One-side atomic oxygen resistant polyimide composite film and preparation method thereof

A technology of polyimide base film and anti-atomic oxygen, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc. Poor performance and other problems, to achieve the effect of excellent anti-atomic oxygen performance, good mechanical properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

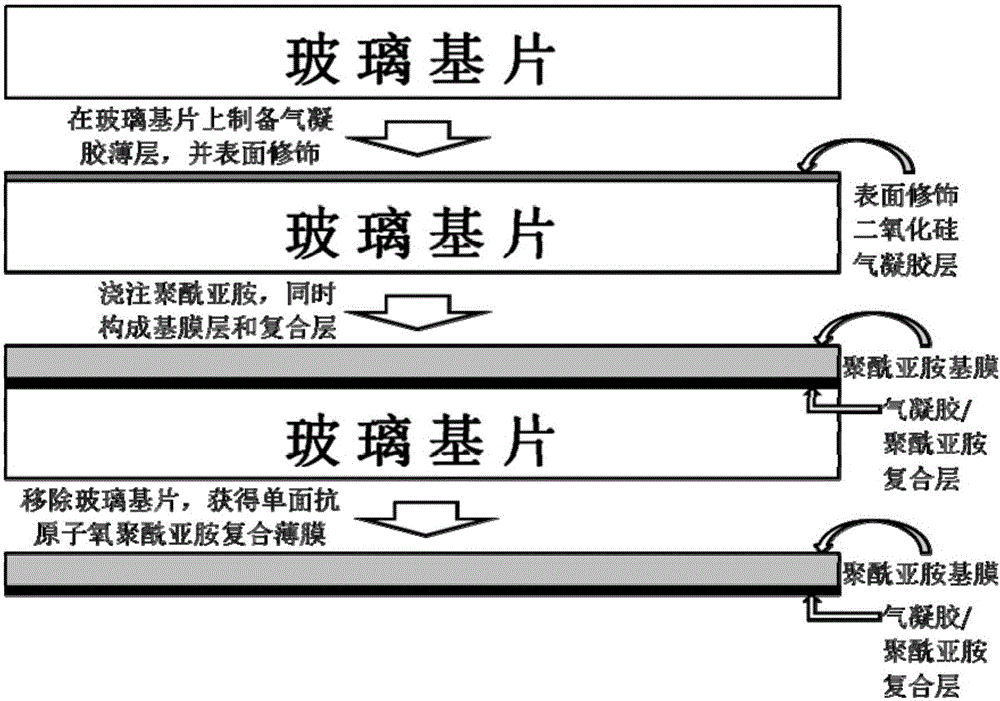

preparation example Construction

[0050] (3) Preparation of silica airgel film: adopt dipping and pulling method to prepare silica airgel film, the specific steps are: pour the silica sol obtained in step (2) into a container, and quickly pour the silica sol obtained in step (2) (1) Insert the obtained substrate vertically into the silica sol in the container, and lightly press the top of the substrate with your hands to keep it fixed, while keeping the silica sol flowing out at a speed of 5-30cm / min, After the silica sol has flowed out, take out the substrate and quickly immerse it in an anhydrous ethanol solution for aging and then take it out, repeat the immersion-out process three times, immerse for 6-24h each time, and then use n-hexane for solvent exchange, solvent exchange 12-24h, so that all the water and absolute ethanol in the silica airgel film are replaced by n-hexane to obtain the silica airgel film.

[0051] The surface modification method of described silica airgel film is:

[0052] (1) Soak th...

Embodiment 1

[0072] A polyimide composite film with single-sided anti-atom oxygen, the composite film includes two layers, the upper layer is a composite material layer, the lower layer is a polyimide base film layer, the composite material layer includes a polyimide matrix and Surface-modified silica airgel film;

[0073] The preparation method of described silica airgel film is:

[0074] (1) The surface of the glass substrate is ultrasonically cleaned and then dried; the cleaning steps are: first use acetone to ultrasonically clean, then use anhydrous ethanol to ultrasonically clean, and finally use distilled water to ultrasonically clean; the substrate used must be strictly treated before it can be used Carry out dipping and pulling operation, which is mainly to remove pollutants such as dust adhered to the surface, and ensure the uniformity of the prepared airgel film; (2) preparation of silica sol: adopt acid / alkali two-step catalytic process To prepare silica sol, the specific steps...

Embodiment 2

[0090] A polyimide composite film with single-sided anti-atom oxygen, the composite film includes two layers, the upper layer is a composite material layer, the lower layer is a polyimide base film layer, the composite material layer includes a polyimide matrix and Surface-modified silica airgel film;

[0091] The preparation method of described silica airgel film is:

[0092] (1) The surface of the glass substrate is ultrasonically cleaned and then dried; the cleaning steps are: first use acetone to ultrasonically clean, then use anhydrous ethanol to ultrasonically clean, and finally use distilled water to ultrasonically clean; the substrate used must be strictly treated before it can be used Carry out dipping and pulling operation, which is mainly to remove pollutants such as dust adhered to the surface, and ensure the uniformity of the prepared airgel film; (2) preparation of silica sol: adopt acid / alkali two-step catalytic process To prepare silica sol, the specific steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com