Patents

Literature

259results about How to "Creamy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Papaya ice cream and method for preparing same

The invention discloses papaya ice cream which is composed of, by weight, 30% to 35% of plant lipid cream, 10% to 15% of milk powder, 8% to 12% of white granulated sugar, 0.2% to 0.3% of sucrose fatty acid ester, 0.1% to 0.2% of xanthan gum, 0.1% to 0.5% of papaya essences, and the balance water. The method for preparing the papaya ice cream comprises sequential steps of mixing the white granulated sugar with the sucrose fatty acid ester and the xanthan gum evenly, slowly adding the mixture in the water at a temperature ranging from 30 DEG C to 35 DEG C in the condition of stirring, adding the milk powder after the mixture is dissolved fully, dissolving the milk powder and stirring the mixture evenly, heating the mixture to a temperature of 80 DEG C+ / - 2 DEG C, performing insulation for 15 minutes, cooling the mixture to a room temperature, adding the papaya essences and stirring the mixture evenly; and fermenting the plant lipid cream for 3.0 to 3.5 times at a temperature ranging from 10 DEG C to 15 DEG C, adding the mixture in the fermented plant lipid cream in a slow stirring condition, stirring the mixture evenly, and freezing the mixture at a temperature ranging from -18 DEG C to -22 DEG C for 12 hours to obtain the papaya ice cream. The papaya ice cream and method for preparing the same are particularly suitable for baking shops of cake shops, bakeries and the like, are used for developing novel products, and improves economic benefits.

Owner:HARBIN PATERNA BIOTECH DEV

Watermelon ice cream and manufacturing method thereof

The invention relates to watermelon ice cream, which comprises the following components: 30-35% of vegetable cream, 10-15% of milk powder, 8-12% of white sugar, 0.2-0.3% of sucrose fatty acid ester, 0.1-0.2% of xanthan gum, 0.1-0.15% of watermelon essence and the balance of water. A manufacturing method of the watermelon ice cream comprises the following steps of: uniformly mixing the white sugar, the sucrose fatty acid ester and the xanthan gum; during mixing, slowly adding the mixture into the water at the temperature of 30-35 DEG C, and adding the milk powder after the mixture is dissolved; dissolving and uniformly mixing, heating to the temperature of 80+ / -2 DEG C, keeping the temperature for 15min, cooling to the room temperature, then adding the watermelon essence, and uniformly mixing; and whipping the vegetable cream until the volume is increased by 3.0-3.5 times at the temperature of 10-15 DEG C, during slowly mixing, slowly adding the mixture into the whipped vegetable cream, uniformly mixing, standing at the temperature of minus 18-minus 22 DEG C, and refrigerating for over 12h, so as to obtain the watermelon ice cream. The invention is especially suitable for cake shops, bakeries and other baking shops.

Owner:HARBIN PATERNA BIOTECH DEV

Pearl facial-nourishing bean product and its manufacturing method

InactiveCN101077152APromote growthPromote secretionDrug compositionsFood preparationBiotechnologyLilium

The present invention is one kind of face nursing pearl bean product and its making process, and aims at increasing the nutritious components and health functions of bean product. The face nursing pearl bean product is produced with soybean 100 weight portions, pearl powder 0.6 weight portions, tuckahoe 5-10 weight portions, lily 5-15 weight portions, almond 5-10 weight portions, coix seed 10-20 weight portions, and Chinese yam 5-10 weight portions. It may be made into bean milk, bean curd jelly, dried bean curd, bean curd and other bean products.

Owner:浙江金事达食品股份有限公司

Strawberry milk tea powder

The invention discloses strawberry milk tea powder which consists of the following components in percentage by weight: 45-55% of creamer, 35-45% of white granulated sugar, 5-10% of strawberry powder, 2-5% of black tea powder, 0.2-0.5% of sodium carboxymethylcellulose and 0.1-0.3% of sucrose fatty acid ester, wherein the creamer is acid-resisting creamer, and the sodium carboxymethylcellulose is acid-resisting sodium carboxymethylcellulose. The strawberry milk tea powder is prepared by matching, mixing, sterilizing and packaging the components. The strawberry milk tea powder disclosed by the invention has the advantages that (1) when dissolved in water, the strawberry milk tea powder has good dispersibility and stability and is in a uniform emulsion state, and phenomena of demulsification, layering, precipitation and the like are prevented no matter being dissolved in cold water or hot water; (2) the milk tea made of the strawberry milk tea powder is smooth and fine in taste and is thick in milk fragrance, and has the fragrance of both tea and strawberry; (3) the strawberry milk tea powder has the functions of moistening the lung to generate body fluid, strengthening the spleen and stomach, and the like because of the strawberry powder.

Owner:HARBIN AIKEER FOOD TECH

Calcium replenishing flour and preparation method thereof

The invention relates to calcium replenishing flour and a preparation method thereof. The calcium replenishing flour is characterized by being prepared from the following raw materials by weight: 500-550 parts of wheat, 10-12 parts of wheat germs, 8-9 parts of fishbones, 33-35 parts of milk, 30-32 parts of polished glutinous rice, 1-2 parts of grape seed oil, 10-12 parts of green plums, 2-3 parts of aloes, 6-7 parts of white funguses, 15-17 parts of cucumber seed powder, 9-10 parts of lotus root starches, 3-4 parts of dried marine algae powder, 7-8 parts of sweet potato starches, 2-3 parts of lophatherum herbs, 3-4 parts of beautiful millettia roots, 1-2 parts of wrinkled gianthyssop herb leaves, 4-5 parts of roughhaired holly roots, 2-3 parts of sinochasea trigyna, 1-2 parts of ulmus parvifolia stems, and 10-11 parts of nutrient additives. The mouth feel of the flour disclosed by the invention is fine and smooth, and the flour has full-bodied milk fragrance and unique flavor. At the same time, the formula of the flour disclosed by the invention is reasonable and scientific. The raw materials, such as the fishbones and the cucumber seed powder, which are added into the flour, are rich in calcium, so that the nutrition of the flour is enriched. In addition, various Chinese herbal medicine components are also added into the flour, so that the flour has the efficacy of health care, and if a person often eats the flour, the immunity of a human body can be enhanced.

Owner:凤阳县小岗村粮油食品发展有限公司

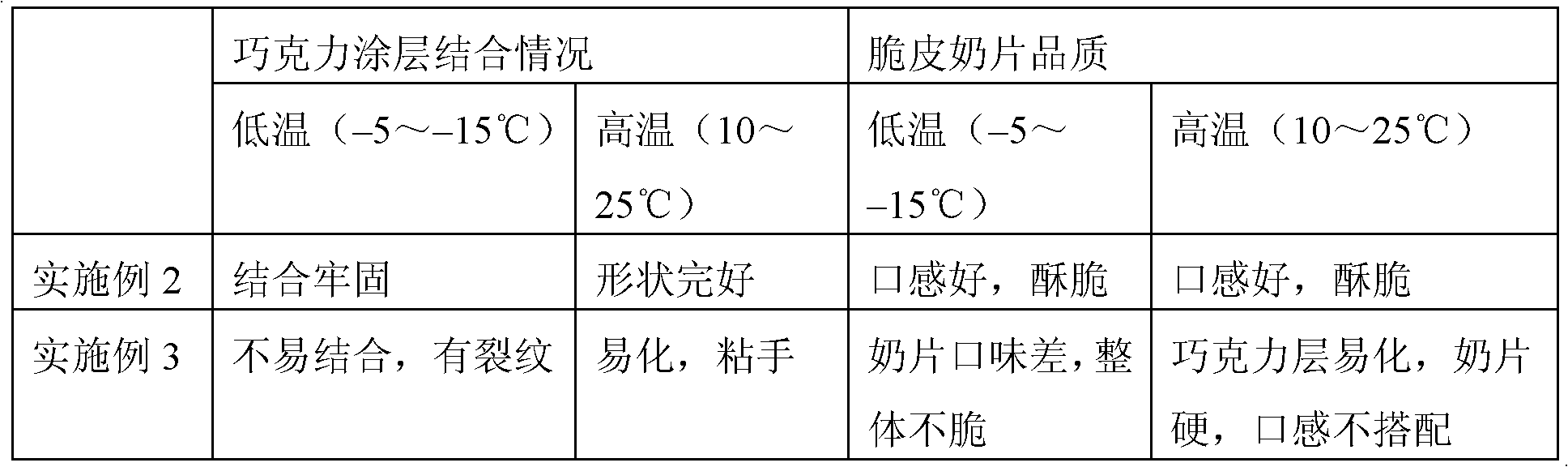

Chocolate coating for crackling milk slice, crackling milk slice and preparation method of chocolate coating

The invention relates to the field of dairy processing, in particular to a chocolate coating for a crackling milk slice, the crackling milk slice and a preparation method of the chocolate coating. The chocolate coating for the crackling milk slice comprises, by weight, 30%-50% of cane sugar, 10%-25% of palm kernel oil, 8%-20% of whole milk powder, 1-15% of inulin, 1%-5% of milk fat, 2%-8% of cocoa powder, 8%-10% of cocoa mass, 0.2-0.6% of lecithin and 0.02%-0.09% of vanillin. The crackling milk slice is crisp in texture, rich in milk fragrance, convenient to carry and eat and unique in taste, enhances tastiness of the milk, and meets the requirements of consumers having different tastes. Simultaneously, the chocolate coating for the crackling milk slice solves the problems that an existing milk slice chocolate coating is not adhered firmly, drops easily and melts easily at high temperature, and guarantees product quality and tastes.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

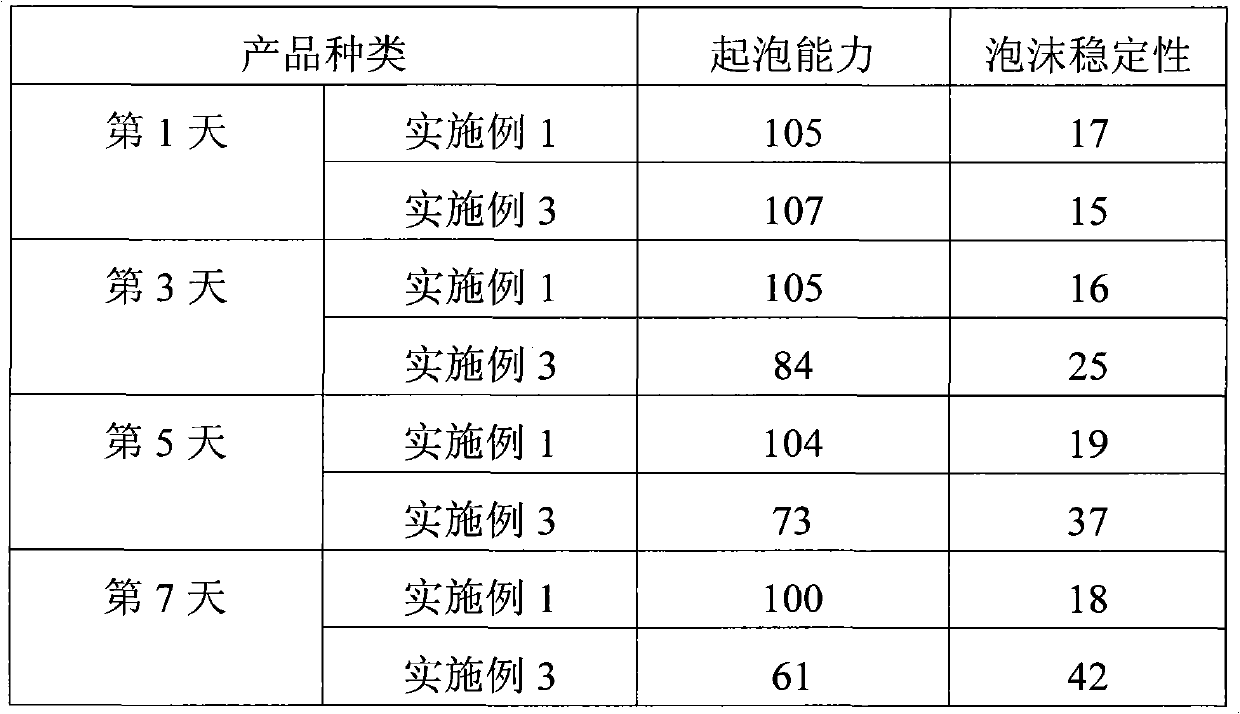

Foaming milk with excellent foaming effect and preparation method thereof

The invention discloses a foaming milk with excellent foaming effects and preparation method thereof. The foaming milk comprises, by weight, the following components: 99.0-99.7% of milk, 0.2-0.6% of milk protein, 0.1-0.4% of microcrystalline cellulose. Compared with common foaming milk on the market, the foaming milk of the present invention has the advantages of more excellent blistering effect,fine milk foams, good stability, strong milk flavor and smooth mouth feel; and is suitable for blistering in cafes, especially for making the steam foaming milk in cappuccino coffee, coffee Latte, and French milk coffee.

