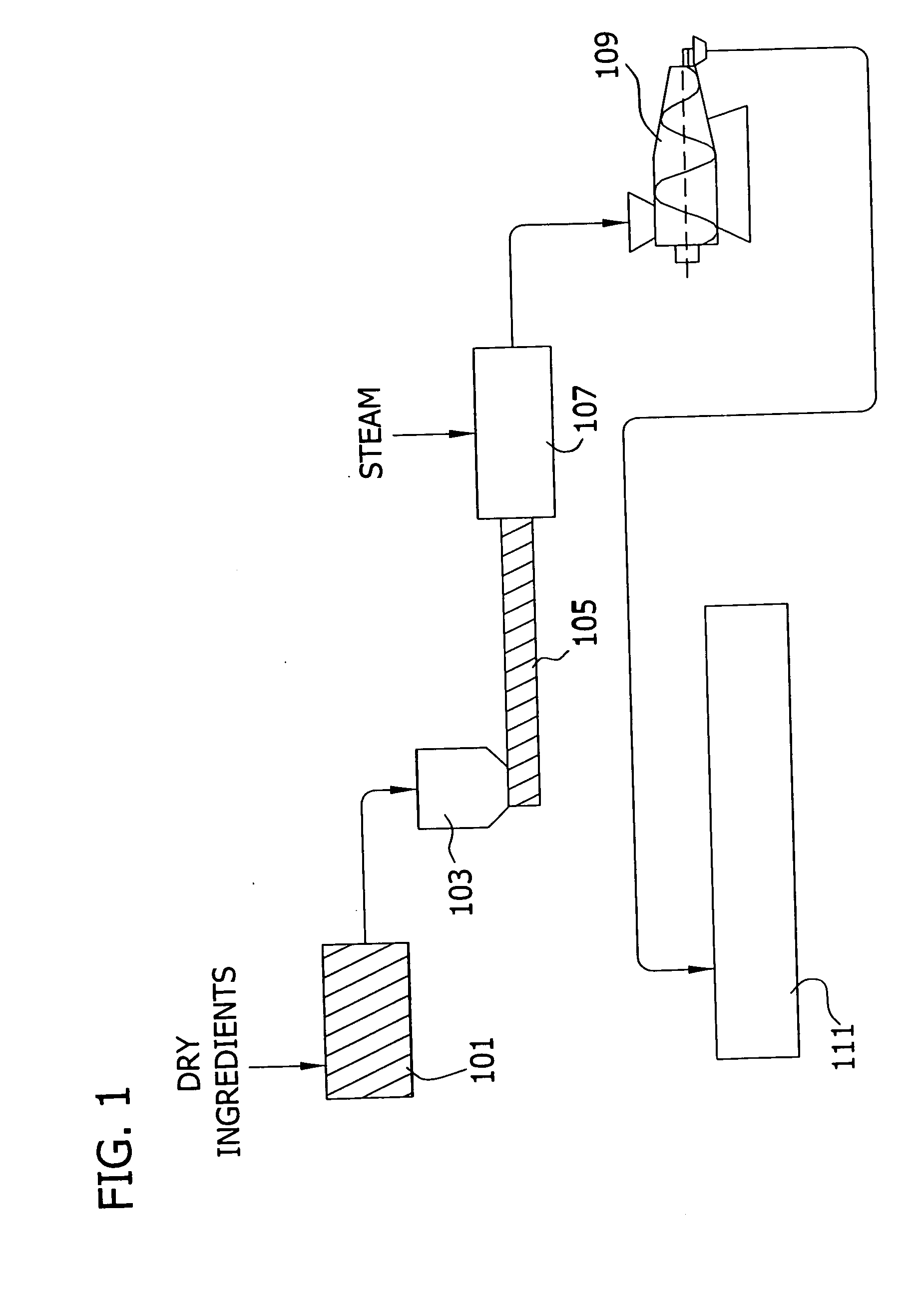

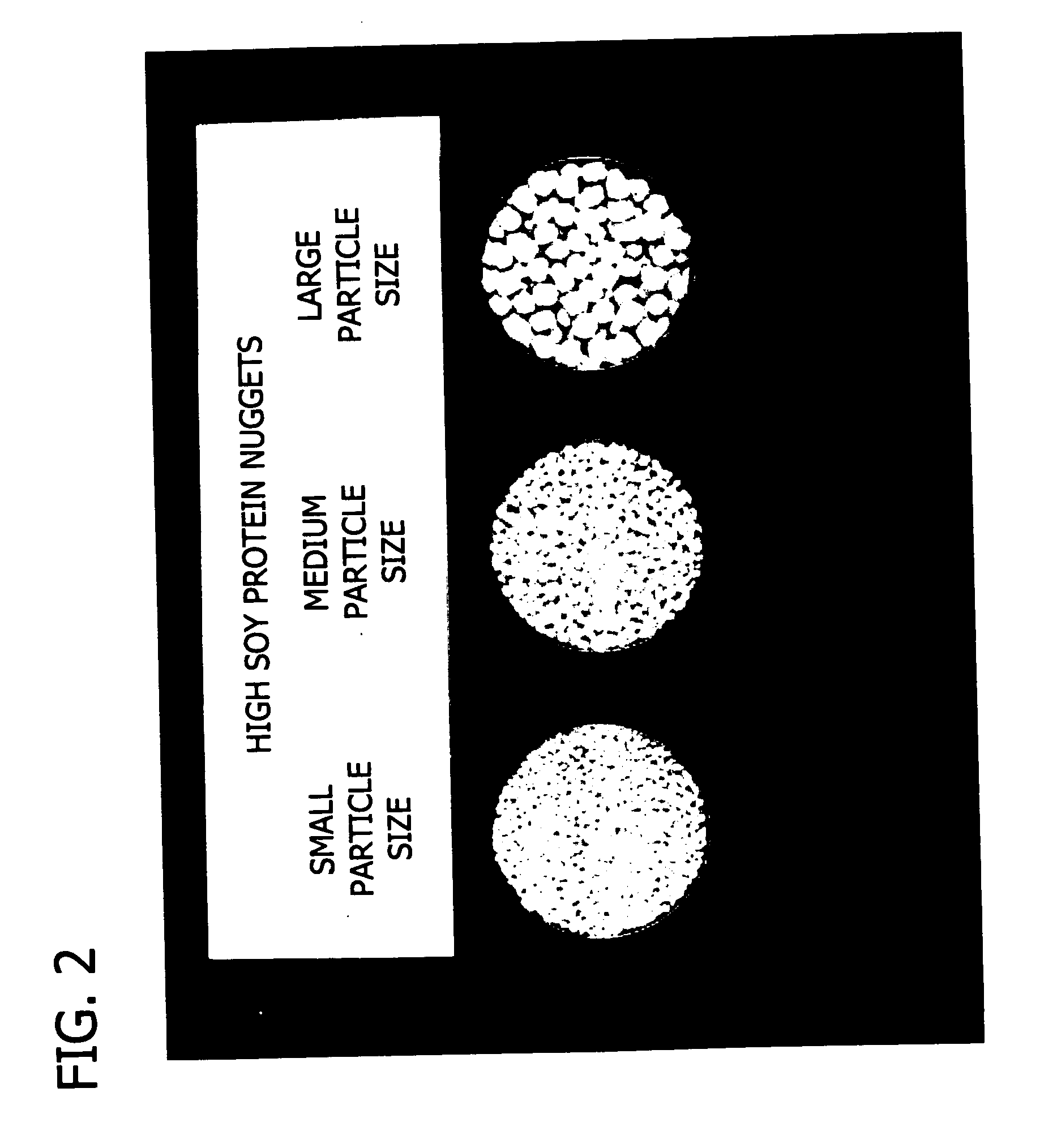

High soy protein nuggets and applications in food products

InactiveUS20050220979A1Crispy textureLow densityProteins working-up by texturisingVegetable proteins working-upHigh concentrationAdditive ingredient

The present invention relates to food materials containing a high concentration of vegetable protein and processes for their manufacture. More particularly, the present invention relates to vegetable protein extrudates containing high concentrations of protein and low concentrations of carbohydrates, processes for manufacturing such protein extrudates, and the use of such protein extrudates as functional food ingredients.

Owner:SOLAE LLC

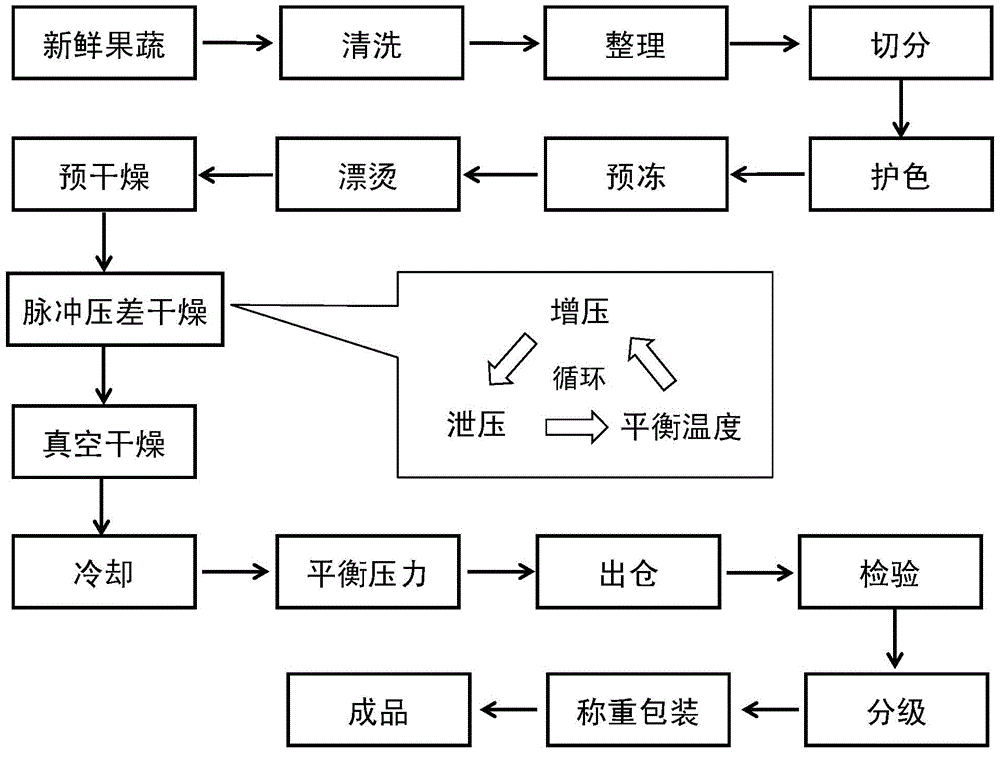

Flash drying method for fruits and vegetables through pulse pressure difference

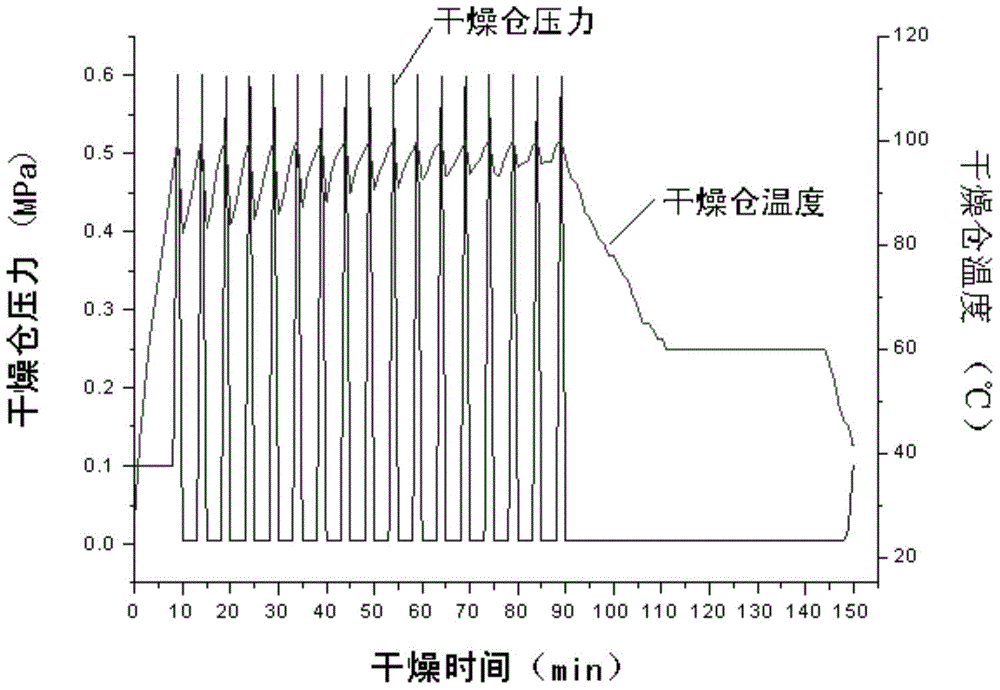

ActiveCN104397616AShorten drying timeImprove drying efficiencyFood preservationFood preparationNutrientMoisture

