Candy taking and overturning mechanism and chocolate candy single-kink packing machine for food packing

A turning mechanism and food packaging technology, which is applied in the field of candy packaging, can solve the problems of packaging speed, no obvious advantage in efficiency, complex action structure, and difficult cleaning, and achieve stable effects, high transmission efficiency, and good transmission stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

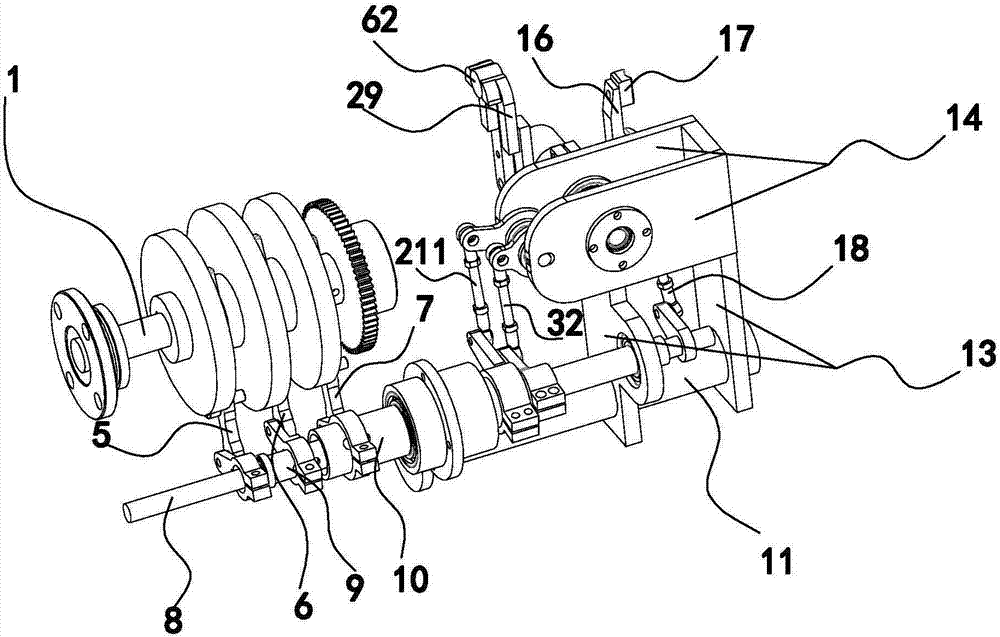

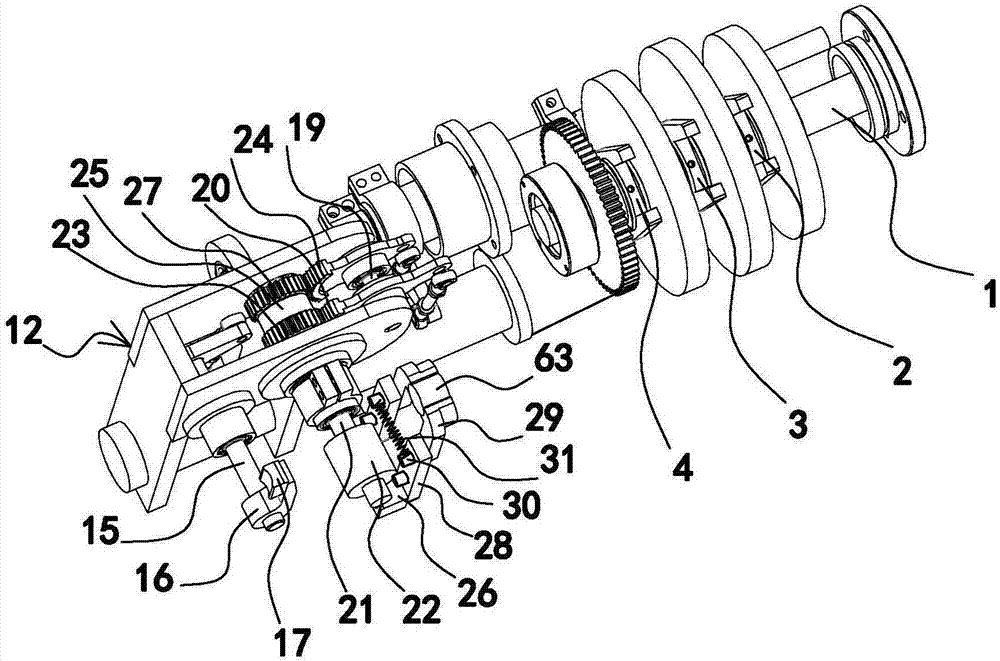

[0036] Such as figure 1 and 2 As shown, the sugar-taking turning mechanism, the candy packaging machine includes a drive motor 33 and a frame 34, and the sugar-taking turning mechanism includes a camshaft 1, a transmission shaft-8, a frame structure and a candy block for positioning at the sugar-taking place. 62 carries out the stopper structure of limit stopper, is used to clamp and take sugar place candy 62 and turns over 90 degree jaw structure and tensioning structure, certainly also can turn over as other angles such as 180 degree, 60 degree as required. The jaw structure has two jaws 29, and the tensioning structure drives the loosening or clamping of the two jaws 29. The material retaining structure, jaw structure and tensioning structure are all