Patents

Literature

35results about How to "Strong wheat flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing stabilized whole wheat flour

InactiveCN102150840ASolving Shelf Life ProblemsStabilized storage timeFood preparationBiotechnologyAnimal science

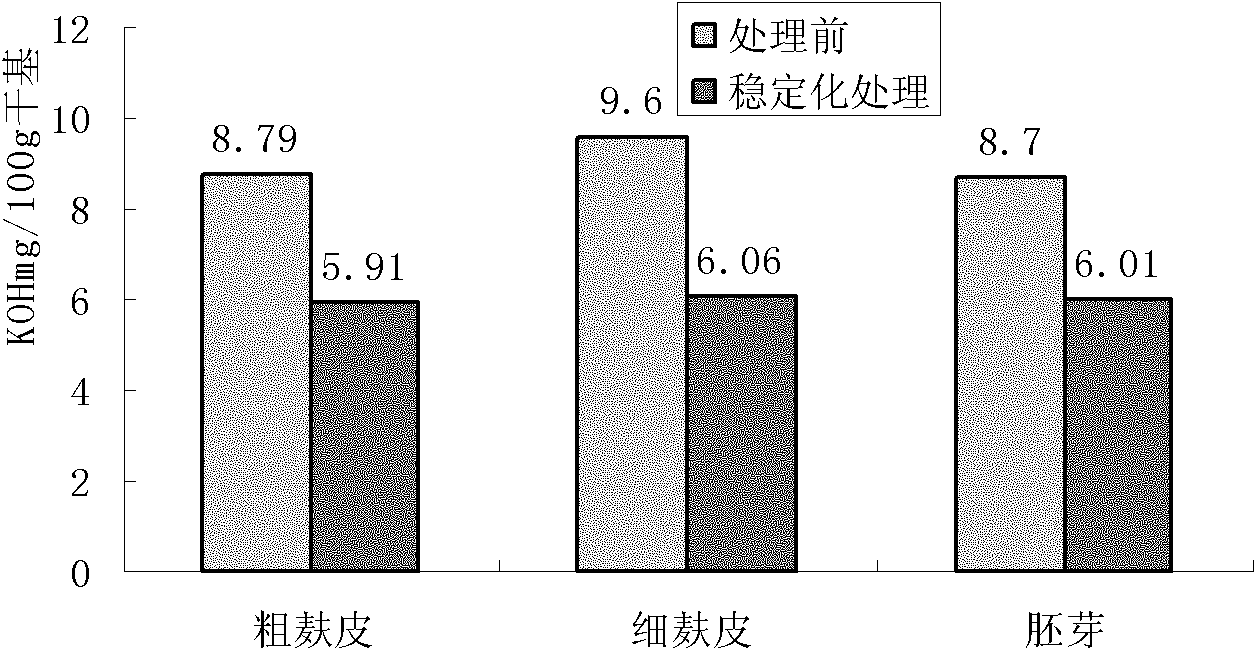

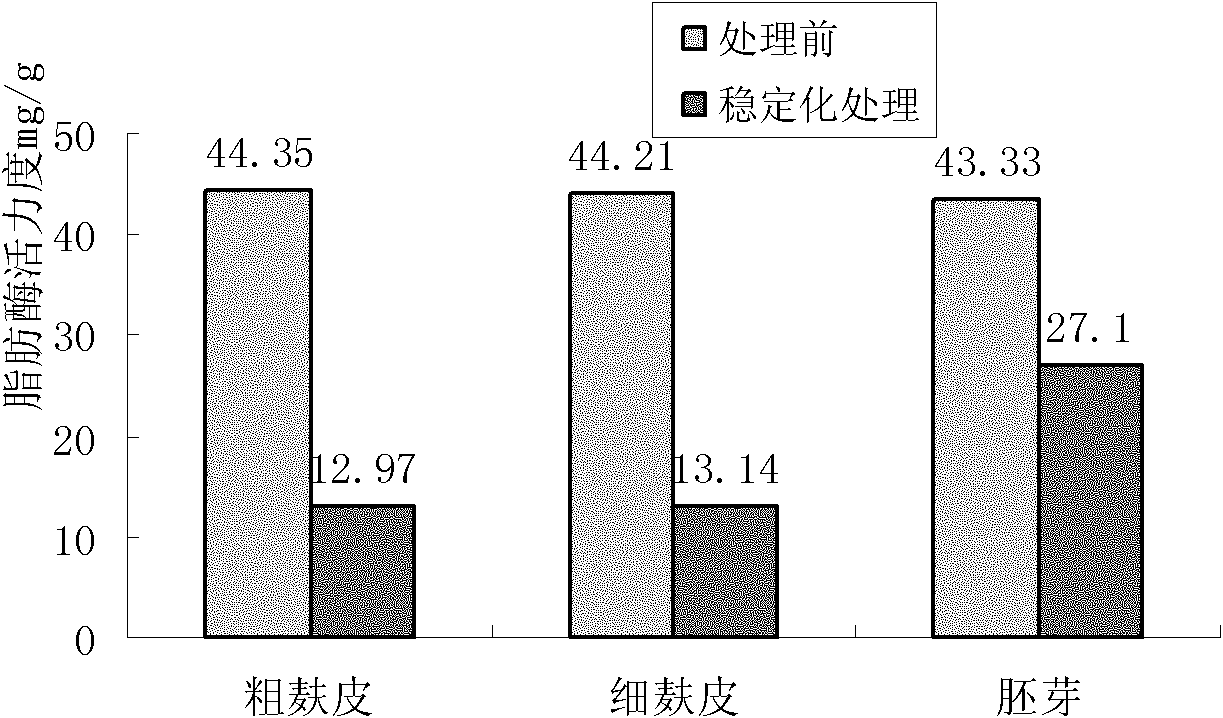

The invention discloses a method for preparing stabilized whole wheat flour, which comprises the following steps of: (1) in the process of processing flour, respectively collecting albumen, embryo and bran; (2) performing stabilization treatment on the bran and the embryo by adopting an extrusion method to obtain an extruded material; (3) drying the stabilized material, crushing (sieving by using an 80-mesh sieve) or performing super micron milling (to make the grain size less than or equal to 74 mu m); and (4) uniformly mixing the albumen obtained in the step (1) with the embryo powder and bran powder obtained in the step (3) in a ratio of the albumen to the embryo to the bran collected in the step (1), and packaging to obtain the stabilized whole wheat flour. By the method, lipase activity and fatty acid content in the bran and the embryo can be effectively reduced, the whole wheat flour product keeps the nutrient components of the natural whole wheat, the storage stability is improved, the flour property and processing and edible quality are improved, and the utilization rate and value-added benefit of wheat are improved.

Owner:ACAD OF STATE GRAIN ADMINISTRATION

Health-care coarse-grain flour, dried noodle, and preparation processes thereof

ActiveCN102349553AGuaranteed not to break downGuaranteed conditioning functionDough treatmentFood preparationBiotechnologyGizzard

The invention discloses health-care coarse-grain flour which is prepared from the following raw materials in parts by weight: (1) coarse cereals: 60-70 parts of wheat, 4-6 parts of corn, 4-6 parts of polished round-grained rice, and 4-6 parts of barley; (2) auxiliary raw materials: 0.2-1 parts of walnut, 0.1-0.8 parts of cattle blood, 0.15-0.6 parts of goose blood, 0.1-0.6 parts of yam, and 0.1-0.8 parts of endodermis of chicken gizzard; meanwhile, the auxiliary raw materials of the health-care coarse-grain flour disclosed by the invention further comprise0.1-0.8 parts of pig blood, 0.1-0.6 parts of edible fungus, 0.2-1 parts of peanuts, and 0.2-1 parts of cassia seeds; in addition, the coarse-grain flour also can comprises 8-12 parts of one of tapioca, broad bean meal, peameal, soybean meal and millet or sorghum flour, or an arbitrary mixture thereof. The invention discloses a process for preparing the health-care coarse-grain flour. Meanwhile, the invention also discloses a health-care coarse-grain dried noodle prepared from the health-care coarse-grain flour above and a preparation process thereof.

Owner:SHEHONG YIMIN FOOD

Production method and application of 3D-whole wheat flour

The invention relates to a production method and application of 3D-whole wheat flour, and belongs to the technical field of food processing. The production process of the 3D-whole wheat flour comprises the six steps of wheat cleaning, wheat wetting and sterilization, milling and sieving, dewatering and dust removal, bran and germ pulverization, and full-component mixed packaging, and the 3D-wholewheat flour is obtained. The 3D-whole wheat flour prepared by means of the production process completely keeps all physiologically active ingredients of each whole grain of wheat, not only contains all nutrients of the germs, endosperm and bran, but also can keep the activity of dietary fibers and be rich in alpha-linolenic acid, enzymes, SOD and other nutrients; moreover, since the 3D-whole wheatflour keeps natural antioxidant components and is packaged in cooperation with nitrogen filling, the 3D-whole wheat flour can be preserved for one year at normal temperature and used for preparing 3D-whole wheat flour noodles, 3D-whole wheat flour steamed buns, 3D-whole wheat flour dumpling wrappers and the like, and is resistant to boiling and freezing, good in taste and high in nutritional value.