The invention discloses a flash drying method for fruits and vegetables through pulse pressure difference. The flash drying method comprises the following steps: (1) putting pretreated fruits and vegetables in a drying bin after heating, and then carrying out pressure relief on the drying bin; (2) carrying out pressure boost on the drying bin, and carrying out pressure maintaining; (3) carrying out pressure relief on the drying bin; (4) heating the drying bin; (5) repeating the step (2) to the step (4) until the mass moisture content of the fruits and vegetables is 10-25%; carrying out vacuum drying to realize drying for the fruits and vegetables. The flash drying method has the advantage that high-temperature and high-pressure water inside the fruits and vegetables is subjected to explosively acute gasification for multiple times, so that quick migration of the water towards the outside of the materials is realized. Quick dehydration of the materials can be realized through the repeated pulse flash evaporation, so that the drying time is greatly shortened, the drying efficiency is improved, and the cost is reduced; moreover, pores among internal organizational structures of the materials are increased, so that the product has the unique crispy mouthfeel and character, and nutrient substances are better stored.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Non-fried apple chips and processing method thereof

InactiveCN102696988AAvoid serious problems such as lossAvoid problems such as excessive sulfur contentFood preparationHigh humiditySulfite

The invention relates to the field of a leisure instant food processing technology, and particularly relates to non-fried apple chips and a processing method thereof. The processing method comprises the following steps of: selecting, washing and slicing, blanching and inactivating enzyme, soaking sugar, drying and cooling. According to the processing method disclosed by the invention, a non-fried production method is adopted and high-temperature and high-humidity gas jet impacting blanching enzyme inactivation is adopted to avoid a serious problem of nutrition loss caused by hot water blanching; the sugar soaking is adopted to process and protect the color so that a problem of over high sulfur content caused by chemical reagents odium sulfite and sodium pyrosulfite adopted in the traditional method is avoided. The produced non-fried apple chips having the advantages of no oil, low caloric value, long shelf life, intense original fruit flavor, bright color, uniform puffing and crisp texture are useable as a leisure instant food.

Owner:CHINA AGRI UNIV

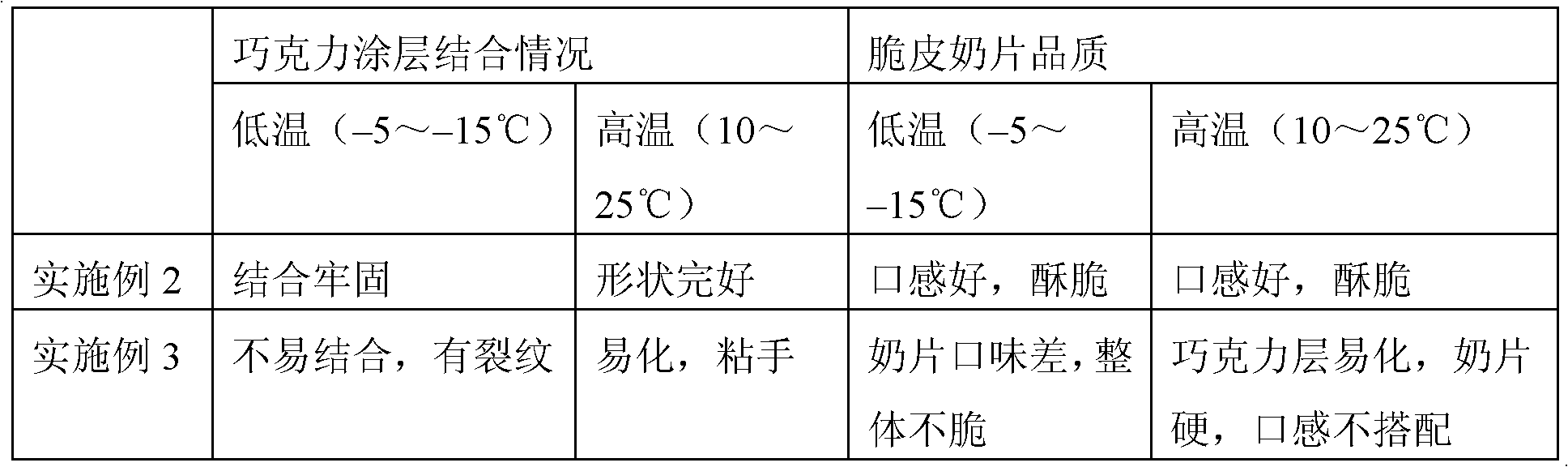

Chocolate coating for crackling milk slice, crackling milk slice and preparation method of chocolate coating

The invention relates to the field of dairy processing, in particular to a chocolate coating for a crackling milk slice, the crackling milk slice and a preparation method of the chocolate coating. The chocolate coating for the crackling milk slice comprises, by weight, 30%-50% of cane sugar, 10%-25% of palm kernel oil, 8%-20% of whole milk powder, 1-15% of inulin, 1%-5% of milk fat, 2%-8% of cocoa powder, 8%-10% of cocoa mass, 0.2-0.6% of lecithin and 0.02%-0.09% of vanillin. The crackling milk slice is crisp in texture, rich in milk fragrance, convenient to carry and eat and unique in taste, enhances tastiness of the milk, and meets the requirements of consumers having different tastes. Simultaneously, the chocolate coating for the crackling milk slice solves the problems that an existing milk slice chocolate coating is not adhered firmly, drops easily and melts easily at high temperature, and guarantees product quality and tastes.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

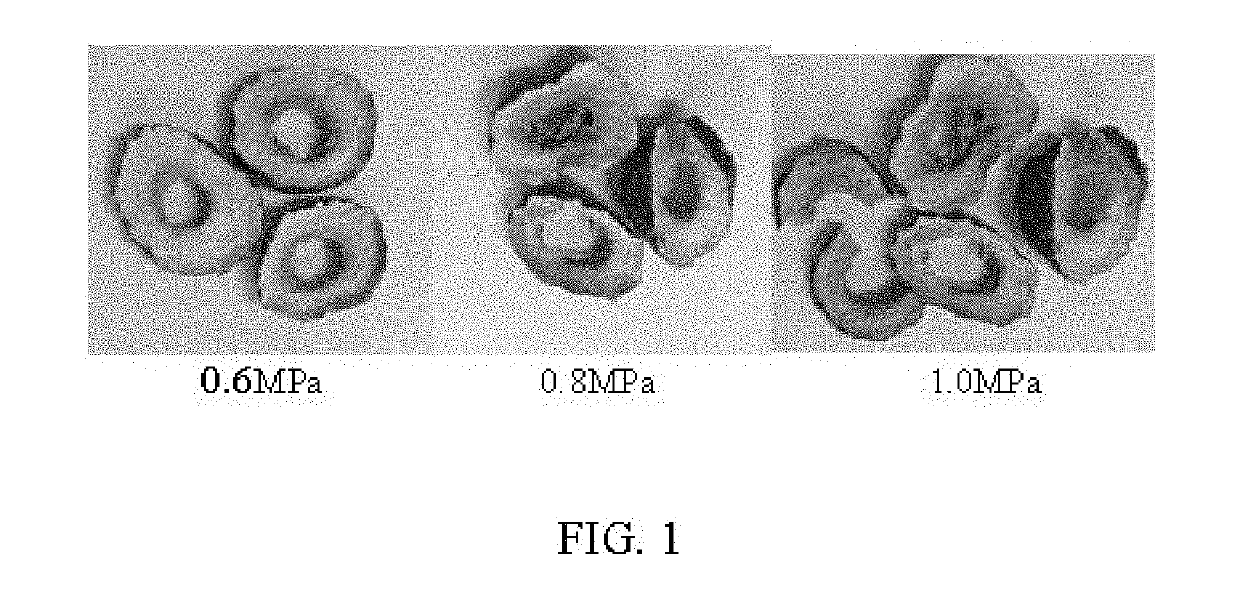

Dried fresh jujube slices and energy-saving process technology for differential pressure expansion drying

PendingUS20190269160A1Difficult to chewIncrease investmentFood coatingFood shapingFreeze-dryingDifferential pressure

A method for processing dried fresh jujube slices includes the following steps: preparing jujube slices, coring and removing stems, quick-freezing and retaining freshness of the jujube slices, thawing frozen jujube slices, protecting color treatment, expanding jujube slices under differential pressure, preparing superfine mixed seasoning powder, and coating of the superfine mixed seasoning powder. For one hand, this method solves problems that the dried fresh jujube slices will be deeply oxidized and brown when dried by the hot air at a high temperature of 90-110° C., the jujube slices with compacted cells will become harder and be difficult to chew because of 6-8 h rapid dehydration. On the other hand, it solves problems that exist in freeze drying at a vacuum degree of 1.3-13 Pa, and at a low temperature of −10-50° C., such as high energy consumption, long processing cycle, high equipment investment, small size of slices, and poor taste.

Owner:NINGXIA ZHONGXI JUJUBE IND LTD LTD +1

Processing method for coarse cereal rice crust

ActiveCN103815294ACrispy textureGreat tasteFood shapingFood preparationPolygonum fagopyrumFood science

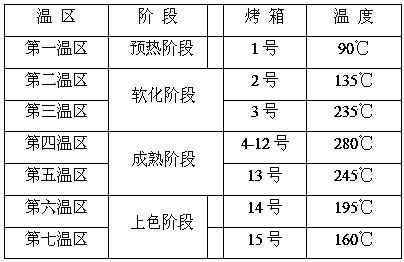

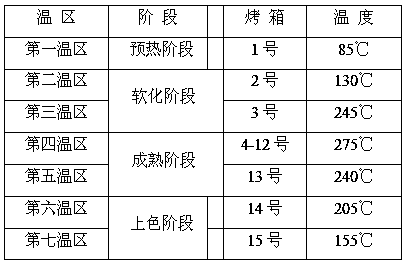

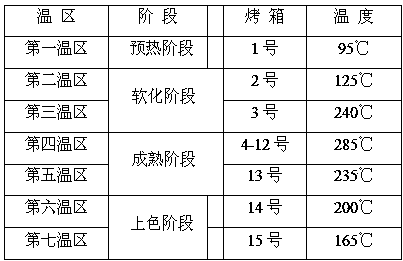

The invention relates to a processing method for coarse cereal rice crust. The processing method comprises the following steps: step 1, performing batching of the following components in percentage by weight: 85 to 95% of rice, 1.0 to 3.0% of oat, 1.0 to 3.0% of corn, 2.0 to 2.5% of buckwheat and 0.8 to 1.0% of black sesame, and the sum of the raw materials is 100%; step 2, mixing; step 3, stewing; step 4, cooling; step 5, stirring; step 6, shaping; step 7, baking: baking according to seven temperature zones and four periods, wherein the seven temperature zones are respectively a first temperature zone at 85 to 95 DEG C, a second temperature zone at 125 to 135 DEG C, a third temperature zone at 235 to 245 DEG C, a fourth temperature zone at 275 to 285 DEG C, a fifth temperature zone at 235 to 245 DEG C, a sixth temperature zone at 195 to 205 DEG C, a seventh temperature zone at 155 to 165 DEG C; step 8, cooling so as to obtain the rice crust. The coarse cereal rice crust provided by the invention is good in taste, crisp, rich in nutrition and suitable for being eaten directly.

