Unflavored steamed bun flour and production method thereof

A technology of steamed bread powder and raw materials, which is applied in the field of flour processing, can solve the problems of endangering human health, excessive additives, and low pass rate of spot checks, etc., and achieve the effect of good standing, high yield, and pure luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

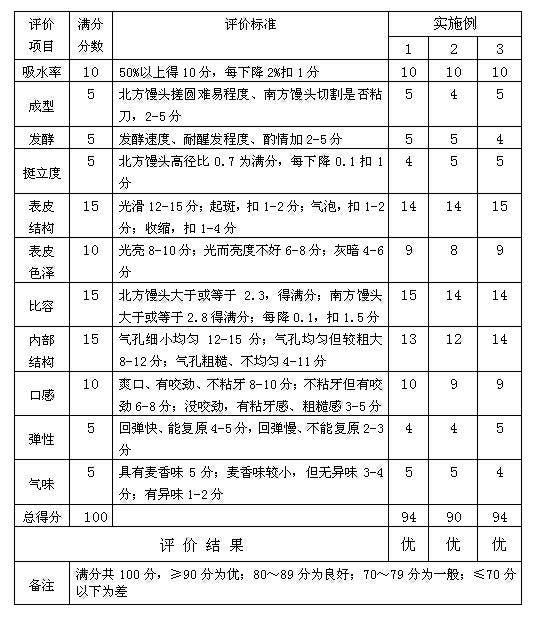

Embodiment 1

[0015] The original steamed bun powder is made of the following raw materials in weight percentage: 80% of medium-gluten wheat and 20% of strong-gluten wheat. The whiteness of medium-gluten wheat is 61, the gluten is 27%, the hardness rate is 20%, the water absorption rate is 61%, the degree of weakening is 100BU, the resistance is 400BU in 135 minutes, the farinity index is 70, and the stretching area in 135 minutes is 100cm 2 , 135 minutes elongation 140mm. The whiteness of strong gluten wheat is 60, the gluten is 32%, the hardness rate is 80%, the water absorption rate is 67%, the degree of weakening is 30BU, the resistance is 480BU in 135 minutes, the farinity index is 80, and the tensile area in 135 minutes is 140cm 2 , 135 minutes elongation 180mm.

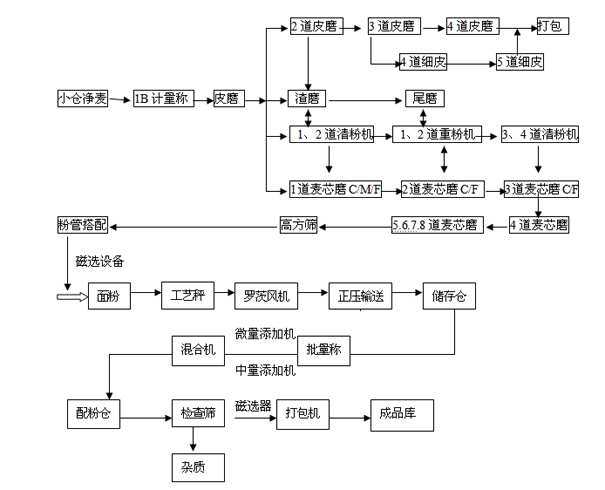

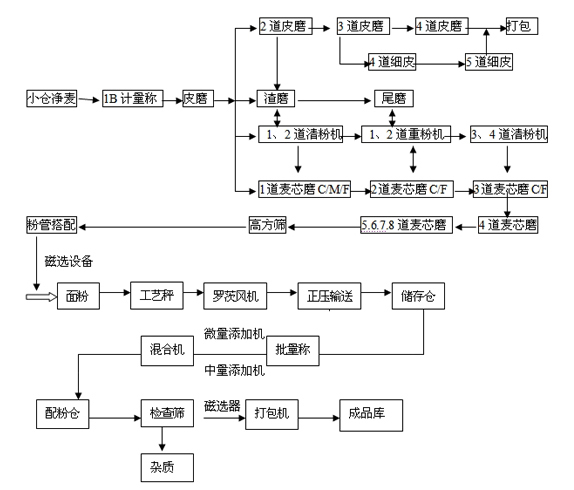

[0016] The production method of the original steamed bun powder: After the raw wheat is mixed, it is sieved, stone-removed, selected, buckwheat thrown into a car, washed, and moistened to obtain clean wheat, which is then s...

Embodiment 2

[0018] The original steamed bun powder is made of the following raw materials in percentage by weight: 95% of medium-gluten wheat and 5% of strong-gluten wheat. Whiteness of medium-gluten wheat is 69, gluten 29%, hardness 30%, water absorption 63%, weakening 80BU, resistance 350BU in 135 minutes, farinity index 80, stretching area 107cm in 135 minutes 2 , 135 minutes elongation 160mm. The whiteness of strong gluten wheat is 58, the gluten is 35%, the hardness rate is 90%, the water absorption rate is 71%, the degree of weakening is 10BU, the resistance is 200BU in 135 minutes, the farinity index is 90, and the tensile area in 135 minutes is 170cm 2 , 135 minutes elongation 189mm.

[0019] The production method of the original steamed bun powder: After the raw wheat is mixed, it is sieved, stone-removed, selected, buckwheat thrown into a car, washed, and moistened to obtain clean wheat, which is then subjected to a flour milling process, that is, five skin mills, slag Milling...

Embodiment 3

[0021] The original steamed bun powder is made of the following raw materials in weight percentage: 90% of medium-gluten wheat and 10% of strong-gluten wheat. The whiteness of medium-gluten wheat is 63, the gluten is 28%, the hardness rate is 40%, the water absorption rate is 65%, the degree of weakening is 70BU, the resistance is 150BU in 135 minutes, the farinity index is 86, and the tensile area in 135 minutes is 120cm 2 , 135 minutes elongation 170mm. The whiteness of strong gluten wheat is 59, the gluten is 33%, the hardness rate is 85%, the water absorption rate is 69%, the degree of weakening is 15BU, the resistance is 380BU in 135 minutes, the farinity index is 92, and the tensile area in 135 minutes is 200cm 2 , 135 minutes elongation 230mm.

[0022] The production method of the original steamed bun powder: After the raw wheat is mixed, it is sieved, stone-removed, selected, buckwheat thrown into a car, washed, and moistened to obtain clean wheat, which is then subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com