Processing method for coarse cereal rice crust

A processing method and technology for rice noodles, which are applied in the field of processing miscellaneous grain rice noodles, can solve the problems of long time required, complicated production methods, bad taste, etc., and achieve the effects of rich nutrition, crisp texture and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

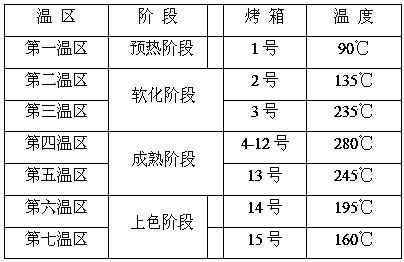

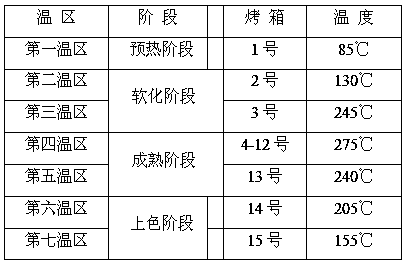

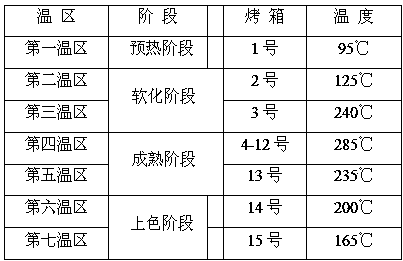

Image

Examples

Embodiment 1

[0024] This embodiment relates to a processing method of miscellaneous grain crispy rice, comprising the following steps:

[0025] Step 1, ingredients according to the following proportions:

[0026] 90 kg of rice,

[0027] Oats 3.0 kg,

[0028] Corn 3.0 kg,

[0029] buckwheat 3.0 kg,

[0030] Black sesame 1.0 kg;

[0031] Step 2, add the above ingredients to the rice steaming tray according to the volume ratio of 1:1 with water, stir and mix evenly, and then put it into the steamer;

[0032] Step 3, steaming: turn on the rice steamer, first steam for 1.5 hours, then stew for 10 minutes;

[0033] Step 4, cooling: take out the rice steaming tray and put it on a cooling rack to cool for 4 minutes, then turn it upside down and cool for 3 minutes until the temperature in the rice steaming tray drops to 40°C;

[0034] Step 5, stirring: Add the ingredients rice, oats, corn, buckwheat, and black sesame into the blender according to the ratio of step 1, first stir at a low speed...

Embodiment 2

[0042] This embodiment relates to a processing method of miscellaneous grain crispy rice, comprising the following steps:

[0043] Step 1, ingredients according to the following proportions:

[0044] 93 kg of rice,

[0045] Oats 1.8 kg,

[0046] Corn 1.8 kg,

[0047] buckwheat 2.6 kg,

[0048] Black sesame 0.8 kg;

[0049] Step 2, add the above ingredients to the rice steaming plate according to the volume ratio of 1.05:1 to water, stir and mix evenly, and then put it into the steamer;

[0050] Step 3, steaming: Turn on the rice steamer, first steam for 1.25 hours, then stew for 12 minutes;

[0051] Step 4, cooling: take out the rice steaming tray and place it on a cooling rack to cool for 3 minutes, then turn it upside down and cool for 4 minutes until the temperature in the rice steaming tray drops to 35°C;

[0052] Step 5, stirring: Add the ingredients rice, oats, corn, buckwheat, and black sesame into the blender according to the ratio of step 1, first stir at a low ...

Embodiment 3

[0060] This embodiment relates to a processing method of miscellaneous grain crispy rice, comprising the following steps:

[0061] Step 1, ingredients according to the following proportions:

[0062] 95 kg of rice,

[0063] Oats 1.1 kg,

[0064] Corn 1.0 kg,

[0065] buckwheat 2.0 kg,

[0066] Black sesame 0.9 kg;

[0067] Step 2, add the above ingredients to the rice steaming tray according to the volume ratio of 1.1:1 to water, stir and mix evenly, and then put it into the steamer;

[0068] Step 3, steaming: Turn on the rice steamer, first steam for 1.5 hours, then stew for 15 minutes;

[0069] Step 4, cooling: take out the rice steaming tray and place it on a cooling rack to cool for 2 minutes, then turn it upside down and cool for 5 minutes until the temperature in the rice steaming tray drops to 30°C;

[0070] Step 5, stirring: Add the ingredients rice, oats, corn, buckwheat, and black sesame into the blender according to the ratio of step 1, first stir at a low speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com