Tungsten-copper alloy with low skeleton connectivity and preparation method thereof

A technology of tungsten-copper alloy and alloy materials, which is applied in the direction of coating, etc., can solve the problems of uneven mixing of ingredients and difficulty in meeting special requirements of tungsten-copper alloy, and achieve good uniformity of structure, high density, and high density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Select tungsten powder with a diameter of 4 μm, use HCl, SnCl 2 , PdCl 2 Activation and sensitization of raw tungsten powder, the activators are HCl and SnCl 2 , the concentration is 10%, the activation time is 30min; the sensitizer is PdCl 2 , the sensitization time is 30min;

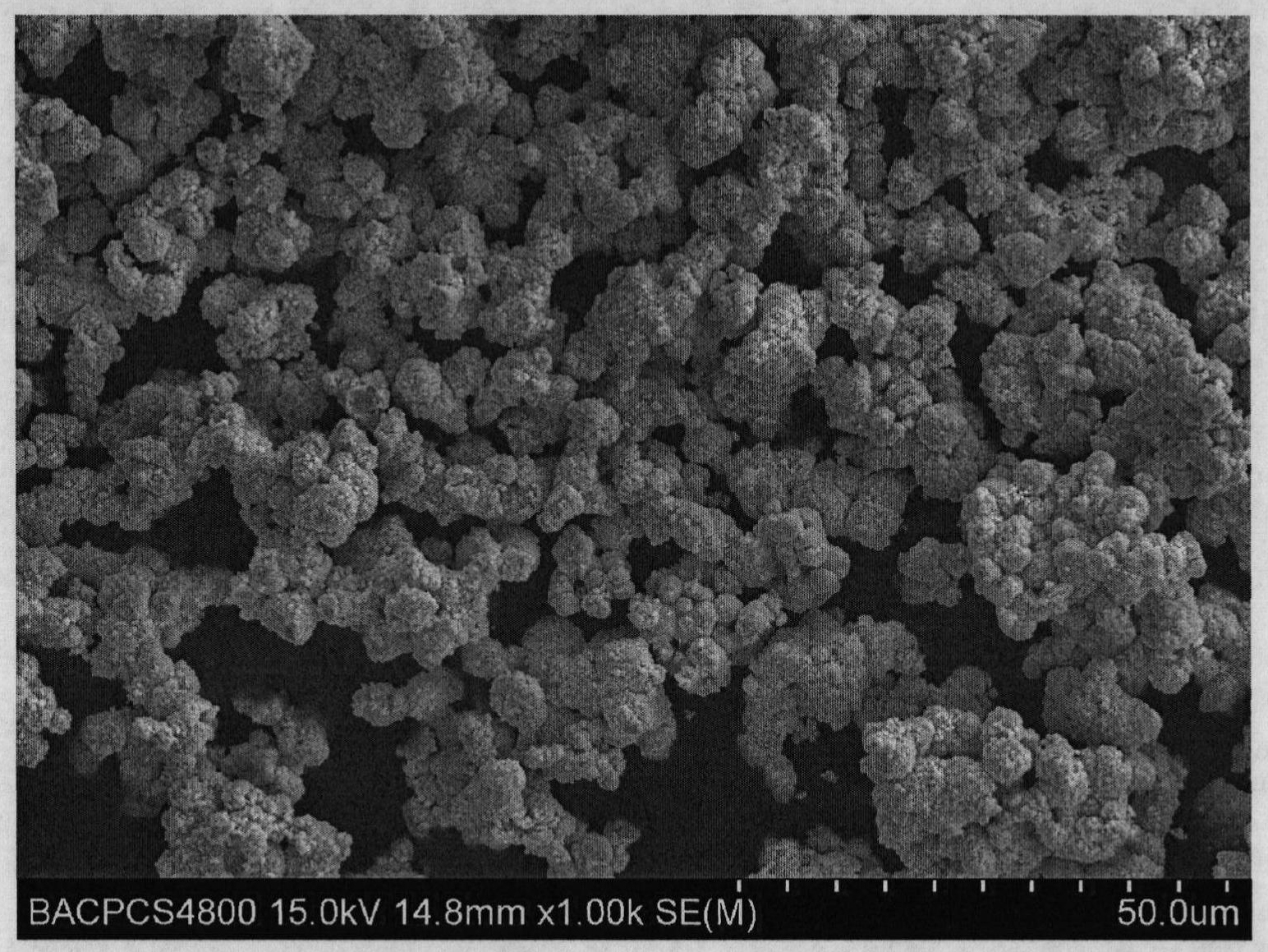

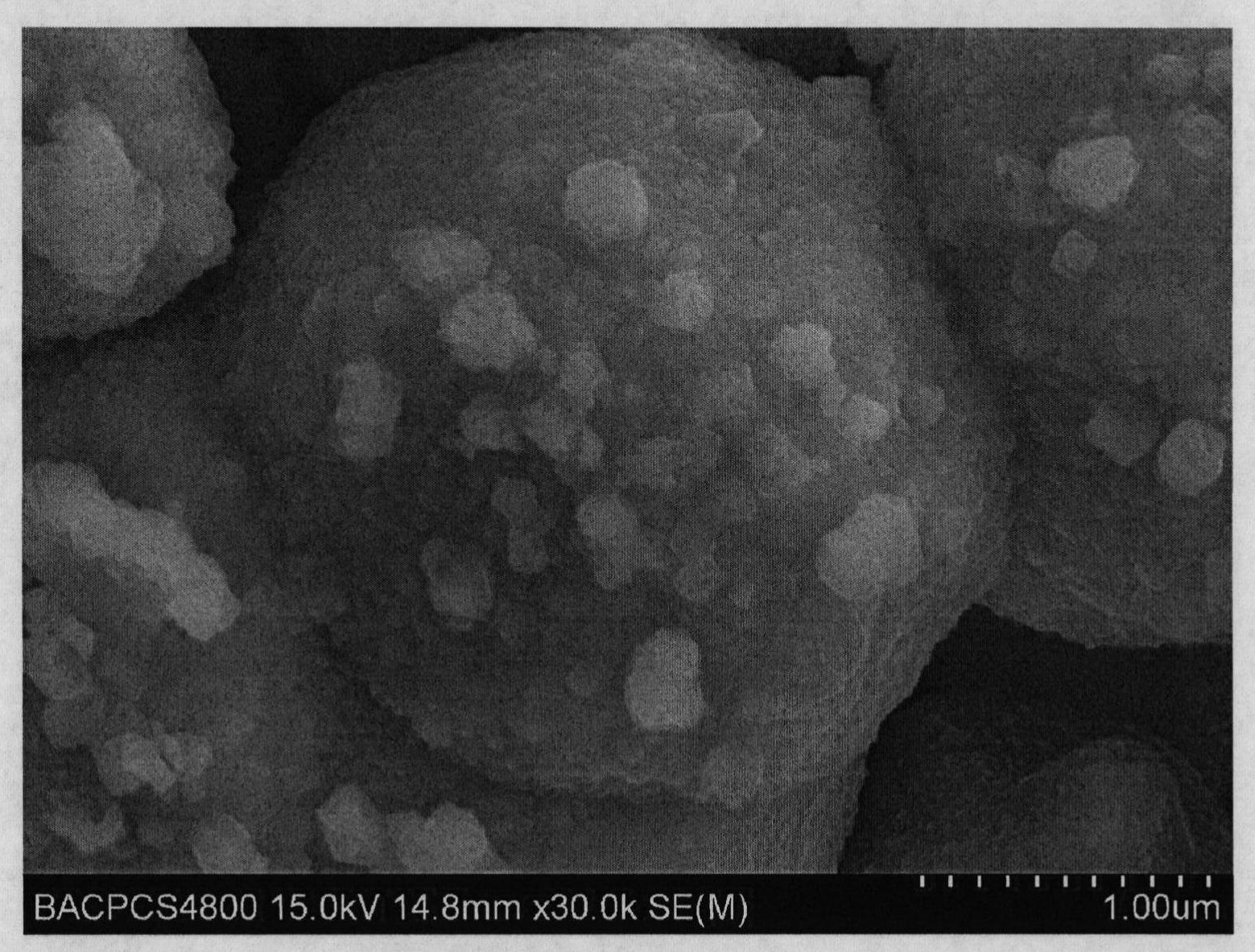

[0024] 2. The copper-coated tungsten composite powder is prepared by electroless plating, the pH value of the plating solution is 13, and the temperature is 50°C, and then the copper-coated tungsten composite powder is mixed with a certain proportion of copper powder by a planetary ball mill to form a mixed Powder, the mass fraction percentage in the final mixed powder is that the Cu content is 20%, the W content is 80%, and the ball milling time is 4h;