Owner:CHONGQING TECH & BUSINESS UNIV +1

Wheat germ healthy food and preparation method thereof

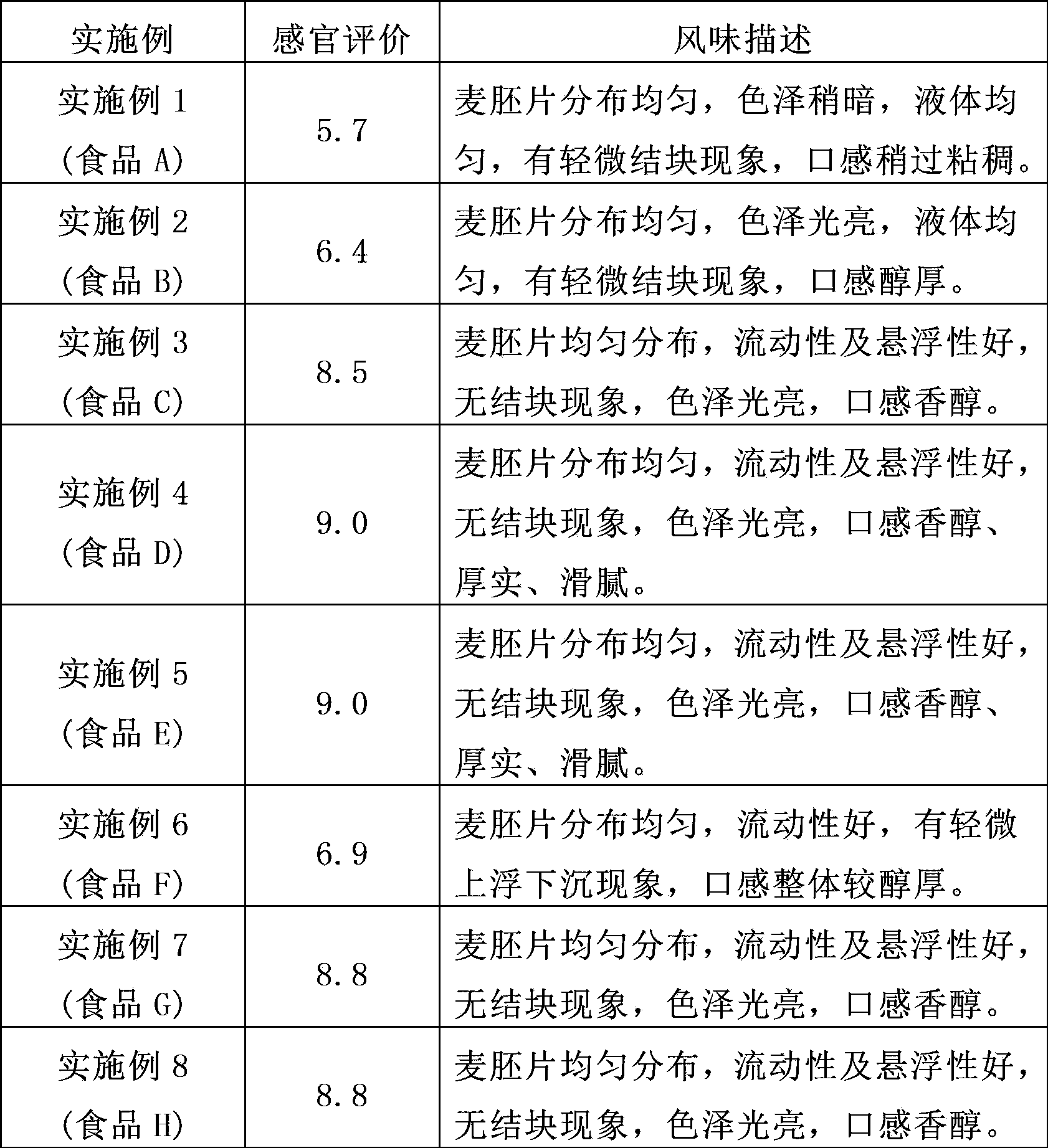

The invention provides a wheat germ healthy food. The wheat germ healthy food is prepared from the following raw materials in parts by weight: 30-70 parts of wheat germ powder, 10-20 parts of maltodextrin, 10-20 parts of milk powder, 1-5 parts of hydroxypropyl-beta-cyclodextrine, 1-10 parts of radix puerariae powder, 0.5-3 parts of inulin, 1-3 parts of red date powder, 1-2 parts of whey protein, 0.5-5 parts of soya bean lecithin, 0.2-1.3 parts of tricalcium phosphate, 0.2-1.3 parts of silicon dioxide, 0.005-0.1 parts of se-enriched yeast, 0.01-0.1 parts of zinc lactate, 1-5 parts of fructo-oligosaccharide, 1-20 parts of white granulated sugar, 1-5 parts of xylitol, 0.01-0.2 parts of neotame, 0.01-0.2 parts of aspartame, 0.02-0.1 parts of vitamin C, 0.02-0.2 parts of vitamin E, 0.05-0.2 parts of beta-carotene, 0.1-0.3 parts of alpha-linolenic acid, 0.01-0.5 parts of sodium alginate, 0.1-2 parts of xanthan gum, and 0.1-2.5 parts of CMC-Na.

Owner:姚德义

Nutritional food, and preparation method thereof

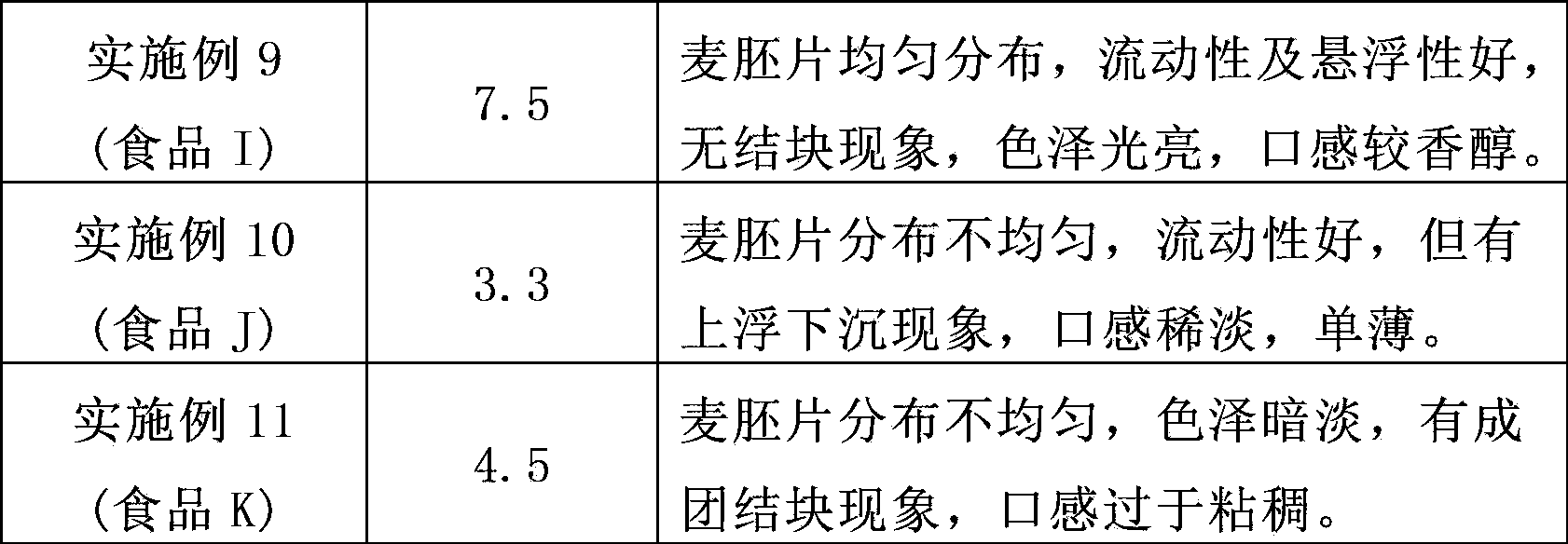

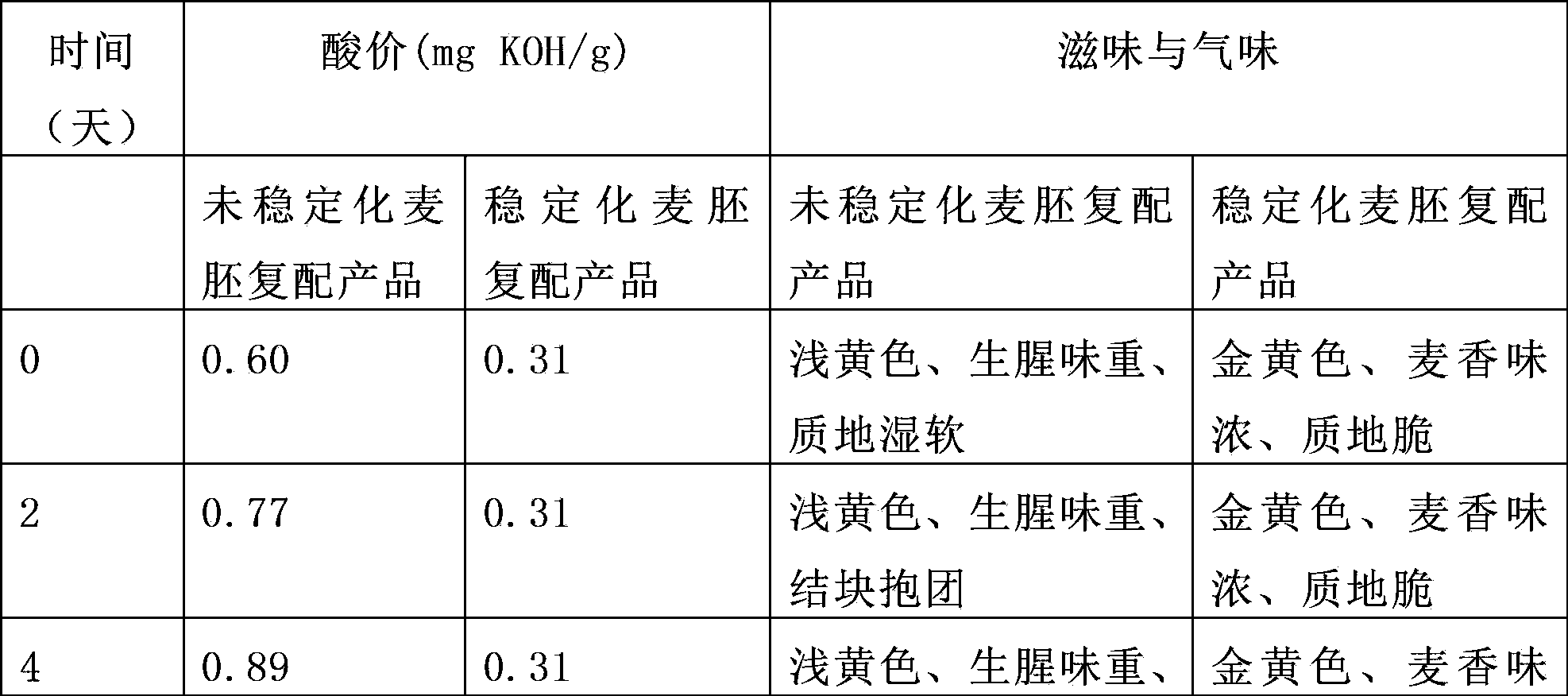

InactiveCN103844249AGreat tasteWith health functionFood shapingFood preparationWheat germSkin protection

