Ultra-thin wheat germ protein flakes and production method thereof

A technology of wheat germ and production method, which is applied in the directions of food ingredients as taste improvers, food ingredients as taste improvers, and functions of food ingredients, etc., can solve the problems of wheat germ being easily spoiled and moldy, not being well utilized, and the like, To achieve the effect of thick wheat aroma, strong wheat aroma and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

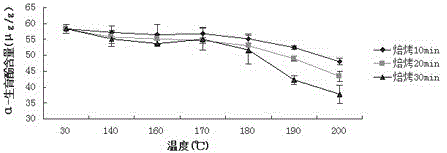

Embodiment 1

[0027] Embodiment 1, a kind of wheat germ natto protein ultra-thin slice is made of wheat germ powder of 50%-95% by weight, 1%-10% natto powder, and 4%-40% auxiliary material, described The auxiliary material is one of flour, rice flour, white granulated sugar, whole egg powder, milk powder, sesame or any mixture. Adopt wheat germ powder 80kg, natto powder 10kg, auxiliary material 10kg among the present embodiment, auxiliary material is rice flour, water 30kg. Crush wheat germ into 60 meshes, mix wheat germ powder, auxiliary materials and water in a powder mixer, feed them into a twin-screw extruder for uniform extrusion, and roll the extruded dough into ultra-thin sheets Shape, the thickness of the shaped slices is 0.5mm; bake the sliced slices in an oven at 150-190°C for 10 minutes to obtain ultra-thin slices of wheat germ protein, which has a small loss of vitamin E and produces a good aroma of roasted wheat. The baked wheat germ slices are fed into the seasoning drum, a...

Embodiment 2

[0028] Embodiment 2, a kind of wheat germ natto protein ultra-thin sheet, present embodiment is to adopt wheat germ powder 60kg, natto powder 5kg, auxiliary material 35kg, auxiliary material is flour 30kg and black sesame 5kg, adds water 40kg. Crush wheat germ into 120-mesh powder, mix wheat germ powder, flour, black sesame and water in a powder mixer, feed it into a twin-screw extruder and extrude it, and roll the extruded sheet dough into shape It is in the shape of ultra-thin slices, and the thickness of the formed slices is 0.8mm; bake the cut slices in a continuous oven at 180 degrees for 12 minutes to obtain ultra-thin slices of wheat germ protein, which has a small loss of vitamin E and produces a good aroma of roasted wheat. The baked wheat germ slices are fed into the seasoning drum, and natto powder is fed into the seasoning drum at the same time. During the rotation of the seasoning drum, the natto powder is attached to the wheat germ ultra-thin slices, and finally t...

Embodiment 3

[0029] Embodiment 3, adopt wheat germ powder 95kg, natto powder 1kg, auxiliary material 4kg in the present embodiment, auxiliary material is black sesame, water 30kg. Crush wheat germ into 120-mesh fine powder, mix wheat germ powder, auxiliary materials and water in a powder mixer, feed it into a twin-screw extruder and extrude it uniformly, and roll the extruded flake dough into a super Flake shape, the thickness of the formed flakes is 0.3 mm; the pressed and cut flakes are baked in a 160-degree oven for 8 minutes to obtain wheat germ protein ultra-thin flakes, which have a small loss of vitamin E and produce good wheat flavor. The baked wheat germ slices are fed into the seasoning drum, and natto powder is fed into the seasoning drum at the same time. During the rotation of the seasoning drum, the natto powder is attached to the wheat germ ultra-thin slices, and finally the wheat germ natto protein is ultra-thin Packed in slices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com