Chocolate coating for crackling milk slice, crackling milk slice and preparation method of chocolate coating

A technology of chocolate coating and milk flakes, which is applied in the direction of milk preparations, applications, dairy products, etc., can solve the problems of hidden quality problems, inability to guarantee quality, and unbrittle taste, so as to ensure product quality and taste, crisp texture, taste unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Preparation of Crispy Milk Chips with Chocolate Coating

[0050] Crispy milk slices are coated with chocolate, raw materials by mass ratio, including: 30% sucrose, 10% palm kernel oil, 8% whole milk powder, 1% inulin, 1% milk fat, 2% cocoa powder, cocoa mass 8%, lecithin 0.2%, vanillin 0.02%.

[0051] The method for preparing the above-mentioned crispy milk slices with chocolate coating comprises the following steps:

[0052] 1) Melt low-trans fatty acid ester cross-transformed palm kernel oil, and control the melting temperature at about 42°C, then add cocoa mass, whole milk powder, sugar powder, inulin, and milk fat, and stir well. The temperature of the material is controlled within 60°C.

[0053] 2) The chocolate material also needs to go through the process of fine grinding, refining, heat preservation and so on. Before the refining is finished, add vanillin and lecithin, and then it is best to homogenize once with a colloid mill, and keep it in a heat...

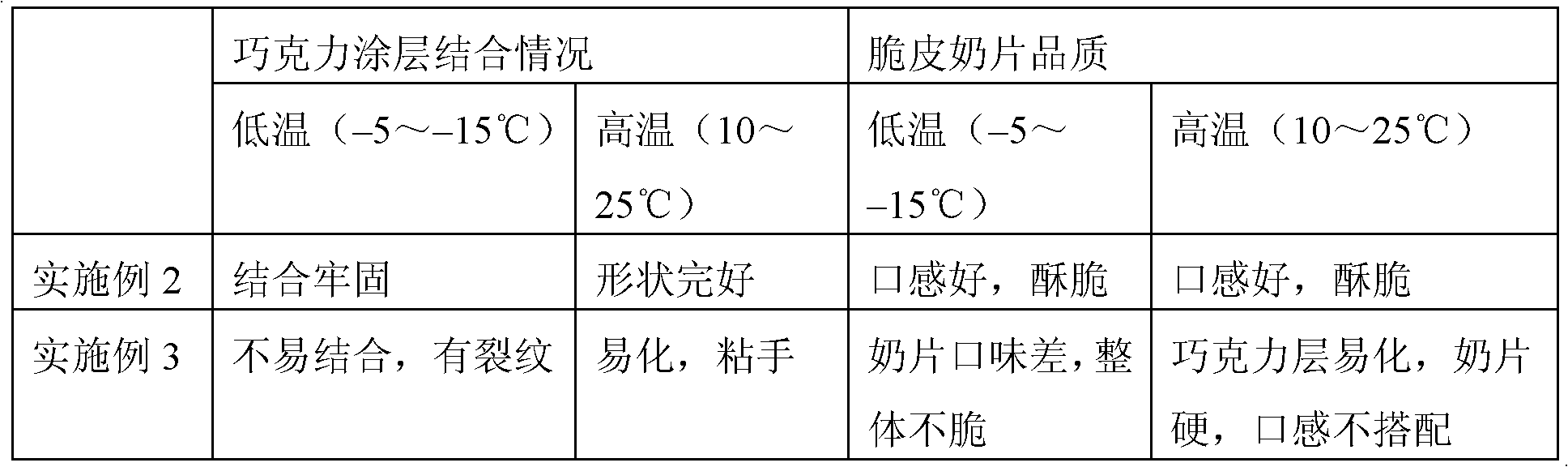

Embodiment 2

[0055] Embodiment 2 prepares crispy milk slices (100 parts by weight)

[0056] Crispy milk flakes are coated with chocolate, raw materials by mass ratio, including: 50% sucrose, 25% palm kernel oil, 20% whole milk powder, 5% inulin, 5% milk fat, 8% cocoa powder, cocoa mass 10%, lecithin 0.6%, vanillin 0.09%.

[0057] The preparation method is the same as in Example 2.

Embodiment 3

[0058] Embodiment 3 prepares crispy milk slice (100 parts by weight)

[0059] Milk tablet formula: based on 100 parts by weight of milk tablets, raw materials include: raw milk is 200-540 parts by weight (dry matter content is 11.8%), glucose syrup is 8-40 parts by weight (dry matter content is usually 75%), protein Powder or whey powder is 2-25 parts by weight, vegetable oil is 3-12 parts by weight, white sugar is 2-10 parts by weight, oligosaccharide is 1-5 parts by weight, sodium caseinate is 0.1-3 parts by weight, Silicon dioxide is 0.1-0.3 parts by weight, and essence is 0.5-2.0 parts by weight.

[0060] The method for preparing above-mentioned crispy milk piece comprises the following steps:

[0061] To prepare milk flakes:

[0062] 1. Ingredients

[0063] (1) carburetion

[0064] Put the vegetable oil into the oil pot and start stirring. When the oil temperature reaches 60°C, continue to heat up to about 68-70°C until it is completely dissolved.

[0065] (2) Protein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com