The invention provides a nutritional food, and a preparation method thereof. The nutritional food comprises, by weight, 50 to 80 parts of stabilized wheat germ, and 2 to 25 parts of radix puerariae powder. When the nutritional food is mixed with water, mouthfeel is smooth, mellow and thick; color is bright; an uniform liquid is obtained; clustering or caking is not observed; and the nutritional food is capable of realizing face beautifying and skin protection.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Wheat-flavor self-rising flour and production technology thereof

The invention discloses wheat-flavor self-rising flour which comprises the following raw materials, by weight, 98.2-98.5% of wheat flour, 1.2-1.5% of dried yeast and 0-0.6% of a food leavening agent. The wheat flour is processed by using flour with the following parameters: 28-30% of gluten; unit weight is 750-850; unsound grain is less than or equal to 5%; water absorption is 55-60; stabilization time is 6-8 min; softening degree is less than 60; and extensibility is greater than 150. The invention also discloses a production technology of the wheat-flavor self-rising flour. The production technology comprises flour blending process. The method comprises the following steps: firstly, flour, yeast and the food leavening agent are added in batches into a mixer; and a circle-vibrating sieve with larger sieve pore than a minor sifter is used to sieve the mixture after mixing is finished. By selecting specific wheat-processed flour, steamed buns have rich wheat flavor, bright color, fine texture and fine and smooth mouthfeel. As the circle-vibrating sieve with larger sieve pore is used to replace a traditional minor sifter during the flour blending process, blending uniformity of the self-rising flour is greatly raised.

Owner:COFCO CHENGDU GRAIN & OIL IND

Wheat-flavored essence using wheat bran as raw material and preparation method thereof

InactiveCN108041548AAvoid disadvantagesNatural and healthy raw materialsFood scienceHydrolysateFlavoring essences

The present invention discloses a wheat-flavored essence using wheat bran as a raw material. The wheat-flavored essence comprises the following components in parts by weight: 1-3 parts of maltol, 0.25-0.75 part of 2-acetylpyrazine, 0.5-1.5 parts of ethyl maltol and 94.75-98.25 parts of wheat bran hydrolysate. The essence is mainly composed of the wheat bran hydrolysate, maltol, 2-acetylpyrazine and ethyl maltol, has advantages of being natural in raw materials, enables products to be pure and rich in wheat aroma, natural and harmonious in aroma, etc., can be added into various food, solves a problem that current essences use a large amount of organic reagents as solvents, and expands application prospects of a grain by-product of the wheat bran.

Owner:TIANJIN UNIV OF SCI & TECH

Production method of tartary buckwheat coffee

The invention relates to a production method of tartary buckwheat coffee, and belongs to the technical field of food processing. The production method comprises the following steps of (1) primary screening; (2) soaking and cleaning; (3) floating screening, cleaning and dewatering; (4) steam evaporation, and selecting by grading; (5) husk removal and screening; (6) swelling and crushing: swelling standby tartary buckwheat crude embryo husks into a milky yellow viscose glue tubular swelling article in a swelling machine at the temperature of 150 to 200 DEG C; cooling, and grinding into 60 to 100-mesh powder by a powder grinding machine; (7) roasting; (8) inspecting; (9) sterilizing; (10) packaging. The production method has the advantages the produced tartary buckwheat coffee has similar luster, mouth feel and fragrance with the traditional coffee; the produced tartary buckwheat coffee can be used for replacing the traditional coffee, the side effect to a human body due to excessive drinking of coffee or improper drinking is effectively avoided, the health-care function on the human body is enhanced, and the health of a human body is promoted.

Owner:水城县三高荞麦食品有限公司

Coarse food grain flour

The invention discloses a coarse food grain flour having the advantages of simple processing and high nutritional value. The coarse food grain flour is composed of (1) coarse food grain and (2) auxiliary raw materials; wherein the coarse food grain (1) is composed of the following components in parts by weight: 60 to 70 parts of wheat, 2 to 4 parts of black rice, 3 to 5 parts of mung bean, 4 to 6 parts of corn, 4 to 6 parts of sorghum, 4 to 6 parts of barley, and 5 to 15 parts of soybean; and the auxiliary raw materials (2) are composed of the following components in parts by weight: 0.2 to 1 part of walnut, 0.1 to 0.6 part of Chinese yam, 0.2 to 0.6 part of mushroom, 0.5 to 1 part of egg, 0.1 to 0.6 part of agaric, 0.2 to 1 part of peanut, and 0.2 to 1 part of cassia seed. The coarse food grain flour comprises a plurality of coarse food grains, and is capable of guaranteeing the taste of noodles prepared from the provided flour.

