Production process of whole wheat flour prepared by stone mill

A production process and technology for whole wheat flour, which is applied in the field of stone grinding to prepare whole wheat flour production technology, can solve the problems of high processing cost, high maintenance intensity, high labor intensity and the like, and achieve the effects of high quality, food hygiene and safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

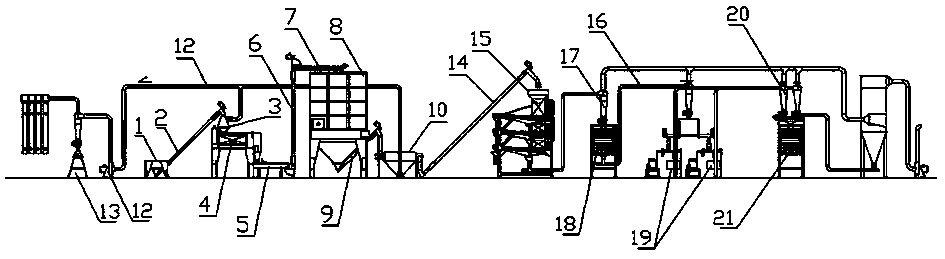

[0010] like figure 1 As shown, the stone mill of the present invention prepares the whole wheat flour production process, the wheat grain is fed into the feeding hopper 1, and is transported to the winnowing device 3 by the inclined shaftless screw conveyor 2 to remove the shell and rod impurities, remove the shell, The wheat grains with rod-like impurities enter the cylindrical cleaning sieve 4 for cleaning, and the cleaned wheat grains are mixed evenly by adding water through the water auger 5 (due to the different moisture content of the raw grains, the weight p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com