Owner:BRIGHT DAIRY & FOOD CO LTD

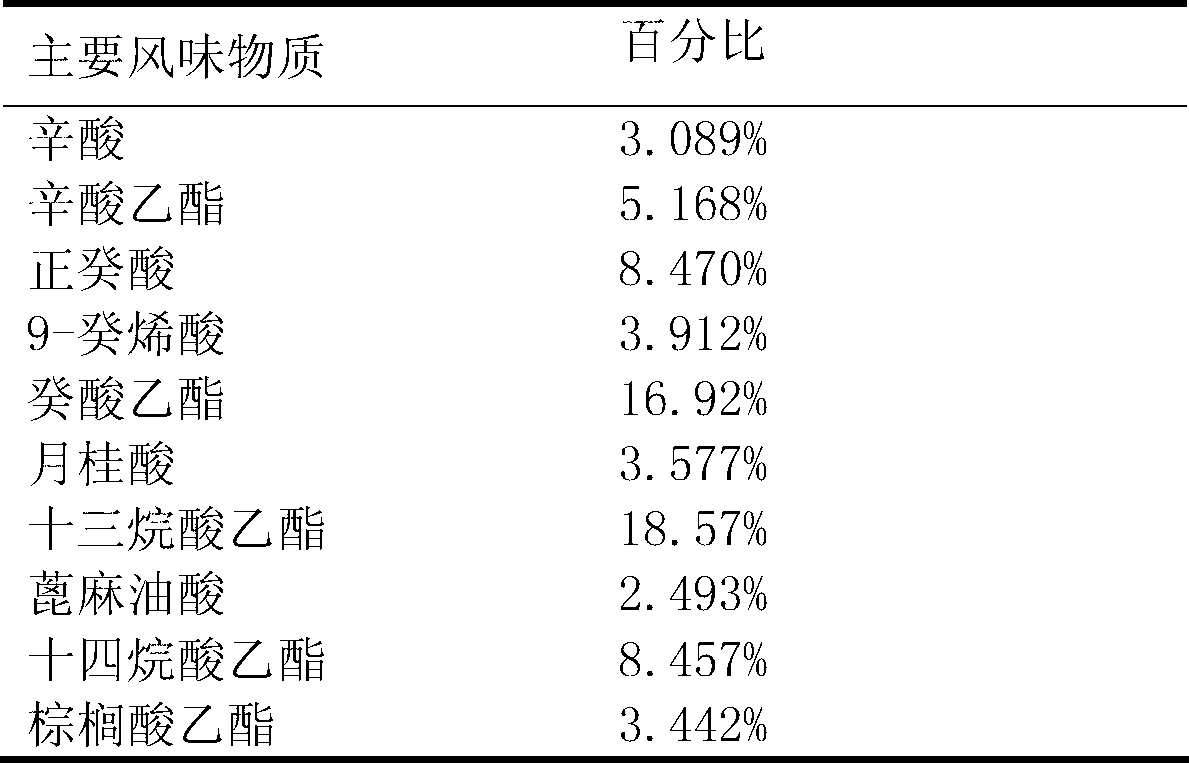

Cheese flavor enhancer as well as preparation method and application thereof

The invention relates to a cheese flavor enhancer as well as a preparation method and application thereof, belonging to the field of food additives. For overcoming the defects in the prior art, the flavor enhancer with natural cheese flavor components is prepared by an enzymolysis approach. The preparation method comprises the following steps of: firstly, adding anhydrous milk fat to fresh animal milk or reconstituted milk prepared from whole milk powder, which is taken as a raw material, and homogenizing the milk fat and the milk to homogenate by a colloid mill for future use; secondly, successively adding compounded protease and lipase to the freshly prepared homogenate to form enzymatic hydrolysate; thirdly, quickly adding yeast extracts to the enzymatic slurry, quickly heating up the slurry to 85 DEG C to 95 DEG C, keeping the slurry at the temperature for 5-15 minutes, and then carrying out aroma enhancement and enzyme deactivation on the enzymatic hydrolysate; fourthly, adding embedding media to the enzymatic slurry to form homogenate by a high-pressure homogenizer; and finally, spraying and drying the homogenate. The cheese flavor enhancer provided by the invention has the advantages of low production cost, short production period, stable quality of finished products, and thick and delicious flavor of cheese.

Owner:天津北洋百川生物技术有限公司

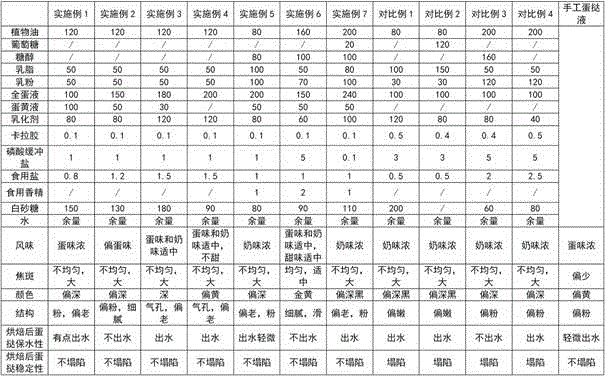

Conditioning cream for egg tart pudding and application of conditioning cream

The invention discloses conditioning cream for egg tart pudding and application of the conditioning cream.The conditioning cream is prepared from, by weight, 80-200 parts of vegetable oil, 0-20 parts of glucose, 1-200 parts of white granulated sugar, 0-200 parts of sugar alcohol, 50-100 parts of butterfat, 50-100 parts of milk powder, 100-250 parts of liquid whole eggs, 0-100 parts of liquid egg yolks, 60-120 parts of emulsifier, 0.1-0.5 part of carrageenan, 0.1-5 parts of phosphate buffer salt, 0.5-2 parts of edible salt, 0-2 parts of flavoring essence and the balance water, and the raw materials are added to 1,000 parts.The conditioning cream can replace traditional manual liquid egg tars and pudding liquid, time and labor are saved, the quality is stable, frost resistance and high temperature resistance are achieved, user using or DIY is convenient, the conditioning cream can also be added to desserts to enhance the flavor, and the baking quality is improved; the conditioning cream is moderate in milk flavor, the egg flavor is rich, high temperature resistant baking is achieved, the unique flavor of animal fat is achieved, and use is convenient; meanwhile, the texture state of a product is improved, the stability is good, baking resistance and collapsing are achieved, and the Portuguese-style egg tart or Hong Kong-style egg tart state can be achieved through baking according to needs.

