Method for preparing PU (polyurethane) synthetic leather additive

A synthetic leather and additive technology, applied in textiles and papermaking, raw material separation, paper recycling, etc., can solve problems such as price reduction, and achieve the effect of low price, wide source and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

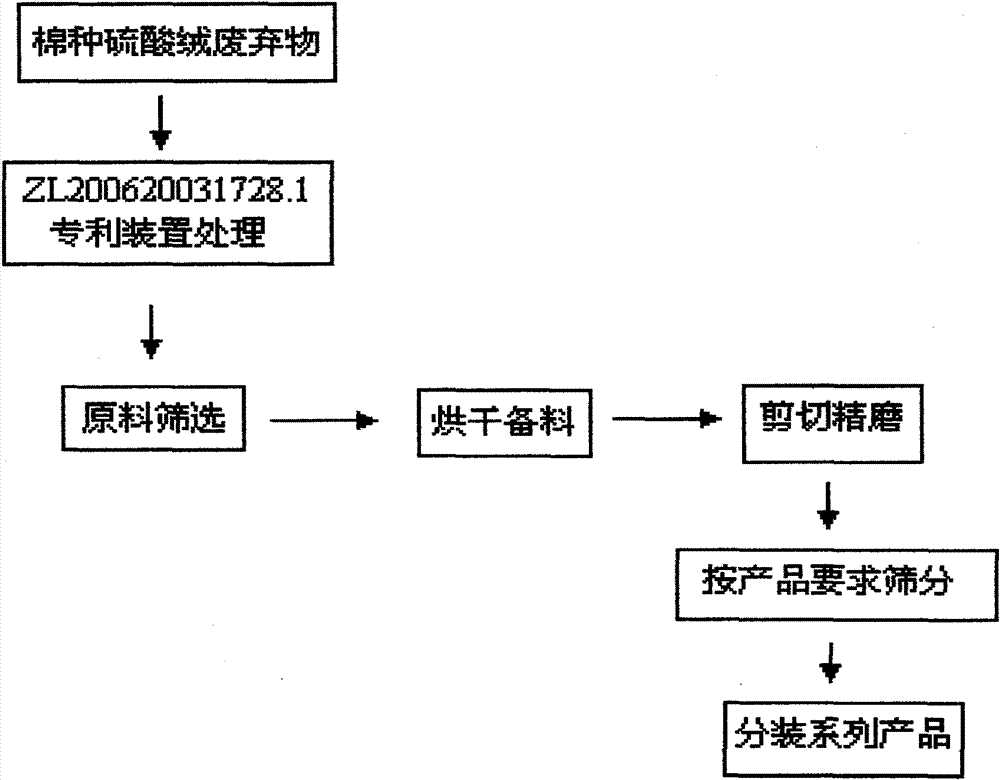

[0023] A preparation method of PU nubuck leather cellulose powder additive: it is characterized in that the following steps are completed:

[0024] A. Raw material screening: After treating waste sulfuric acid velvet with ZL200620031728 patented technology of Zhang Nan, the obtained ash content is 0.4-1.5%, whiteness ≥ 65, cellulose content ≥ 98%, polymerization degree of about 300, and fineness of 60 mesh Cotton pulp powder industrial raw material left and right.

[0025] B. High-temperature drying: use drying equipment to dry the purified cotton pulp powder industrial raw materials at high temperature, and the moisture content of the dried cotton pulp powder must not exceed 10%;

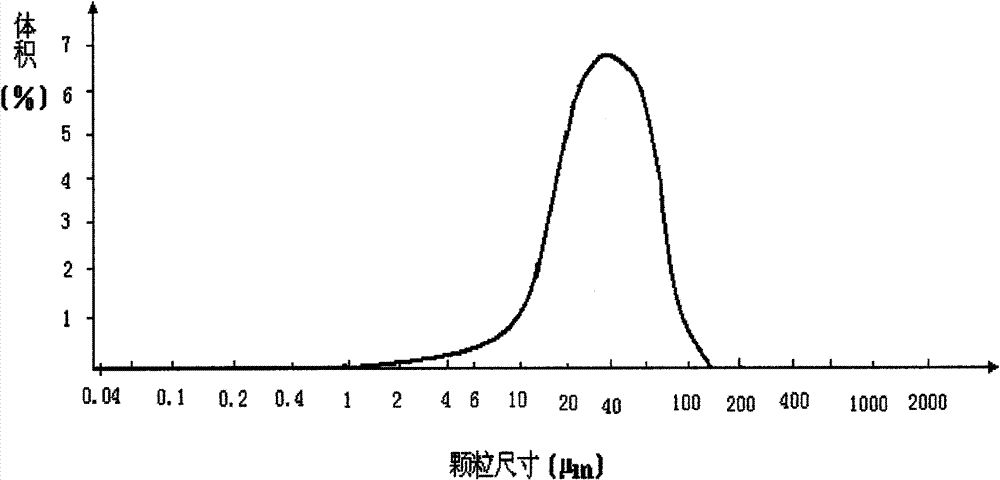

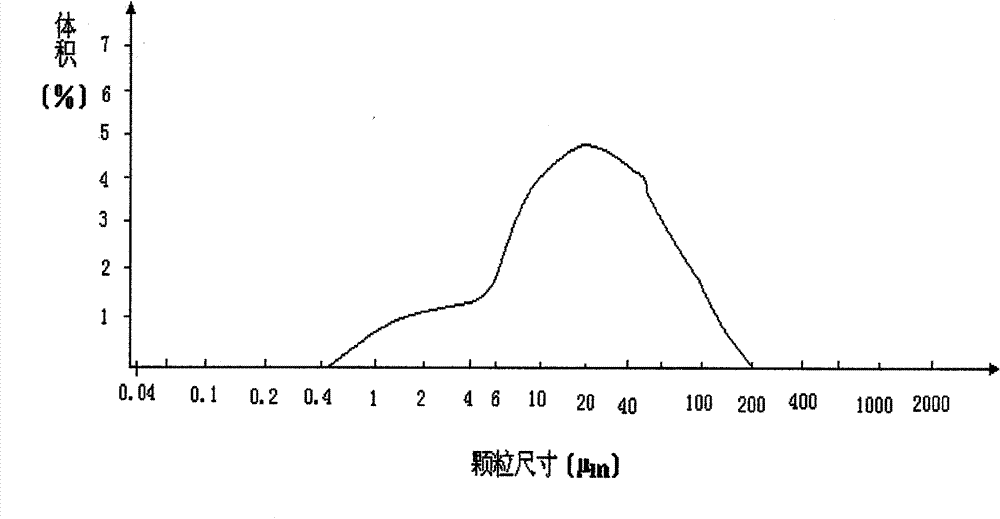

[0026] C, extruding, shearing and grinding: select roller mill and shearing fine mill, after mixing 65% of cotton pulp powder and 35% of poplar wood pulp (powder), physically extrude and shear together. Cut and grind to 325-1000 mesh to prepare cellulose fine powder additive with fiber length 16-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com