Preparation method of aluminum hydroxide gel and microlite alpha-Al2O3 aggregate

A technology of aluminum hydroxide gel and aluminum hydroxide, applied in the direction of aluminum hydroxide preparation, aluminum oxide/hydroxide preparation, ammonium nitrate, etc., can solve the complex process, uneven dispersion of sintering aids, impurities High content and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

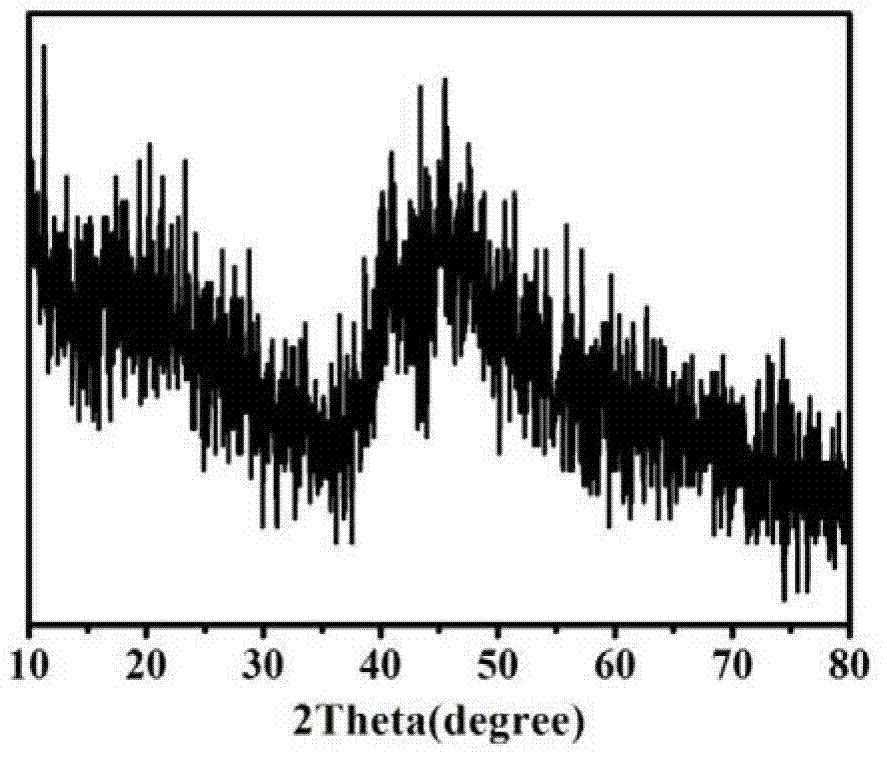

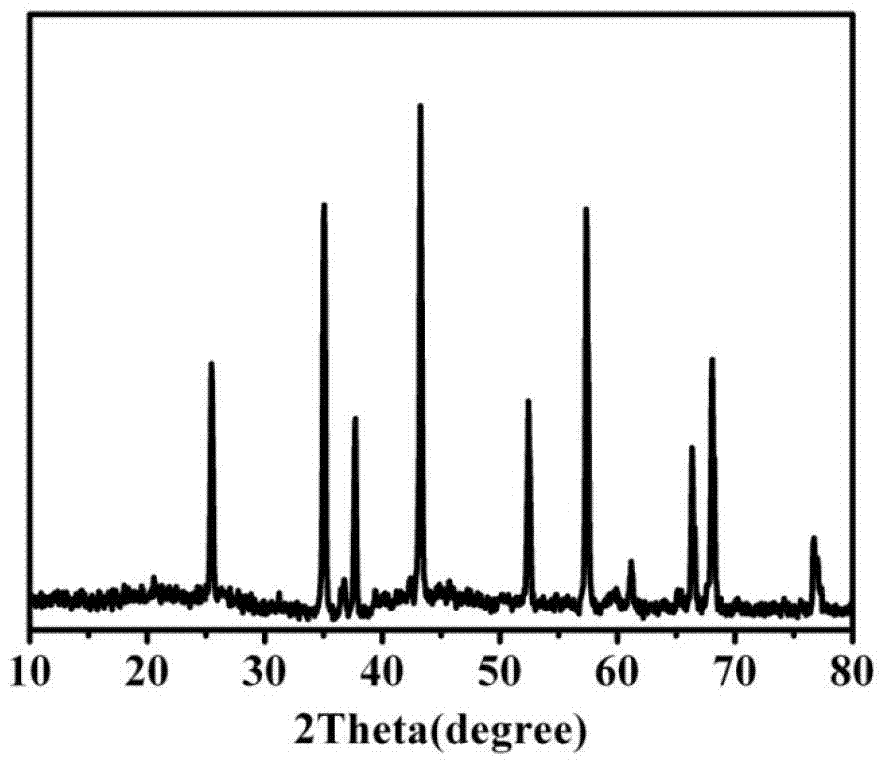

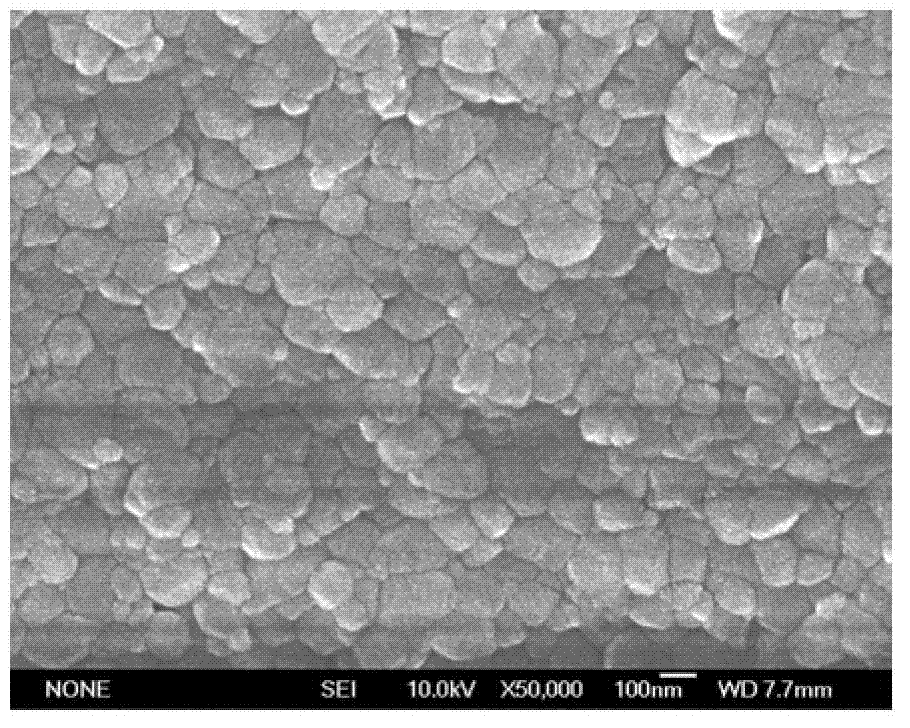

[0013] A kind of aluminum hydroxide gel, wherein the aluminum hydroxide is amorphous, for preparing microcrystalline α-Al 2 O 3 Aggregates; were prepared as follows:

[0014] (1) NH with a concentration of 25 to 28 wt% 3 ·H 2 O is added to water and Al(NO 3 ) 3 ·9H 2 In the mixed solution of O, Al(NO 3 ) 3 ·9H 2 O:H 2 O:NH 3 ·H 2 The molar ratio of O is 1:(3-8):(4.5-12), and the suspension is obtained after stirring evenly; centrifugation or suction filtration is performed, and the precipitate is washed 2~3 times with deionized water to obtain aluminum hydroxide; the filtrate For the recovery of by-product ammonium nitrate.

[0015] (2) adding water to the aluminum hydroxide obtained in step (1) to prepare a suspension with a solid content of 5 to 15 wt %, and adding concentrated nitric acid with a concentration of 65 to 69 wt %; the molar ratio of the aluminum hydroxide to the concentrated nitric acid (5 -12): 1, stir for 2~5h, add alumina ball milling medium to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com