Owner:ANHUI TRUELOVE FOODS

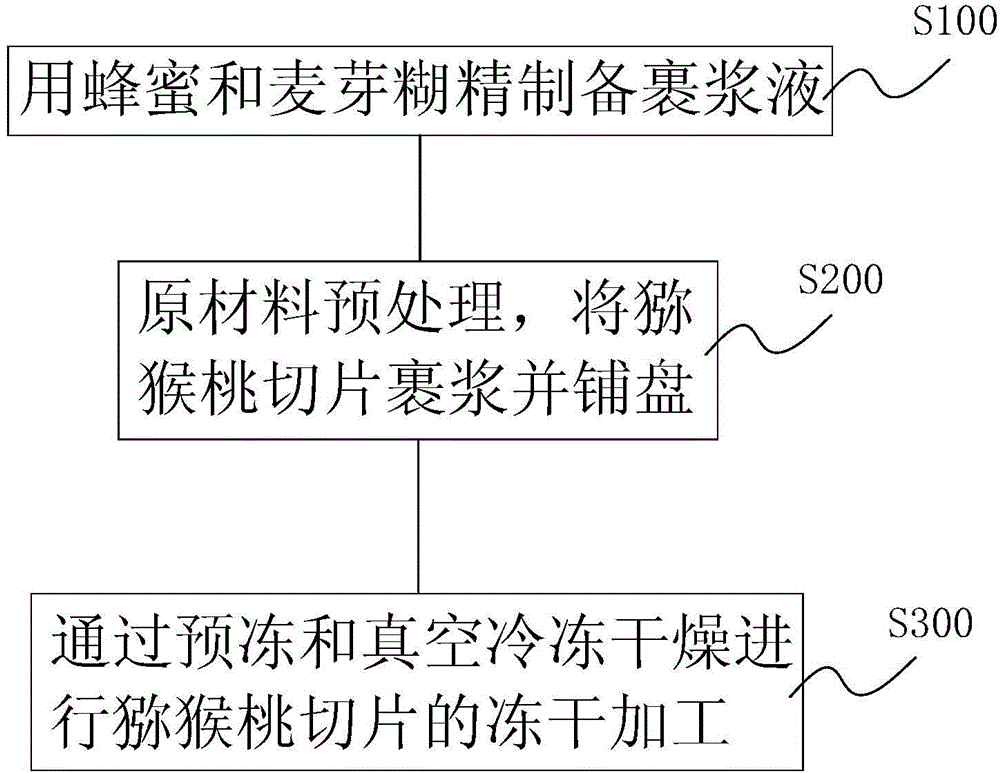

A freeze-dried kiwi fruit slice and a processing method thereof

InactiveCN105433194ASolve the change of color and fragranceSettle the lossFood preservationFood preparationFreeze-dryingKiwi fruit

A freeze-dried kiwi fruit slice and a processing method thereof are provided. The freeze-dried kiwi fruit slice is prepared by the processing method as follows. The processing method includes a step of preparing a starching liquid, namely a step of selecting honey and maltodextrin, adding the maltodextrin into the honey with the maltodextrin being 25-35% of the honey, adding drinking water for regulation until the content of soluble solids is 10-20%, stirring fully to obtain the starching liquid and keeping for later use; a step of raw material pretreatment, namely a step of cleaning prepared kiwi fruit, peeling, slicing, putting the kiwi fruit slices into the starching liquid in order, fully starching, taking out and spreading on a material tray; and a step of freeze-drying including prefreezing and vacuum freeze drying, namely a step of putting the material tray containing the kiwi fruit slices into a freezing chamber, prefreezing, setting the vacuum degree of a vacuum freeze drying device to be not more than 100 Pa, and performing staged heating and drying by setting a staged drying curve according to the water sublimation rate of the starched kiwi fruit slices so as to prevent loss of heat-sensitive components of the starched kiwi fruit slices and to protect product color from browning.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Method of processing spicy and crispy lima bean

InactiveCN101228941AReactive aroma is obviousCrispy textureFood preparationMaillard reactionSalty taste

The invention relates to an agricultural product processing, in particular to a processing method of a spicy crisp lima bean. The invention comprises the following steps: preparing raw materials, removing pod, precooking, quick freezing, defrosting and separating, vacuum frying, deoiling, seasoning, etc. The beneficial effects of the invention are that the product is crispy, and the maillard reaction flavor is obvious; by adding different natural condiments, the snack food can be made with original taste, spicy taste, fruit taste, sour-sweet taste and salty taste. The series product can be packaged by common plastic food bags and stored for more than nine months at normal temperature.

Owner:LONGYAN UNIV

Coarse cereal cookie and preparation method thereof

The invention provides a coarse cereal cookie. The coarse cereal cookie is prepared from the following raw materials including, by weight, 30-50 parts of buckwheat flour, 30-50 parts of naked oat flour, 10-30 parts of corn flour, 50-70 parts of fat, 30-50 parts of powdered sugar, 40-60 parts of eggs and 0.1-1 part of baking soda. The fat is a combination of cream and milk or butter. The preparation method comprises the first step of mixing and sieving the buckwheat flour, the naked oat flour and the corn flour and sieving the powdered sugar, the second step of whisking the eggs and the powdered sugar into a creamy egg paste, the third step and the fourth step of mixing the fat and the creamy egg paste into a flocculent shape, the fifth step of pouring the buckwheat flour, the corn flour, the naked oat flour mixture into the paste and stirring the mixture to be uniform, the sixth step of extruding a semi-finished cookie, and the seventh step of baking. The coarse cereal cookie is rich in dietary fiber, protein and minerals, has golden color, oatmeal flavor, crisp texture and a simple formula, and is suitable for a cake shop, a snack food processing enterprise and home making.

