Shallow fringe transparent hard coating film for in-mold decoration

A technology of in-mold decoration and interference patterns, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve problems that affect product applications and affect product visual effects, and achieve the effect of solving interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

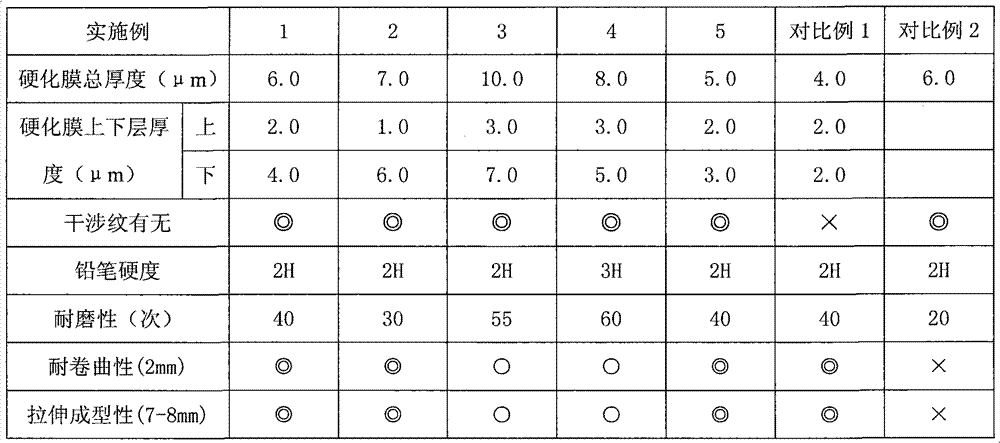

Examples

Embodiment 1

[0035] Underlayer Coating Material

[0036] 611A-85 16.0 parts by weight;

[0037] 184 1.6 parts by weight;

[0038] BYK 377 0.1 parts by weight;

[0039] Butanone 22.3 parts by weight;

[0040] Dissolve 16.0 parts by weight of aliphatic polyurethane diacrylate prepolymer 611A-85 [manufactured by Changxing Chemical Industry Co., Ltd., functionality 2] into 22.0 parts by weight of methyl ethyl ketone solvent, add 0.1 parts by weight of polydimethyl The leveling agent BYK 377 [manufactured by BYK] with siloxane skeleton structure and 1.6 parts by weight of photoinitiator 184 [manufactured by Tianjin Tianjiao Chemical Co., Ltd.] were used to obtain the coating materials.

[0041] The above-mentioned coating material is applied to one side of a polyethylene terephthalate film [manufactured by China Lucky Film Group Corporation, trade name; PG12-125] with a thickness of 125 micrometers of optical grade, and heated at 70-90° C. After the formed coating dries for 2min, with 250mJ...

Embodiment 2

[0052] Underlayer Coating Material

[0053] 611A-85 16.0 parts by weight;

[0054] 184 1.6 parts by weight;

[0055] BYK 377 0.1 parts by weight;

[0056] Butanone 22.3 parts by weight;

[0057] Dissolve 16.0 parts by weight of aliphatic polyurethane diacrylate prepolymer 611A-85 [manufactured by Changxing Chemical Industry Co., Ltd., functionality 2] into 22.0 parts by weight of methyl ethyl ketone solvent, add 0.1 parts by weight of polydimethyl The leveling agent BYK 377 [manufactured by BYK] and 1.6 parts by weight of photoinitiator 184 [manufactured by Tianjin Tianjiao Chemical Co., Ltd.] were used to obtain coating materials.

[0058] The above-mentioned coating material is applied to one side of a polyethylene terephthalate film [manufactured by China Lucky Film Group Corporation, trade name; PG12-125] with a thickness of 125 micrometers of optical grade, and heated at 70-90° C. After the formed coating dries for 2min, with 250mJ / cm 2 The amount of light, the dried...

Embodiment 3

[0069] Underlayer Coating Material

[0070] 611A-85 16.0 parts by weight;

[0071] 184 1.6 parts by weight;

[0072] BYK 377 0.1 parts by weight;

[0073] Butanone 22.3 parts by weight;

[0074] Dissolve 16.0 parts by weight of aliphatic polyurethane diacrylate prepolymer 611A-85 [manufactured by Changxing Chemical Industry Co., Ltd., functionality 2] into 22.0 parts by weight of methyl ethyl ketone solvent, add 0.1 parts by weight of polydimethyl The leveling agent BYK 377 [manufactured by BYK] with siloxane skeleton structure and 1.6 parts by weight of photoinitiator 184 [manufactured by Tianjin Tianjiao Chemical Co., Ltd.] were used to obtain the coating materials.

[0075] The above-mentioned coating material is applied to one side of a polyethylene terephthalate film [manufactured by China Lucky Film Group Corporation, trade name; PG12-125] with a thickness of 125 micrometers of optical grade, and heated at 70-90° C. After the formed coating dries for 2min, with 250mJ / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com