A double-layer structure polyimide composite material with extreme environmental resistance and its preparation method

A double-layer structure, polyimide technology, applied in the field of material chemistry, can solve the problems of insufficient high temperature stability, insufficient mechanical properties, weak anti-ultraviolet radiation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing a double-layer structure polyimide composite material with extreme environmental tolerance, comprising the following steps:

[0039] S1) Carry out calcination, acid leaching and sodium treatment on the mica powder, then use small organic molecules to intercalate the mica powder, and then disperse the intercalated mica powder in a solvent for ultrasonic crushing to obtain a suspension of mica nanosheets ;

[0040]S2) Mix the mica nanosheet suspension with the polyamic acid solution to obtain the mica nanosheet-polyamic acid dispersion; It is a low-concentration mica nanosheet-polyamic acid dispersion; 60wt%-80wt% mica nanosheet-polyamic acid dispersion is recorded as a high-concentration mica nanosheet-polyamic acid dispersion;

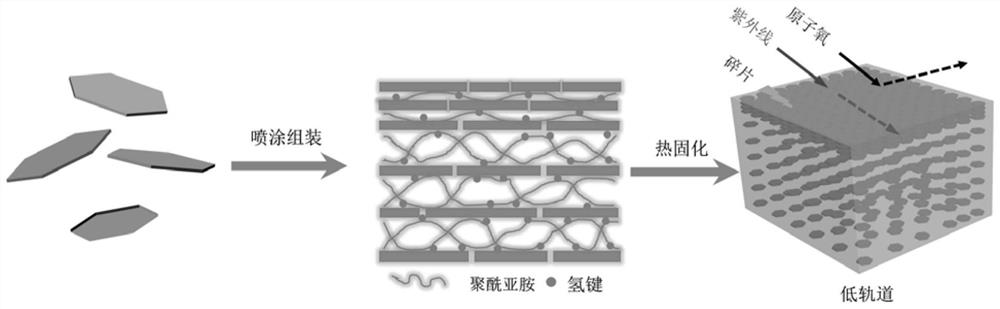

[0041] S3) Using the combined method of spraying assembly and thermal curing, spray the low-concentration mica nanosheet-polyamic acid dispersion and the high-concentration mica nanosheet-polyamic a...

Embodiment 1

[0074] Preparation of double-layer polyimide composites:

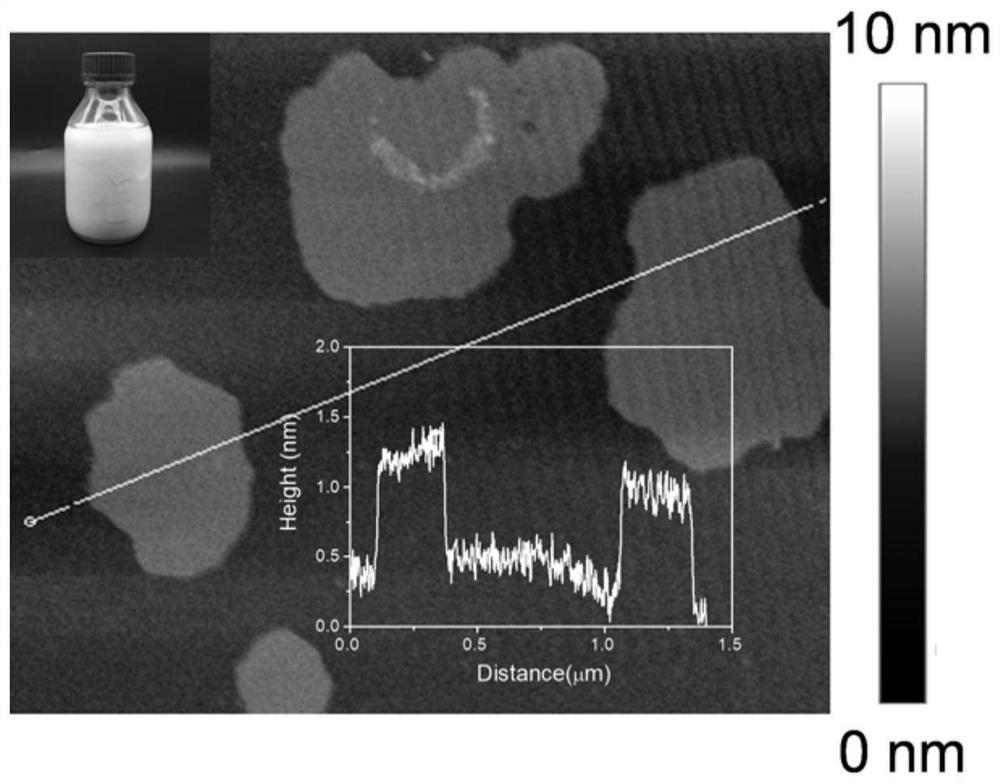

[0075] a. First, put the mica powder into the electric furnace at a heating rate of 5°C / min to 800°C and keep it warm for 1 hour; then, take 15g of calcined mica powder and add it to 500mL of 5mol / L nitric acid solution at 95°C React for 5h, filter, wash, and dry; then, take 15g of acid-leached mica powder, add it to 500mL of 40wt.% sodium chloride solution, react for 3h at 95°C, filter, wash, and dry; then, take Add 5g of sodium mica powder and 15g of cetyltrimethylammonium chloride into 500mL of deionized water and react at 80°C for 24 hours, filter, wash, and dry; finally, take 20g of intercalated mica powder and add into 500mL of ethanol, under the condition of magnetic stirring, adopt 665W power to sonicate and collect the supernatant suspension by centrifuging at 3000r / min for 10min every 0.5h to obtain mica nanosheet suspension. figure 2 It is an atomic force microscope photo of mica nanosheets in Example 1 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com