Loose milk lumps and preparation method thereof

A milk lump and loose technology, applied in the field of loose milk lump and its preparation, can solve the problems of prolonged drying time, hard texture of milk lump, high moisture content, etc., and achieve good palatability, small browning, and good film-forming performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

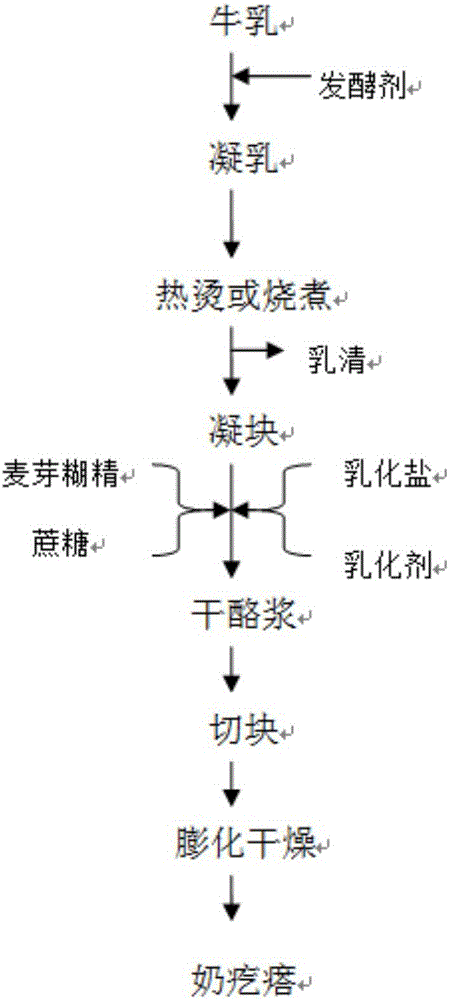

[0055] Such as figure 1 As shown, the present invention provides a kind of preparation method of loose type milk lump, it comprises the following steps:

[0056] After the fermented yogurt is boiled and whey drained, cheese curds are obtained. Hot boiling can accelerate protein denaturation, promote casein denaturation and precipitation, and drain whey as much as possible;

[0057] Adding ingredients to the cheese curd for stirring and emulsifying treatment to obtain cheese slurry;

[0058]The cheese slurry is extruded and then dried to obtain a finished product of loose milk lumps.

[0059] In the preparation method of the loose milk lump, the boiling temperature is 70°C-100°C, the blanching time is 20min-60min, and stirring is continued during the boiling process.

[0060] In the preparation method of described loose type milk lump,

[0061] The ingredients include emulsifying salt, water, maltodextrin and sucrose;

[0062] The added amount of the emulsifying salt is 1% ...

Embodiment 1

[0095] Example 1. Loose milk bumps prepared by different drying methods

[0096] (1) Weigh 3L of fresh milk and pasteurize it. When it is cooled to 40°C, add 0.1% starter, and ferment it in a 42°C incubator until the acidity is greater than 80°T.

[0097] (2) The fermented yogurt is boiled, that is, the temperature is heated at 70-100°C for half an hour, and the stirring is continued, so that the protein in the milk can be completely precipitated as much as possible. Then the whey is drained, so that the cheese curd is obtained.

[0098] (3) Add 2%-4% compound emulsified salt (trisodium citrate: disodium hydrogen phosphate = 1:1-10), 10% maltodextrin and 9% sucrose to the cheese curd, and heat to melt. Wherein the emulsification temperature is 70° C., the emulsification speed is 1000 rpm, and the emulsification time is 15 minutes, and the cheese pulp with a uniform state is obtained.

[0099] (4) Squeeze the cheese pulp into a square mold with a side length of 2cm to 3cm whi...

Embodiment 2

[0118] Example 2, the influence of different drying methods on the microstructure of loose milk bumps

[0119] (1) Weigh 3L of fresh milk and pasteurize it. When it cools down to 40°C, add 0.1% starter, and ferment in a 42°C incubator until the acidity is greater than 80°T.

[0120] (2) The fermented yogurt is boiled, that is, the temperature is heated at 90°C for half an hour, and the stirring is continued, so that the protein in the milk can be completely precipitated as much as possible. Then the whey is drained, so that the cheese curd is obtained.

[0121] (3) Add 2%-4% compound emulsified salt (trisodium citrate: disodium hydrogen phosphate = 1:1-10), 10% maltodextrin and 9% sucrose to the cheese curd, and heat to melt. Wherein the emulsification temperature is 70° C., the emulsification speed is 1000 rpm, and the emulsification time is 15 minutes, and the cheese pulp with a uniform state is obtained.

[0122] (4) Squeeze the cheese slurry into a square mold with a sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com