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI

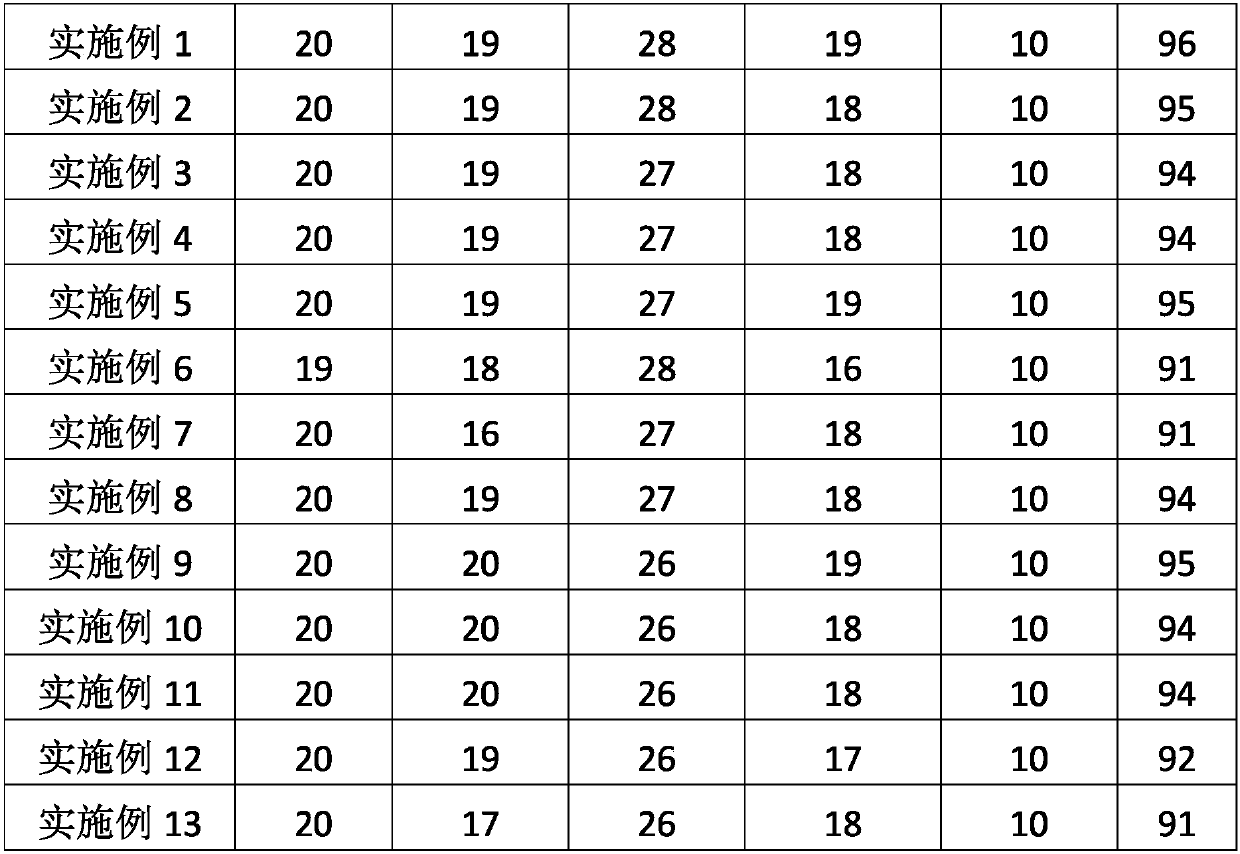

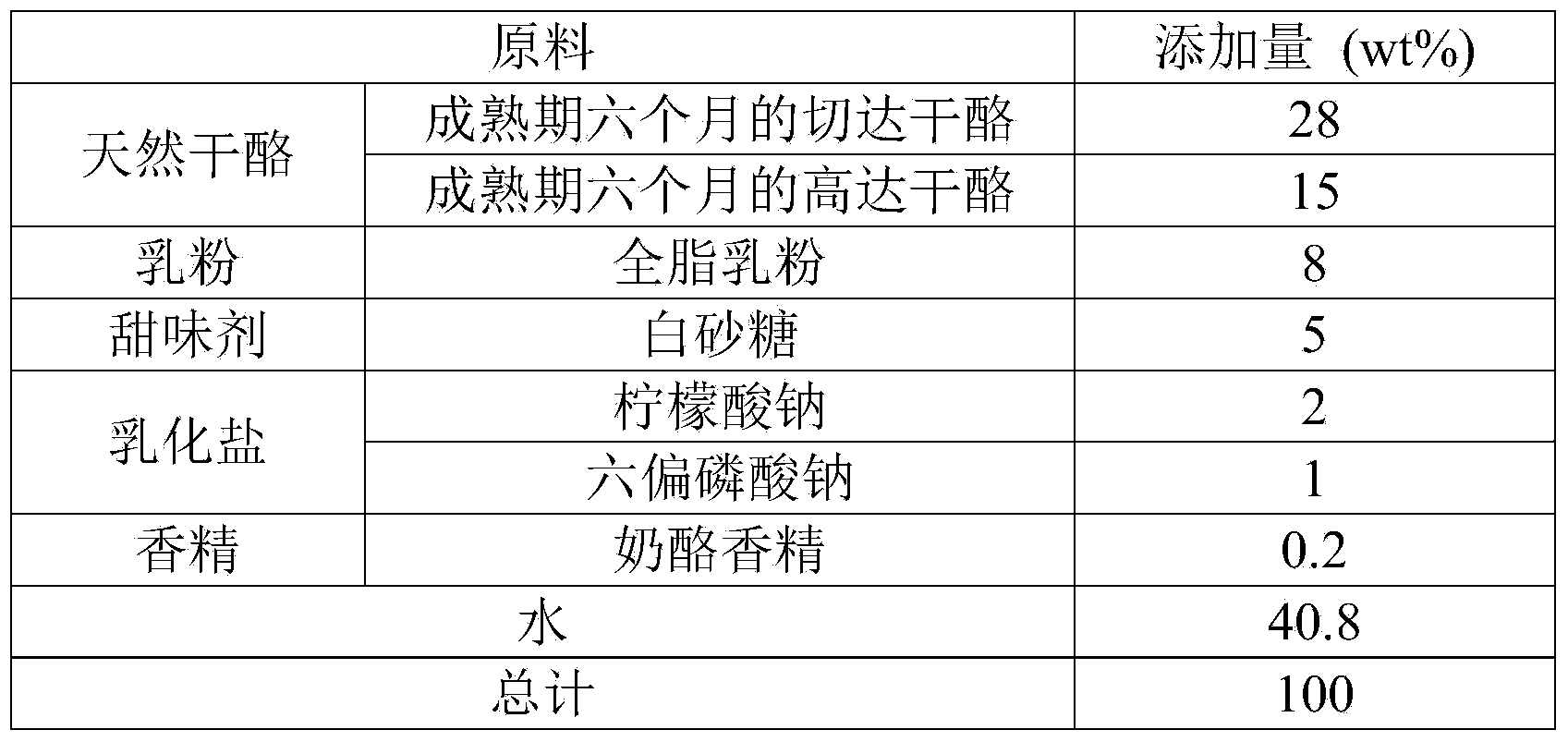

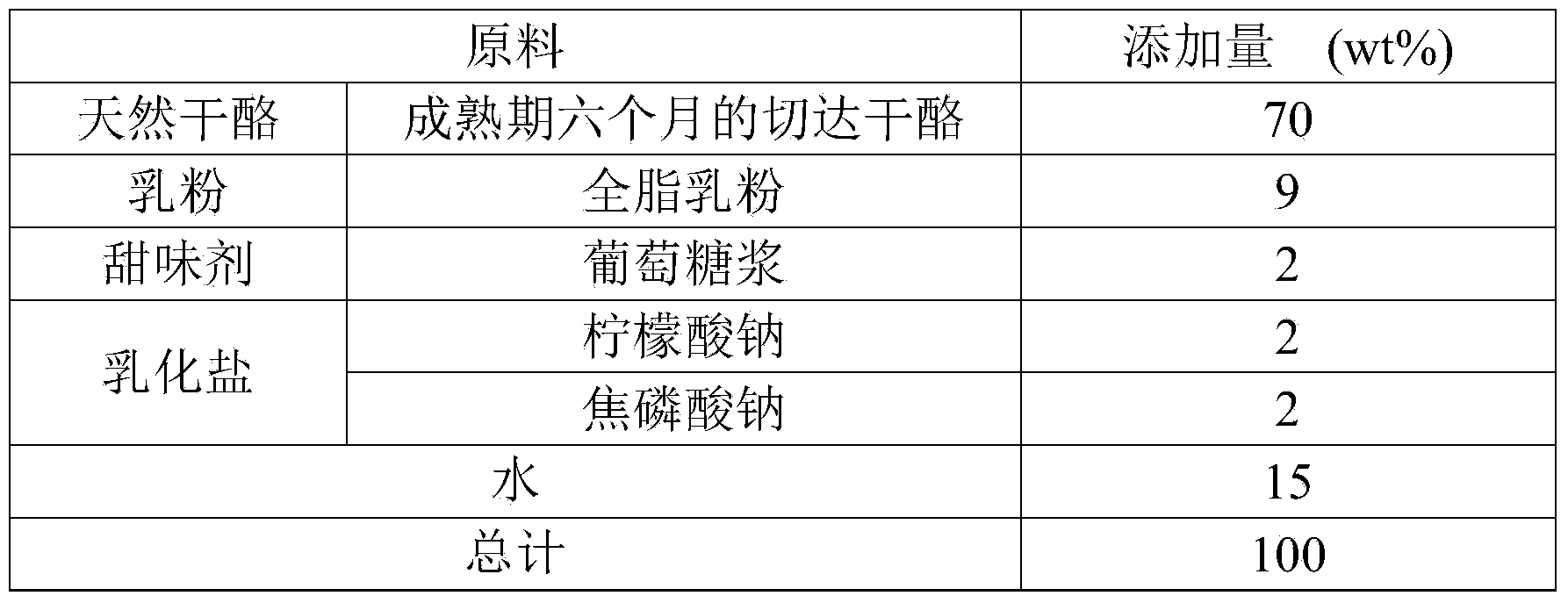

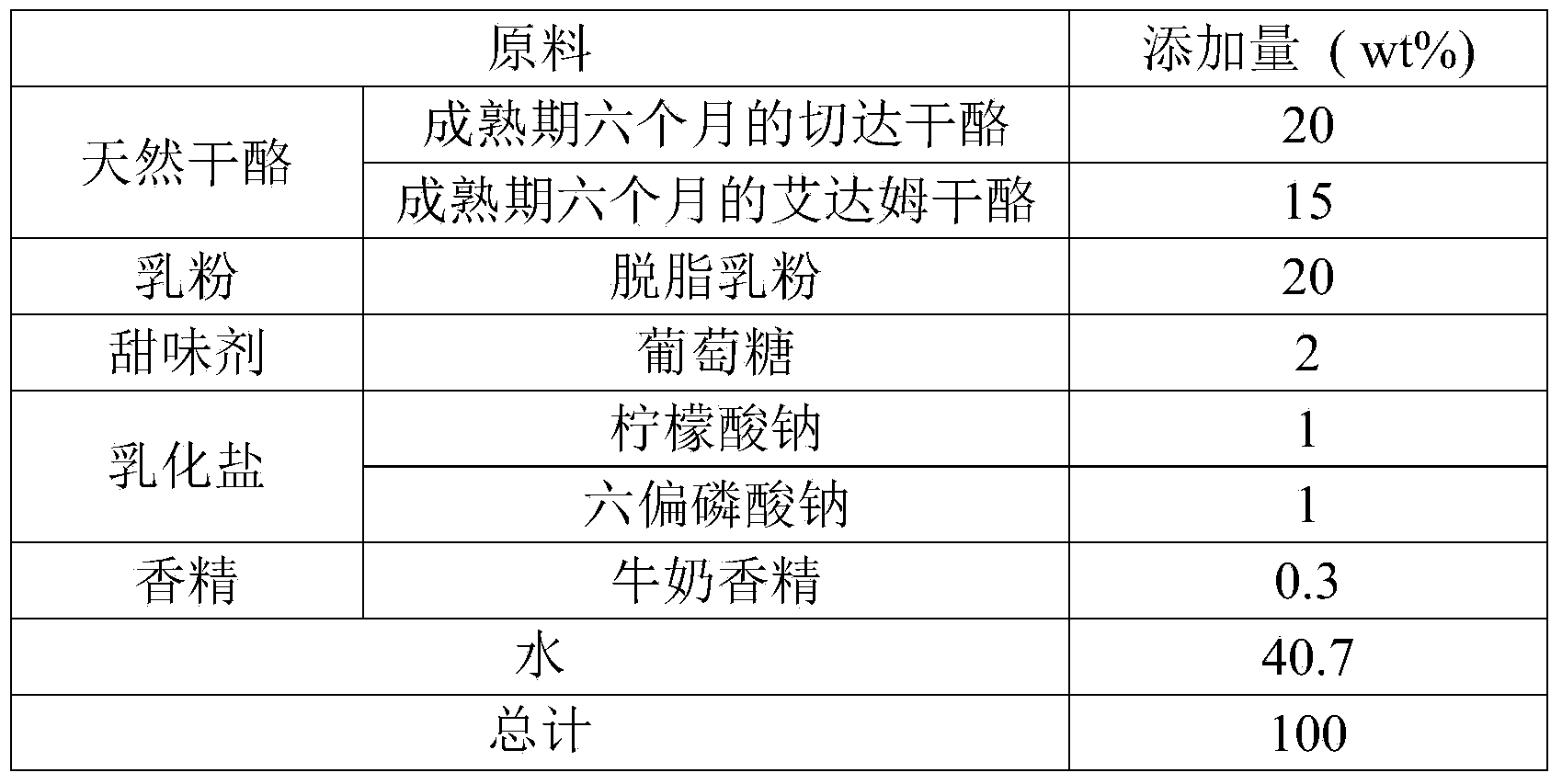

Preparation method for reproduced cheese preserved at normal temperature and product

The invention discloses a preparation method for reproduced cheese preserved at normal temperature and a product. The preparation method comprises the following steps: (1) mixing raw materials for reproduced cheese preserved at normal temperature, heating and evenly agitating to obtain feed liquid; (2) injecting the feed liquid into a die, cooling to room temperature and then primarily pre-freezing at -5 DEG C to -25 DEG C for 2-12 hours, demolding to obtain the reproduced cheese; (3) pre-freezing the reproduced cheese at -35 to -60 DEG C for 4-24 hours, so as to obtain pre-frozen reproduced cheese; (4) keeping the temperature of the pre-frozen reproduced cheese at 15-35 DEG C under the vacuum degree of 100-20Pa, wherein the thermal insulation time at least is the time required for cooling the center temperature of the pre-frozen reproduced cheese to 0 DEG C; and (5) heating up to 35-50 DEG C under the vacuum degree of 80-20Pa, and keeping the temperature for 4-10 hours. The reproduced cheese preserved at normal temperature prepared by the method can be preserved for over six months at normal temperature of 25 DEG C, and is good in flavor, mouthfeel and texture.

Owner:BRIGHT DAIRY & FOOD

Tuckahoe mildewed soybean chilli sauce and preparation method thereof

InactiveCN103919111AUnique flavorUnique flavor, spicy and deliciousNatural extract food ingredientsFood ingredient functionsBiotechnologySalty taste

The present invention provides a tuckahoe mildewed soybean chilli sauce, which is prepared from the following raw material components by weight: 20-40 parts of soybean, 0.1-0.2 part of tuckahoe, 0.1-0.2 part of medlar, 0.4-0.5 part of coix seed, 40-60 parts of green pepper, 8-12 parts of fresh caridina, 4-6 parts of gravy salt, 0.4-0.6 part of fresh ginger, 0.1-0.12 part of garlic, 4-5 parts of sweet flour paste, 0.3-0.6 part of stachyose, 0.4-0.6 part of yellow wine, 0.01-0.02 part of tea polyphenol, and 0.04-0.06 part of a health Chinese herb additive. According to the mildewed soybean chilli sauce, based on the preservation of the traditional process, the tuckahoe, the green pepper, the dried shrimp and other auxiliary materials are added, and the health Chinese herb additive is added, such that the singleness disadvantage of the traditional variety is changed, the nutrition is rich, and the health effects of spleen strengthening and stomach strengthenin are increased; the tuckahoe mildewed soybean chilli sauce does not contain any preservatives, such that the eating is safe; and the tuckahoe mildewed soybean chilli sauce has characteristics of yellow and bright color, delicious taste, crisp and tender texture, fragrance, rich nutrition, delicious and mellow taste, moderate salty taste, unique, spicy and delicious flavor, and long shelf life.

Owner:何爱华

DHA (docosahexaenoic acid) cheese sandwich biscuit and preparation method thereof

InactiveCN103947731AStrong targetingDysregulationBakery productsFood preparationBiotechnologyPhyllochinon

The invention discloses a DHA (docosahexaenoic acid) cheese sandwich biscuit and a preparation method of the DHA cheese sandwich biscuit, and belongs to the technical field of nutritious food processing. The DHA cheese sandwich biscuit is characterized by comprising two parts including a biscuit and a DHA cheese sandwich material, wherein the biscuit is selected from one kind of crispy biscuits, hard biscuits, soda biscuits, cookie biscuits, wafer biscuits and thin and brittle biscuits made in the prior art, the DHA cheese sandwich material consists of raw materials including cheese powder, mycose, erythritol, cream, algae oil, DHA and lutein ester, and the mass ratio of the sandwich material to the biscuit is 1:(3 to 3.5). The DHA cheese sandwich biscuit and the preparation method thereof have the advantages that the effects of nutrition complementation and synergetic gain are fully realized, and the market blank is filled; the mouth feeling is better, the eating is convenient, the safety is good, the acceptability is high, and no toxic or side effect exists; after eating, the visual fatigue can be obviously relieved, the digestion is promoted, the intestinal flora imbalance is regulated, the memory is improved, auxiliary protection effects can be realized on hypertension, hyperlipidemia and high blood glucose cardiovascular diseases, the immunity is improved, and the body health is maintained; the production process is simple, the control is easy, and great market development potential is realized.