Owner:ZENGCHENG LEGO FOODS CO LTD

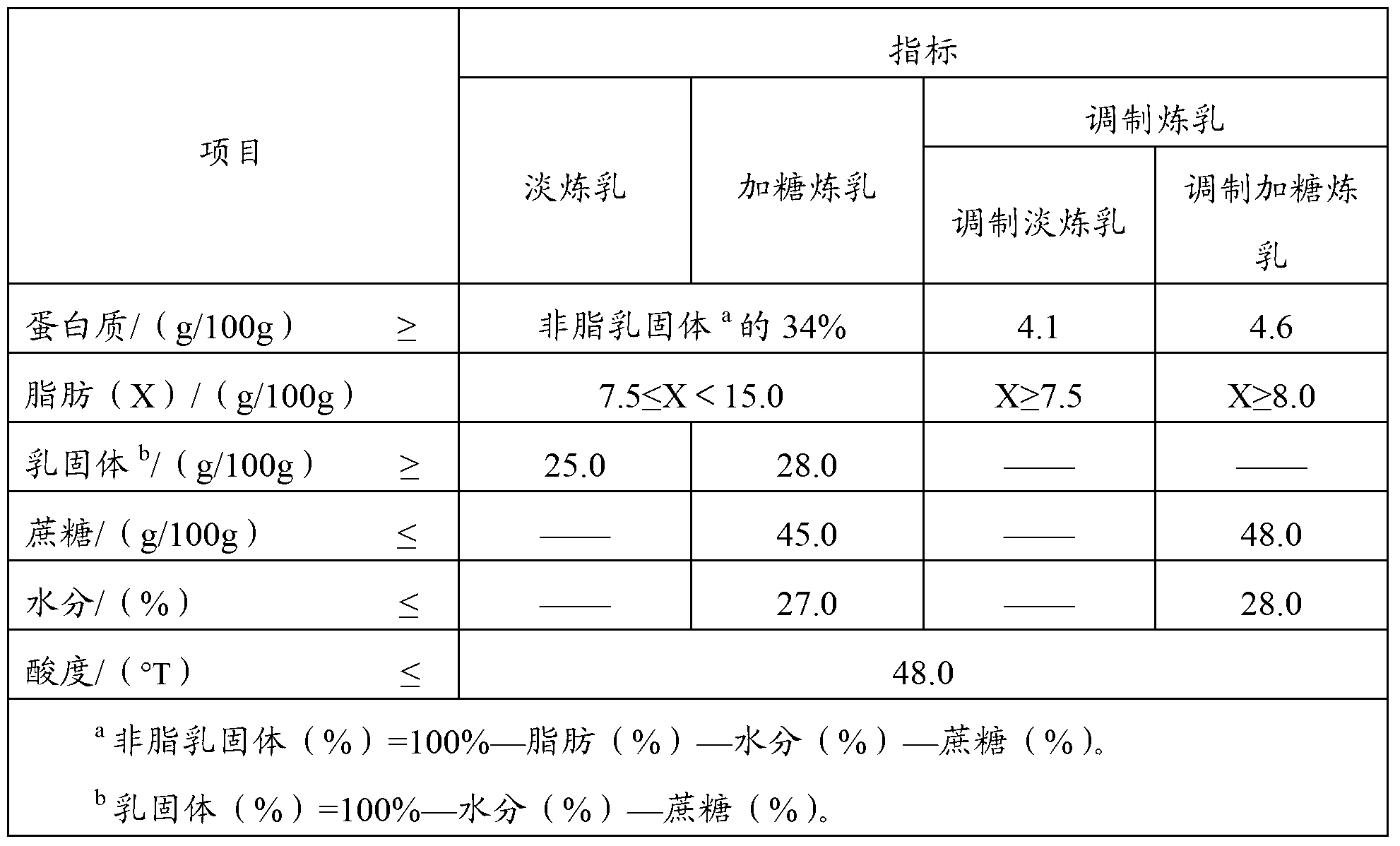

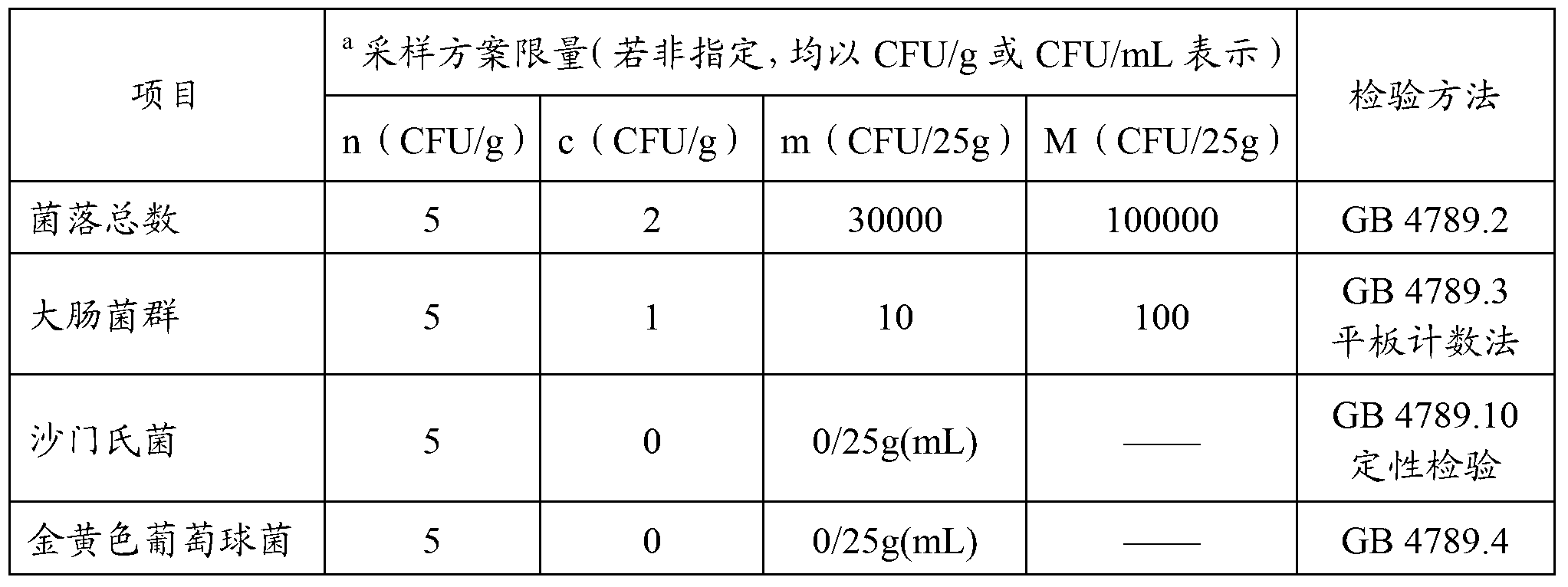

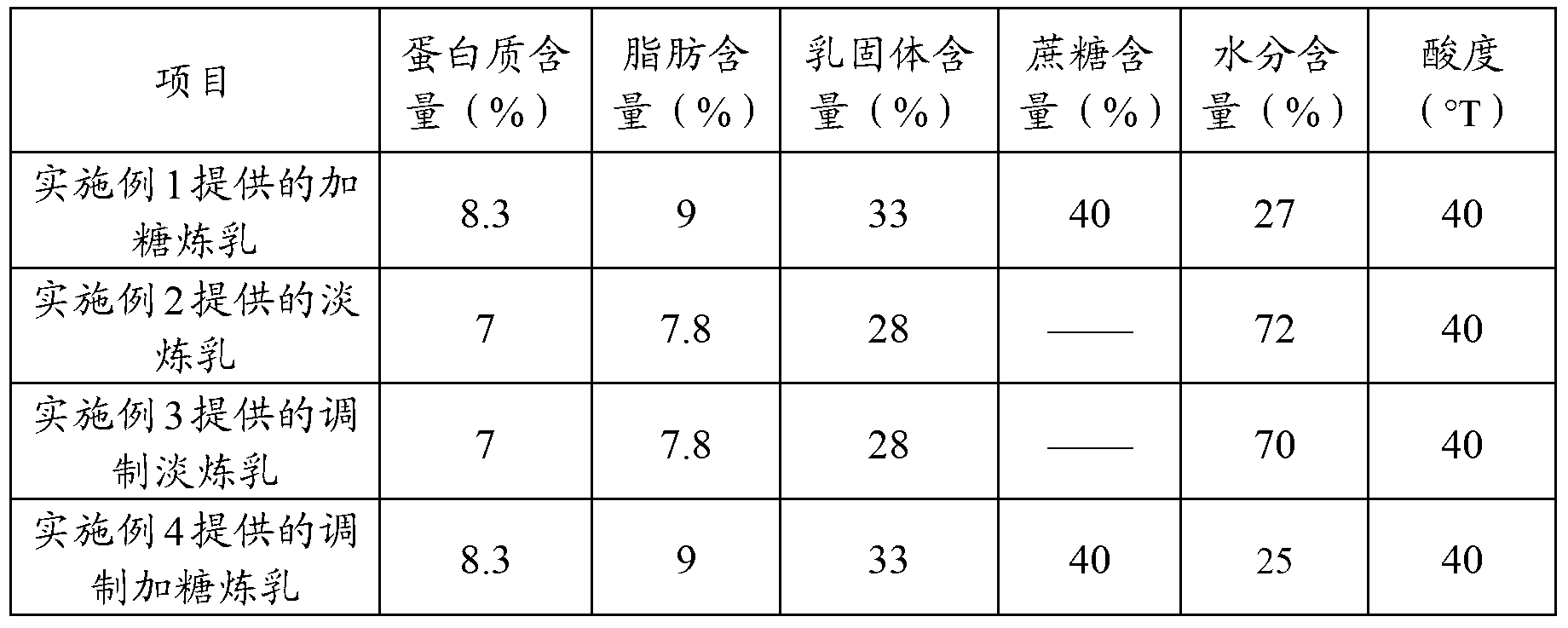

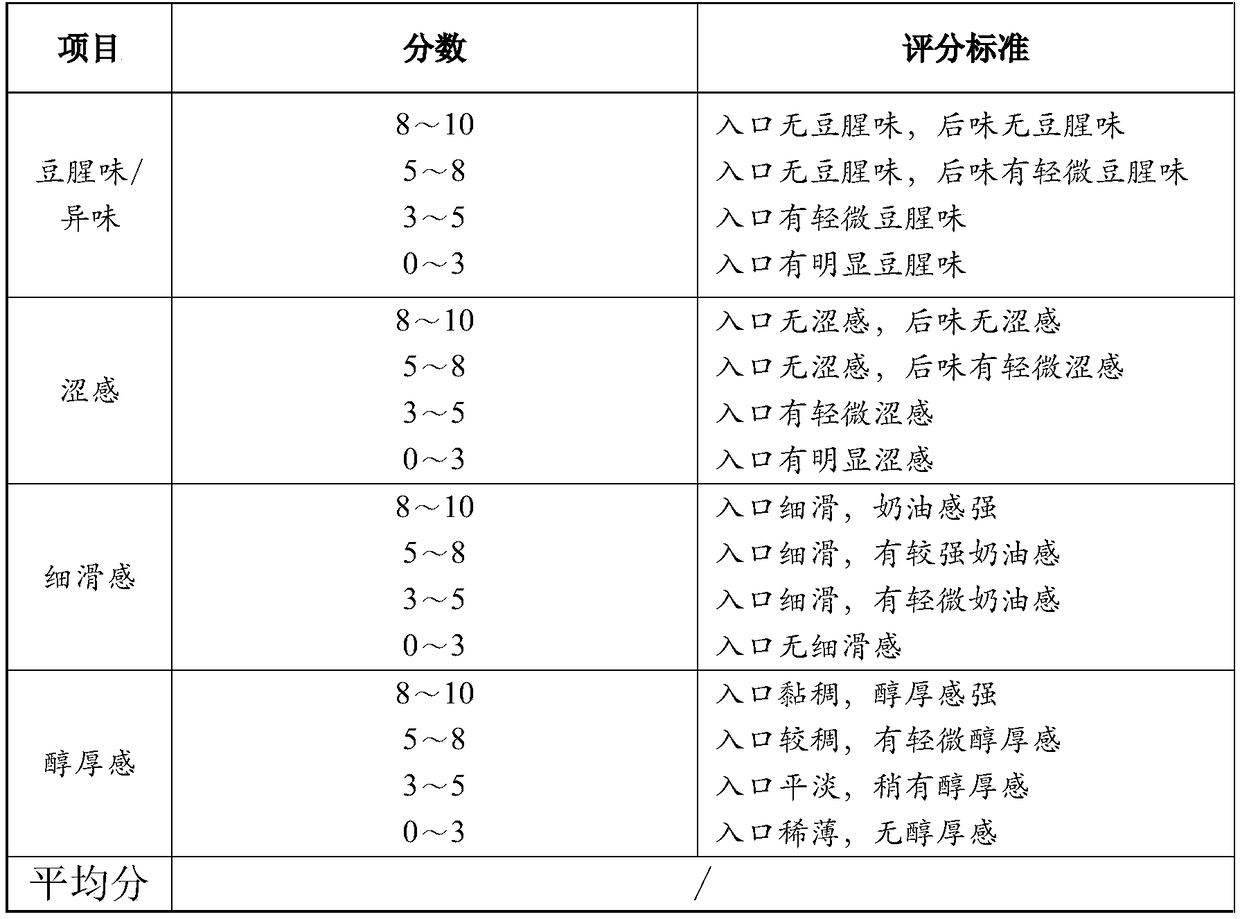

Condensed milk preparation method

The invention relates to the field of dairy products, and in particular relates to a condensed milk preparation method. The method comprises the following steps of: mixing condensed milk raw materials with water under the vacuum condition of -0.01 to -0.6bar so as to obtain a condensed milk emulsion; taking the condensed milk emulsion to sterilize at 110-120 DEG C for 300s-800s, and post-processing so as to obtain a mixture or the dairy product which is prepared by the condensed milk raw materials of the dairy product or food acceptable auxiliary materials. By utilizing the condensed milk preparation method provided by the invention, operation steps are simplified, the production time is shortened, and the method is suitable for industrial production; and various physical and chemical indexes and microbiological indicators of the condensed milk which is prepared by utilizing the preparation method provided by the invention meet national standards, and the condensed milk has strong milk taste and a good flavor.

