Preparation method and evenness measurement method for carbon fiber synthetic paper

A measurement method, carbon fiber technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, fiber dispersant addition, etc., can solve the problem of insufficient funds to purchase imported instruments, uneven manufacturing levels, sales High price and other problems, to achieve the effect of excellent heating uniformity, wide application range and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

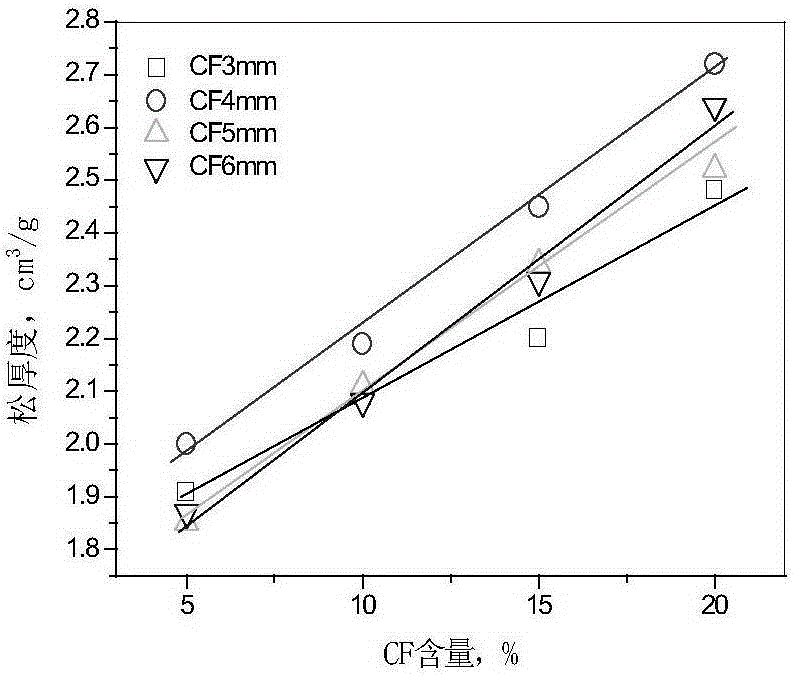

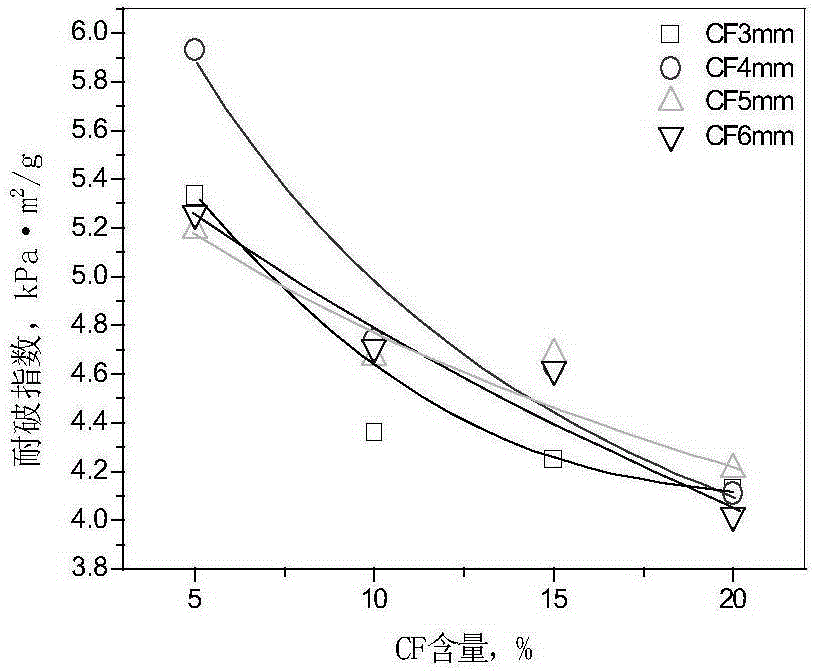

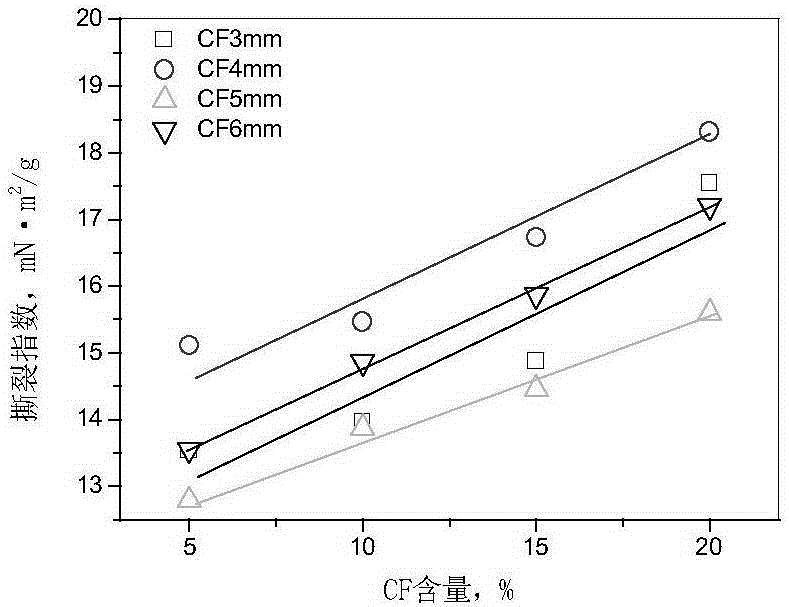

[0035] The invention discloses a method for preparing carbon fiber synthetic paper, which comprises mixing pulping of carbon fibers and plant fibers, papermaking, pressing, and drying. % by weight of plant fibers, 0.1 to 1.0% by weight of dispersants are placed in a decomposer according to the mixing ratio and added with water to decompose; use a British Messmer paper sheet former to carry out manual sheeting, copy paper sheets, and put them into a constant temperature and humidity testing room for drying.

[0036] The invention also discloses a method for detecting the evenness of the synthetic fiber paper. The light source used in the method can be a commercially available scanner with an optical resolution of 4800×2400dpi or higher. The light source: LED, and the paper sample to be tested is placed on the scanner flat plate Above, the LED light source emits uniform and stable light, and the paper pattern enters the camera to convert it into a digital signal, forming an image...

