Method for preparing carbon nanometer conductive solution and conductive fibers by using ionic liquids

A technology of ionic liquid and conductive solution, applied in dyeing, textile and papermaking, etc., can solve problems such as environmental pollution and easy agglomeration of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

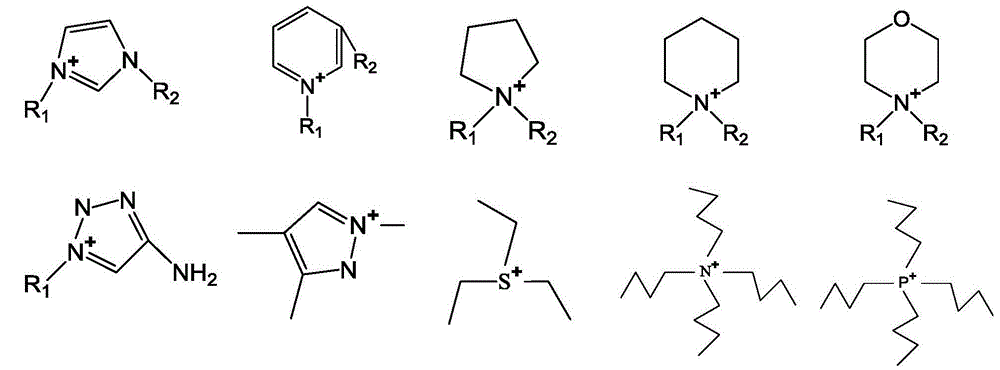

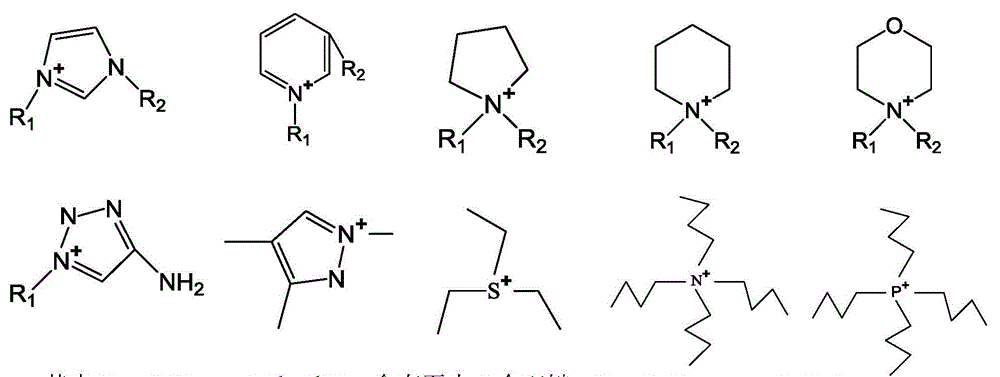

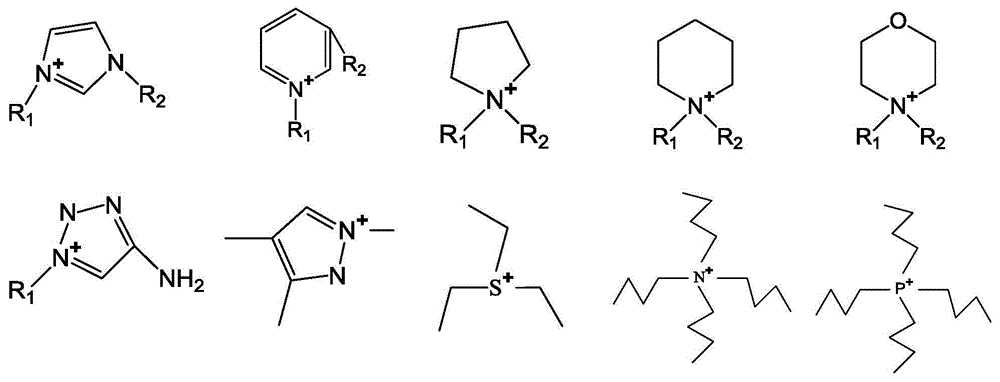

Method used

Image

Examples

Embodiment 1

[0014] Weigh 100.0g of one-component water-based polyurethane resin, 5.0g of wetting agent BYK190, 200.0ppm of [BMIM]Cl, add the above-mentioned wetting agent and ionic liquid dropwise into the weighed water-based polyurethane resin, and 800 Stir at a speed of -1000rpm for 1h to obtain a water-based polyurethane resin composite solution; weigh 894.8g of hydroxylated modified multi-walled carbon nanotubes (5%, wt%, the following units are the same), adjust the speed of the disperser to 1500-2000rpm, Slowly add the water-based polyurethane resin composite liquid obtained above to the multi-walled carbon nanotube dispersion liquid, after stirring at room temperature for 2 hours, add a certain amount of RM8W, stir at room temperature for 1 hour, adjust the viscosity of the conductive solution to 400mPa·s, statically After standing for 1 day, use the above-mentioned conductive solution to use 300D polyester yarn and wool yarn respectively, and carry out the dyeing experiment of the ...

Embodiment 2

[0016] Weigh 100.0g of one-component water-based polyurethane resin, 5.0g of wetting agent BYK190, 200.0ppm of [BMIM]Cl, add the above-mentioned wetting agent and ionic liquid dropwise into the weighed water-based polyurethane resin, and 800 Stir at a speed of -1000rpm for 1h to obtain a water-based polyurethane resin composite solution; weigh 844.8g of hydroxylated modified multi-walled carbon nanotubes (5%), and 50.0g of graphene dispersion (15%) in a stirred tank to adjust the dispersion The speed of the machine is 1500-2000rpm, slowly add the water-based polyurethane resin composite liquid obtained above to the multi-walled carbon nanotube and graphene dispersion liquid, stir at room temperature for 2 hours, add a certain amount of RM8W, and stir at room temperature for 1 hour, Adjust the viscosity of the conductive solution to 400mPa·s. After standing for 1 day, use the above conductive solution and wool silk thread to carry out the dyeing experiment of the conductive solu...

Embodiment 3

[0018] Weigh 700.0g of one-component water-based acrylic resin, 5.0g of wetting agent BYK349, 200.0ppm of [BMIM]BF 4 , the above wetting agent and ionic liquid were added dropwise to the weighed water-based acrylic resin, stirred at a speed of 800-1000rpm at room temperature for 1h to obtain a water-based acrylic resin composite liquid; weighed 294.8g graphene dispersion (15% ) in a stirred tank, adjust the speed of the disperser to 1500-2000rpm, slowly add the water-based acrylic resin composite liquid obtained above to the graphene dispersion liquid, stir at room temperature for 2 hours, add a certain amount of RM8W, and stir at room temperature 1h, adjust the viscosity of the conductive liquid to 400mPa·s, after standing for 1 day, use the above conductive solution at a temperature of 40°C, dye with 150D aramid yarn, and dry it at a temperature of 170-200°C to obtain a conductive fiber. The dyeing speed is 10-15m / min, and the dried conductive thread is wound on the roller c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com