Owner:淮安旺旺食品有限公司

Protein coconut milk yogurt and preparation method thereof

InactiveCN109452367AIncrease nutritionCreamyMilk preparationMilk substitutesVegetable oilManufacturing technology

The present invention discloses a non-additive plain yoghurt and a preparation method thereof. The yoghurt is composed of the following components in mass percentages: 2-4% of soybean proteins, 5-20%of coconut milk, 0.5-2.5% of vegetable oil, 5-10% of sugar, 0.01-0.1% of bacterium strain and the balance water. The manufacture method comprises the following steps of protein emulsified slurry preparing; double slurry mixing; preheating and homogenizing; sterilizing; inoculating; mixed fermenting; and post-aging. The prepared non-additive plain yoghurt is prepared from plant source raw materials. The mixed fermentation manufacture technology is used, the coconut milk is subjected to secondary fermenting, the fermented coconut milk retains natural coconut scent to mask a produced beany smellby the fermentation of the soybean proteins, unique flavor and nutrients of coconuts are retained, at the same time, the preparation method compensates for mouthfeel thinness caused by the unique fermentation of the soybean proteins and low cream feeling, and the finished product is delicate and smooth in mouthfeel, and mellow but not greasy in the coconut scent.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

Red date ice cream and production method thereof

The invention relates to red date ice cream which is composed of, by weight, 30%-35% of non-diary cream, 10%-12% of milk powders, 8%-10% of white granulated sugar, 5%-7% of red date powders, 0.2%-0.3% of sucrose fatty acid ester, 0.1%-0.2% of xanthan gum, 0.1%-0.15% of red date essence and the balance water. A production method of the red date ice cream includes the following sequential steps of evenly mixing the white granulated sugar, the sucrose fatty acid ester and the xanthan gum, slowly adding the mixture into water with the temperature of 30 DEG C-35 DEG C under the stirring condition, completely dissolving the mixture, then adding the milk powders and the red date powders for dissolving, evenly stirring the mixture, heating the mixture to 80 DEG C+ / -2 DEG C, keeping the mixture warm for 15 minutes, cooling the mixture to the room temperature, adding the red date essence, and evenly mixing the mixture; and whipping the non-diary cream at the temperatures of 10 DEG C-15 DEG C to be 3.0-3.5 times of quantity of the non-diary cream, then slowly adding the mixture to the well whipped non-diary cream under the condition of low-speed stirring, evenly mixing the mixture, and freezing the mixture for over 12 hours at the temperature between -18 DEG C and -22 DEG C to obtain the red date ice cream. The production method of the red date ice cream is particularly applicable to baking shops of cake shops and bakeries for developing new products so that economic benefits are improved.

Owner:HARBIN PATERNA BIOTECH DEV

Strawberry pudding powder

InactiveCN103652652AAttractive appearanceSmooth tasteFood ingredient as flavour affecting agentFood ingredient as gelling agentSucroseSaccharum

The invention relates to a strawberry pudding powder which is prepared from the following components in percentage by weight: 40-50% of white granulated sugar, 25-35% of milk powder, 10-15% of egg white powder, 8-12% of strawberry powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin, 0.6-0.8% of sucrose ester and 0.03-0.05% of monascus red. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The strawberry pudding prepared from the strawberry pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, fresh strawberry flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

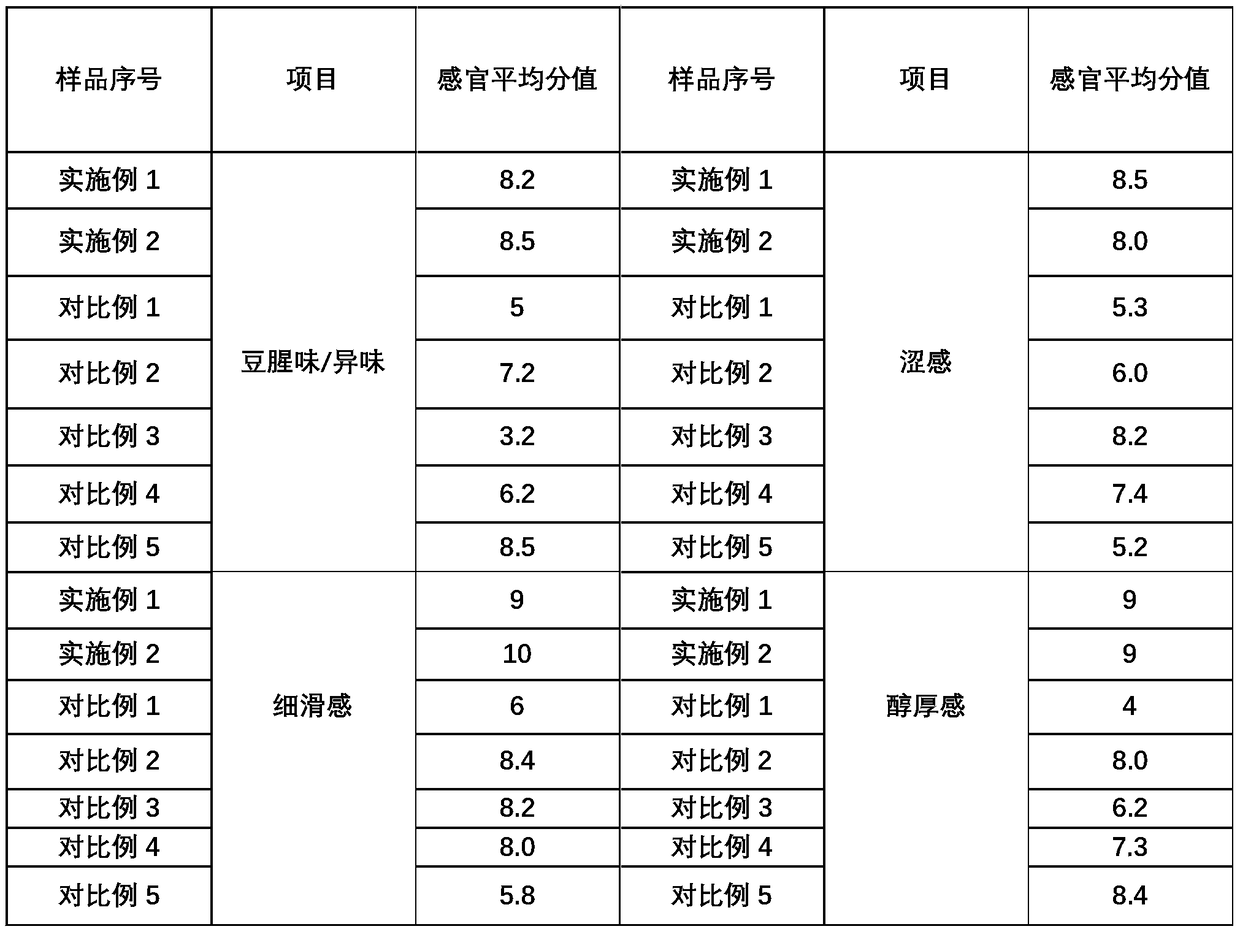

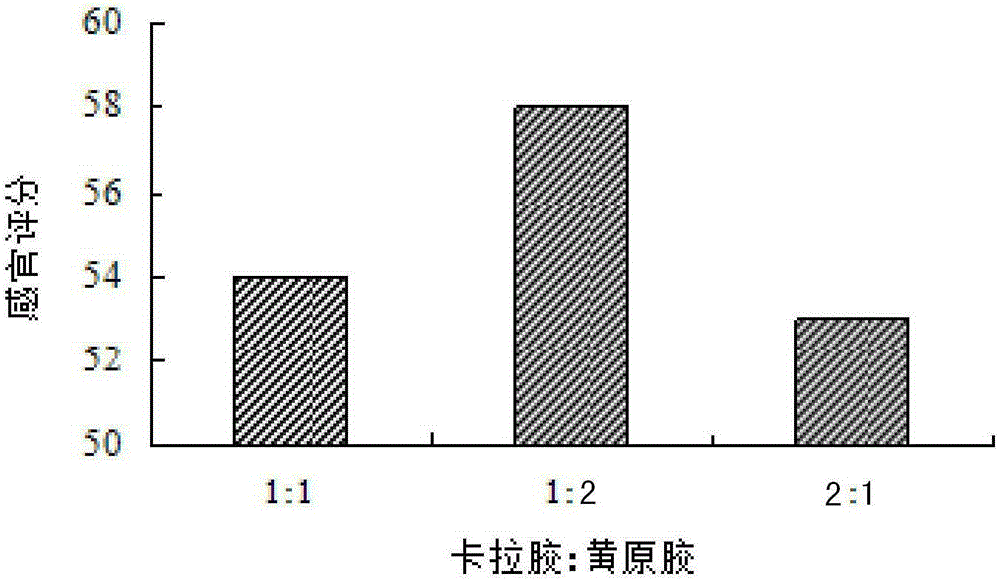

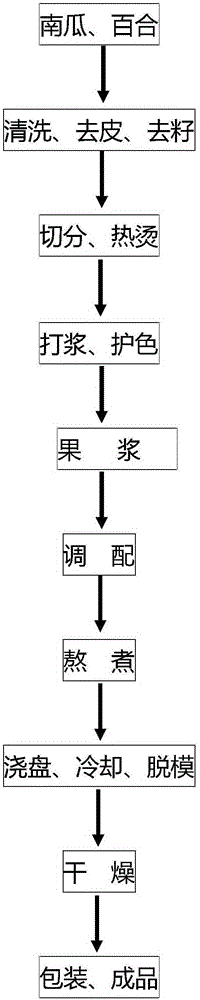

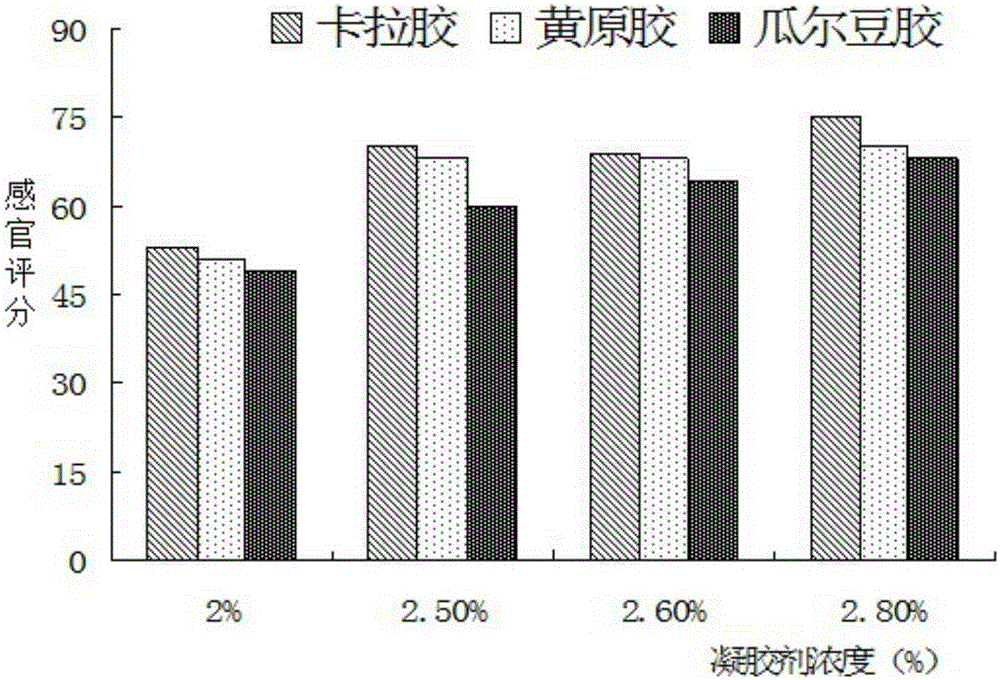

Cucurbita lily compound fruitcake and preparation method thereof

InactiveCN105166617ADelicate tasteScientific and reasonable production processFood preparationFruit cakeCarrageenan

The invention provides a cucurbita lily compound fruitcake composed of 20-22% of fresh cucurbita, 10-12% of fresh lily, 20-22% of white granulated sugar, 45%-50% of water, and 2-5% of a composite gelling agent. The composite gelling agent is formed by mixing of carrageenan, xanthan gum, guar gum and agar. The production process includes: selection of cucurbita and lily, cleaning, peeling and seed removal, segmentation and blanching, pulping and color protection, fruit pulp making, blending, boiling (at 95-100DEG C for 20min), plate pouring, cooling, demoulding, drying (at 40DEG C for 16h), and packaging, thus obtaining a finished product. The compound fruitcake has the raw material characteristics and nutrient composition of both cucurbita and lily, has the characteristics of delicate taste and moderate hardness, also is rich in dietary fiber, multiple amino acids, alkaloid, mineral substances and other nutrients, and well fills the current market gap.