Owner:扬州美瑞食品有限公司

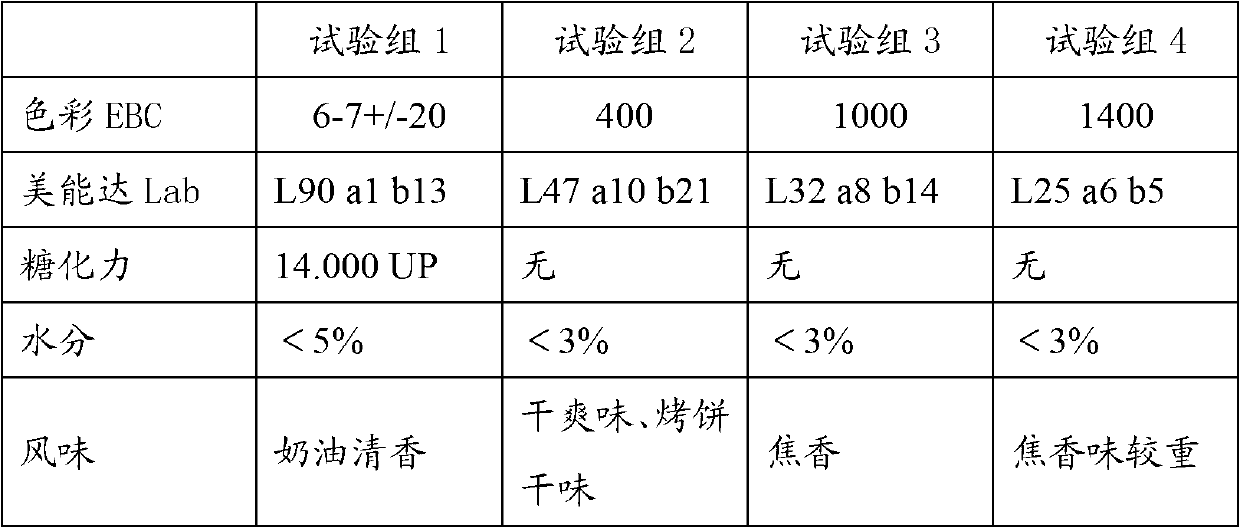

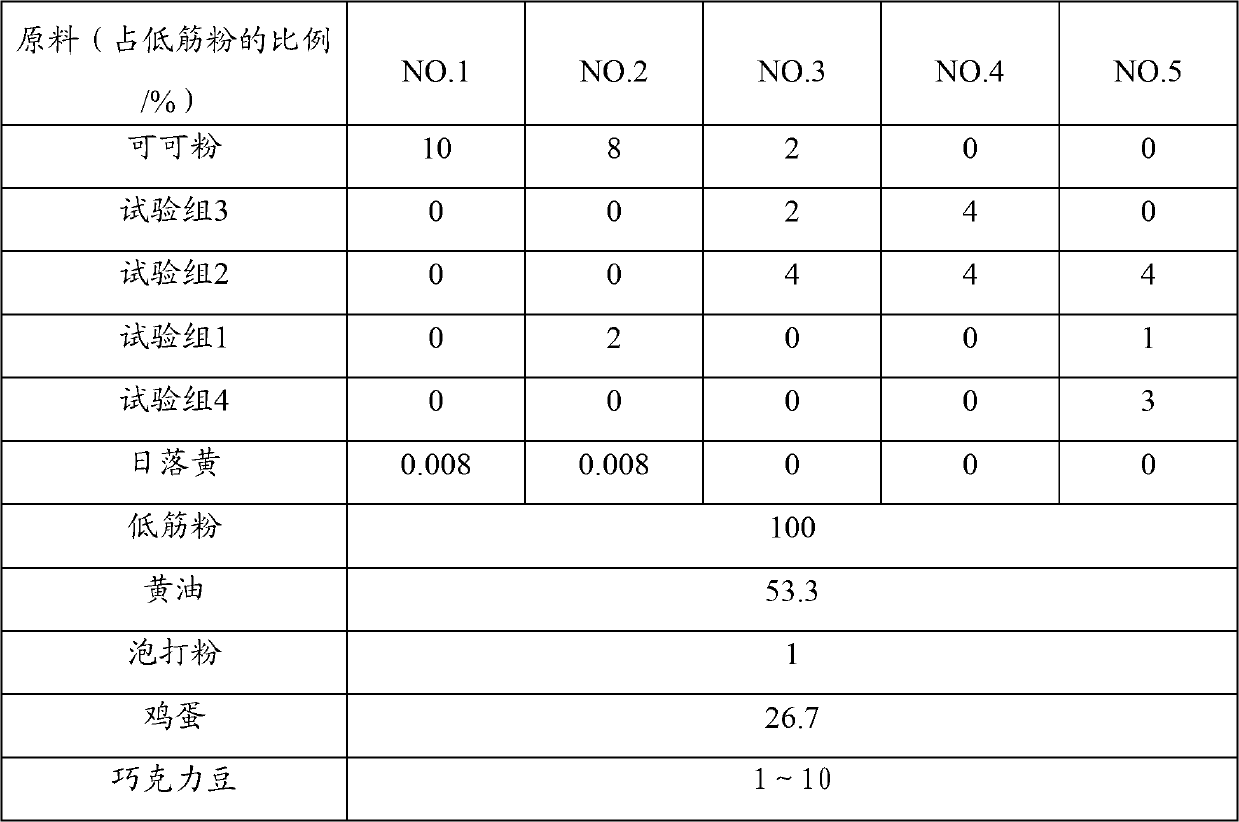

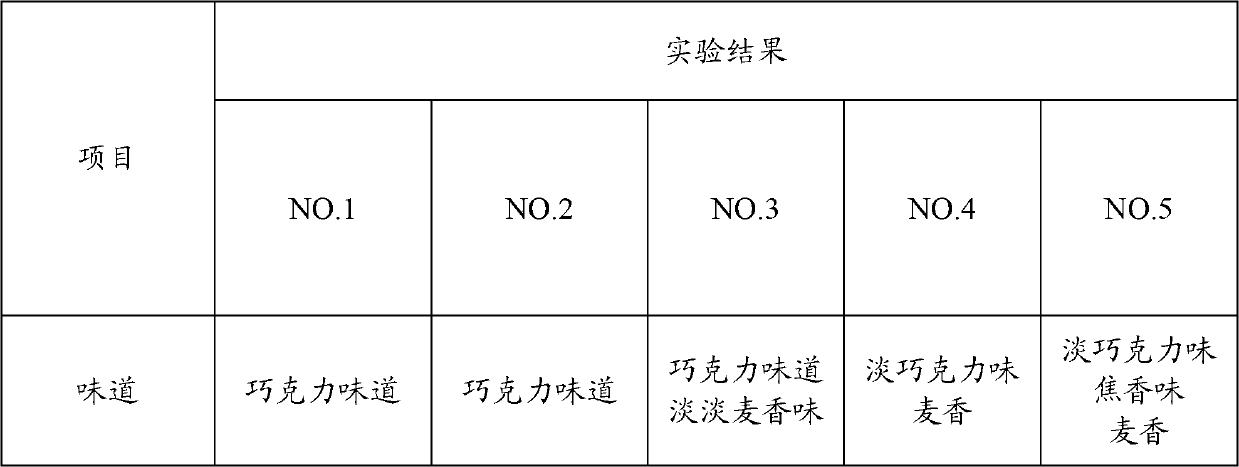

Application of malt flour in manufacturing biscuits and manufacturing method of biscuits

InactiveCN103098852AGood coloring effectStrong umamiDough treatmentBakery productsFlavorColor effect

The invention relates to the field of food processing, and particularly relates to application of malt flour in manufacturing biscuits and a manufacturing method of the biscuits. In the manufacturing process of the biscuits, the malt flour is additionally added, and can realize an ideal color effect by adjusting the additive amount and can replace usage of artificially synthesized pigment. The biscuits can be provided with a plurality of favorite flavors such as wheat smell, coffee smell and chocolate by adjusting the additive amount of the malt flour according to personal hobbies, and therefore requirements of different consumers can be satisfied. Furthermore, the malt flour is conveniently added in the manufacturing process of the biscuits and in the dough kneading process. Thus, the malt flour added in the manufacturing process of the biscuits can prevent damage of oil oxidization. Accordingly, damage to quality of biscuits and health of an eater because of oil oxidization of traditional biscuits is solved, and shelf life of the biscuits is prolonged.

Owner:沈阳科纳提克生物科技有限公司

Human body sub-health state adjusting braised duck and making method thereof

InactiveCN103211239AStrong fragranceGood effect of removing fishy smellFood preparationBiotechnologySweet taste

The invention provides a human body sub-health state adjusting braised duck and making method thereof, which includes the following steps: pulling out and removing gill from belly of an entire duck, washing and draining, kneading with fried salt materials with vacuum, sealing and preserving, placing water and flavoring bags and medicinal diet materials, adding a proper amount of medicinal diet into the abdominal cavity, marinating, packing the duck and soup juice together with vacuum after cooling, and sterilizing the human body sub-health state adjusting duck. The braised duck of the present invention has the advantages of wheat fragrance, yellow color and sweet taste without greasiness, maintained fragrance of the braised duck, and simultaneously increased function for adjusting the human body sub-health state.

Owner:安徽香泉湖禽业有限公司

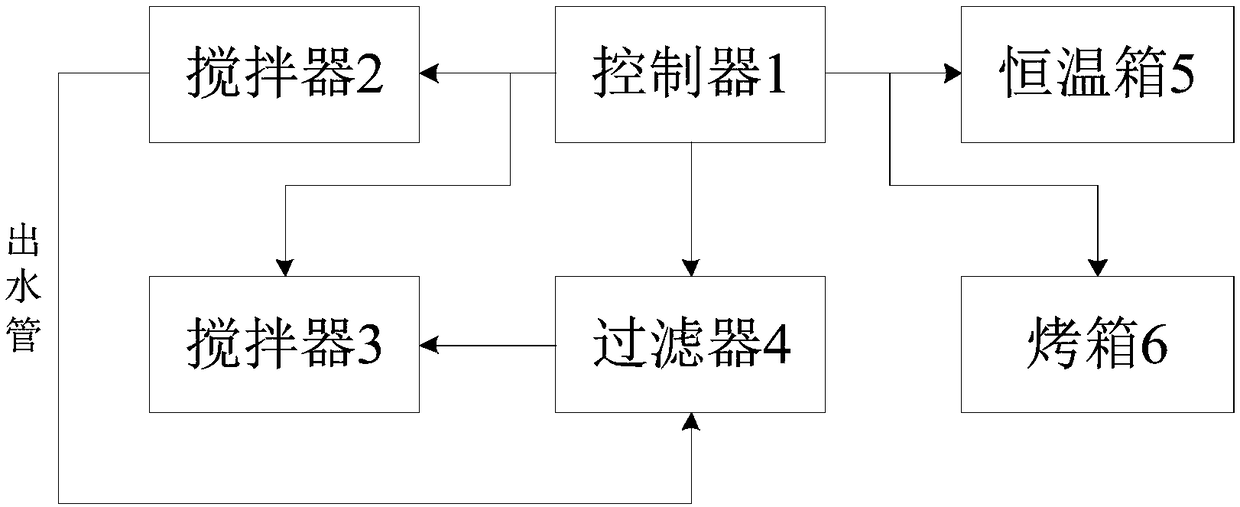

Natural yeast and brown rice bread and preparation method and preparation device thereof

InactiveCN108522609ATight textureEnhance immune functionFungiPre-baking dough treatmentBiotechnologyNutritive values

The invention relates to the technical field of food and discloses a preparation device of natural yeast and brown rice bread. The preparation device comprises a controller, two stirrers, a filter, athermostat and an oven, wherein one stirrer is connected with the filter by virtue of a water outlet pipe, the filter is connected with the other stirrer, and the controller is connected with the twostirrers, the filter, the thermostat and the oven. The invention also discloses the natural yeast and brown rice bread prepared by the preparation device of the natural yeast and brown rice bread. Theinvention also discloses a preparation method of the natural yeast and brown rice bread, and the preparation method comprises the following steps: preparation of a brown rice and natural yeast solution; preparation of brown rice and natural yeast paste; boiling of germinated brown rice; preparation of dough; fermentation; dough standing; flattening; shaping; secondary fermentation; and baking. The prepared natural yeast and brown rice bread can effectively improve the coarse and compact-textured mouthfeel of brown rice, so the brown rice and natural yeast bread has the nutritional values of the brown rice and also can maintain spongy, delicious, mellow and fragrant mouthfeel.

Owner:SUZHOU GARDEN WEIYE FOOD DEV CO LTD

Rice wine potato health-care steamed buns and making method thereof

The invention relates to rice wine potato health-care steamed buns. According to a formula, the steamed buns comprise, by weight, 90-120 parts of flour, 25-35 parts of potato powder, 40-52 parts of water, 35-45 parts of old dough, 4-6 parts of rice wine fermentation liquor, 0.20-0.35 part of sodium carbonate and 0.20-0.30 part of salt. The made buns are good in elasticity and natural white inside and outside, have a strong wheat flavor and a tough and chewy taste, are tasted sweet and overcome the defect that in the prior art, yeast steamed buns adhere to teeth.

