Anti-cracking quick-frozen hand-grasped pancake and preparation process thereof

A preparation process and technology of finger cakes, which are applied in the field of anti-cracking quick-frozen finger cakes and their preparation, can solve the problems of easy cracking, poor integrity, and affecting appearance, etc., and achieve the goal of not easy cracking, no delamination, and reduced oil loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

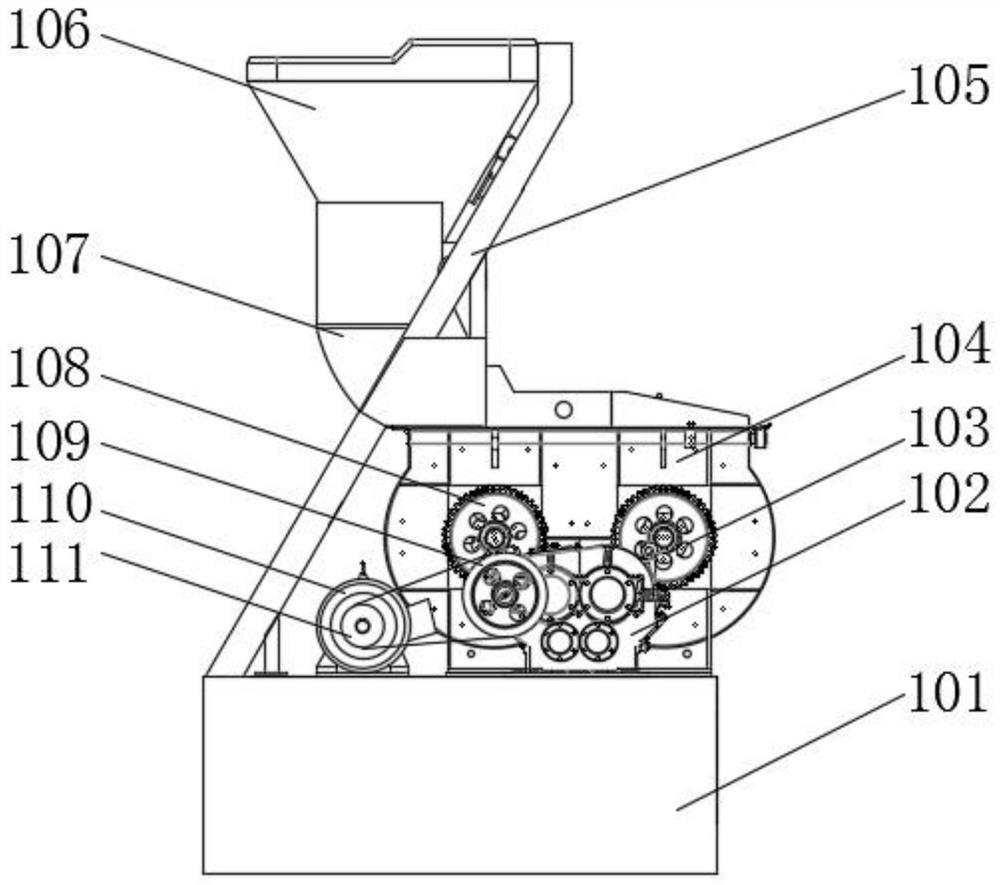

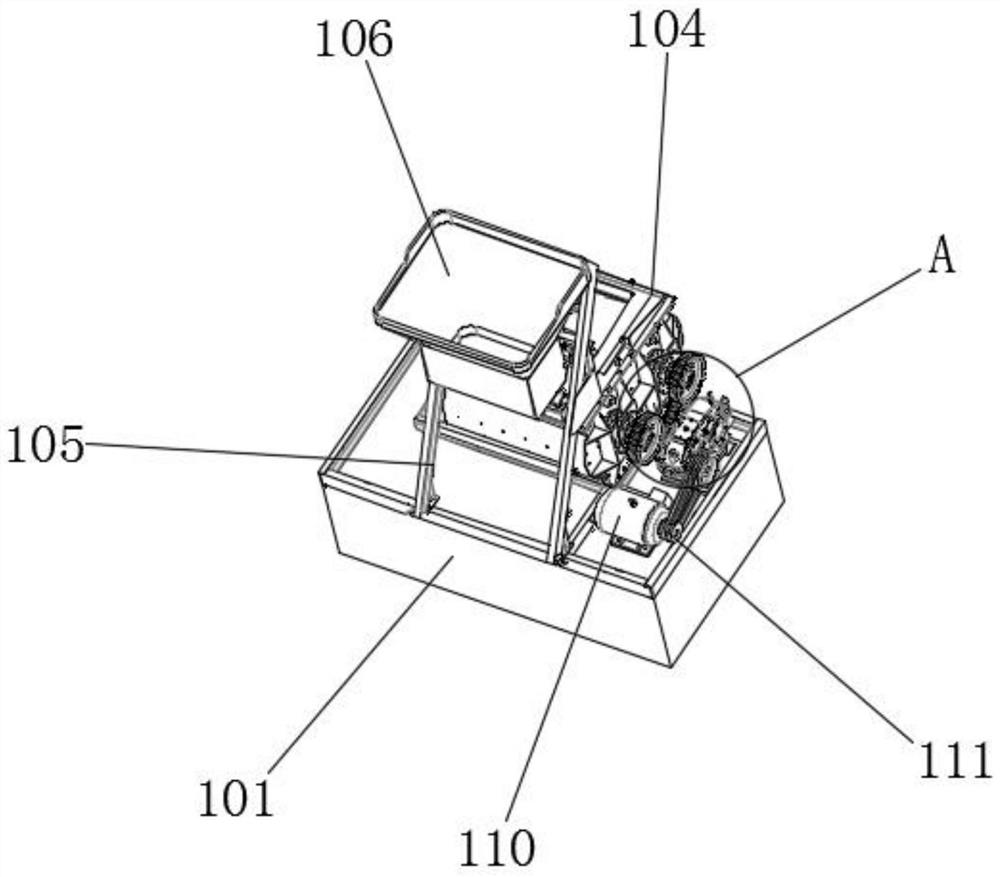

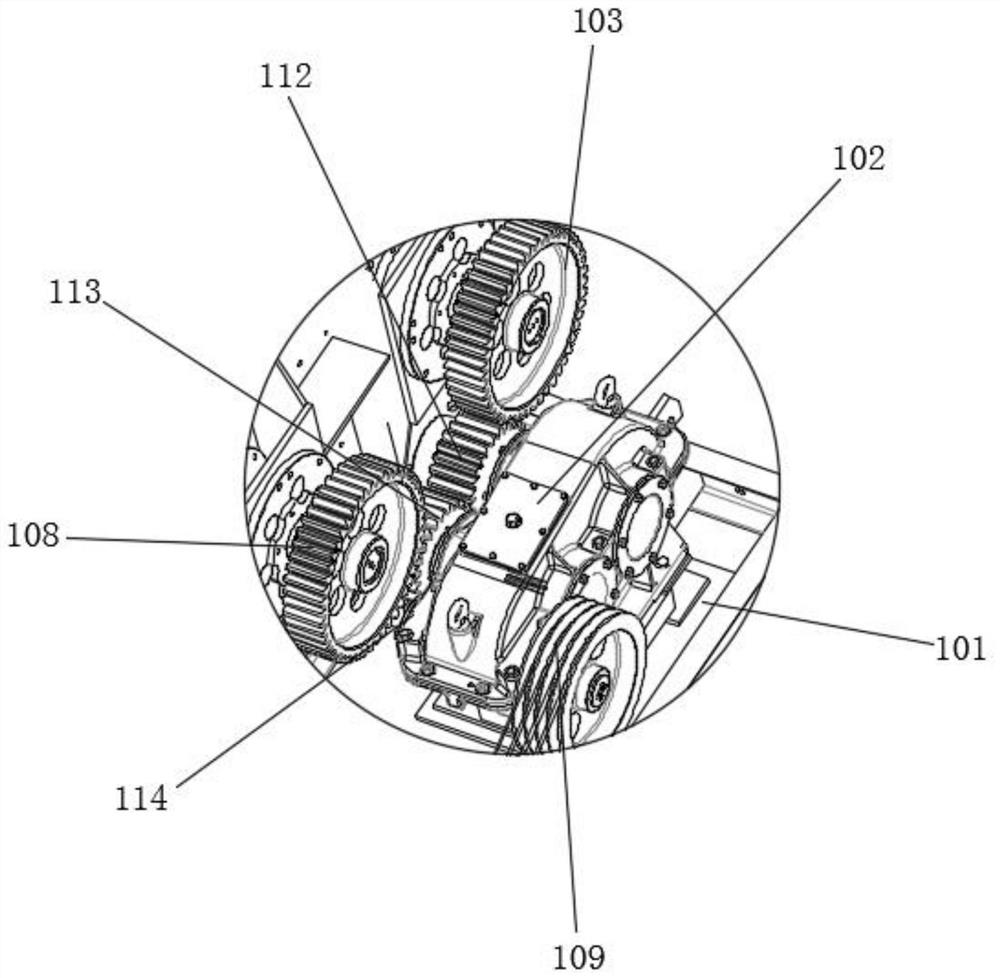

[0056] see Figure 1-7 As shown, the present embodiment is an anti-cracking quick-frozen finger cake, comprising the following components in parts by weight: 190 parts of all-purpose flour, 15 parts of tapioca modified starch, 35 parts of lard, 15 parts of palm oil, 3 parts of salt, 3 parts of white sugar 1 part of chicken essence, 1.5 parts of vitamin E, 5 parts of shallot, 3 parts of sesame, 0.1 part of ginger, 