Owner:GANSU AGRI UNIV

Sweet potato ice cream and making method thereof

The invention relates to sweet potato ice cream. The sweet potato ice cream consists of 30 to 35 percent of non-dairy cream, 10 to 12 percent of milk powder, 8 to 10 percent of white granulated sugar, 5 to 7 percent of sweet potato powder, 0.2 to 0.3 percent of sucrose fatty acid ester, 0.1 to 0.2 percent of xanthan gum, 0.1 to 0.15 percent of baked sweet potato essence, and the balance of water. A making method for the sweet potato ice cream comprises the following steps of: mixing the white granulated sugar, the sucrose fatty acid ester and the xanthan gum uniformly, slowly adding the mixture into the water of 30 to 35 DEG C with stirring, adding the milk powder and the sweet potato powder after dissolving, dissolving, stirring uniformly, heating to the temperature of 80+ / -2 DEG C, preserving the heat for 15 minutes, cooling to room temperature, adding the baked sweet potato essence, and stirring uniformly; and fermenting the non-dairy cream by 3.0 to 3.5 times at the temperature of between 10 and 15 DEG C, slowly adding the mixed materials into the fermented non-dairy cream with slow stirring, stirring uniformly, freezing for more than 12 hours at the temperature of between 18 DEG C below zero and 22 DEG C below zero, and thus obtaining the sweet potato ice cream. The invention is applied to baking shops such as cake shops and bakeries.

Owner:HARBIN PATERNA BIOTECH DEV

Liquid dairy product added with rice bran polypeptides and preparation method thereof

The invention relates to the field of liquid milk processing, in particular to a liquid dairy product added with rice bran polypeptides and a preparation method thereof. Based on 1,000 weight parts of raw materials, the liquid dairy product added with the rice bran polypeptides comprises the following raw materials in part by weight: 300 to 999.5 parts of milk, 0.1 to 3 parts of rice bran polypeptide, 0.15 to 7 parts of thickener, 0.1 to 3.0 parts of emulsifier and 0.1 to 6 parts of acidity regulator. The milk beverage has the strong and pure milk fragrance and the functionality of the rice bran polypeptides, and do not have bitter taste of the rice bran polypeptides, so that the two flavors are combined perfectly, and the aim of long quality guarantee period of over 6 months is fulfilled.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Blueberry milk tea powder

InactiveCN105248724ACreamyFull of nutritionPre-extraction tea treatmentSodium carboxymethylcelluloseChemistry

The invention discloses blueberry milk tea powder which comprises the following raw materials in parts by weight: 40 to 50 parts of minced plant fat, 10 to 20 parts of green tea powder, 10 to 20 parts of rock candies, 10 to 20 parts of blueberry powder, 5 to 10 parts of tomato powder, 5 to 10 parts of pomegranate, 0.1 to 0.3 part of sodium carboxymethylcellulose and 0.1 to 0.3 part of sucrose fatty acid ester. The blueberry milk tea powder is mellow in milk fragrance and rich in nutrition and has effects of clearing away the heart-fire and improving the eyesight.