Owner:韦殿辉

Preparation method of yeast

ActiveCN106906151AShort fermentation timeEasy to storeFungiYeast food ingredientsSingle crystalSugar

The invention discloses a preparation method of yeast. The preparation method comprises the following steps: successively weighing the following solid substances: steamed bread residue, Chinese koji, high-activity yeast, monocrystal rock sugar and Daqu, wherein the mass ratio of steamed bread residue to Chinese koji to high-activity yeast to monocrystal rock sugar to Daqu is 8:5:3:2:2; weighing liquids including purified water and glutinous rice wine to guarantee that mass ratio of purified water to glutinous rice wine is 5:3; uniformly mixing the liquids and the solid substances according to a certain ratio, putting the mixture into a fermentation tank and fermenting at the constant temperature of 28-30 DEG C for 30 min; successively adding glutinous rice flour or purified water by four steps into the fermented substance, successively fermenting, making the yeast into a pancake, and air-drying in the shade to directly obtain the white, slightly grey yeast which is shaped as glutinous rice flour and has strong mellow fragrance. The yeast is cultivated through five-step fermentation. The yeast is shaped as glutinous rice flour and is convenient to use and store, and the preparation technology is simple.

Owner:王春元

Formula of self-leavening flour and processing method thereof

The invention provides a processing method of a formula of self- leavening flour. The formula comprises the following components in percentage by weight by taking 100 Kg of four as a proportioning unit: 2-2.4% of dough leavening yeast, 0.8-1% of baking soda and 8-10% of dry yellow lees. The processing method comprises the steps of mixing according to weight proportion and then mechanically finely grinding the dough leavening yeast, the baking soda and the dry yellow lees, and adding the sieved mixture of the dough leavening yeast, the baking soda and the dry yellow lees into the flour to be mixed uniformly. The self-leavening flour produced by the invention can not lose efficacy within 180 days, and food steamed with the self-leavening flour has short proofing time, saves time and labor, is bulked, and has good taste and rich wheat flavor.

Owner:HUBEI XIANGFAN JIUKANG GRAIN & OIL

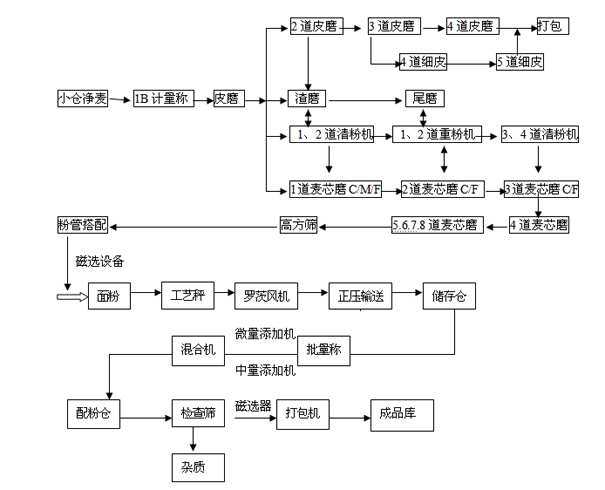

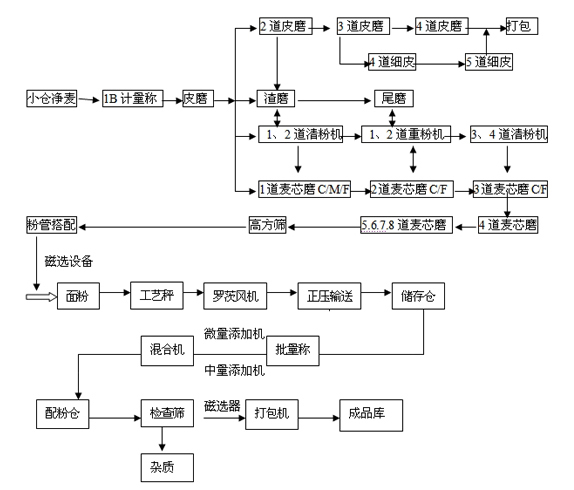

Unflavored steamed bun flour and production method thereof

The invention discloses unflavored steamed bun flour and a production method thereof. The unflavored steamed bun powder contains the following materials by weight percentage: 80-95% of middle-gluten wheat and 5-20% of strong-gluten wheat. The production method of the unflavored steamed bun powder includes the steps of: sieving the materials of wheat, removing the stones contained in the wheat, selecting, separating the buckwheat seeds, washing the wheat, wetting the wheat to get clean wheat, shelling the clean wheat for five times, sizing, tail grinding, purifying the flour for four times, purifying the flour again for two times, and core grinding for eight times. In this way, unflavored steamed bun flour can be obtained. The unflavored steamed bun powder dose not contain any additive, and is pure green food. The steamed bun made of the steamed bun flour has a bright, glossy and pure surface and delicate internal structure, good stiffness, big specific volume, good elasticity and tenacity, fragrant and sweet taste and strong flavor of wheat, and particularly, the steamed bun flour has high water absorption rate and high yield.

Owner:YIJIAYI NATURAL FLOUR

Anti-fatigue naked oat cooked product formed noodles and preparation method thereof

InactiveCN107821955AImprove fatigue resistanceImprove sub-health physiqueFood ingredient functionsBalsamGluten

The invention belongs to the technical field of health-care foods, aims at solving the problems of tedious operations and difficulty in processing in the practical eating process of existing naked oats and provides anti-fatigue naked oat cooked product formed noodles and a preparation method thereof. The anti-fatigue naked oat cooked product formed noodles are prepared by mixing naked oat flour, high gluten wheat flour, sweet potato powder, spirulina powder, table salt, a balsam pear juice, a sea buckthorn juice, a blueberry juice and water according to a certain ratio. After the raw materialsare compounded, the health-care efficacy of resisting fatigue, improving the sub-health constitution and the like of naked oat noodles are improved. The prepared anti-fatigue naked oat cooked productformed noodles are fine and smooth in taste and strong in wheat smell, contains light tastes of sea buckthorns and blueberries at the same time to enable an eater who does not like the naked oat taste to also be capable of accepting the taste, are liable to store and carry, can be formed as well after being soaked and softened again and are suitable for being supplied to the market by small workshops or industrial production of the small workshops.

Owner:解园园

Noodle processing method

The invention discloses a noodle processing method which comprises steps as follows: (1) wheat is cleaned up, aired and then fried to be half-cooked, and the wheat is cooled to the room temperature; (2) the wheat is placed into a mill to be ground into flour, and 88-90% of flour output rate is required; (3) the flour and salt-containing water are placed into a dough mixer to be evenly mixed, and the mass ratio of the flour to the water to salt is 10:(2.8-3):(0.09-0.1); (4) mixed dough is placed into a noodle press to be pressed into a dough sheet; (5) the dough sheet is cut into noodles. According to the method, the wheat is fried to be half-cooked before grinding, the wheat is ground into half-cooked flour which is better in viscosity, and the processed noodles are tough, chewy, boiling-resistant and stronger in wheat aroma.

Owner:王为治

Coffee wholewheat healthcare biscuit

The invention belongs to a field of food processing and specifically relates to a coffee wholewheat healthcare biscuit. The coffee wholewheat healthcare biscuit is characterized by being made from coffee beans, Chinese yam, hawthorn, pumpkin, wholewheat flour, condensed milk, egg, yeast, corn syrup, vegetable oil, salt and granulesten. The biscuit is crispy and delicious, and has a coffee flavor. Compared with biscuit products in the current market, the biscuit provided by the invention is reasonable in nutrition arrangement, so that nutrition balance is improved; the biscuit also has efficacies of refreshing, appetizing, promoting digestion, tonifying spleen, astringe intestine and the like. Through improvement of processing technology, the bitterness of coffee is reduced substantially and not much sugar is needed for flavor adjustment, so that the biscuit becomes healthier. Besides, a problem of cracking proneness is solved, finished product qualification rate is improved and a shortcoming of rough and butter taste of wholewheat flour due to containment of wheat bran is made up distinctively.

Owner:南陵星火众创空间管理有限公司

Anti-cracking quick-frozen hand-grasped pancake and preparation process thereof

PendingCN111631242AKeep the scentKeep the tasteMixing/kneading with horizontally-mounted toolsPre-baking dough treatmentMonoglycerideFatty acid glycerol esters

The invention discloses an anti-cracking quick-frozen hand-grasped pancake and a preparation process thereof. According to the preparation process, through the mode of controlling the water adding amount, the water adding temperature, the oil adding amount and the dough kneading mode, the hand grasping pancake can be chewy, tough, crispy, fragrant and soft; rapid cooling is conducted after oil brushing, so that rapid solidification of mixed oil is promoted, oil loss is reduced, meanwhile, fragrance and taste of the hand-grasped pancake are reserved, and quality of the hand grasping pancake isgood; and the main raw materials of the mixed oil are lard oil and palm oil, and when fatty acid monoglyceride and lecithin are jointly added into the lard oil and the palm oil and stirring is carriedout at a high speed, the obtained mixed oil is good in emulsifying effect and is free of layering, so that the quick-frozen hand-grasped pancake made from the mixed oil is not prone to cracking. According to the preparation process, dough kneading and pressing equipment is used for uniformly mixing raw materials, so that the obtained dough is good in chewiness, quality of the hand-grasped pancakeis further improved, meanwhile, working efficiency is improved, and production cost is reduced.

Owner:安徽省皖美食品有限公司

Bean-flavor flour

InactiveCN107198091AGuaranteed not to break downGood for healthFood ingredient as flavour affecting agentFood ingredient as mouthfeel improving agentBiotechnologyNutritive values

The invention discloses bean-flavor flour, and provides the bean-flavor flour with simple process and high nutrition value. The bean-flavor flour is prepared from, by weight, (1) main material: 60-70 parts of wheat, 2-4 parts of bean, 3-5 parts of broad bean, 4-6 parts of pea, 4-6 parts of sorghum, 4-6 parts of barley, and 5-15 parts of mung bean; (2) assistant raw material: 0.2-1 part of walnut, 0.1-0.6 part of yam, 0.2-0.6 part of ginseng, 0.5-1 part of egg, 0.1-0.6 part of agaric, 0.2-1 part of peanut and 0.2-1 part of semen cassia. The bean-flavor flour takes multiple cereals and high-quality bean as main raw materials, thus the taste of flour and flour product obtained subsequently is guaranteed.

