High-performance water-based UV cured glazing oil for paper and preparation method thereof

A high-performance, water-based technology, used in paper, paper, textile and paper making, etc., which can solve the problems of polluting the environment, odor, and high viscosity of oligomers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

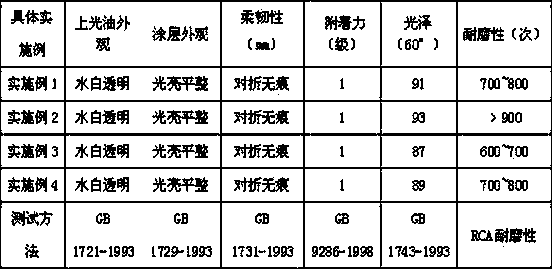

Examples

Embodiment 1

[0025] Step 1: Add 5g of isophorone diisocyanate to the dry reactor, add 3.5g of polyoxypropylene diol dropwise at 40-50°C, dropwise for 0.5h, and keep warm during the dropping process: ice The water bath and the warm water bath are used in turn to ensure that the temperature is stable during the dropwise addition. After the dropwise addition, the temperature is raised to 60-80°C, and the heat preservation polymerization is carried out for 3 hours;

[0026] Step 2: Cool down to 60°C, then add 80g of epoxy resin E51 to the above reactor, after adding, keep it warm at 70-85°C for 2-3h;

[0027] Step 3: Add acrylic acid to the above reactor, react at 90-105°C for 3-5 hours under the action of a certain catalyst 0.64g N,N dimethylbenzylamine and a polymerization inhibitor 0.08g p-hydroxyanisole, Obtain polyurethane-epoxy acrylic acid prepolymer;

[0028] Step 4: Add maleic anhydride to the polyurethane-epoxy acrylic acid prepolymer at 60-75°C, react for 2-3 hours, cool to 50-60°C...

Embodiment 2

[0031] Step 1: Add 20 g of isophorone diisocyanate to the dry reactor, and drop 30 g of a mixture of polytetrahydrofuran ether diol and propylene glycol at 40-50 ° C (polyoxypropylene diol: propylene glycol = 5: 1 (mass ratio)), the dropping time is 2 hours, and the method of heat preservation during the dropping process is: ice water bath and warm water bath are used alternately to ensure that the temperature is stable during the dropping process. ;

[0032] Step 2: Cool down to 60°C, then add 50g of epoxy resin E51 to the above reactor, after adding, keep warm at 70-85°C for 2-3h;

[0033]Step 3: Add acrylic acid to the above reactor, react at 90-105°C for 3-5 hours under the action of a certain catalyst 0.8g tetrabutylammonium bromide and a polymerization inhibitor 0.4g hydroquinone to obtain polyurethane - Epoxy acrylic acid prepolymer;

[0034] Step 4: Add maleic anhydride to the polyurethane-epoxy acrylic acid prepolymer at 60-75°C, react for 2-3 hours, cool to 50-60°C...

Embodiment 3

[0037] Step 1: Add 5g of toluene diisocyanate to the dry reactor, add 10g of polybutylene adipate diol dropwise at 40-50°C, dropwise for 0.5h, and keep warm during the dropping process: The ice water bath and the warm water bath are used alternately to ensure that the temperature is stable during the dropwise addition. After the dropwise addition is completed, the temperature is raised to 60-80°C, and the heat preservation polymerization is carried out for 3 hours;

[0038] Step 2: Cool down to 60°C, and then add 80 parts by weight of epoxy resin E51 to the above reactor, after adding, keep warm at 70-85°C for 2-3h;

[0039] Step 3: Add acrylic acid to the above reactor, and react at 90-105°C for 3-5 hours under the action of a certain catalyst 0.64g triethylamine and a polymerization inhibitor 0.08g2,6-di-tert-butyl-p-cresol , to obtain polyurethane-epoxy acrylic acid prepolymer;

[0040] Step 4: Add maleic anhydride to the polyurethane-epoxy acrylic acid prepolymer at 60-75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com