Owner:刘书元

Lactic acid bacterium beverage and making method thereof

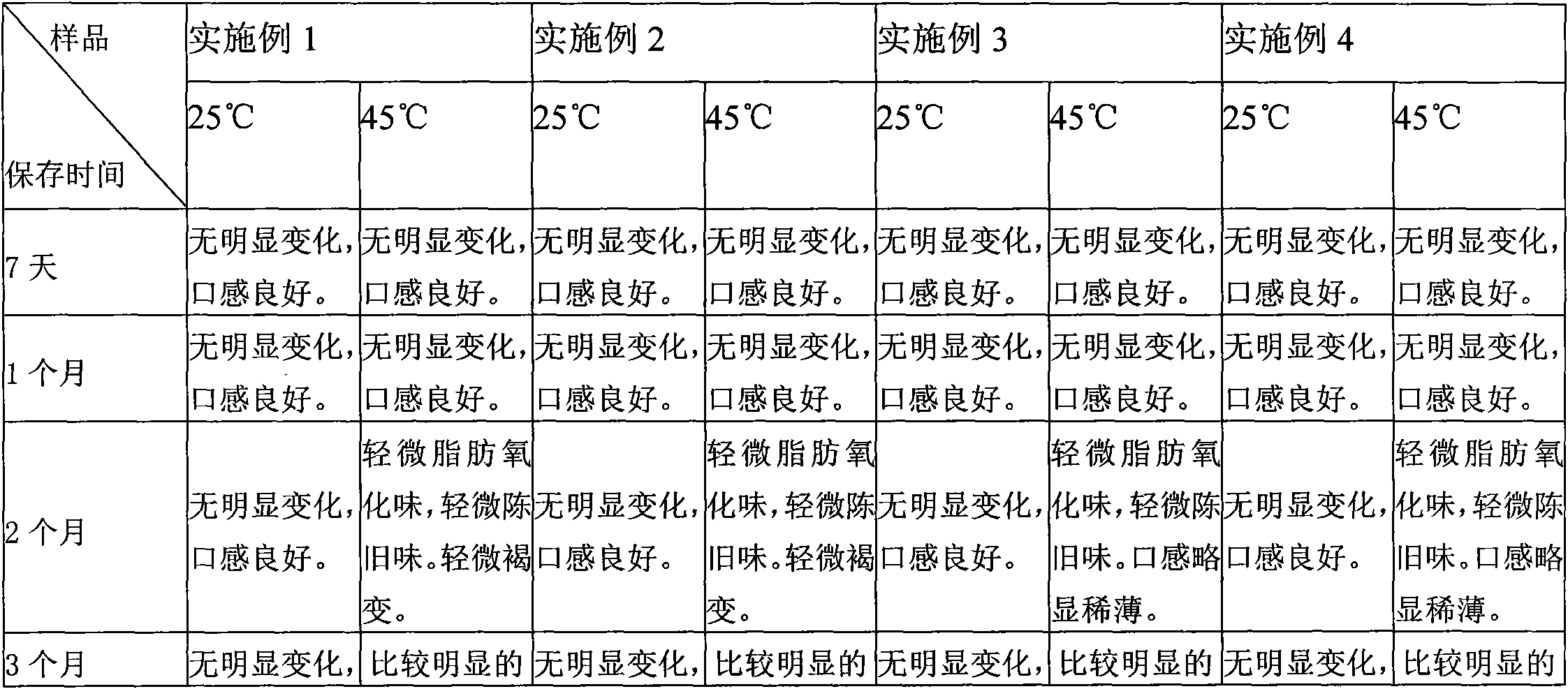

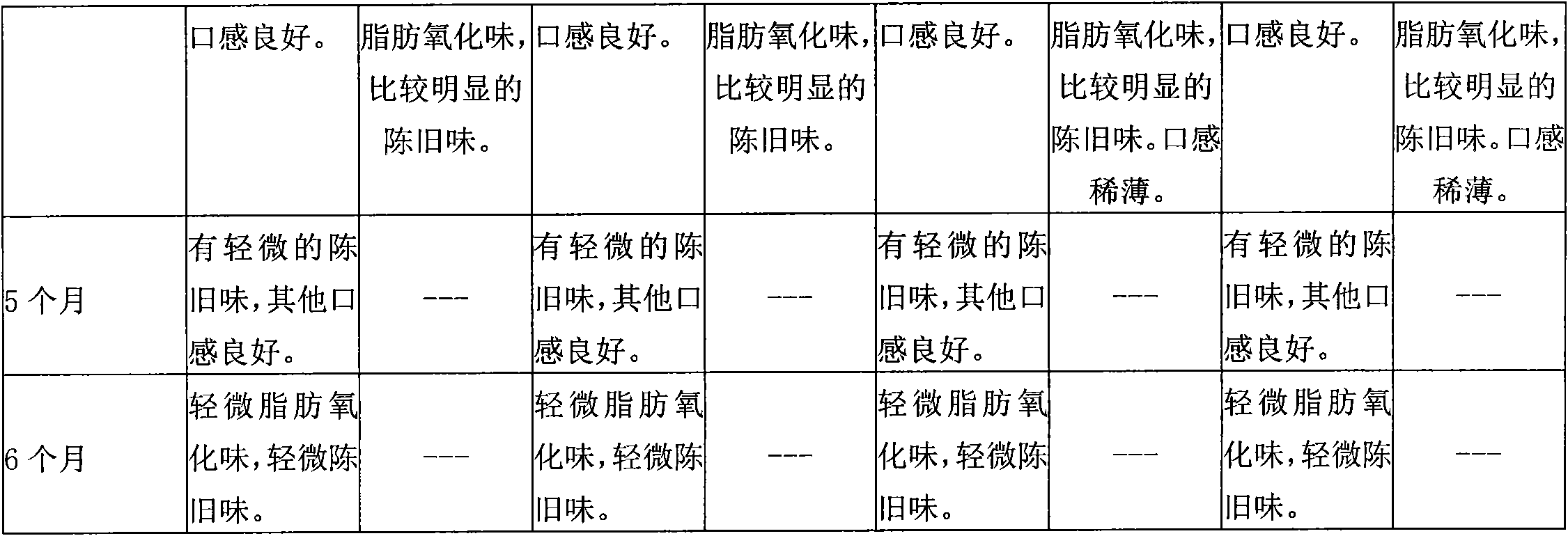

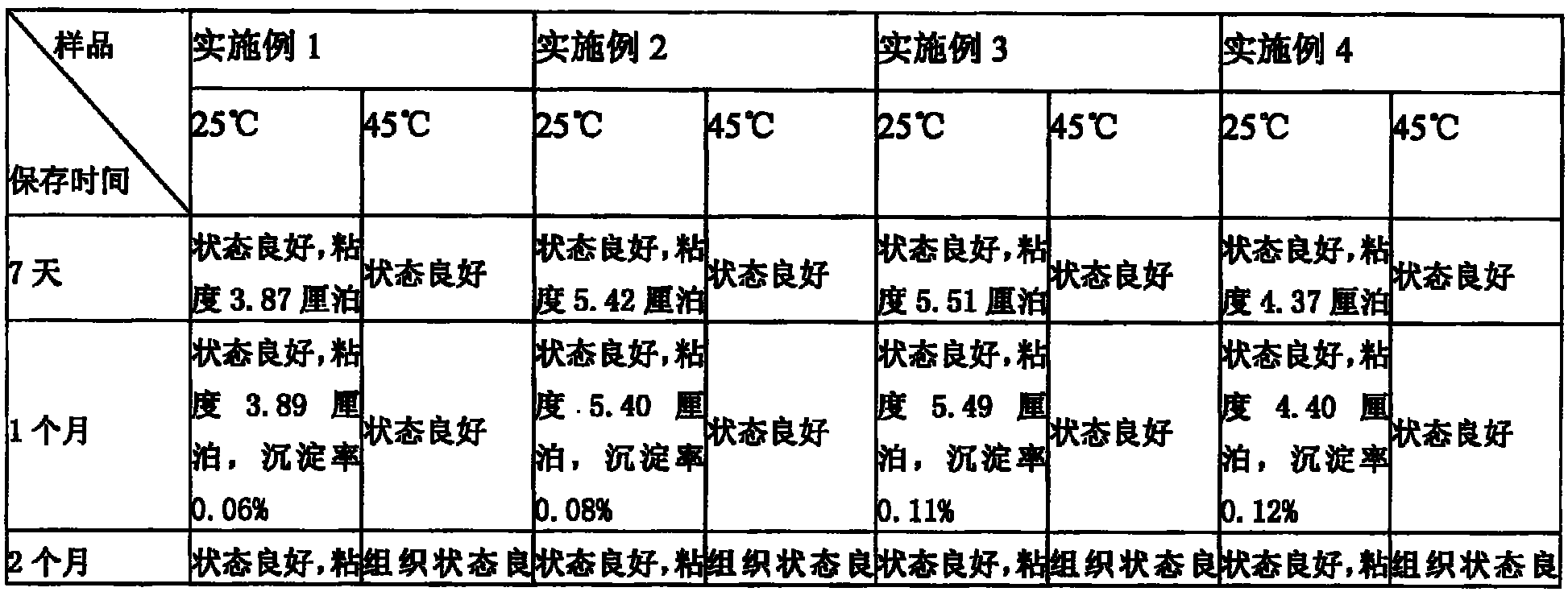

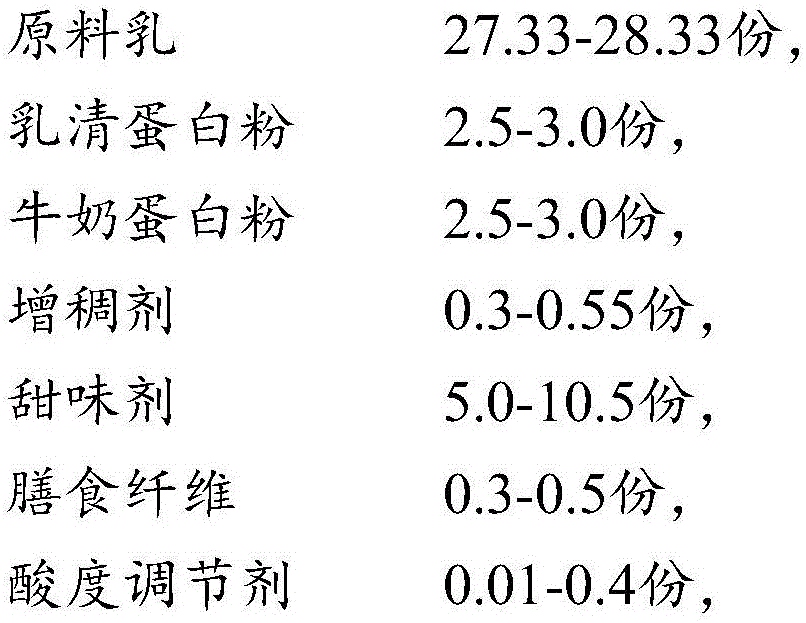

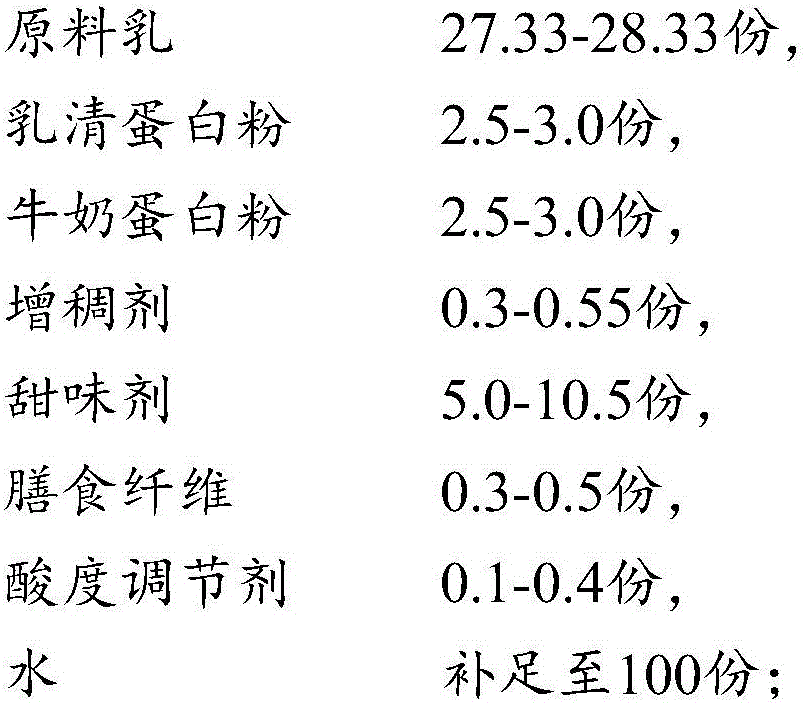

The invention discloses a making method of a lactic acid bacterium beverage. The lactic acid bacterium beverage is made from 27.33-28.33 parts of raw milk, 2.5-3.0 parts of whey protein powder, 2.5-3.0 parts of milk protein powder, 0.3-0.55 part of a thickening agent, 5.0-10.5 parts of a sweetening agent, 0.3-0.5 part of dietary fibers, 0.1-0.4 part of an acidity regulator and water supplementing to 100 parts. The making method comprises the following steps that 1, the whey protein powder and the milk protein powder are added into the preheated raw milk, uniform mixing, homogenizing, sterilizing and cooling are conducted, and raw material liquid is obtained; 2, lactobacillus bulgaricus, streptococcus thermophilus and bifidobacterium lactis are added into the raw material liquid for fertilization, and a fermented milk base material is obtained; 3, the thickening agent, the sweetening agent and the dietary fibers are added into the preheated water, uniform mixing, sterilizing and cooling are conducted, and blended material liquid is obtained; 4, the fermented milk base material and the blended material liquid are mixed to be uniform, the acidity regulator is added for acidity regulating, homogenizing is conducted, and then the lactic acid bacterium beverage is obtained. The lactic acid bacterium beverage contains rich protein and dietary fibers and is good in liquidity and very suitable for being drunk by electric competition players.

