Composite fireproof glass processing device

A processing device and technology for fire-resistant glass, applied in lamination devices, lamination auxiliary operations, control lamination, etc., can solve problems such as difficult to remove, poor fireproof effect, and quality degradation of composite glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

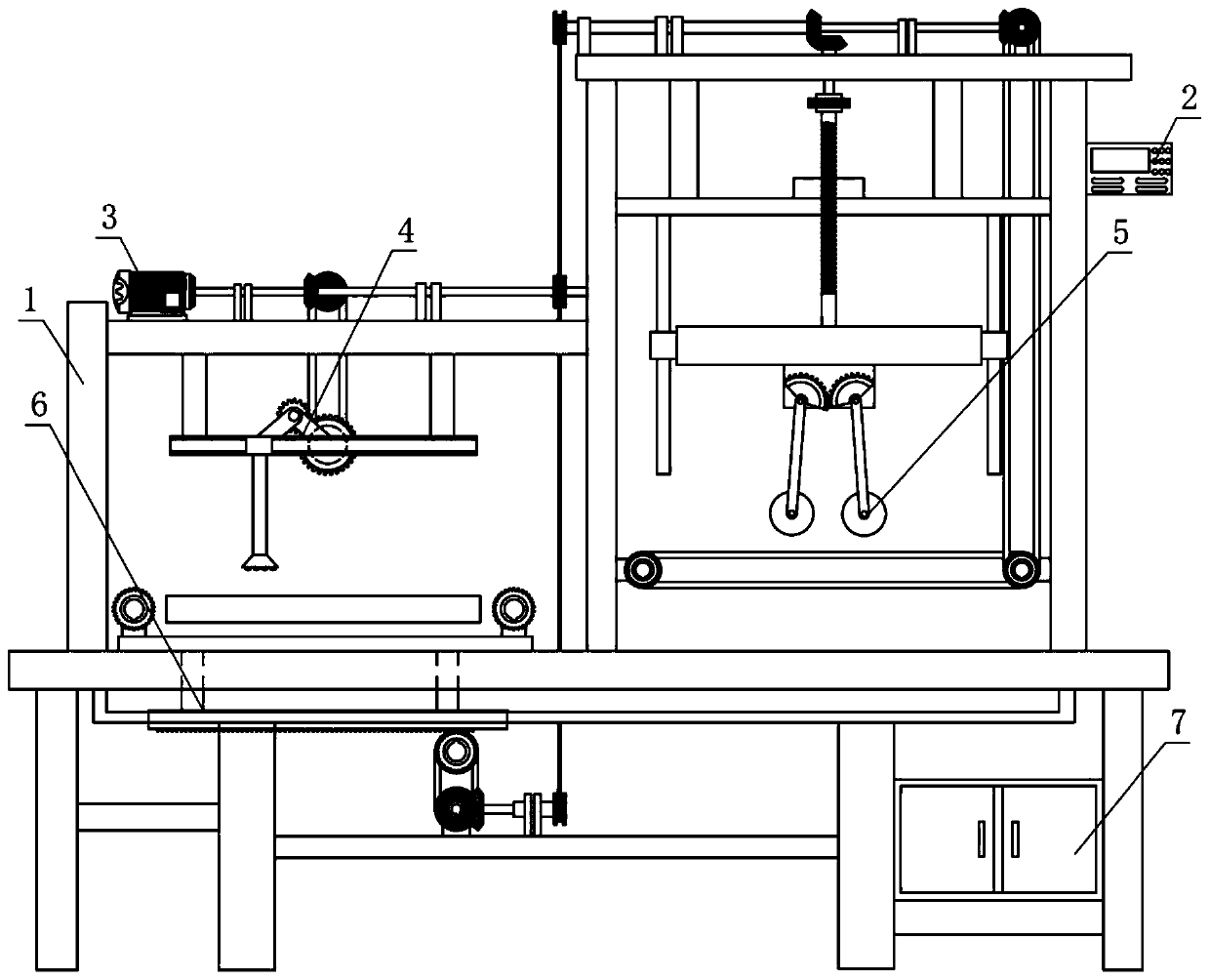

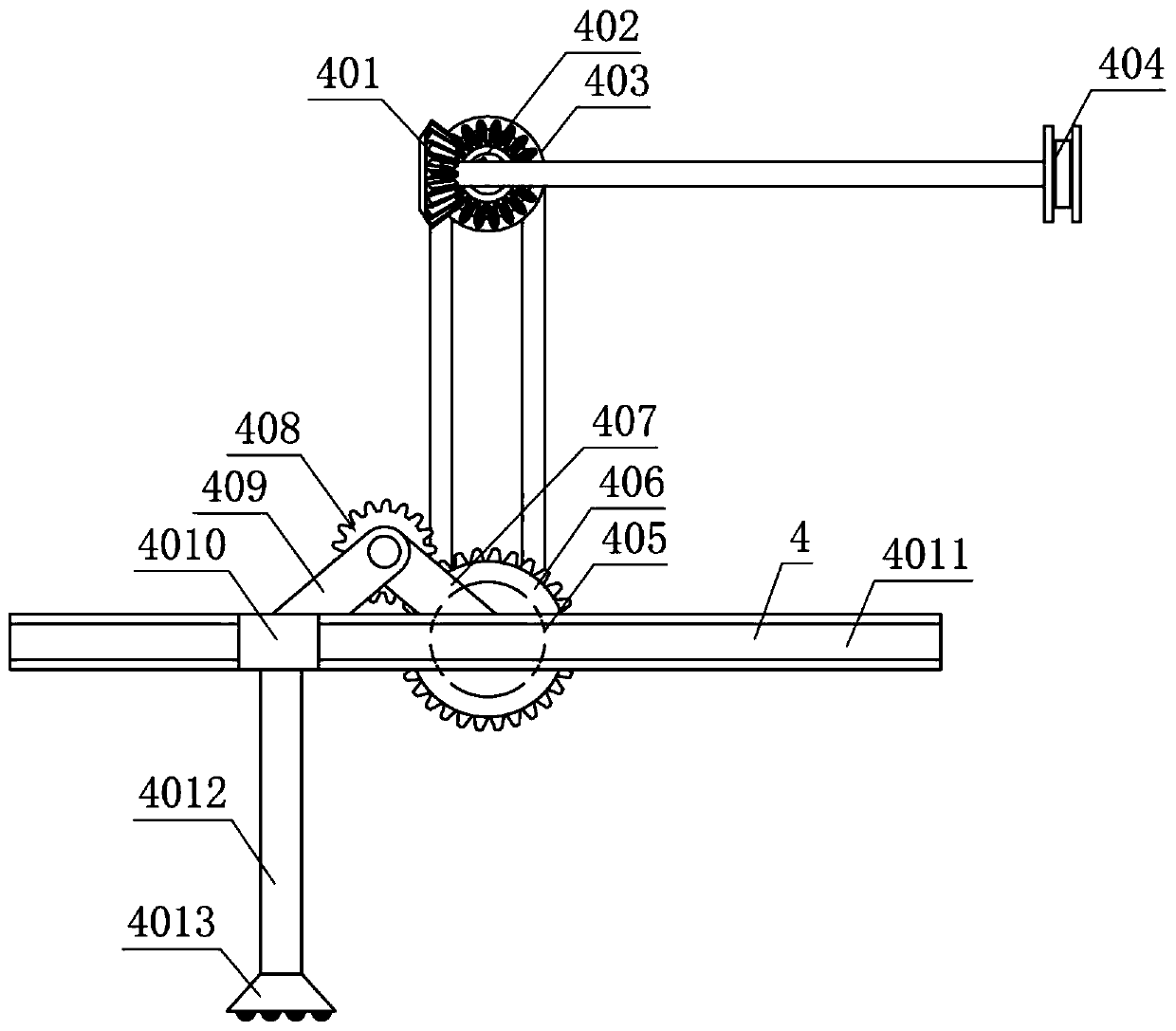

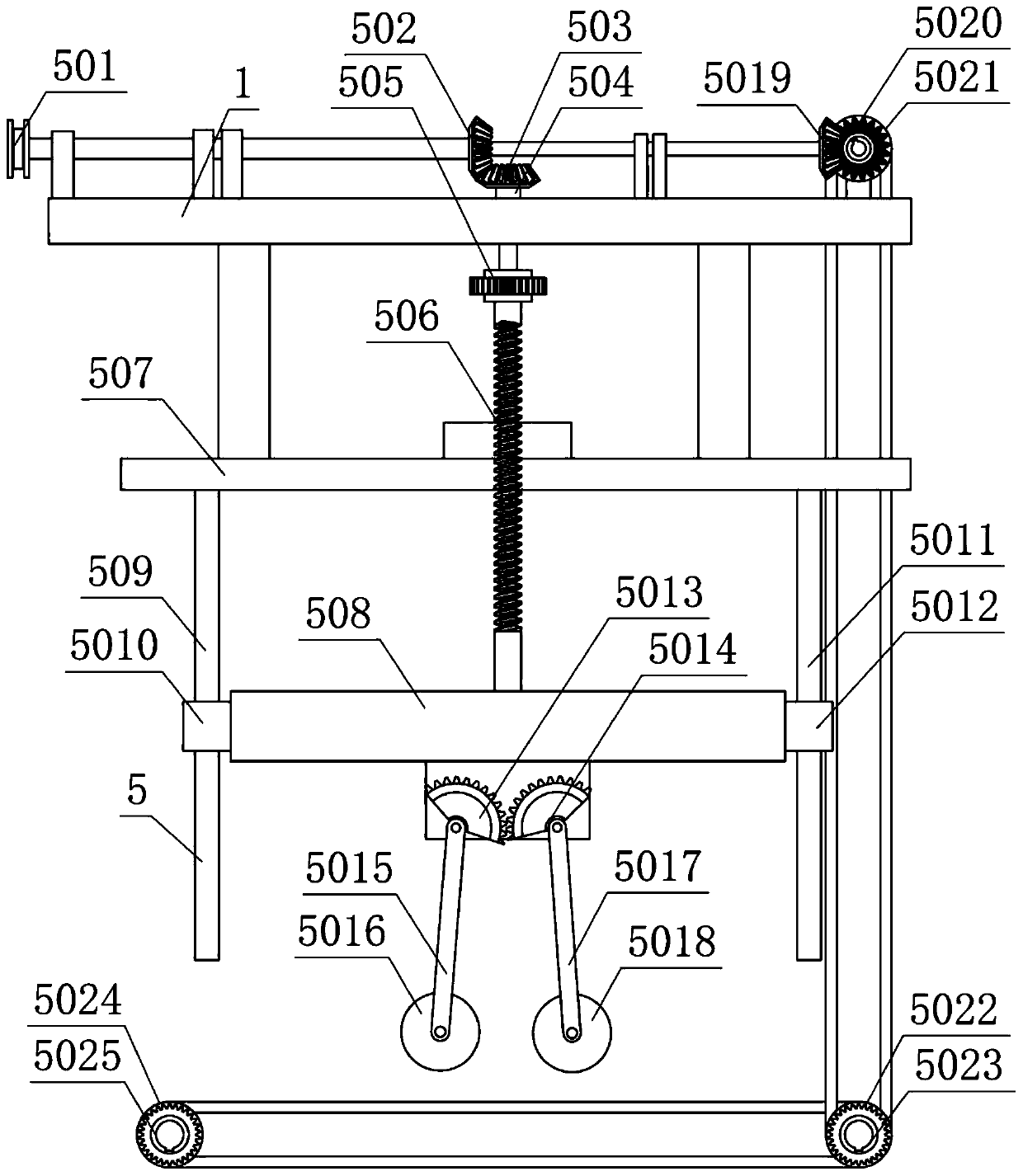

[0027] A composite fireproof glass processing device, such as Figure 1-5 As shown, it includes a support frame 1, a control panel 2, a motor 3, a fireproof glue spraying mechanism 4, a double-layer pressing mechanism 5, an edge scraping mechanism 6 and a storage compartment 7; a control panel 2 is arranged on the top of the right end of the support frame 1; There is a motor 3 on the left top of the frame 1; a fireproof glue spraying mechanism 4 is set on the left top of the support frame 1, and the top left end of the fireproof glue spraying mechanism 4 is connected with the motor 3; Mechanism 5, and the top of the left end of the double-layer pressing mechanism 5 is connected with the fireproof glue spraying mechanism 4; ; The right bottom of the support frame 1 is provided with a storage compartment 7 .

[0028] Working principle: when in use, place the device horizontally at the position to be used through the support frame 1, turn on the power, deploy the device through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com