Owner:李卫平

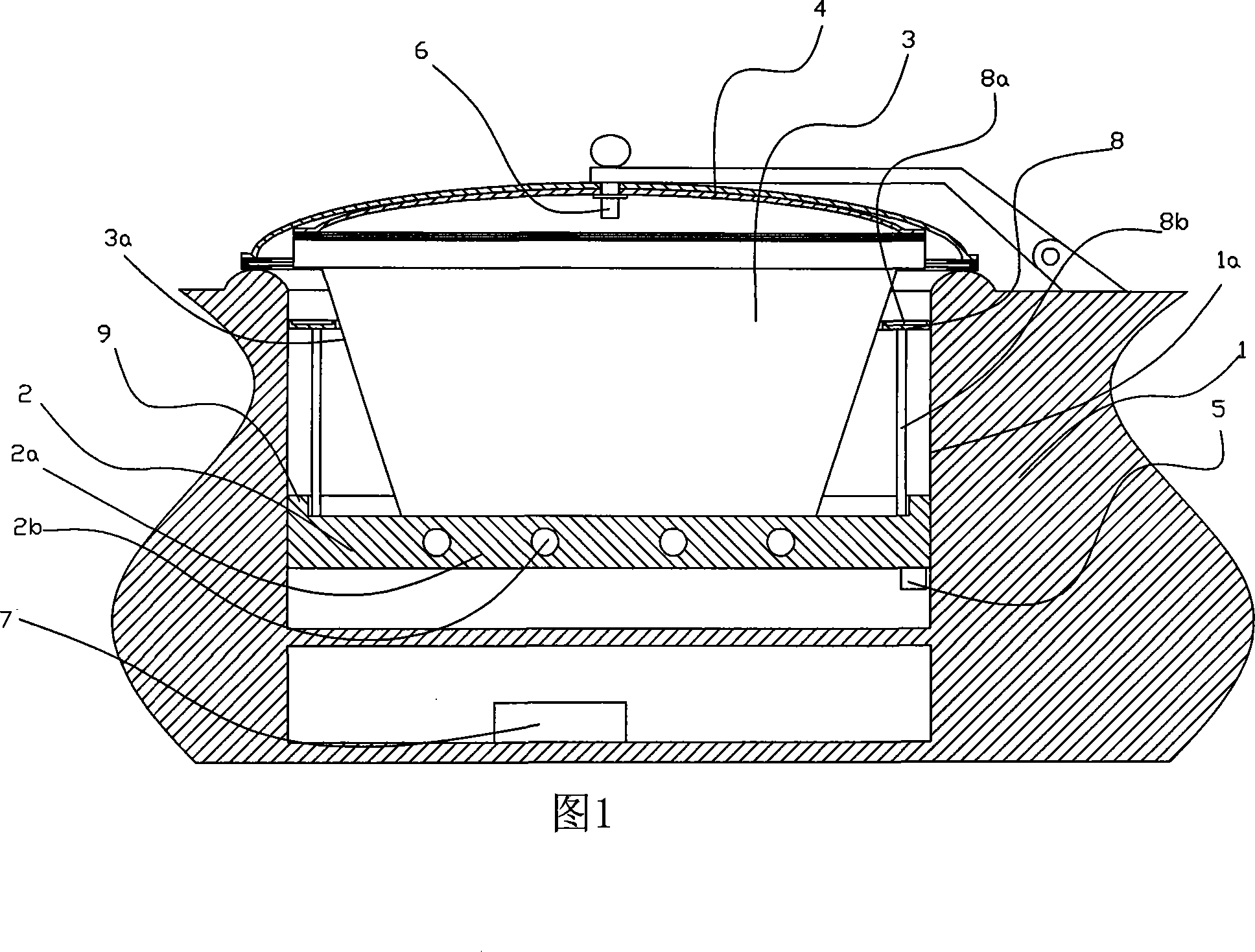

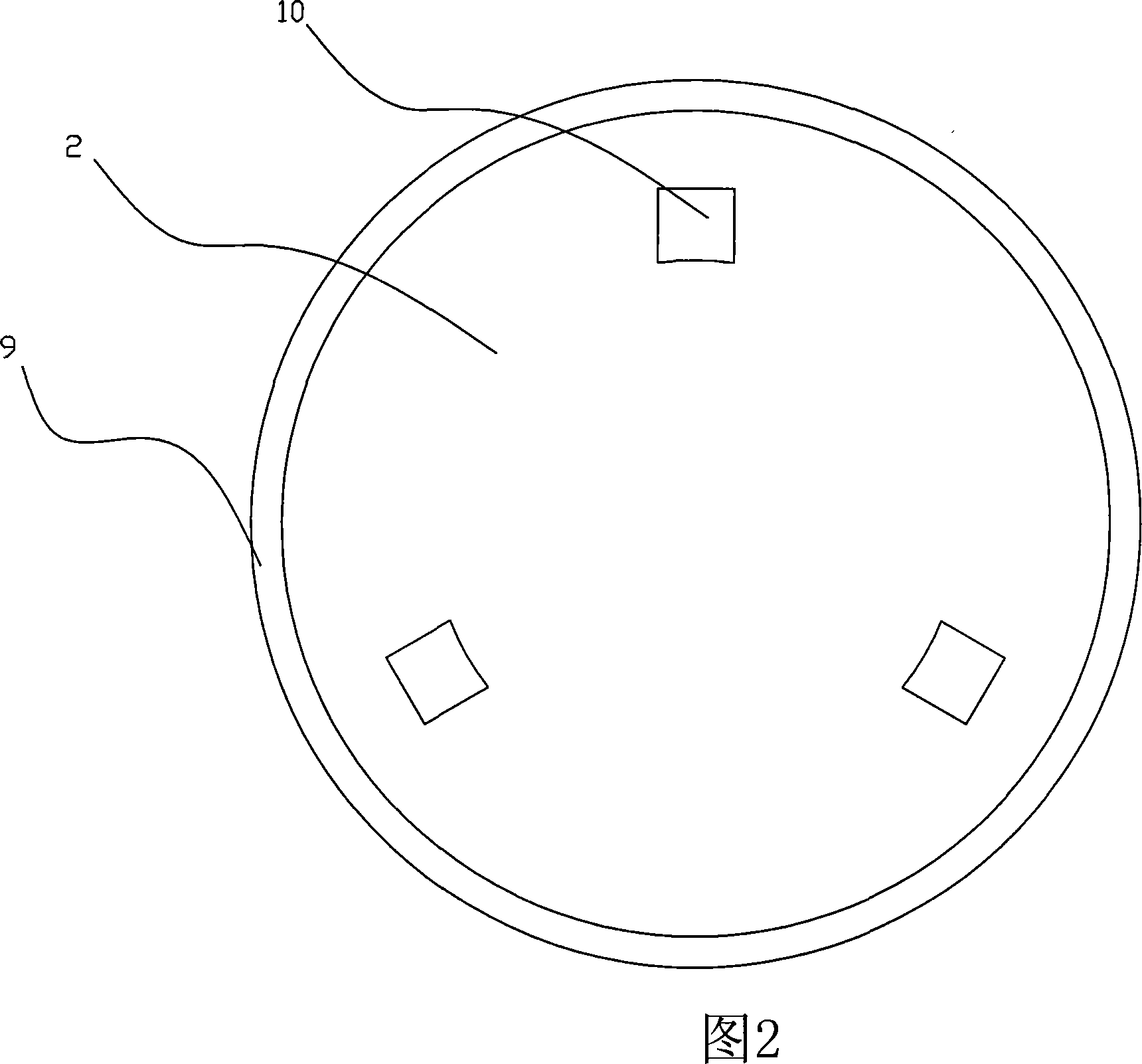

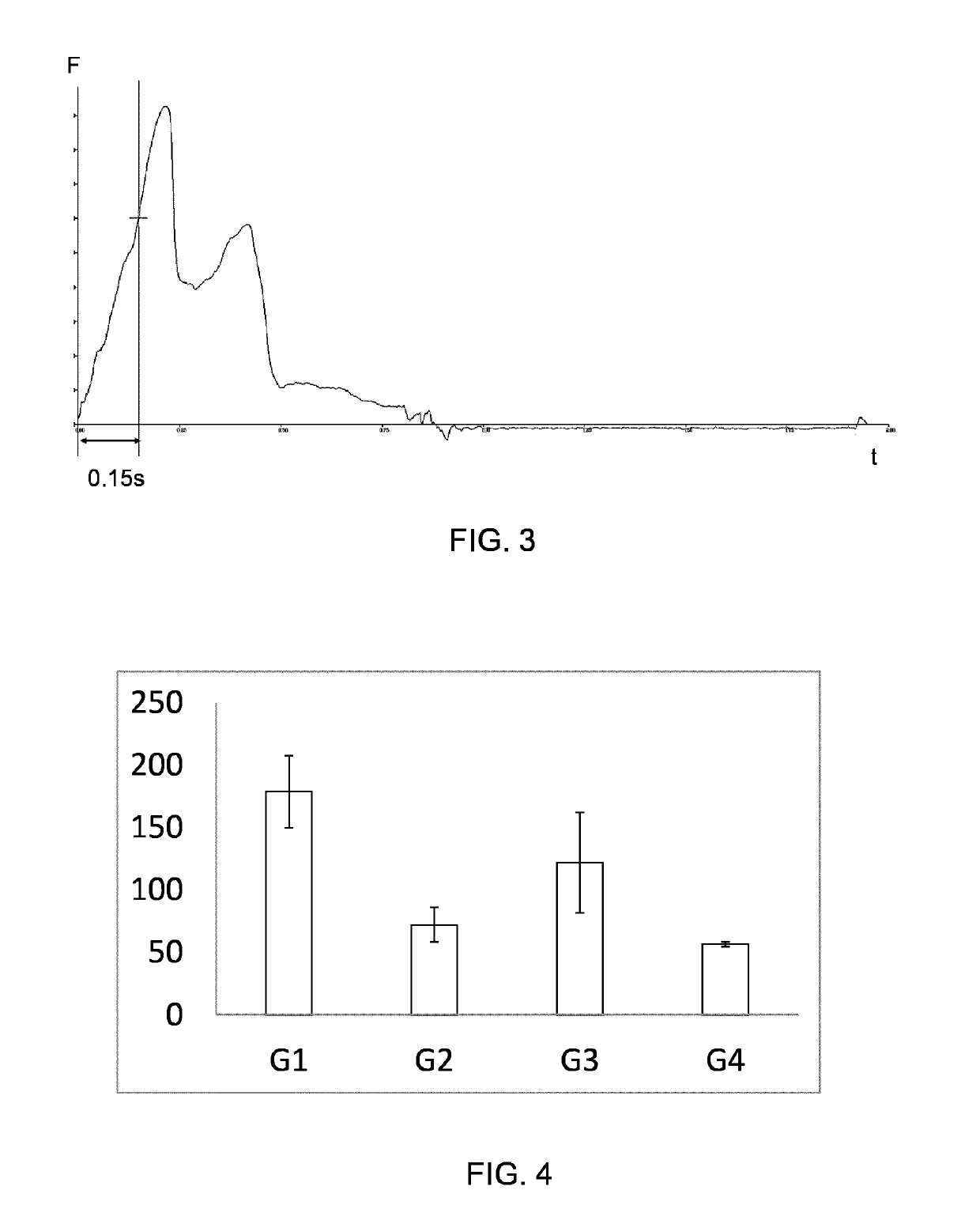

Process for boiling a plurality of steamed rice together with other materials and the arrangement thereof

InactiveCN101116484ANot easy to burnNot easy to scrape offCooking vesselsFood preparationElectricityEngineering

A method to continuously cook a plurality of hotpot rices and the apparatus thereof, which include an early phase of cooking with a strong fire and a latter phase of cooking with a mild fire. The present invention is characterized in that an electrical heating disc arranged on the bottom of the pot is used to supply the heat when the pot is heated, meanwhile, the space between the middle-upper site of the lateral wall of the pot and the electrical heating disc is sealed. Compared with the prior art, the present invention not only can finish cooking a pot of rice in a short time and prevent the crispy rice formed on the pot bottom and on the lateral wall from being burnt, but also has the advantage that the crispy rice with crispy and soft texture is easily taken from the pot.

Owner:梁建华

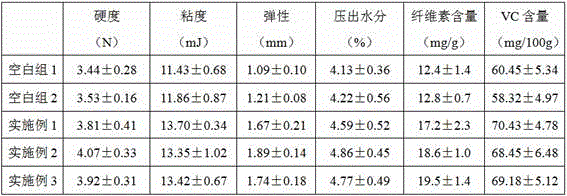

Processing method of instant vegetable and surimi convenient products

InactiveCN105767940ADestroy cell structureGood compatibilityFood scienceUltrasonic assistedProcess engineering

The present invention discloses a processing method of instant vegetable and surimi convenient products. The processing method includes the following steps: pre-processing, meat collecting, rinsing, pre-dehydrating, refinedly filtering and dehydrating, high pressure homogenizing to prepare a vegetable homogenate, ultrasonic assisted grinding, molding, ultrasonic assisted cooking and aging, low-pressure superheated steam drying and packaging. The obtained product is rich in nutrition, excellent in color, smell and taste and good in taste, can maintain color and luster of vegetables, and is high in dietary fiber content and a healthy food suitable for people at all ages.