Owner:BRIGHT DAIRY & FOOD

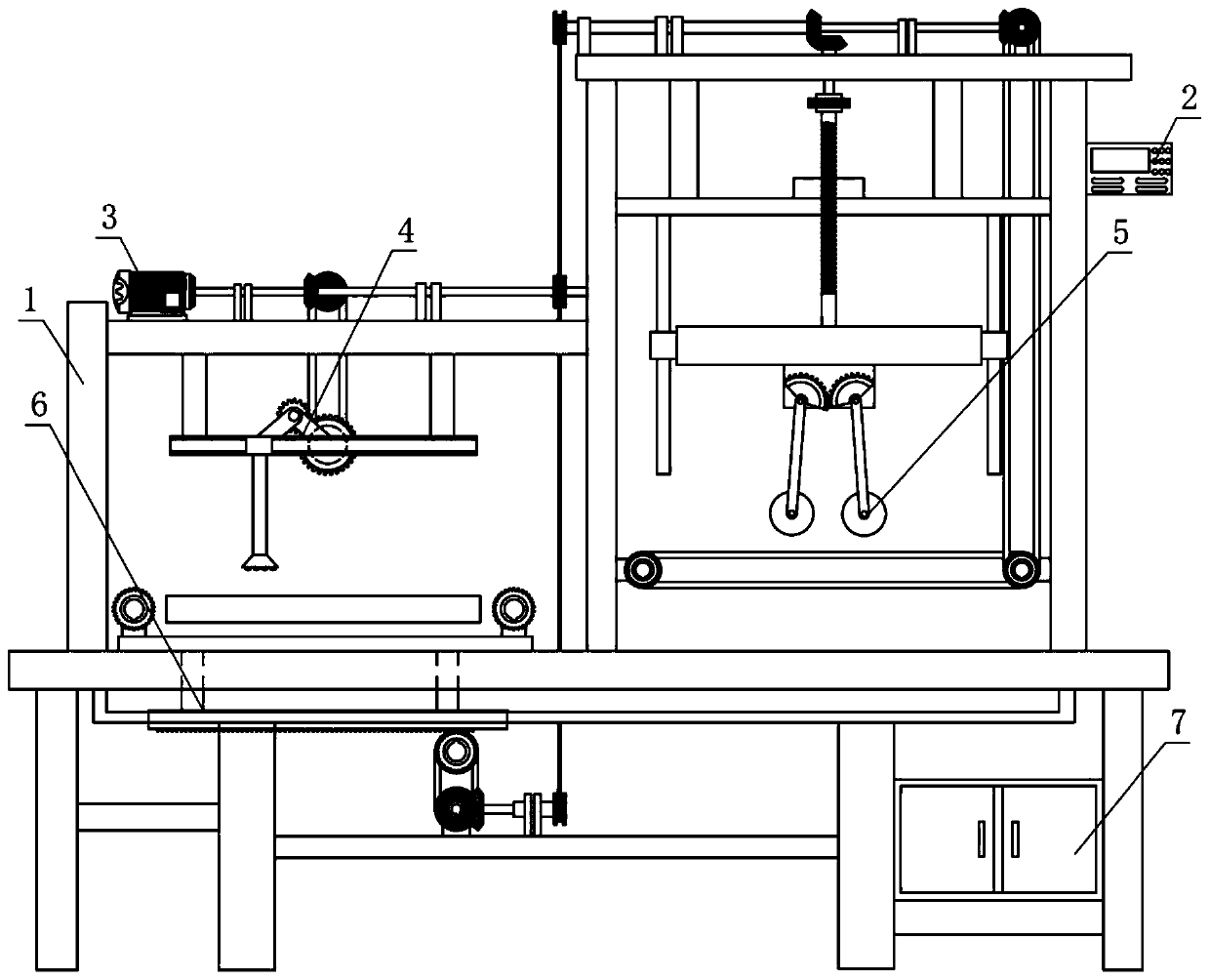

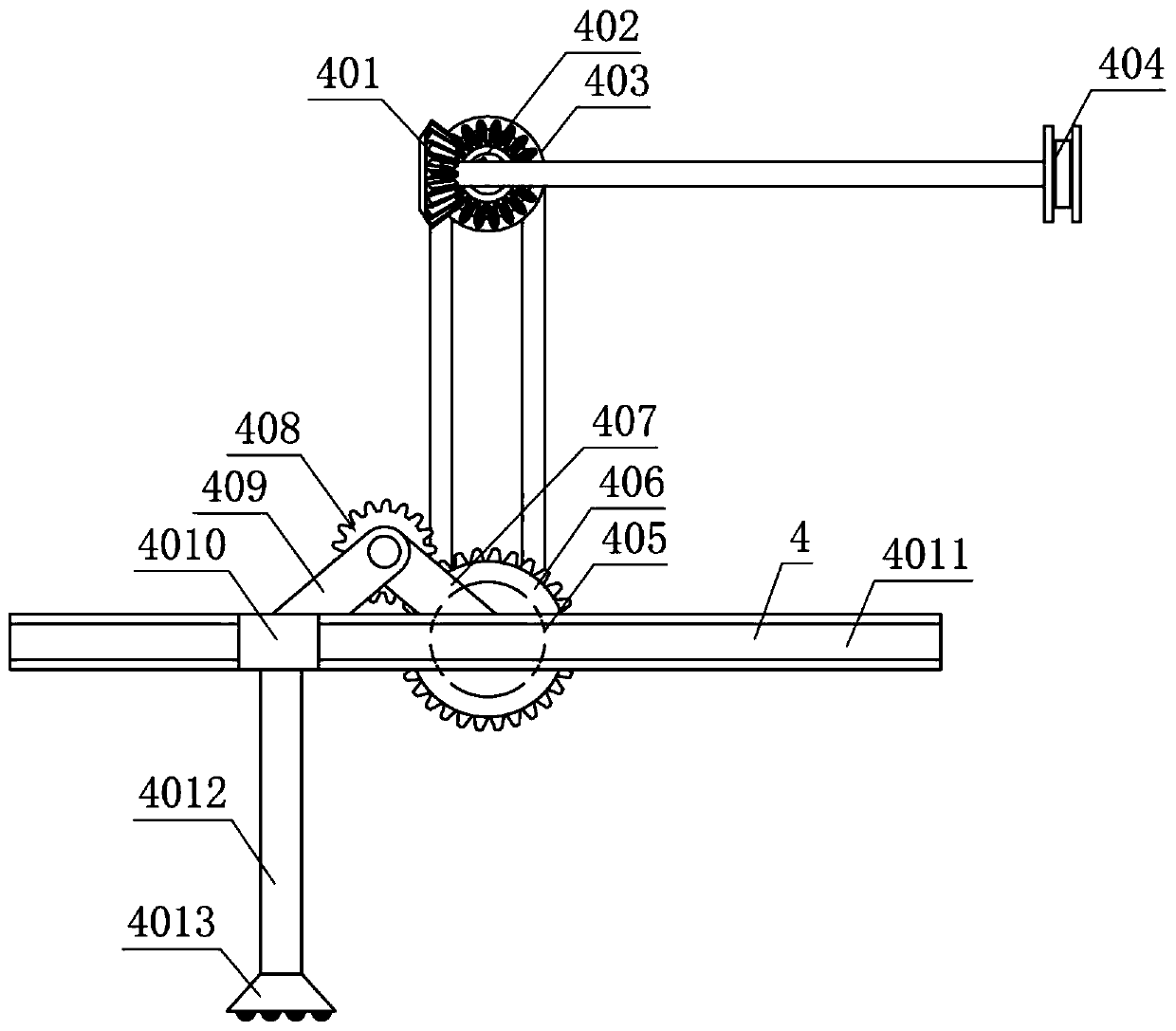

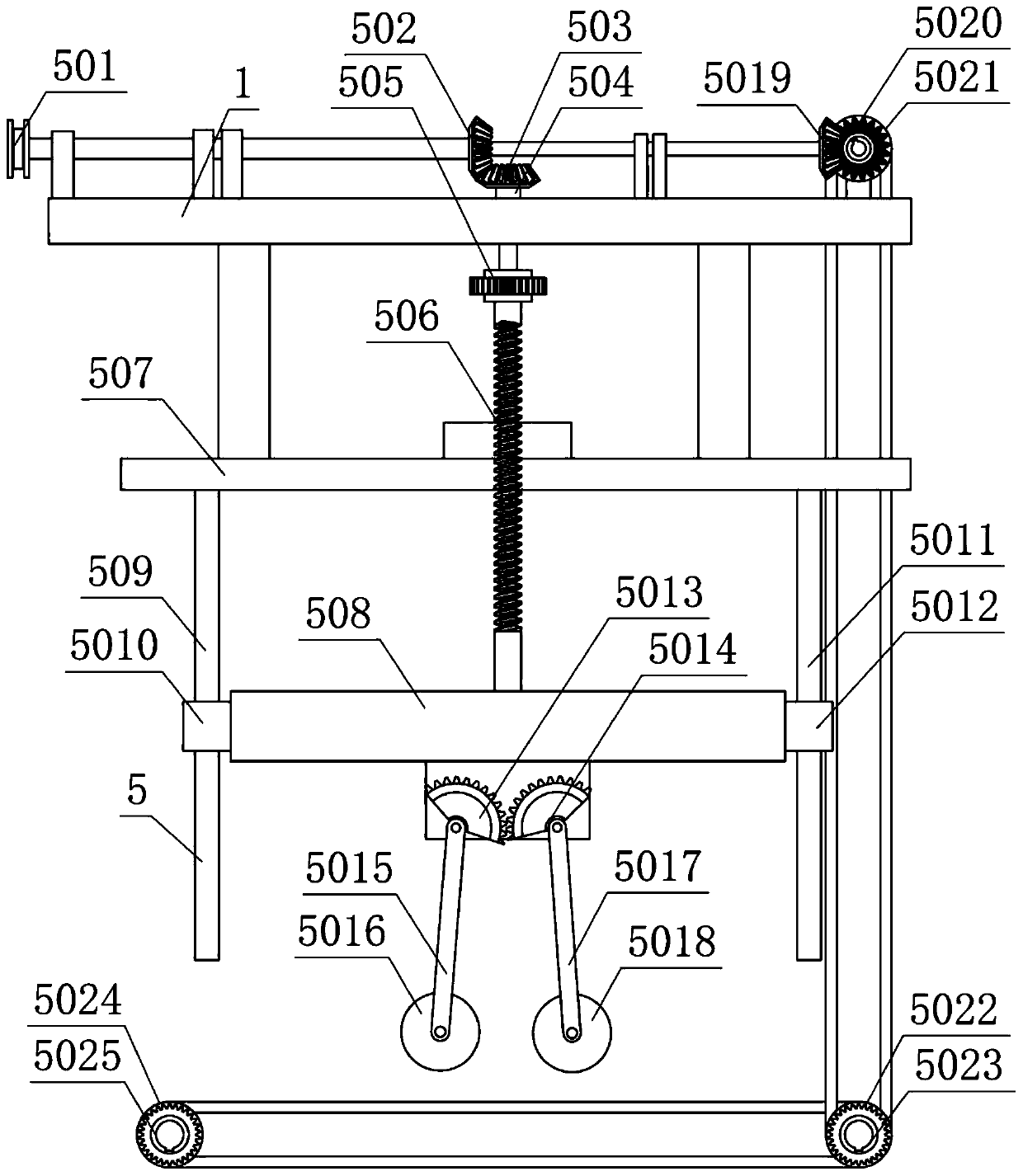

Composite fireproof glass processing device

ActiveCN111300955ACreamySpray evenlyLamination ancillary operationsControlling laminationGlass slideSupport plane

The invention relates to a fireproof material, in particular to a composite fireproof glass processing device. To technical problems in the prior art, the invention provides the composite fireproof glass processing device. The composite fireproof glass processing device comprises a supporting frame, a control screen, a motor, a fireproof glue spraying mechanism, a double-layer pressing mechanism,an edge glue spreading mechanism and a storage cabin, wherein a control screen is arranged at the top of the right end of the supporting frame; and a motor is arranged on the left of the top of the supporting frame. According to the invention, double-layer glass is pushed and pressed from the middle to two sides, so the phenomenon that different thicknesses of fireproof glue in different areas caused by pressing of a part of areas affect fireproof quality and glass flatness is avoided; meanwhile, overflowing fireproof glue at edges is removed in time, so the situation that the overflowing fireproof glue is adhered to the surface of fireproof glass and is difficult to remove after being solidified is avoided; the situation that the glass slides down during carrying due to the fact that theglass is more smooth is prevented; and the edges of the double layers of the glass are aligned, so the two-layer glass is prevented from deviating during pressing.

Owner:浙江四季乐新能源股份有限公司

Barbury wolfberry fruit coffee composite fermented goat's milk and preparation method thereof

The present invention relates to a barbury wolfberry fruit coffee composite fermented goat's milk and a preparation method thereof. The fermented goat's milk is produced from the following raw materials by weight: 80 to 100 parts of fresh goat's milk, 2 to 5 parts of barbury wolfberry fruit and 3 to 8 parts of coffee. The preparation method comprises the following steps: soaking the barbury wolfberry fruit with deionized water 5-10 times the weight of the barbury wolfberry fruit, carrying out mincing and filtering to obtain barbury wolfberry fruit pulp; adding additives into the fresh goat's milk, uniformly mixing the milk with the barbury wolfberry fruit pulp and the coffee, carrying out homogenizing, pasteurizing the mixture, and quickly cooling to 40-45 DEG C, adding a fermentation strain, performing fermentation to obtain a yogurt, proceeding fermentation at 0-5 DEG C for maturing, carrying out packaging to obtain the product, and carrying out cold preservation. The barbury wolfberry fruit coffee composite fermented goat's milk is rich in nutrition, overcomes the shortcomings that prior goat's milk production is single in variety, and limited in nutrition, and has efficacy of invigorating spleen and replenishing qi, moistening lung and promoting fluid production, beautifying and remaining appearance, lengthening one's life and enhancing immunity of human body.

Owner:南京羊小贝乳业有限公司

Yogurt pudding powder

The invention relates to a yogurt pudding powder which is prepared from the following components in percentage by weight: 35-45% of white granulated sugar, 20-30% of yogurt powder, 15-20% of non-dairy creamer, 10-15% of egg white powder, 2.3-2.5% of konjac glucomannan, 1.6-1.8% of carrageenin and 0.6-0.8% of sucrose ester. The pudding powder is prepared by the following steps: proportioning, mixing, microwave sterilization and packaging. The yogurt pudding prepared from the yogurt pudding powder has the advantages of seductive appearance, smooth and delicate mouthfeel, thick milk flavor, typical yogurt flavor and no peculiar smell. The pudding preparation method is simple and convenient, and saves both time and labor; and the proportioning process is completed by adding a certain amount of pure water into the yogurt pudding powder, thereby avoiding the inconvenience of weighing, mixing and preparing every component in the proportioning process, and greatly simplifying the proportioning procedure. The product is powdery, and thus, is easier to store and preserve.

Owner:HARBIN AIKEER FOOD TECH

Foaming milk and preparing method thereof

The invention discloses foaming milk and a preparing method thereof. The foaming milk is prepared from, by weight, 98.07-99.395% of milk, 0.5-1.5% of alpha-cyclodextrine, 0.1-0.4% of microcrystallinecellulose and 0.005-0.03% of gellan gum. The foaming milk can be prepared by adopting a conventional dairy product preparation technology. According to the preparing method, alpha-cyclodextrine, microcrystalline cellulose and gellan gum are added in the milk, and thus the foaming milk product which keeps foaming for a long time can be obtained; the problems are solved that foam bursts and is not stable during delivery of coffee prepared from existing foaming milk.