Owner:戴建诚

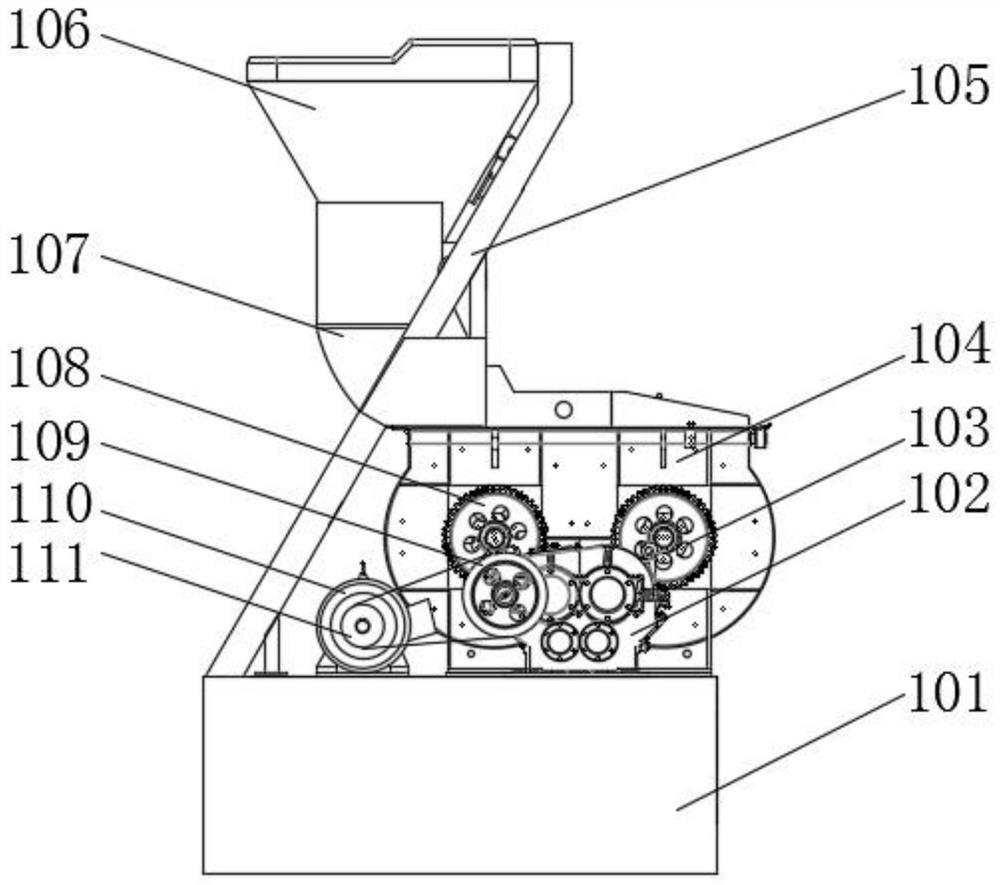

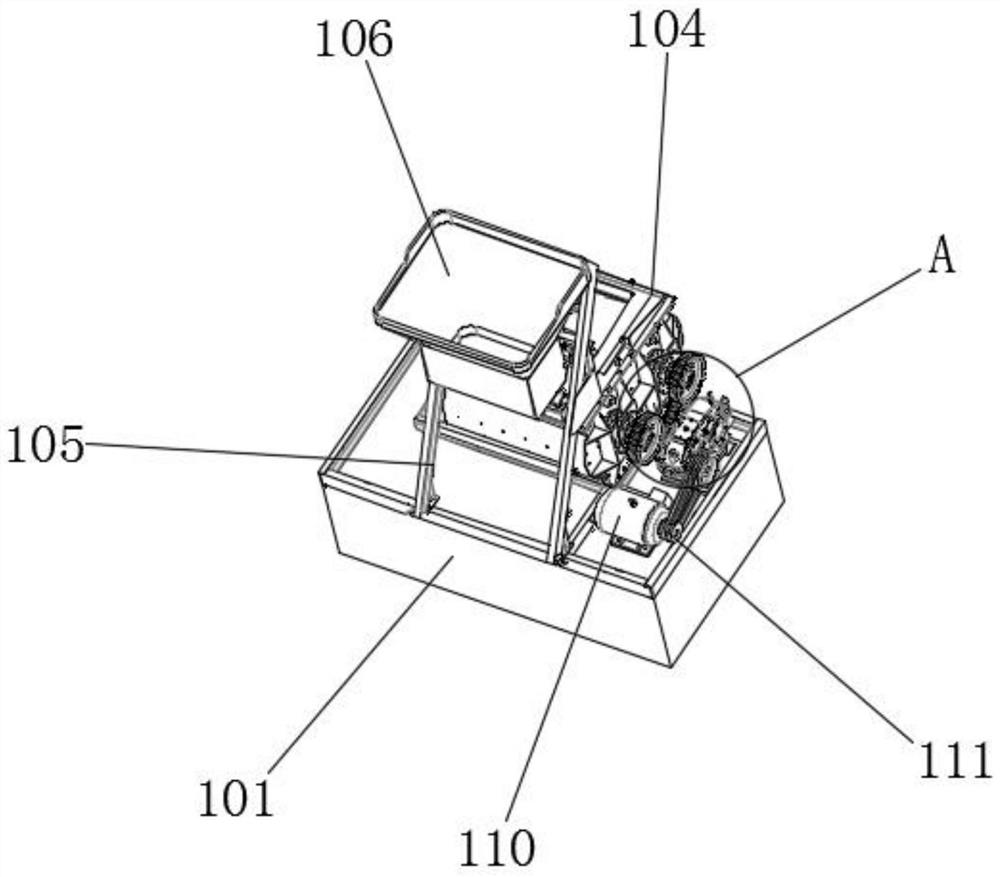

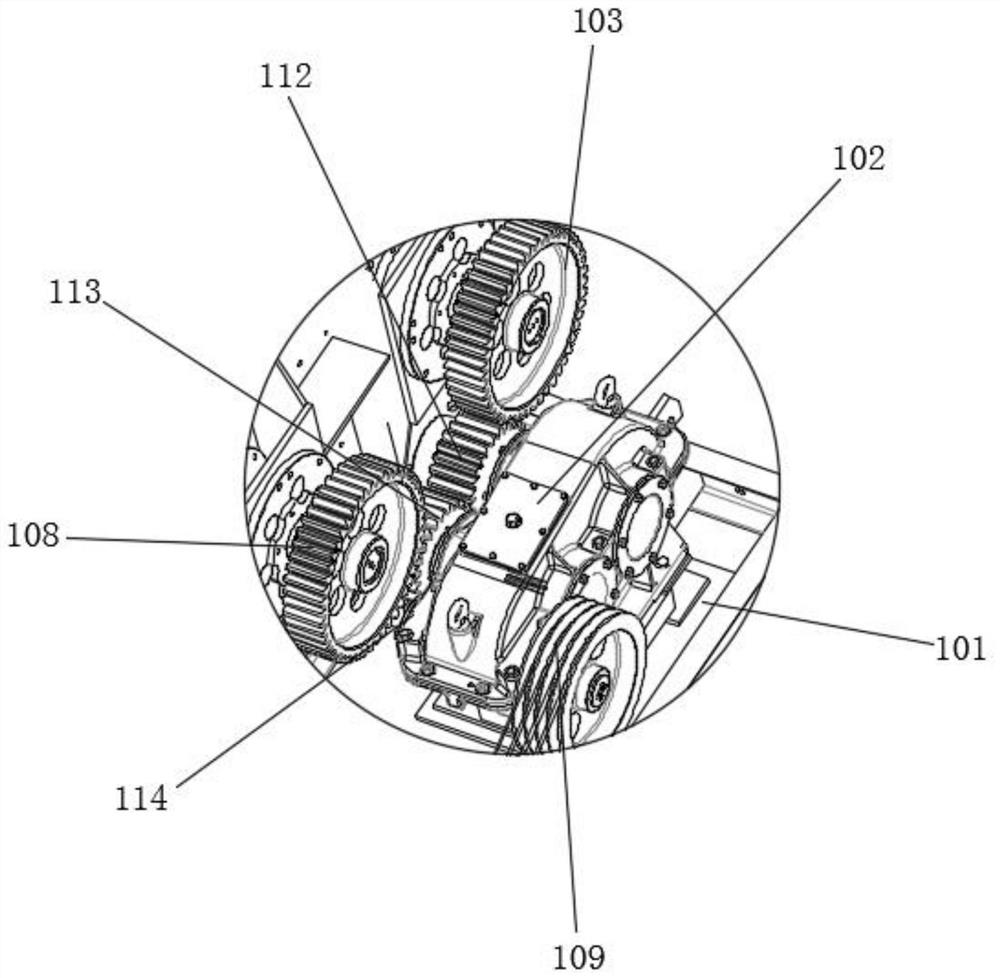

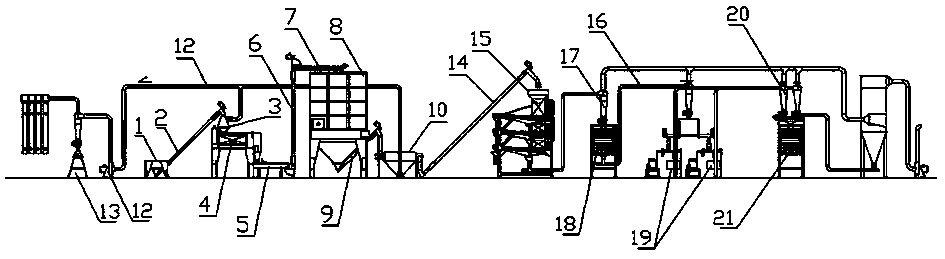

Production process of whole wheat flour prepared by stone mill

The invention discloses a production technology of whole wheat flour by using a stone mill. The production technology is characterized in that wheat grains are fed by a feeding hopper, and are conveyed to an air separator through an oblique shaftless screw conveyor and impurities like shells and straw are removed, then the wheat grains enter a cylinder cleaning sieve for cleaning, the cleaned wheat grains are mixed with water uniformly through a dampening auger, and then a mixture is conveyed a stock bin for wheat wetting temporary storage; and the wetted wheat grains are conveyed to a wheat brushing machine for wheat brushing treatment, then the wheat grains after the wheat brushing treatment are conveyed to a steel flour mill for precrushing treatment twice, then the wheat grains after the precrushing treatment are conveyed into a cyclone unloader and are unloaded to a first minor sifter for classification sifting, a part of front extraction powder is obtained, the rest material is conveyed to the stone mill to be further milled, the material milled by the stone mill is unloaded to a second minor sifter through the cyclone unloader for sifting, and finished whole wheat flour is obtained. The production technology has the advantages that the advantages of a large flour milling technology and the existing stone mill milling technology are integrated, the material is conveyed by pneumatic conveying and the oblique shaftless screw conveyor throughout, the production technology is flexible, the structure is simple, and the design is reasonable.

