Cellulose/titanium dioxide/silica aerogel and preparation method thereof

A titanium dioxide and silicon dioxide technology, which is applied in the field of preparation of cellulose/titanium dioxide/silica aerogels, can solve the problems of easy moulding of cellulose, expensive raw materials and high cost, and achieves excellent biocompatibility, excellent reinforcement performance, the effect of high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

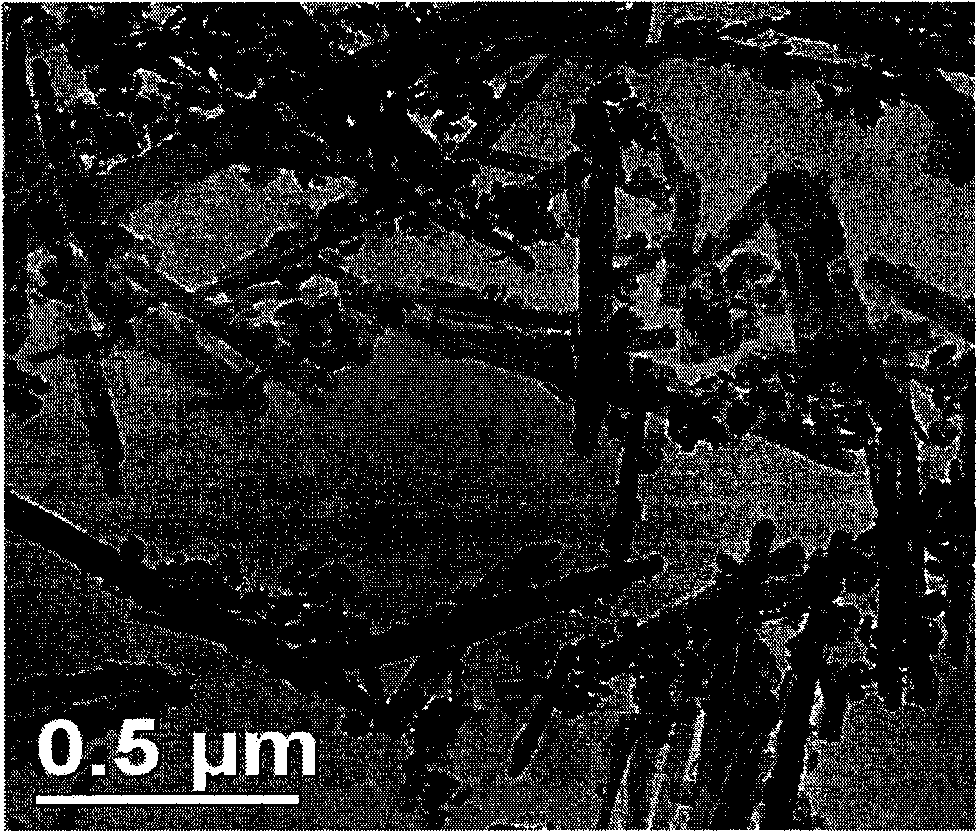

Image

Examples

Embodiment 1

[0035] 1. Preparation of cellulose sol: Add 20.0g of cellulose to 400.0g of water, and use KQ2200DB numerical control ultrasonic cleaner to ultrasonically disperse for 1 hour to make cellulose sol;

[0036] 2. Nano titanium dioxide loaded on the surface: while stirring, add 4.0mol / L TiCl to the cellulose sol 4 Aqueous solution 94.0mL, maintain the reaction temperature at 10°C, then add 2.0mol / L potassium hydroxide aqueous solution to adjust the pH of the system to 1.00, raise the temperature to 100°C, and react at a constant temperature at 100°C for 1 hour to obtain nano-titanium dioxide-supported cellulose Sol;

[0037] 3. Surface-coated silica: under continuous stirring, 300.0mL of 2.0mol / L sodium silicate aqueous solution and 2.0mol / L hydrochloric acid aqueous solution were simultaneously (cocurrently) dropped into the cellulose sol supported by nano-titanium dioxide for reaction , the reaction temperature is maintained at 75°C. After adding the reaction liquid, heat-prese...

Embodiment 2

[0042] 1. Preparation of cellulose sol: Add 20.0g of cellulose into 80.0g of water, and ultrasonically disperse for 1 hour with a KQ2200DB numerical control ultrasonic cleaner to make cellulose sol;

[0043] 2. Nano titanium dioxide loaded on the surface: while stirring, add 0.5mol / L TiCl to the cellulose sol 4 100.0 mL of aqueous solution and 120.0 mL of 0.5 mol / L ammonia solution, maintain the reaction temperature at 21 ° C, after the addition of the reaction solution, the pH of the system is 0.33, raise the temperature to 70 ° C, and react at a constant temperature at 70 ° C for 10 hours to obtain nano-titanium dioxide Loaded cellulose sol;

[0044] 3. Surface-coated silicon dioxide: Under constant stirring, 111.1 mL of 0.3 mol / L sodium silicate aqueous solution and 0.5 mol / L sulfuric acid aqueous solution were simultaneously (cocurrently) dropped into the cellulose sol supported by nano-titanium dioxide for reaction , the reaction temperature is maintained at 95°C. After ...

Embodiment 3

[0049] 1. Preparation of cellulose sol: add 20.0g of cellulose to 200.0g of water, and use KQ2200DB numerical control ultrasonic cleaner to ultrasonically disperse for 1 hour to make cellulose sol;

[0050] 2. Surface-loaded nano-titanium dioxide: While stirring, add 160.0 mL of 4.0 mol / L sodium hydroxide aqueous solution to the cellulose sol, maintain the reaction temperature at 50 ° C, and then add 2.5 mol / L TiCl 4 Aqueous solution 100.0mL, TiCl 4 After adding the aqueous solution, the pH value of the system is 0.10, the temperature is raised to 85°C, and the reaction is carried out at a constant temperature of 85°C for 3 hours to obtain a cellulose sol supported by nano-titanium dioxide;

[0051] 3. Surface-coated silicon dioxide: Under continuous stirring, 100.0 mL of 1.0 mol / L sodium silicate aqueous solution and 1.0 mol / L acetic acid aqueous solution were dropped into the slurry at the same time (parallel flow) to react, and the reaction temperature was maintained at 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com