Embodiment 1

[0050] Example 1 Preparation and formation measurement of carbon fiber synthetic paper.

[0051] Prepare synthetic fiber paper in the following proportions:

[0052] Carbon fiber (4mm) 5 parts by weight

[0053] Plant fiber (degree of beating 16 ° SR) 95 parts by weight

[0054] Dispersant 0.5 parts by weight

[0055] The carbon fiber, plant fiber and dispersant with the above content are decomposed in a plant decomposer, and the decomposer rotation speed is set to 15,000 rpm. The decomposed pulp is made into paper on a paper former, and then undergoes two pressing processes: First, make the effective pressure on the paper sheet be 400±10kPa, keep this pressure for 5min±15s, perform a press, replace the absorbent paper and perform the second press, the effective pressure on the paper page is 400±10kPa, keep this pressure 2min±15s, put it into a constant temperature and humidity environment after the pressing process and dry to obtain synthetic fiber paper. The results of me...

Embodiment 2

[0059] Example 2 Preparation and formation measurement of carbon fiber synthetic paper.

[0060] Prepare synthetic fiber paper in the following proportions:

[0061] Carbon fiber (4mm) 5 parts by weight

[0062] Plant fiber (degree of beating 50 ° SR) 95 parts by weight

[0063] Dispersant 0.5 parts by weight

[0064] In this embodiment 2, the degree of beating of the plant fiber is adjusted to 50 ° SR, and other raw materials and proportioning are unchanged, and the results obtained are listed in Table 4:

[0065] Table 4

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com