Owner:河南天香面业有限公司

Processing method of self-leavening flour

The invention provides a processing method of a formula of self- leavening flour. The formula comprises the following components in percentage by weight by taking 100 Kg of four as a proportioning unit: 2-2.4% of dough leavening yeast, 0.8-1% of baking soda and 8-10% of dry yellow lees. The processing method comprises the steps of mixing according to weight proportion and then mechanically finely grinding the dough leavening yeast, the baking soda and the dry yellow lees, and adding the sieved mixture of the dough leavening yeast, the baking soda and the dry yellow lees into the flour to be mixed uniformly. The self-leavening flour produced by the invention can not lose efficacy within 180 days, and food steamed with the self-leavening flour has short proofing time, saves time and labor, is bulked, and has good taste and rich wheat flavor.

Owner:HUBEI XIANGFAN JIUKANG GRAIN & OIL

Improver of flour for fresh-wet noodles and flour for fresh-wet noodle

The invention discloses an improver of flour for fresh-wet noodles and meanwhile also discloses flour for the fresh-wet noodles, to which the improver is added. The improver is prepared from the following raw materials in weight percent: 7 to 15 percent of vitamin C, 20-40 percent of trigonella bean gum, 0.5-1.5 percent of azodicarbonamide, 25-35 percent of monopotassium phosphate, 1-3 percent ofpotassium hydrogen tartrate and 20-40 percent of starch. Various fresh-wet noodles made of the flour for the fresh-wet noodles, such as alkaline fresh-wet noodles, beans-made fresh-wet noodles and the like, have bright and pure color, long preservation time, fine and smooth and slippery mouth feel, strong wheat flavor, good palatability and rich nutrition and can not generate invert color or brown after being put for long. The flour for the fresh-wet noodles is suitable for use in the industrial production of the noodles and meanwhile is also the household flour of family life.

Owner:郑州天地人面粉实业有限公司

Preparation method of wheat fragrance nutritional health-care shredded squid

InactiveCN106262029AEasy to prepareDelicious productFood ingredient as taste affecting agentNatural extract food ingredientsHerbFlavor

The invention discloses a preparation method of wheat fragrance nutritional health-care shredded squid. The preparation method of the wheat fragrance nutritional health-care shredded squid, disclosed by the invention, is simple; the wheat fragrance nutritional health-care shredded squid is delicious in taste and strong in wheat fragrance, has the efficacy of promoting appetite, covering the fishy smell of squid and has high product yield; by adding haraella retrocalla leaf and sweet basil herb, a health-care effect of the product is increased while the palatability of the product is rendered; by adding origanum vulgare herb, the delicate flavor of a marine product is improved; meanwhile, an antioxidant effect is enhanced.