Owner:FUJIAN AGRI & FORESTRY UNIV

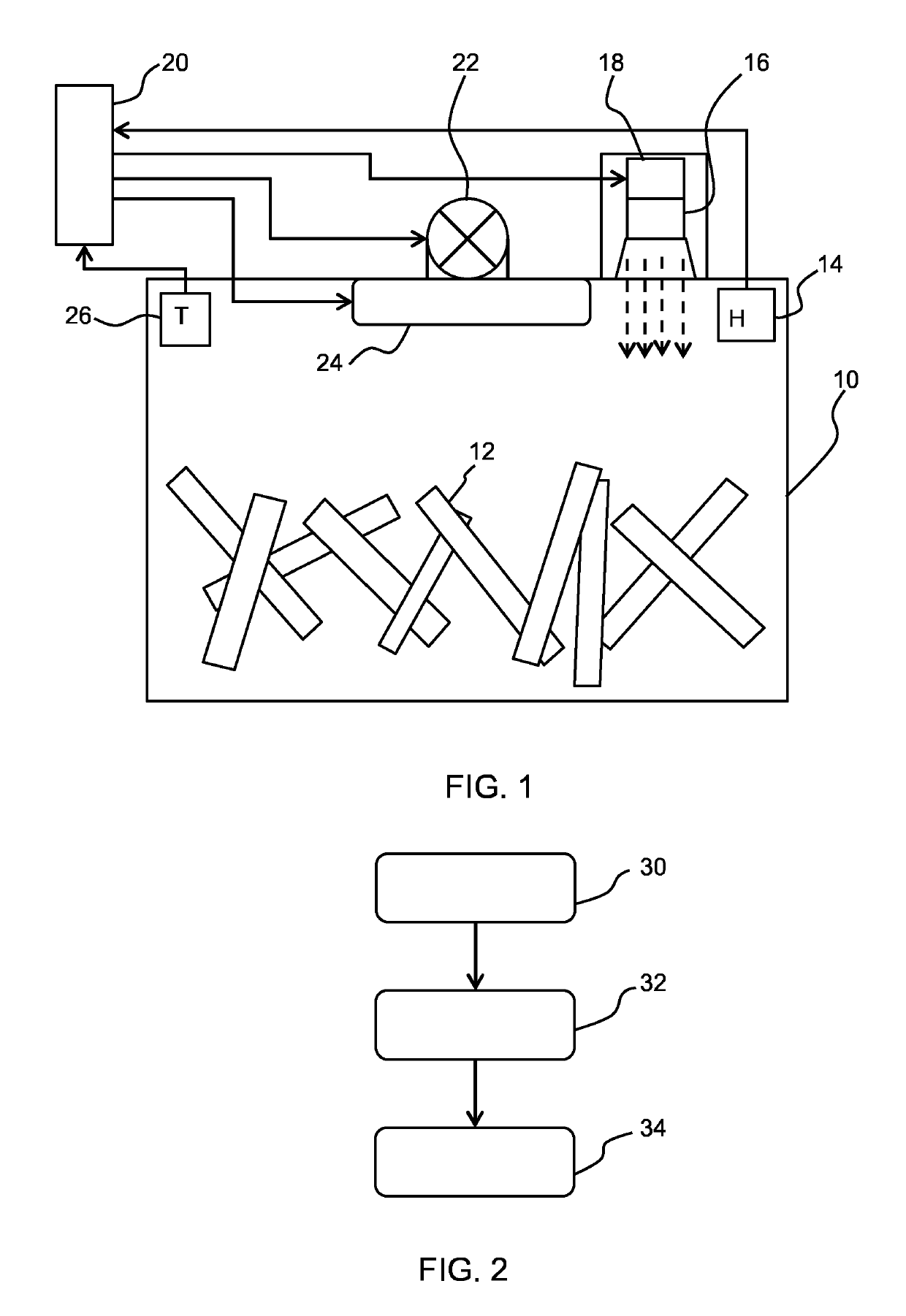

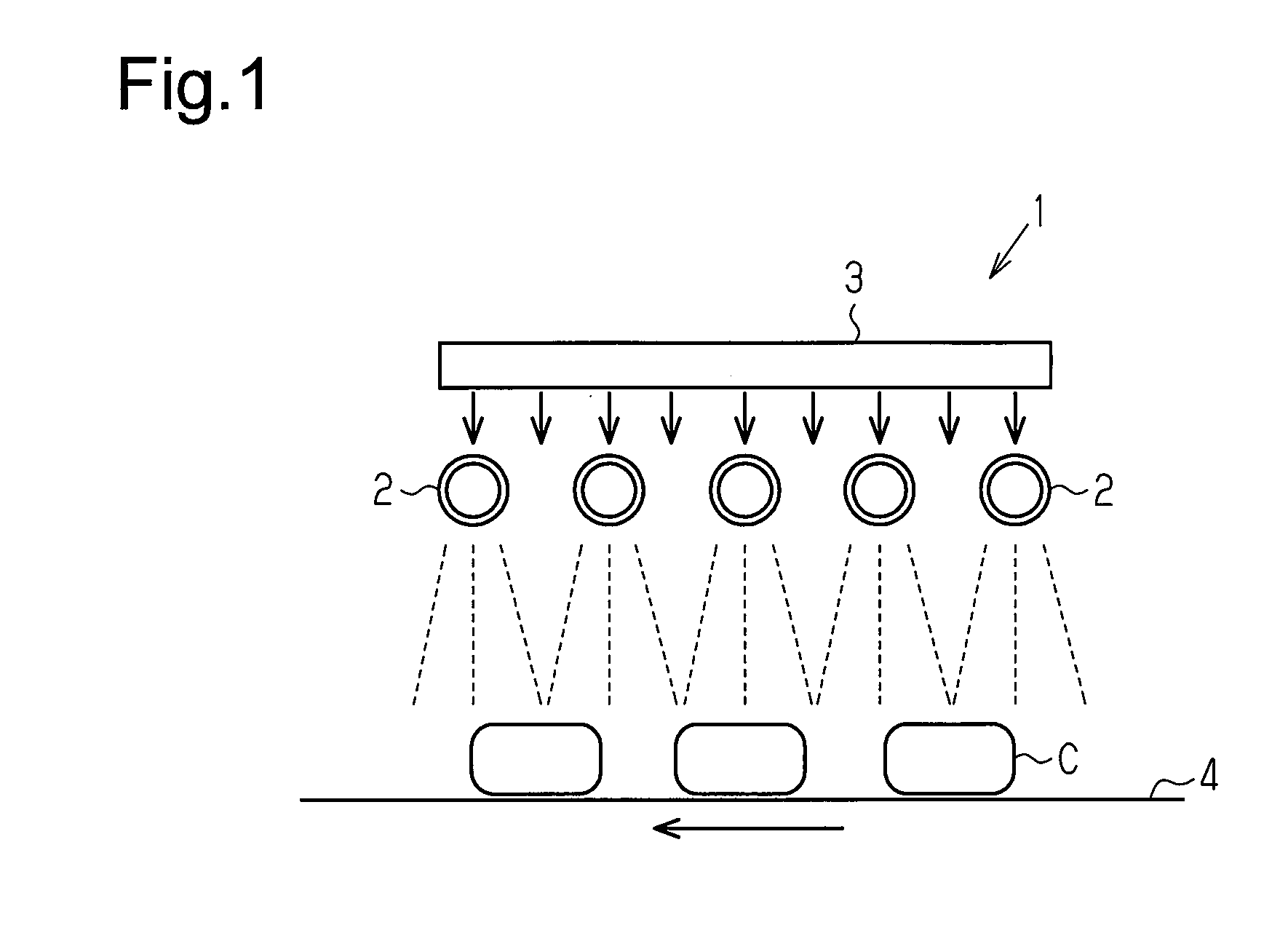

Appliance and method for cooking potato chips

InactiveUS20190110504A1Improve textureCrispy textureFruits/vegetable preservation by dehydrationChipped potatoesHigh humidity

A cooking appliance and method for cooking potato chips are provided. The appliance has a humidity control system, an air flow generation system and a heating system. The cooking process has a relatively low temperature and high humidity cooking cycle, a low humidity dehydration process and a relatively high temperature low humidity browning process. These three cycles enable good crisp crust formation for fresh non-frozen chips which are cooked using an air / steam based cooking process rather than a deep fat frying process.

Owner:KONINKLJIJKE PHILIPS NV

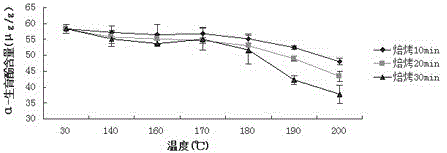

Ultra-thin wheat germ protein flakes and production method thereof

InactiveCN105533459APromote growth and developmentMake full use ofFood ingredient as taste affecting agentFood shapingBiotechnologyWheat germ

The invention discloses ultra-thin wheat germ protein flakes and a production method thereof. The ultra-thin wheat germ protein flakes are made from, by weight, wheat germ powder 50%-95%, natto flour 1%-10% and auxiliary materials 4%-40%, wherein the auxiliary materials are one or any combination of flour, rice flour, white granulated sugar, whole egg powder, milk powder and sesames. Wheat germs are smashed into powder by using a smashing machine, then the wheat germ powder and other auxiliary materials are mixed, the mixture is fed into a double-screw extruding and bulking machine to be mixed, stirred, sheared and extruded into dough, the dough is made into flakes in an outlet die head of the extruding machine, the flakes are rolled to form ultra-thin flakes, the ultra-thin flakes are fed into an oven to be baked and then are fed into a seasoning roller to be seasoned, and the natto flour is input into the seasoning roller during seasoning to enable the natto flour to attach to the ultra-thin wheat germ flakes. The ultra-thin wheat germ protein flakes contain rich vitamin E, folic acid, protein, unsaturated fatty acid, dietary fiber and other nutrients, are easily absorbed by a human body, are ultra-thin in thickness, very crisp in quality and structure and mellow in wheat fragrance, and meanwhile the added natto contains active factors.

Owner:烟台金富基生物科技有限公司

Baked chocolate confectionery

ActiveUS20150289535A1Easily broughtCrispy textureMilk preservationConfectioneryChocolate confectionerySurface structure

A technique for imparting a mild soft texture inherent to chocolate, particularly a melt-like texture, to the inside of a baked chocolate confectionery obtained by baking a surface of a chocolate molded article. In the present invention, the inside of a baked chocolate confectionery obtained by baking a surface of a chocolate molded article comprising a chocolate dough, a surface structure of the baked chocolate confectionery not adhering to the fingers at 40° C., includes a soft portion in which the maximum particle size of solids as measured by a micrometer is 40 μm or less.

Owner:MORINAGA & COMPANY

Processing method of instant bamboo charcoal oyster

The invention provides a processing method of an instant bamboo charcoal oyster. The method takes dried oyster, flour, bamboo charcoal powder, sweet potato powder, white sugar, and table salt as main raw materials, and adopts a sugar solution as an auxiliary material. By means of the processes of sugar blending, powder wrapping, frying, deoiling and packaging, the dried oyster can be processed into instant bamboo charcoal oyster leisure food with the characteristics of dark black color, fresh and fragrant mouthfeel, crisp texture, and rich nutrition. The method provided in the invention is characterized in that the introduction of the bamboo charcoal powder into processing of leisure seafood endows the instant oyster with attractive dark black color and crisp texture, and covers the fishy smell of the oyster. Also, the bamboo charcoal has the effects of coordinating intestines and stomach and eliminating vivotoxin, so that the obtained product can be a healthy instant seafood product.