0.2 part of white radish, 0.4 part of onion, 0.2 part of pepper, 0.3 part of sodium hexametaphosphate, 0.1 part of monoglyceride 0.1 part of lecithin and 125 parts of water;

[0057] The anti-cracking quick-frozen finger cake is prepared by the following steps:

[0058] Step 1, the preparation of mixed oil:

[0059] Heat lard to 125-135°C, mince ginger, white radish and onion, put them into lard together with Chinese prickly ash and boil for 12-18 minutes, filter to remove the residue in the oil, and continue heating lard to 155-165°C , then after cooling for 15-20...

Embodiment 2

[0087] see Figure 1-7 As shown, the present embodiment is an anti-cracking quick-frozen finger cake, comprising the following components in parts by weight: 200 parts of all-purpose flour, 30 parts of tapioca modified starch, 65 parts of lard, 30 parts of palm oil, 5 parts of salt, and 5 parts of white sugar 2 parts of chicken essence, 2.5 parts of vitamin E, 7 parts of shallot, 5 parts of sesame, 0.3 part of ginger, 0.3 part of white radish, 0.6 part of onion, 0.3 part of pepper, 0.4 part of sodium hexametaphosphate, 0.3 part of monoglyceride part, 0.3 part of lecithin and 135 parts of water;

[0088] The anti-cracking quick-frozen finger cake is prepared by the following steps:

[0089] Step 1, the preparation of mixed oil:

[0090] Heat lard to 125-135°C, mince ginger, white radish and onion, put them into lard together with Chinese prickly ash and boil for 12-18 minutes, filter to remove the residue in the oil, and continue heating lard to 155-165°C , then after coolin...

experiment example 1

[0118] experimental method:

[0119] The anti-cracking quick-frozen finger cakes of Example 1 and Example 2 were grilled on-site in an oven, and 100 people were randomly selected to eat the finger cakes that had just been taken out of the oven, and then the appearance, smell, and taste were evaluated. The full score is 10 points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com