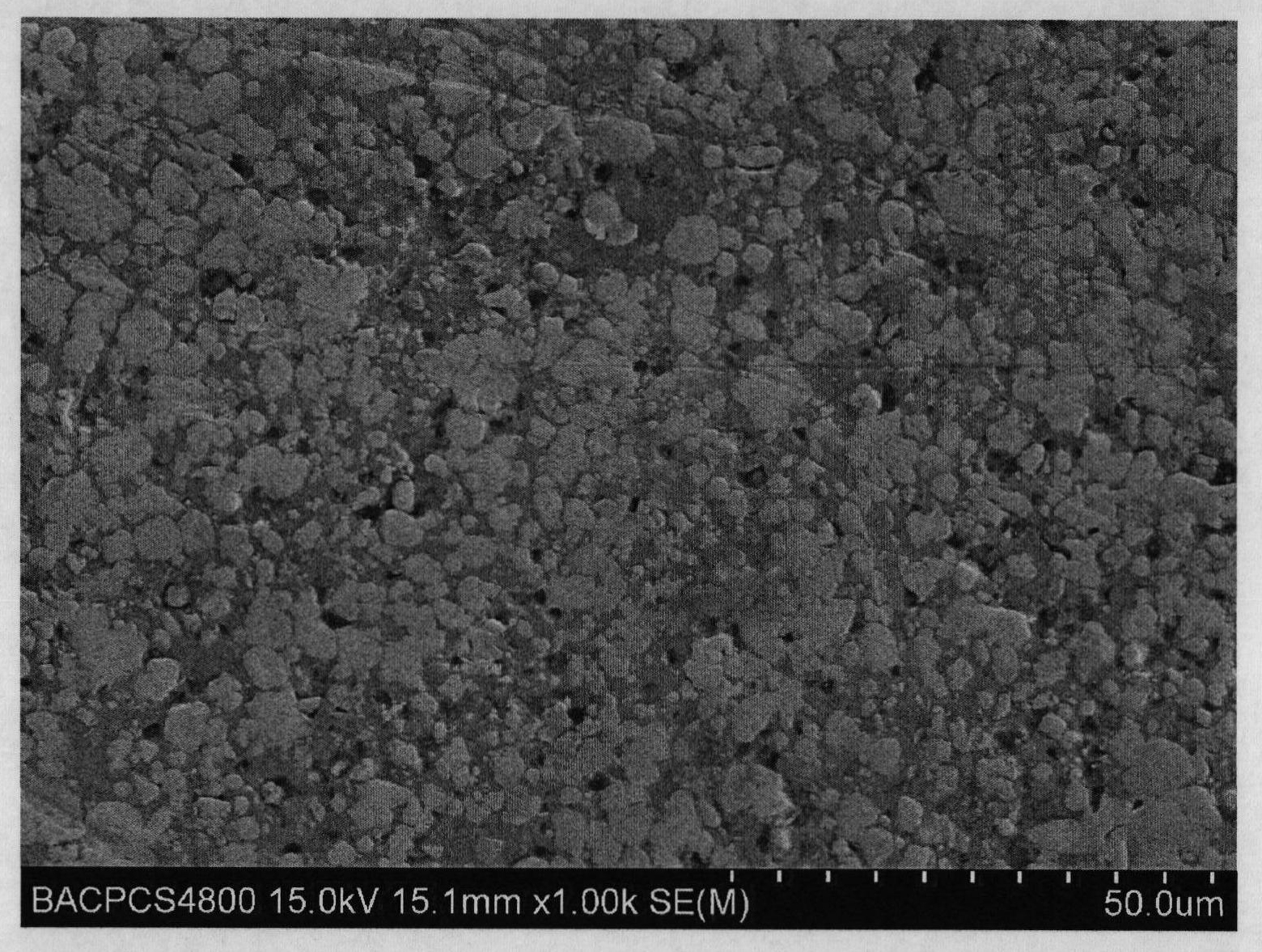

[0025] 3. The mixed powder is sintered by spark plasma sintering technology. The sintering temperature is 800°C, the heating rate is 50°C / min, and the holding time is 5min. Finally, a tungsten-copper alloy with high density and low skelet...

Embodiment 2

[0027] 1. Select tungsten powder with a diameter of 4 μm, use HCl, SnCl 2 , PdCl 2 Activation and sensitization of raw tungsten powder, the activators are HCl and SnCl 2 , the concentration is 10%, the activation time is 35min; the sensitizer is PdCl 2 , the sensitization time is 35min;

[0028] 2. The copper-coated tungsten composite powder is prepared by electroless plating, the pH value of the plating solution is 13, and the temperature is 55°C, and then the copper-coated tungsten composite powder is mixed with a certain proportion of copper powder by a planetary ball mill to form a mixed Powder, the mass fraction percentage in the final mixed powder is that the Cu content is 25%, the W content is 75%, and the ball milling time is 4h;

[0029] 3. The mixed powder is sintered by spark plasma sintering technology. The sintering temperature is 850°C, the heating rate is 100°C / min, and the holding time is 5min. Finally, a tungsten-copper alloy with high density and low skele...

Embodiment 3

[0031] 1. Select tungsten powder with a diameter of 3 μm, use HCl, SnCl 2 , PdCl 2 Activation and sensitization of raw tungsten powder, the activators are HCl and SnCl 2 , the concentration is 10%, the activation time is 40min; the sensitizer is PdCl 2 , the sensitization time is 40min;

[0032] 2. Prepare copper-coated tungsten composite powder by electroless plating. The pH value of the plating solution is 13 and the temperature is 60°C. Then use a planetary ball mill to mix the copper-coated tungsten composite powder with a certain proportion of copper powder to make a mixed Powder, the mass fraction percentage in the final mixed powder is that the Cu content is 30%, the W content is 70%, and the ball milling time is 4h;

[0033] 3. The mixed powder is sintered by spark plasma sintering technology. The sintering temperature is 900°C, the heating rate is 150°C / min, and the holding time is 5min. Finally, a tungsten-copper alloy with high density and low skeleton connectivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com