Metal honeycomb material used in aerospace and aircraft separation layer, and preparation method thereof

A space vehicle, metal honeycomb technology, applied in the field of metal honeycomb materials and its preparation, can solve the problems of cracking and detachment of metal sheets, low bonding strength, low use temperature, etc., to improve thermal stability and carrying capacity, and improve the production process Efficient and low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The upper and lower panels are made of titanium, and the middle multi-layer metal sheet is made of LY12CZ aviation aluminum alloy.

[0015] Its preparation method:

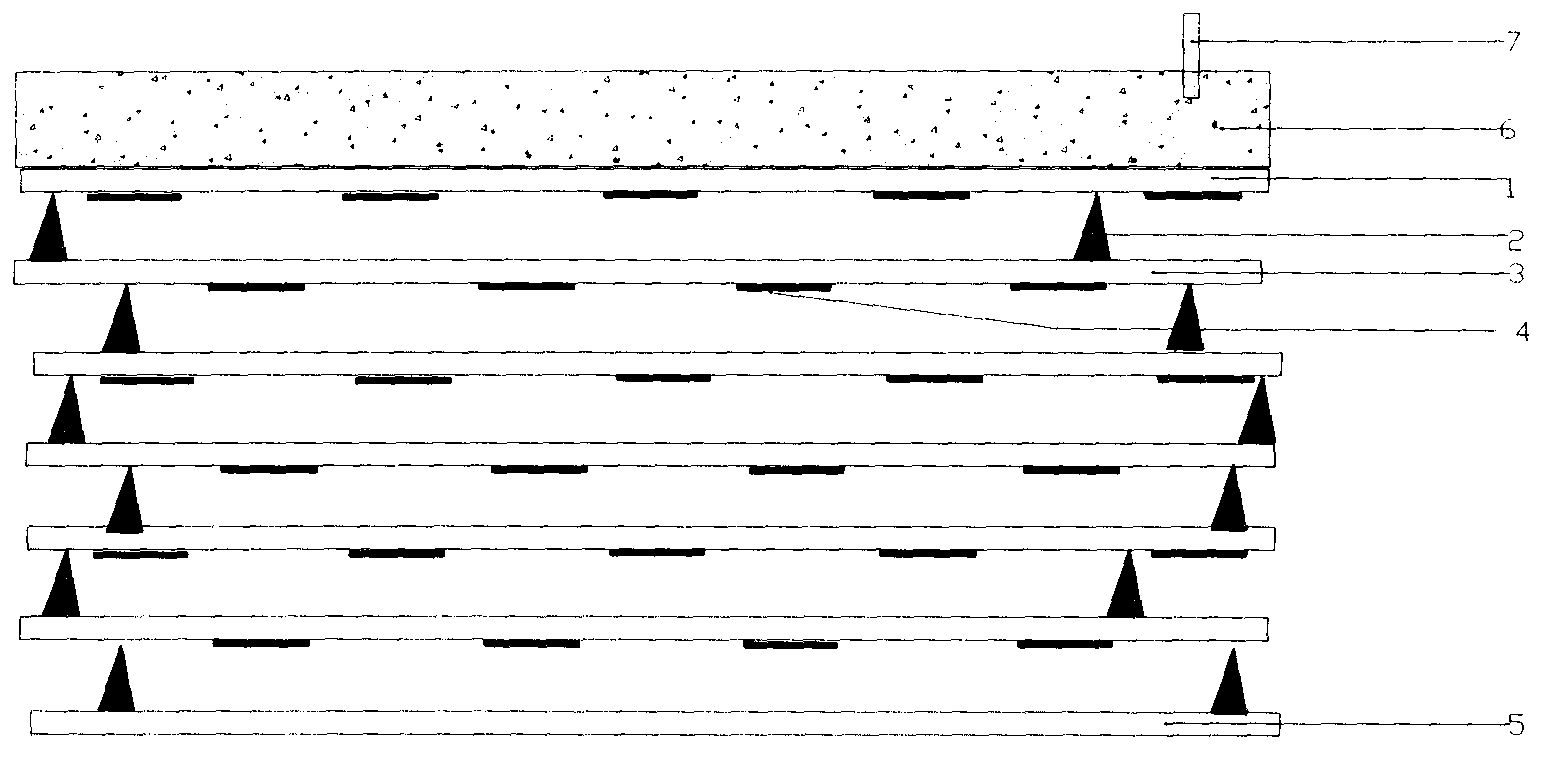

[0016] (1) The metal honeycomb material includes an upper panel (1), a lower panel (5) and a metal honeycomb interlayer. The interlayer material is common aviation lightweight materials such as aluminum alloy or titanium alloy, and the panel material is heat-resistant aviation materials such as titanium alloy, nickel-based alloy or stainless steel.

[0017] (2) Polish and polish the upper and lower surfaces of the upper panel (1), the lower panel (5) and the plurality of thin metal plates (3) with a grinding wheel and a polishing machine until the surface roughness Ra<6nm.

[0018] (3) Place the lower panel (5) on a flat foundation, put the gap column (2) on it to support the multi-layer thin metal plate (3), and coat the metal plate with a certain width of anti-corrosion at intervals. Solder (4), the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com