installed on the frame structure. Transmission shaft one 8 is installed on the frame 34, and drive motor 33 is connected with camshaft 1 through gear structure, and gear structure is the meshing connection transmission structu...

Embodiment 2

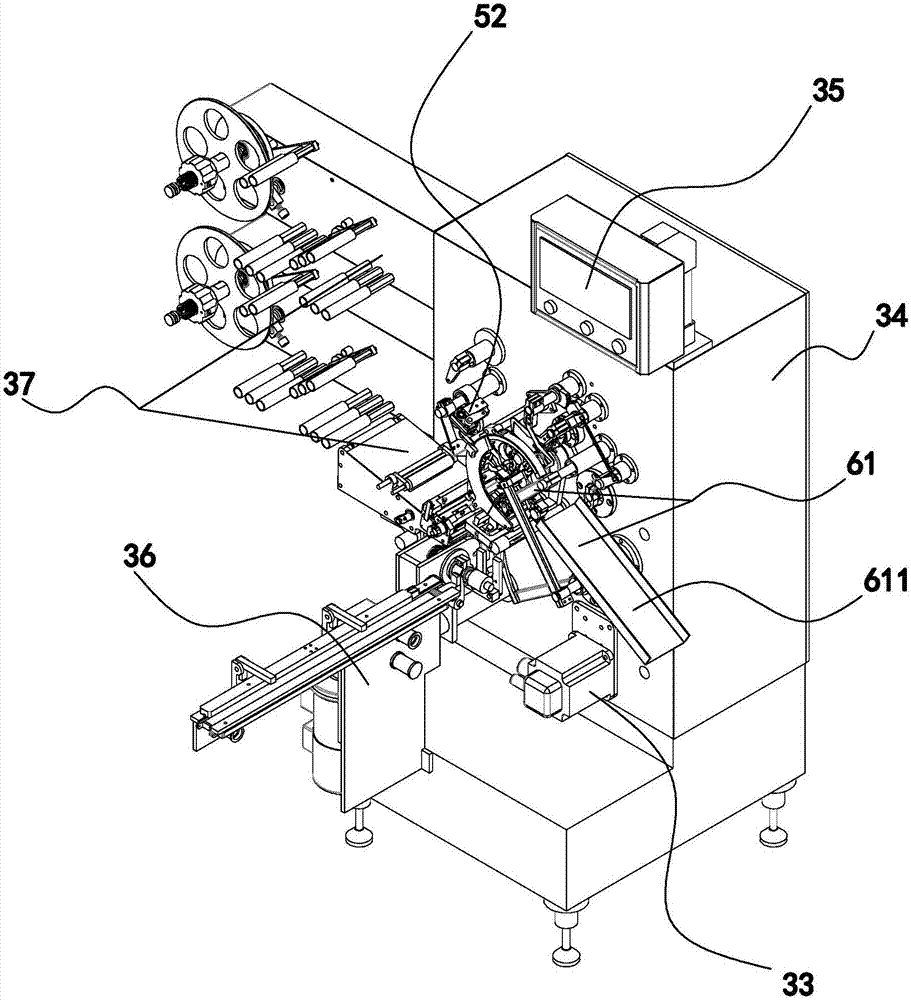

[0044] Such as image 3 and 4 As shown, the chocolate candy single-twist packaging machine used for food packaging includes a frame 34, a controller, a drive motor 33 connected to the controller, and a human-computer interaction platform 35, which includes:

[0045] The sugar delivery mechanism 36 is used to deliver the sugar cube 62 to the sugar extraction place;

[0046] The above-mentioned sugar-taking turning mechanism is used to grab and rotate the candy block 62 located on the above-mentioned sugar-taking place to the top sugar place by 90 degrees;

[0047] The paper feeding and cutting mechanism 37 is used to smoothly transport the wrapping paper to the top sugar place and place it on the top of the candy 62, and then cut the wrapping paper;

[0048] The sugar pressing mechanism is used for pressing the wrapping paper on the candy block 62 and sending the wrapping paper and the candy block 62 into the sugar wrapping mechanism together;

[0049] The sugar wrapping mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com