Owner:FUJIAN JIUAN AQUATIC PROD +1

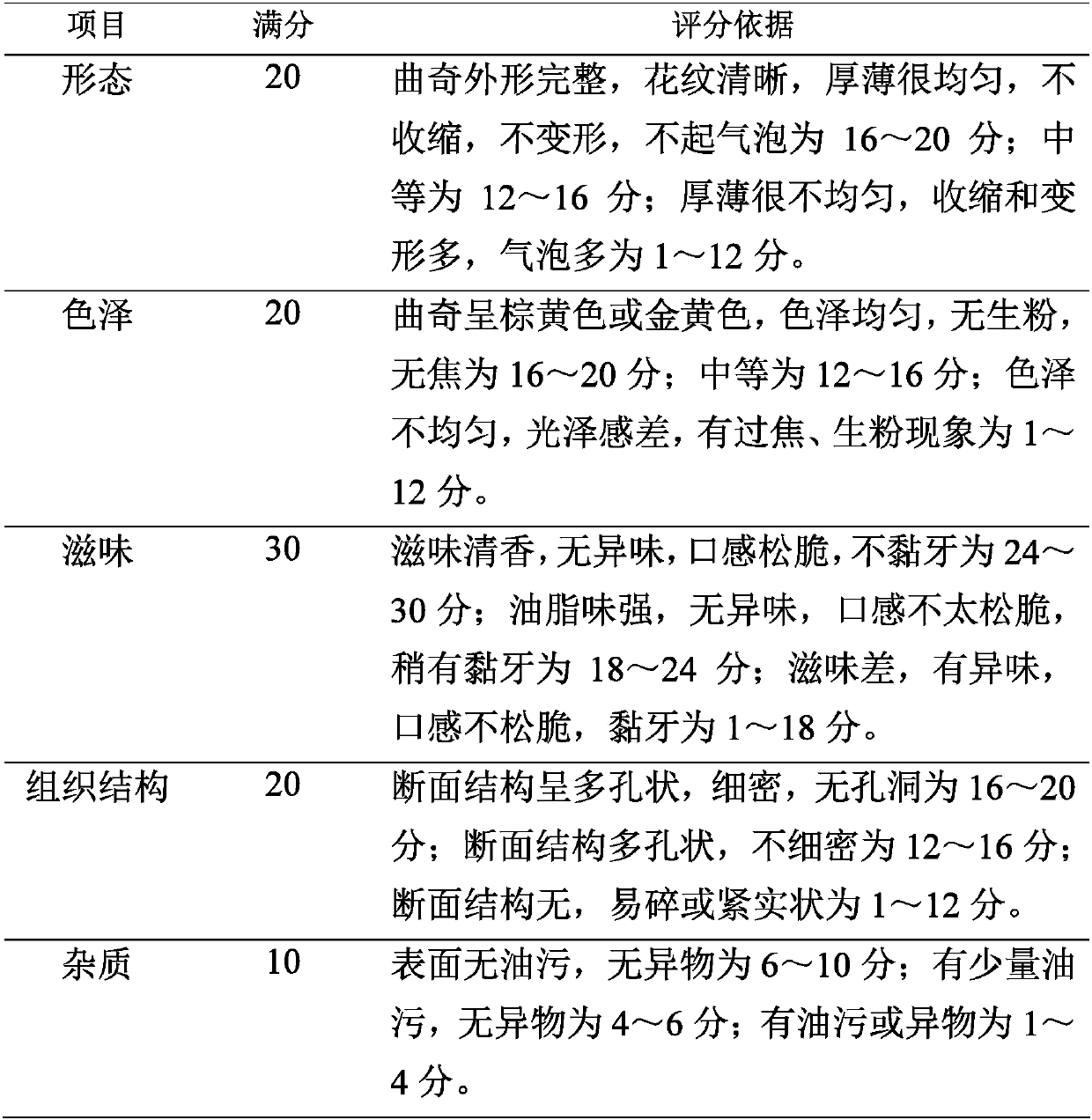

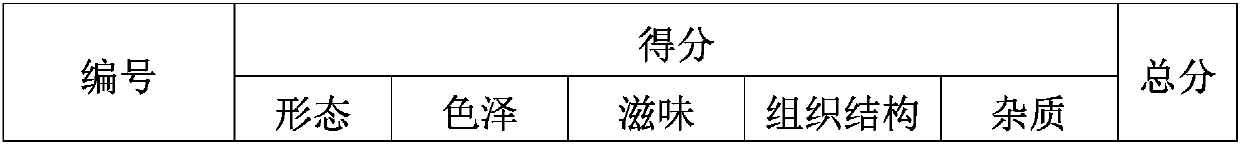

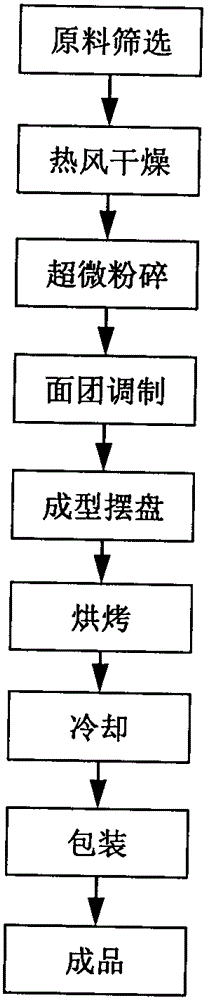

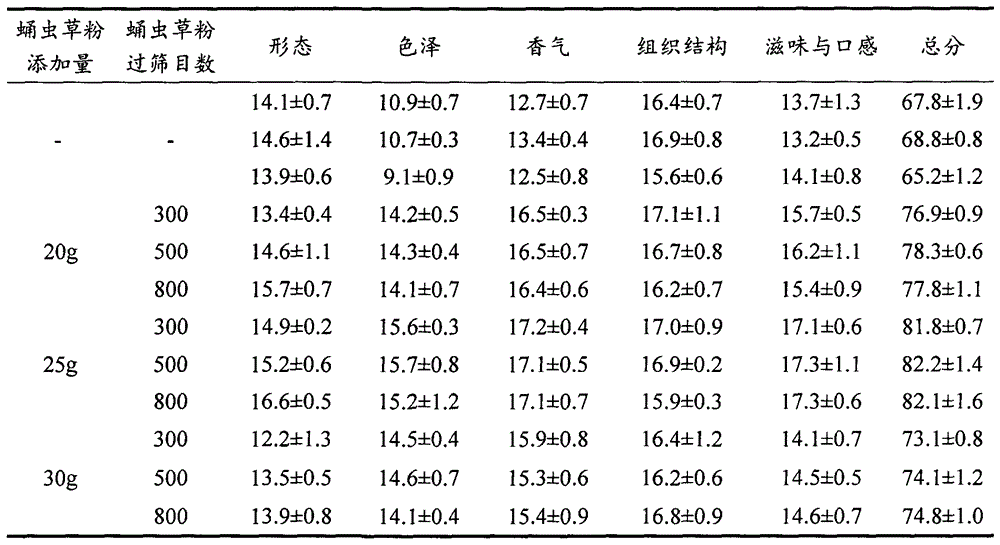

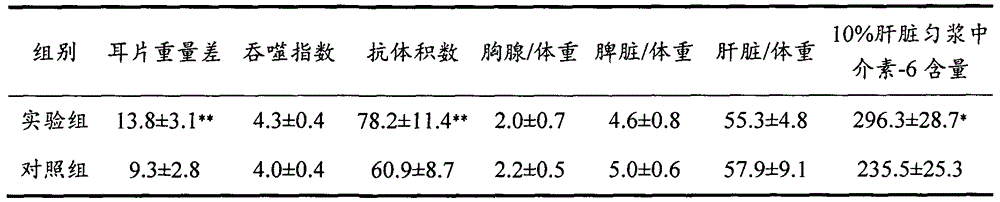

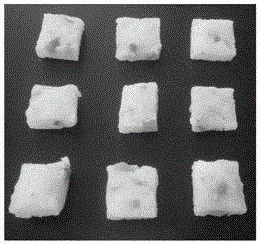

Cordyceps militaris cookies capable of improving body immune functions in auxiliary manner and preparation method thereof

The invention relates to cordyceps militaris cookies capable of improving body immune functions in an auxiliary manner and a preparation method thereof, belonging to the technical field of agricultural product deep processing. The cordyceps militaris cookies are produced by the following main processes: raw material screening, hot air drying, superfine grinding, dough preparing, forming and putting on a dish, baking, cooling, and the like. The cordyceps militaris cookies have the beneficial effects that white bean paste is used as the main material instead of weak flour used as the main material in cookies in traditional methods, and cordyceps militaris powder is added to the white bean paste to prepare the cookies, thus expanding application of bean raw materials to baked products and also increasing the comprehensive utilization ratio of the nutritional and health care ingredient cordyceps militaris; and the health care leisure food which is rich in nutrients and has special flavors of edible fungi is finally obtained by introducing the health care function of cordyceps militaris in improving body immune functions in an auxiliary manner to the products. The process is simple and is suitable for industrial production.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Granular powder

InactiveUS20130202772A1Light and soft textureImprove adhesionDough treatmentFood coatingFood materialWheat flour

Provided is a granular powder for a food product containing wheat flour, the granular powder: having good adhesion to food materials when used for coating them without causing scattering of powder, thereby attaining good handling properties; achieving both a light and soft texture inside and a crispy texture on the surface; and further, being capable of maintaining a favorable texture even some time after cooking. Also disclosed is a granular powder obtained by subjecting wheat flour and dextrin to hydrothermal treatment.

Owner:NISSHIN DCA FOODS INC

Production process of coconut paste coated walnut sandwiched jujube

The invention discloses coconut paste coated walnut sandwiched jujubes and a production process thereof. The production process includes following steps: selecting materials, washing, preliminarily drying, stoning, sterilizing, sandwiching walnuts in jujubes, sticking sugar, sticking coconut paste, air-drying for the second time, packaging, and warehousing. Crisp walnuts are added into stoned jujube pulp bodies, sweetness of the jujubes ingeniously covers astringency of the walnuts, crispness of the walnuts neutralizes glutinousness of the jujubes, and the outsides of the jujubes are stuck with the coconut paste fully, so that the sweetness of the jujubes, the crispness of the walnuts and fragrance of the coconut paste are integrated, so that the coconut paste coated walnut sandwiched jujubes are crisp in texture, strong in coconut fragrance and convenient to carry and use, and variety of walnut sandwiched jujubes is enriched.

Owner:SHANDONG BAIZAOGANGMU BIOTECH CO LTD

Production method of spicy and hot salangid peanuts

ActiveCN103829278AMaintain nutrientsGuaranteed crispnessFood preparationMonosodium glutamateZanthoxylum bungeanum

The invention provides a production method of spicy and hot salangid peanuts. The production method comprises the following steps: 1. salting and curing salangid, namely uniformly mixing a yeast extract, a mixed salting material and water, adding the salangid, salting at normal temperature for 1-1.5 hours, drying and curing at 60-65 DEG C for 1-1.5 hours, and drying and curing at 80-85 DEG C for 1-1.5 hours; 2. frying zanthoxylum bungeanum maxim and chili at low temperature; 3. shelling and curing peanuts, namely salting the shelled peanuts and frying; and 4. stirring, namely uniformly mixing the salted and cured salangid, the fried chili, the fried zanthoxylum bungeanum maxim, the fried peanuts, salt and monosodium glutamate in a stirring pot. The spicy and hot salangid peanuts produced by the method provided by the invention are rich in nutrition, crisp in texture, good in mouth feel and outstanding in spicy and delicious flavor, have good sensory effects of visual sensation and taste sensation, and are good in color, aroma and taste.

Owner:ANHUI TRUELOVE FOODS

Processing method for instant local flavor green bean sprout dish

The invention provides a processing method for an instant local flavor green bean sprout dish, which comprises the steps of preliminary raw material processing, marinade production, spice bag production, ingredient preparation, fermentation, sterilization, packaging and the like. The processing method mainly has the beneficial effects that the quality guarantee period of the local flavor green bean sprout product which is produced according to the method provided by the invention is longer than the quality guarantee period of green bean sprouts, the quality guarantee period can be obviously prolonged, the structure of the green bean sprouts is intact, the green bean sprout dish is fragrant and crisp, the color is fresh, the taste is pure and the edible value and the economic value are very great.

Owner:ZHEJIANG UNIV OF TECH

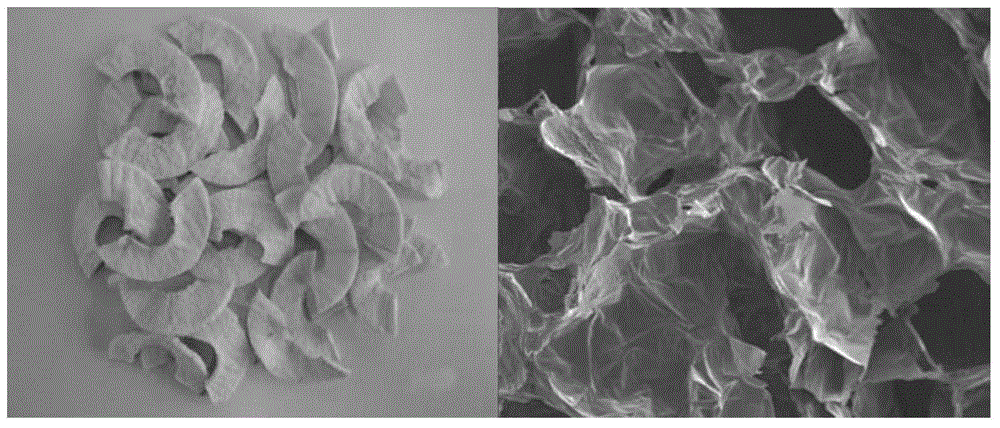

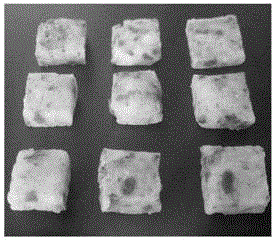

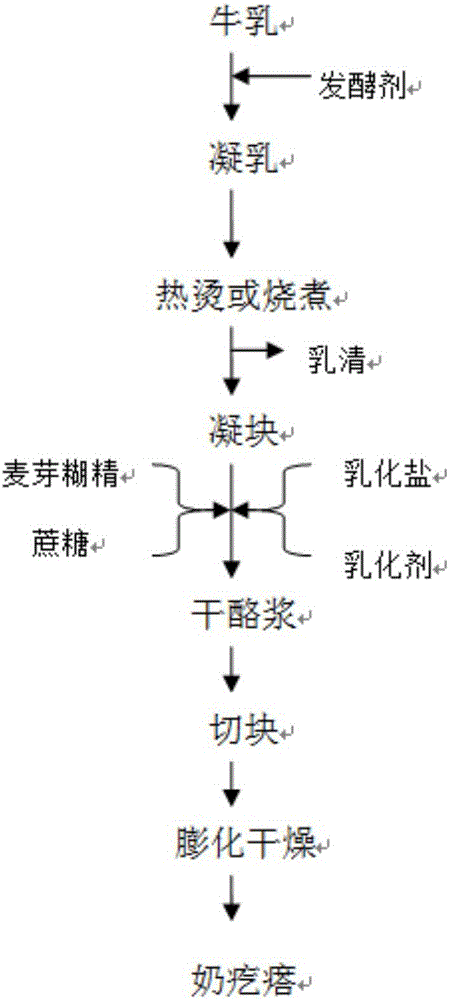

Loose milk lumps and preparation method thereof

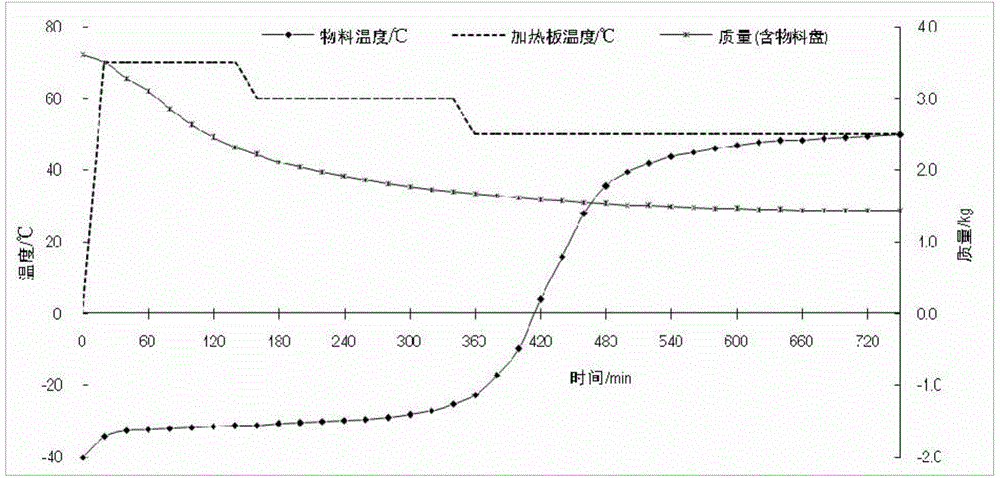

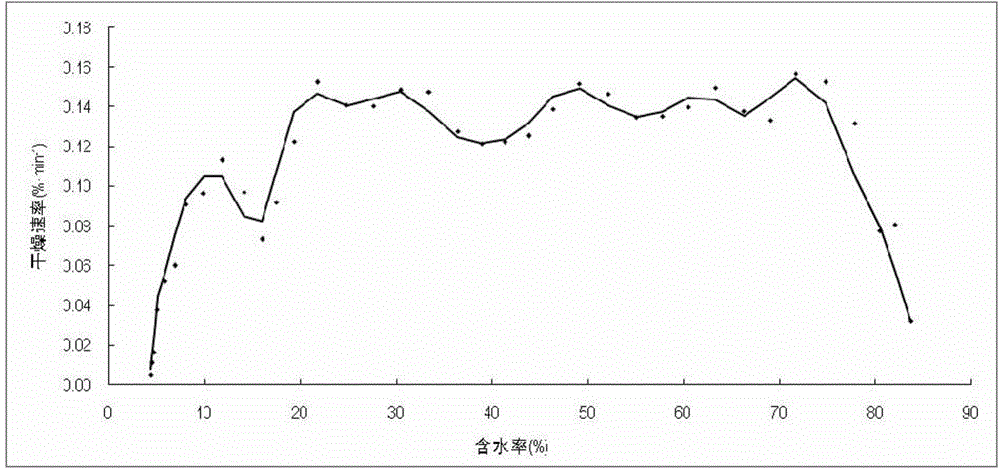

ActiveCN106417634ASolving emission difficultiesAvoid product defects with a sour tasteCheese manufactureBiotechnologyBrowning