Owner:汪恒森

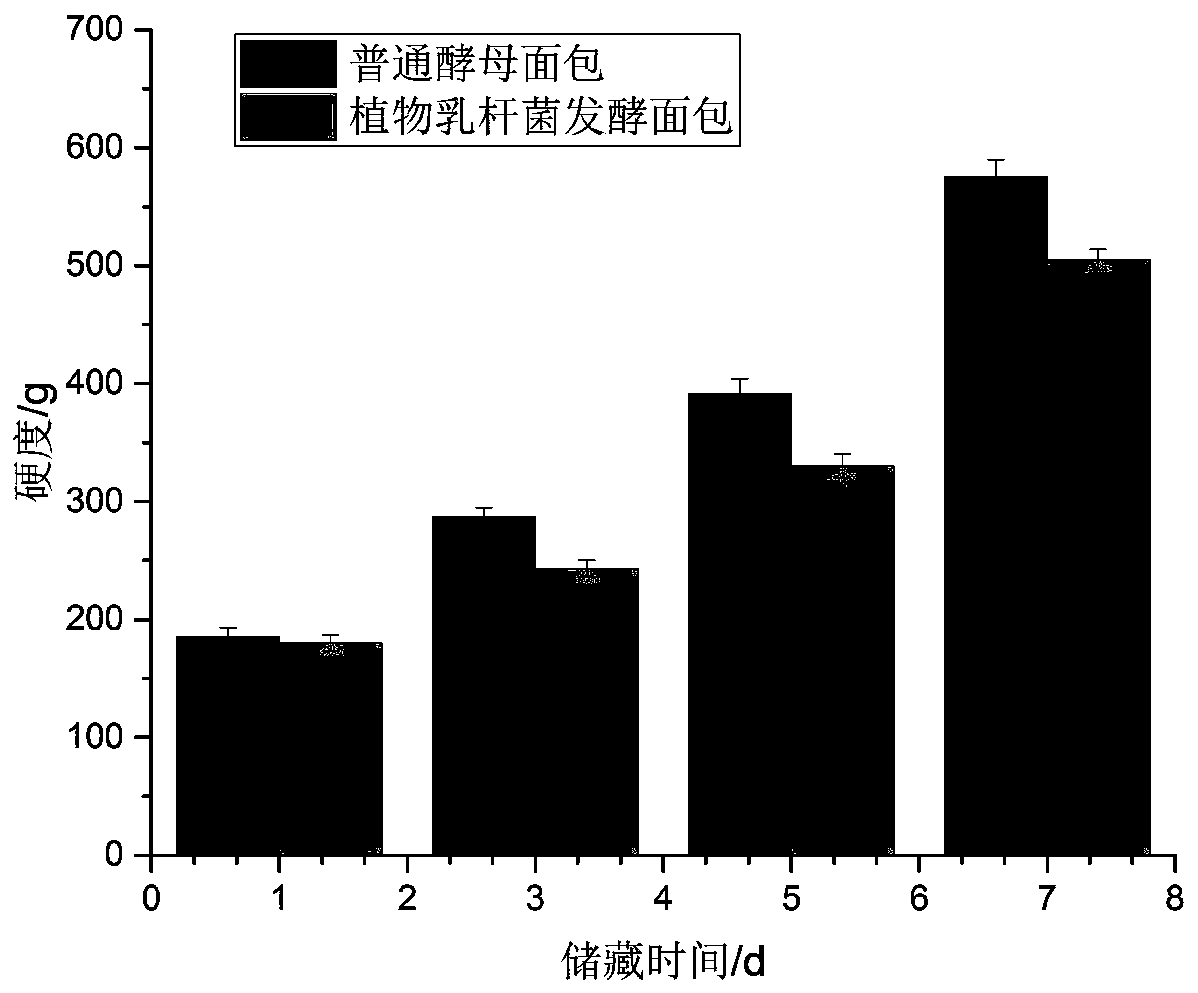

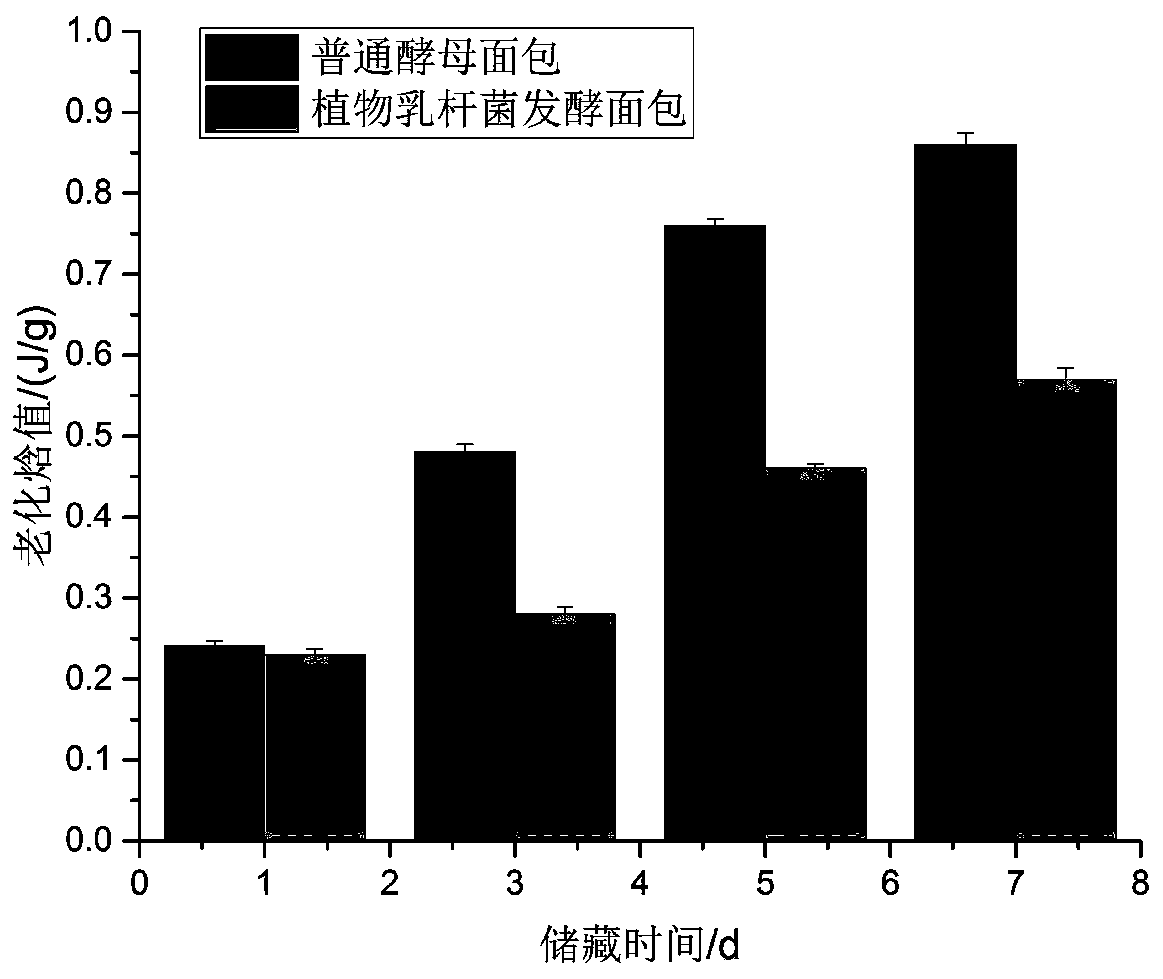

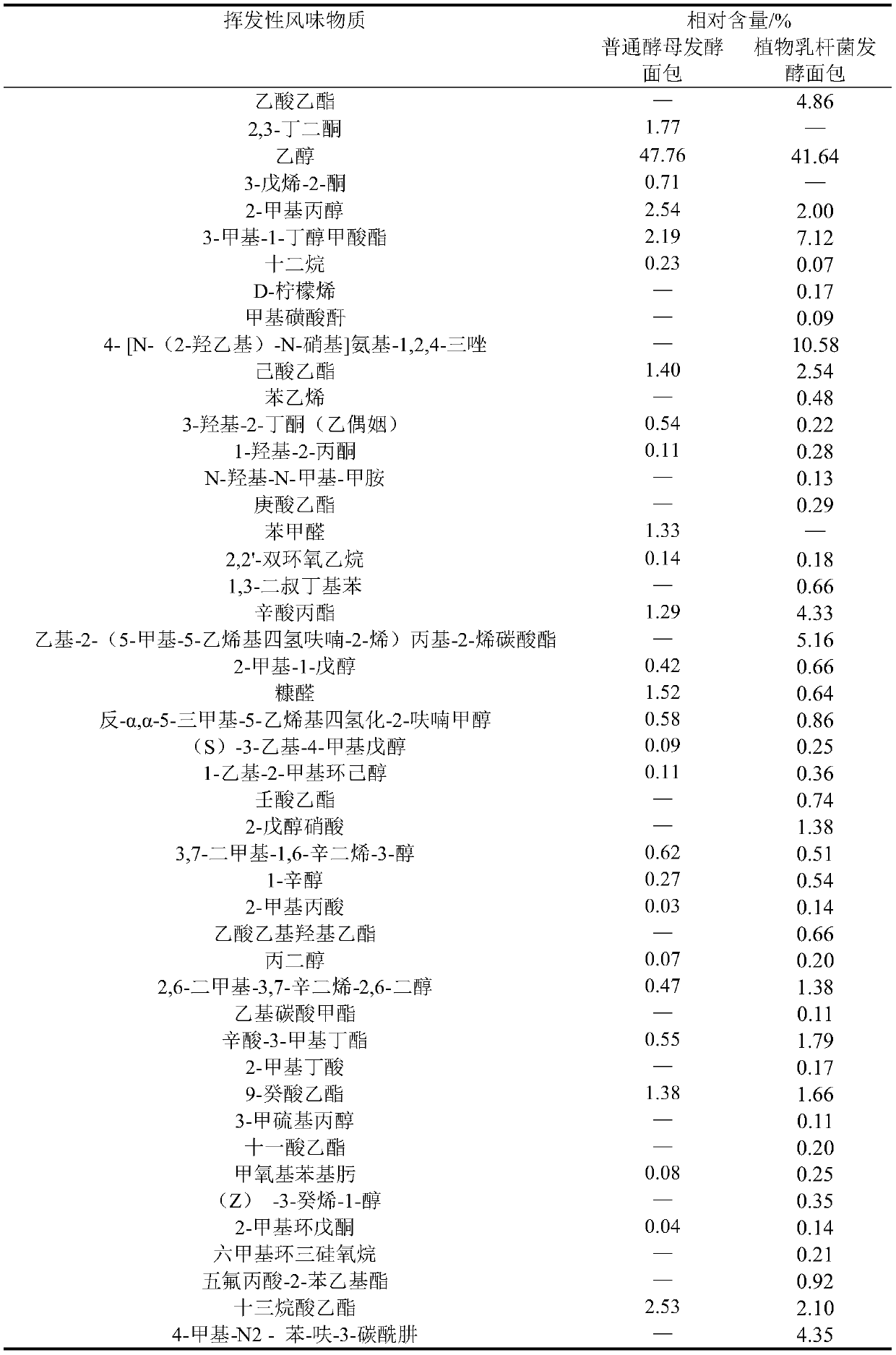

A strain of Lactobacillus plantarum and its application

ActiveCN106434460BExtended shelf lifeModerate acidity, not irritatingBacteriaPre-baking dough treatmentMicroorganismFlavor

The invention discloses a plant lactobacillus and application thereof, belonging to the technical field of food microbes. The Lactobacillus plantarum WJ-02 (Lactobacillus plantarum WJ-02) has been preserved in the China Center for Type Culture Collection on July 20, 2016, and the preservation number is CCTCC NO: M 2016406. When the strain assists the fermentation of yeast, it has the advantages of improving the quality of fermented pastries and increasing the types and contents of flavor substances, and can extend the shelf life of prepared bread from 5 days to 14 days, significantly prolonging the shelf life and effectively improving the flavor of bread. In the field of food and health care.

Owner:JIANGNAN UNIV

Making method of whole wheat-pea jelly

The invention relates to whole wheat-pea jelly and a processing technique thereof, and particularly discloses a making method of the whole wheat-pea jelly. The processing technique comprises the following steps of (1), raw material proportioning: weighing whole wheat flour, pea starch, drinking water and sodium carbonate, and swelling the pea starch by using warm water for later use; (2), preparation of starch fluid: washing the whole wheat flour by using water to obtain starch fluid; (3), mixing and pouring into a pot: preheating a thick-bottom pot, then applying a small amount of boiled oil at a bottom, completely pouring the washed starch fluid into the pot, next, pouring dissolved sodium carbonate water and the swelled pea starch into the pot, finally, adding a proper amount of the water, and uniformly agitating; (4), heating and decoction: starting heating and increasing heat power, continuously agitating until the viscosity rises after the starch fluid is gelatinized, and decreasing the heat power; (5): taking out from the pot: stopping heating when the starch fluid is increased to a certain extent in viscosity and deepened in color and luster and becomes glossy and further hot air is continuously given off from a liquid level, moving out and holding in a stainless steel basin or bowl, cooling, solidifying, then slitting or slicing, coldly dressing with sauce, and taking as food.

Owner:EASTERN GANSU UNIVERSITY

Five-cereal yellow rice cake and making method thereof

InactiveCN106107527AUnique tasteGreat tasteFood ingredient as flavour affecting agentFood ingredient as mouthfeel improving agentTriticum turgidumSugar

The present invention discloses five-cereal yellow rice cake and a making method thereof, and the five-cereal yellow rice cake is made with, by weight: 80-90 parts of glutinous rice, 5-10 parts of short-grain rice, 6-10 parts of soybean, 6-10 parts of sorghum, 6-10 parts of tender corn kernels, 6-10 parts of wheat, and 5-8 parts of brown sugar. The yellow rice cake made herein has unique and good taste, rarely hardens and is deeply popular with different consumers.

Owner:GUIZHOU WENGAN COUNTY HOUCHANG ZUOS FOOD

Production method of oat-pea bean jelly

InactiveCN107319506AReduce grinding timesStrong fragranceFood ingredient as mouthfeel improving agentWarm waterViscosity

The invention relates to a production method of oat-pea bean jelly. A processing technique of the production method comprises the following steps: (1) preparing raw materials: weighing oat powder, wheat core powder, pea starch, drinking water and sodium carbonate, and swelling the pea starch for later use; (2) preparing starch liquid: respectively washing the wheat core powder and the oat powder to obtain starch liquid; (3) mixing starch liquid into a pot: preheating a thick-bottom pot, adding a small amount of clean oil, pouring all the washed starch liquid into the pot, pouring dissolved sodium carbonate water and the swelled pea starch into the pot, finally adding a proper amount of water, and uniformly stirring; (4) heating for decoction: starting to heat, opening a big fire, continuously stirring until the starch liquid is gelatinized and the viscosity is increased, and opening a small fire; and (5) discharging: stopping heating when the viscosity of the starch liquid is increased to a certain degree, the starch liquid is darkened and glossy and hot air is continuously given off from the liquid level, taking out the starch liquid, putting the starch liquid into a stainless steel pot or bowl, standing for cooling and solidification, carrying out slitting or slicing, and coldly stirring with sauce for eating.

Owner:EASTERN GANSU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com