Owner:BRIGHT DAIRY & FOOD CO LTD

Environment-friendly fabric

InactiveCN101979738AWith sweat absorptionMoisture permeableDyeing processWoven fabricsPolymer scienceCotton fibre

The invention discloses an environment-friendly fabric, which comprises warp yarns and weft yearns in a mass ratio of 40:60, wherein the warp yarns are cotton fibers; the weft yarns are interwoven fibers of tencel, soft bamboo, fibrilia or several other fibers; and the surface of fabric is printed with patterns through an active dye. The environment-friendly fabric has the advantages of no pollution on ambient environment, good dustproof performance and high cleanness, no fading after long washing, and the like.

Owner:JIANGSU LANSIYU HOME TEXTILE

Making method of milk-flavor taro slices

InactiveCN104366354AEnhance immune functionImprove the immunityFood ingredient functionsFood preparationBiotechnologyNutritive values

The invention discloses a making method of milk-flavor taro slices, belonging to the field of food processing. The making method is characterized by comprising the following process flows of selecting raw materials; slicing; dipping in milk powder; dehydrating; frying; and packaging to obtain a finished product. The making method has the beneficial effects that the milk-flavor taro slices are uniform in thickness, fragrant and strong in milk flavor and crisp and have the fragrant and glutinous tastes of taros and the strong milk flavor. The milk-flavor taro slices are rather high in nutritive value, rich in various nutrient substances, capable of appetizing and helping digestion and beneficial to human immunity enhancement and human resistance improvement, and have the effects of strengthening the middle warmer and benefiting vital energy, maintaining beauty and keeping young, detoxifying as well as preventing and resisting cancers so as to be green and nutrient nourishing and health maintaining foods suitable for both the old and the young. The making method is simple in operation and easy to implement.

Owner:陶胜

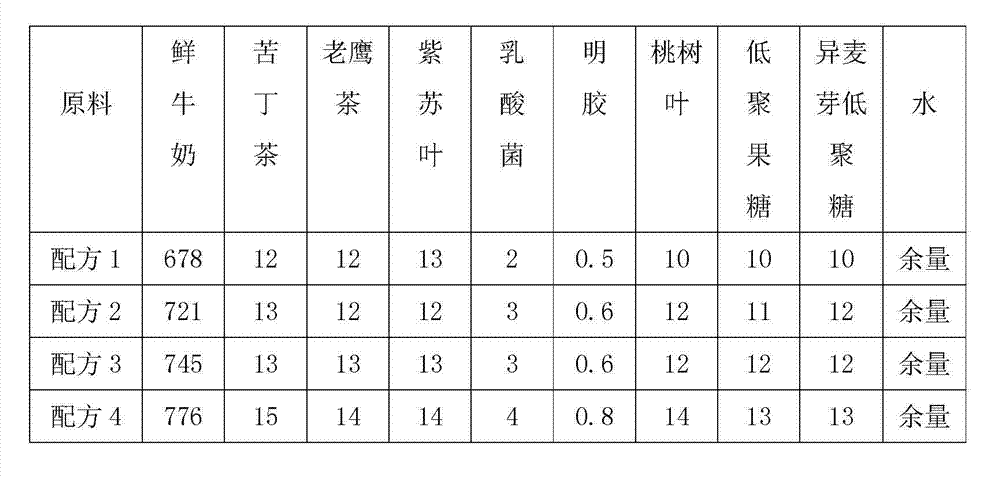

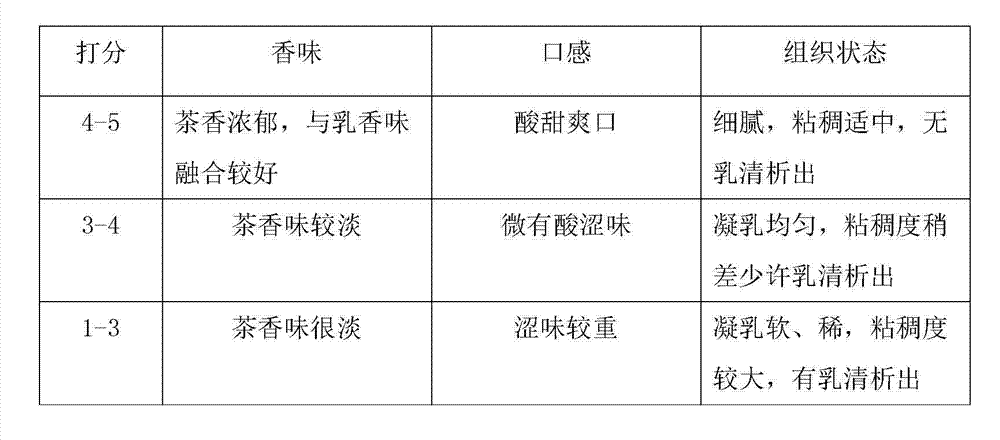

Broadleaf holly leaf yoghourt and preparation method thereof

The invention discloses a broadleaf holly leaf yoghourt which is prepared from the raw materials consisting of fresh milk, broadleaf holly leaves, hawk tea, perilla leaves, lactobacillus, gelatin, peach leaves, fructo-oligosaccharide, isomaltose oligosaccharide and water through steps like preparation of broadleaf holly leaf juice, sterilization, blending and inoculated fermentation. In the broadleaf holly leaf yoghourt provided by the invention, the blending ratio of the fresh milk and the broadleaf holly leaves is proper; the broadleaf holly leaves participate in fermentation of the yoghourt; pure tea fragrance, rich milk flavor and fine and smooth taste are obtained; broadleaf holly leaf fragrance and yoghourt flavor well fuse together, so the broadleaf holly leaf yoghourt can be easily accepted by people; long-term intake of the broadleaf holly leaf yoghourt is beneficial for human health and can improve human immunity.

Owner:ANHUI PROVINCE TIANXU TEA

Purple sweet potato ice cream and preparation method thereof

The invention relates to a purple sweet potato ice cream which comprises the following components: 30-35% of non-dairy cream, 10-12% of milk powder, 8-10% of white granulated sugar, 5-7% of purple sweet potato powder, 0.2-0.3% of sucrose fatty acid ester, 0.1-0.2% of xanthan gum, 0.1-0.15% of purple sweet potato essence and the balance of water. A preparation method of the purple sweet potato ice cream comprises the following steps of: evenly mixing the white granulated sugar, the sucrose fatty acid ester and the xanthan gum; slowly adding into water of 30-35 DEG C while stirring, and dissolving; then, adding the milk powder and the purple sweet potato powder, dissolving, evenly stirring, heating to 80+ / -2 DEG C, keeping the temperature for 15 minutes, and cooling to room temperature; then adding the purple sweet potato essence, and evenly stirring; whipping the non-dairy cream at 10-15 DEG C until the non-dairy cream expands 3.0-3.5 times; and then, slowly adding the mixture into the whipped non-dairy cream while stirring at a low speed, evenly stirring, and freezing at (-18)-(-22) DEG C for more than 12 hours to obtain the purple sweet potato ice cream. The invention is especially applicable to baking workshops such as cake shops, bakeries and the like.

Owner:HARBIN PATERNA BIOTECH DEV

Non-distillated all-nutrition milk wine and its brewing process

InactiveCN101024808ANutritional diversityCreamyMicroorganism based processesAlcoholic beverage preparationYeastLactase

The invention discloses a disrectifying fully nutrition milk wine and the producing method. It adopts lactose in raw material milk decompounds by lactase, taking low temperature fermenting by yeast, and taking fine filtering to gain the wine. It has the advantages of benefit for health, fully nutrition, and has the effects of beautifying the face, enhancing immunity, etc.

Owner:王巴特尔

Carrot ice cream and preparation method thereof

The invention provides a carrot ice cream which comprises the following components by weight percent: 30-35 percent of non-dairy cream, 10-12 percent of milk powder, 8-10 percent of white granulated sugar, 5-7 percent of carrot powder, 0.2-0.3 percent of sucrose fatty ester, 0.1-.02 percent of xanthan gum, 0.1-0.15 percent of Beta-carotene, and water, and the percent sum of all components is 100 percent. The method comprises the following steps in sequence: uniformly mixing white granulated sugar, the sucrose fatty ester and the xanthan gum; during stirring slowly adding the mixture in the water of 30-35 DEG C temperature; after completion of dissolution, adding milk powder and carrot powder for dissolution, and uniformly stirring; heating to 80 plus / moins 2 DEG C temperature, and maintaining 15 min; cooling to the room temperature; adding the Beta-carotene, and uniformly stirring to obtain a mixture b; beating and fermenting non-dairy cream under the 10-15 DEG C temperature until the size is 3-3.5 times the original size, under the slow stirring condition, slowly adding the mixture b into the non-dairy cream, and uniformly stirring to obtain the mixture c; and placing the mixture c at the temperature of between negative 18 and negative 22 DEG C for freezing 12 hours, thereby obtaining the carrot ice cream. The carrot ice cream and the method are particularly suitable for cake shop, bakery and other baking shop to develop new products so as to improve the economic benefits.

Owner:HARBIN PATERNA BIOTECH DEV

Method for producing milky-flavor banana chips

InactiveCN104381889ACreamyCrispy and crispyFood ingredient as taste affecting agentFood preparationNutrientLower blood pressure

The invention discloses a method for producing milky-flavor banana chips and belongs to the field of food processing. The method is characterized by adopting the processing process flows of pretreating raw materials, dipping, carrying out dehydration drying, softening and packaging. The method has the beneficial effects that the product produced by the method is strong in milky flavor and crispy and crunchy in mouth feel, has the unique fragrant and sweet flavor of bananas and is crispy and tasty; the product is very high in nutritive value and rich in a variety of nutrients, is beneficial to the cleaning-off of the intestines and stomach and the promotion of human body metabolism, has the effects of clearing heat, moistening the lung, quenching thirst, detoxifying and lowering blood pressure, and is an economical-and-practical and green-and-healthy food which is suitable for people of all ages.

Owner:张金宝

Anti-oxidization cosmetic composition and preparation method thereof

InactiveCN108125809AGood affinitySuppresses fine linesCosmetic preparationsToilet preparationsChemistryCorrosion

The invention discloses an anti-oxidization cosmetic composition, which is prepared from basic oil, emulsifying agents, humectants, conditioning agents, skin moisturizing agents, pH regulating agents,thickening agents, corrosion preventives and water, wherein the basic oil is prepared from simmondsia chinensis seed oil and argania spinosa kernel oil; the emulsifying agents are prepared from cetostearyl alcohol and coco-glucoside; the humectants are prepared from glycerol, propanediol, butanediol and hyaluronic acid; the conditioning agents are prepared from hydrolyzed collagen, elastin, aloebarbadensis leaf extracts, hydrolyzed pearl, propolis extracts and decoyl hydroximic acid; the skin moisturizing agents are prepared from polyglycol-400, cyclopentasiloxane, isopropyl palmitate and polydimethylsiloxane. The anti-oxidization cosmetic composition has the advantages that under the basic effect of substrate lotion and the humectants, the whitening, anti-oxidization and skin fine winkle generation inhibition are achieved in a cooperative way, so that skin cells are full of water and the vitality is maintained. Meanwhile, the invention also provides a preparation method of the anti-oxidization cosmetic composition.

Owner:广州皓雨投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com