The invention provides a loose milk lump preparation method thereof. The method includes steps: subjecting fermented yoghurt to hot boiling and whey draining to obtain cheese curds; adding ingredients into the cheese curds, and stirring for emulsification to obtain cheese slurry; subjecting the cheese slurry to extrusion forming, and drying to obtain finished products of loose milk lumps. By adoption of a variable-temperature pressure-difference drying method and a low-temperature variable-frequency drying method for preparation of the products of the loose milk lumps, on the one hand, quality of the products is improved, and crispiness in taste and high palatability are realized; on the other hand, product drying time is greatly shortened, and production efficiency is improved. The products are low in browning, and nutrition is greatly retained. The invention further provides the loose milk lumps. The loose milk lumps have advantages of great color, rich flavor, texture crispiness, high palatability and the like, thereby being easy for most customers to accept.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

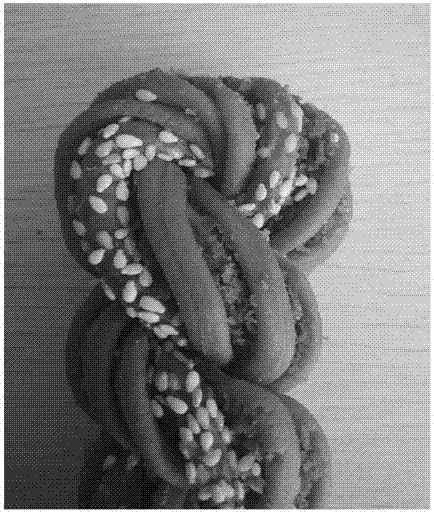

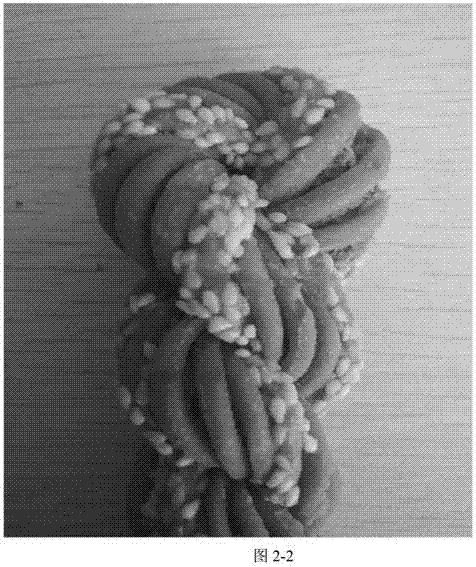

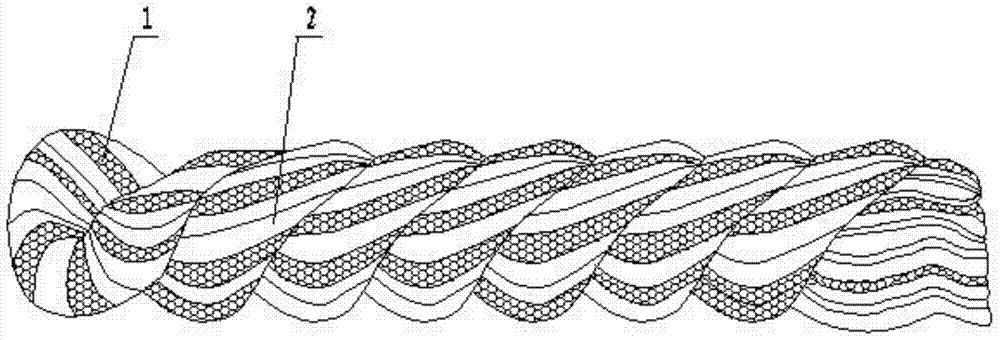

A kind of twisted twist stuffed with whole potato flour and preparation method thereof

ActiveCN104886209BSweet and Crisp PreservedIncrease varietyDough treatmentDeep-fried productsCannabisTriticum turgidum

The invention relates to potato flour-wrapped stuffed twist, which comprises twist noodle strips, sesame strips and stuffing, and the ratio of the mass of the twist noodle strips to the sesame sticks to the total mass of the stuffing is 1:0.25-1. The twist of the present invention replaces wheat flour with whole potato flour in proportion, and through the introduction of crushed corn and the optimization of the ratios between the formulas, the finished twist can form a better honeycomb network, the product tastes crisp, and the frying effect is good, reaching the traditional The standard of twist increases the nutritional value, and the ratio of amino acids is more reasonable. The twist not only retains the sweet and crispy characteristics of traditional twist, but also improves the crispness and nutritional value of twist, and increases the variety of twist. Filled the gap in the market.

Owner:天津桂发祥十八街麻花食品股份有限公司

Making method of nut crisp fritters and nut crisp fritters

ActiveCN108740246AThin and brittle molding stabilityReduce churnConfectionerySweetmeatsEngineeringSugar

The invention discloses a making method of nut crisp fritters and the nut crisp fritters made by the making method, and belongs to the field of food processing. In order to solve the problems that when people eat conventional nut kernels, the nut kernels are knocked and broken with large force so that teeth are damaged possibly, if the nut kernels are swallowed wholly, life risks are caused possibly, besides, seasoning powder is on the external surfaces of the nut kernels, and when people eat the nut kernels, the seasoning powder sticks to hands easily, the invention provides the making methodof nut crisp fritters. The making method comprises the following steps of firstly performing cooking to obtain a sugar solution, then adding nut pieces to the sugar solution, performing cold storage,performing cutting and performing baking. According to the making method disclosed by the invention, the nut kernels are innovatively changed into the nut pieces, and besides, the nut crisp frittersare obtained through subsequent steps of performing cold storage, performing cutting and performing baking; the nut crisp fritters are immediately broken after being bitten, are crisp in mouth feel, can be bitten to be broken without large force when being eaten; and besides, after cold storage and baking, the sugar solution closely coats the surfaces of the nut pieces, so that the nut crisp fritters do not stick to hands when being eaten.

Owner:CHACHA FOOD CO LTD

Caramel treats and preparation method thereof

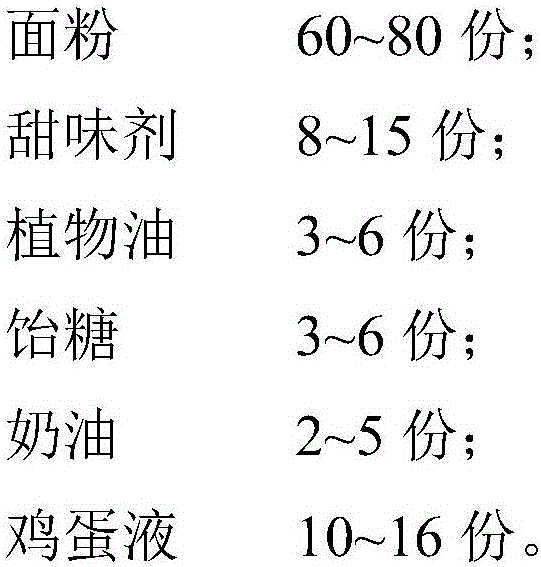

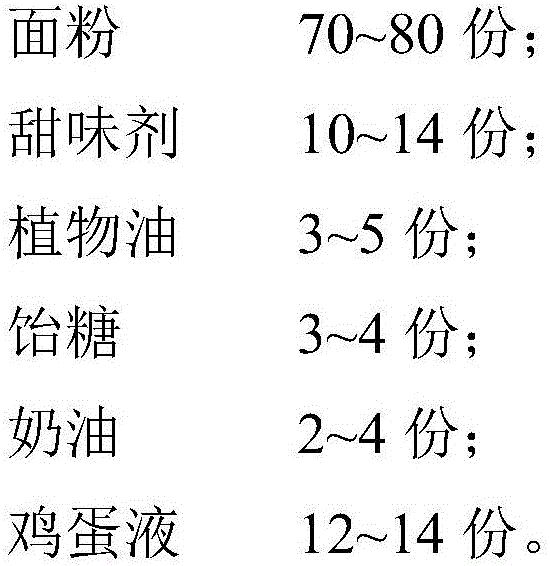

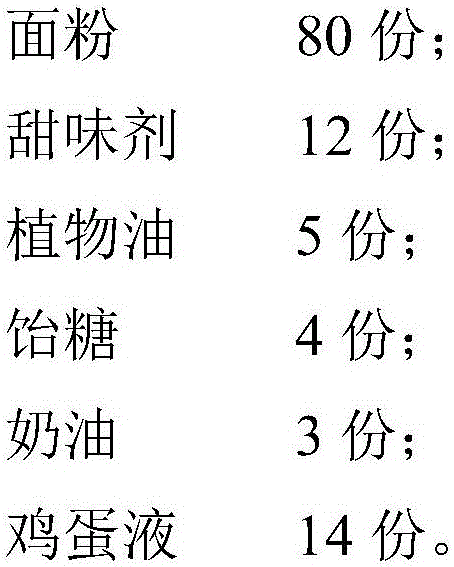

The invention discloses caramel treats and a preparation method thereof. The caramel treats comprise the following raw materials in parts by weight: 60-80 parts of flour, 8-15 parts of a sweetener, 3-6 parts of vegetable oil, 3-6 parts of maltose, 2-5 parts of cream and 10-16 parts of egg liquid. The preparation method of the caramel treats comprises the following steps: (1), mixing the raw materials according to the proportion, adding water and carrying out uniform stirring so as to prepare dough, leavening the dough at a temperature of 55-65 DEG C and a humidity of 75-85% for 3-5 hours, pressing the leavened dough into sheets, and then, cutting the sheets into grains; (2), frying the cut grains with oil of which the temperature is 150-185 DEG C for 3-6 minutes, so that semi-fished grains are prepared; (3), simmering the maltose at 140-160 DEG C for 3-5 hours; and (4), pouring the oil-fried grains into the simmered maltose, and then, carrying out stirring for 15-20 seconds, so that the caramel treats are prepared. The caramel treats disclosed by the invention are crispy in taste. Existing caramel treats are loose and soft in taste, tedious in flavor, and liable to make the eater feel greasy; however, the caramel treats disclosed by the invention are unique in taste, crispy in texture, and relatively low in fat and sugar contents.

Owner:杨坤

Garlic drying processing method

InactiveCN109527072AShorten drying timeIncrease productivityFruits/vegetable preservation by dehydrationMildewDrying time

The invention discloses a garlic drying processing method, which belongs to the technical field of agricultural product processing. The processing method comprises the following steps: (1) selecting fresh, non-corrosive garlic and storing the garlic at low temperature environment; (2) selecting garlic without germinating or mildew, and peeling and slicing the garlic; and (3) putting the cut garlicinto a hot air dryer based on integrated control of temperature and humidity, and using a temperature and humidity stage control process for drying. The garlic has a short storage period and is proneto mildew, and nutrients such as allicin are easily lost during processing. The method aims to improve processing technology, shorten drying time, increase allicin retention rate, and ensure the drying quality. The method is simple, clean, and health.

Owner:CHINA AGRI UNIV +1

Tobacco explant browning prevention method based on activated carbon

ActiveCN107853181AReduce browningImprove differentiation statusPlant tissue cultureHorticulture methodsActivated carbonNicotiana tabacum

The invention relates to a tobacco explant browning prevention method based on activated carbon. The method comprises the following steps of seed sterilization, seed culture, tobacco explant culture,browning prevention culture, rooting culture and hardening-seedling and transplantation. According to the tobacco explant browning prevention method based on activated carbon, the tobacco explant browning phenomenon can be effectively reduced, and the differentiation state of the whole explant can be improved. The root systems grow fast, the texture is pliable, the tobacco is not easily broken, and the survival rate of rooting seedling transplantation is high. The tobacco explant browning prevention method based on activated carbon is convenient to use, low in cost and good in effect.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com