Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of photoelectric conversion efficiency to be further improved, poor stability, etc., to achieve high visible light transmittance, improved stability, and good extension. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is a method for preparing a perovskite solar cell without an electron transport layer, and the preparation process is as follows:

[0041] a) Provide ultra-clear float glass with a thickness of 3.2 mm, ultrasonically clean it in deionized water and absolute ethanol for 10 minutes, and blow dry;

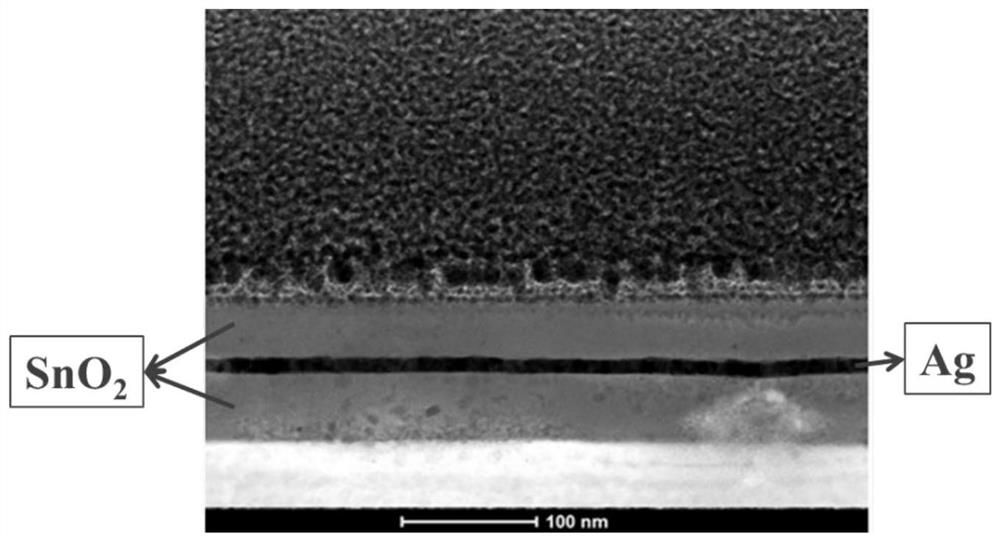

[0042] b) On the upper surface of the cleaned ultra-clear float glass, a dielectric layer of SnO was sequentially deposited by magnetron sputtering. 2 , metal Ag layer, multifunctional SnO 2 layer to form a multilayer film electrode. The thickness thereof is 50 nm, 10 nm, and 50 nm, respectively.

[0043] Among them, SnO 2 Layer preparation process parameters and process are as follows:

[0044] 1) Before coating, use mechanical pump and molecular pump to vacuum the coating chamber to 7×10 -4 Below Pa.

[0045] 2) Select tin oxide ceramic target, sputtering gas with Ar, O at a ratio of 19:1 2 , and select the RF power supply.

[0046] 3) Passing Ar, O 2...

Embodiment 2

[0063] This embodiment is a method for preparing a perovskite solar cell without an electron transport layer, and the preparation process is as follows:

[0064] a) Provide a PET substrate, ultrasonically clean it in absolute ethanol for 10 minutes, and dry it;

[0065] b) On the upper surface of the cleaned PET flexible substrate, a dielectric layer SnO is sequentially deposited by magnetron sputtering 2 , metal Ag layer, nano-suppression layer NiCr, multifunctional SnO 2 layer. The thickness thereof is 50 nm, 8 nm, 1 nm, and 50 nm, respectively.

[0066] Among them, SnO 2 Layer preparation process parameters and process are as follows:

[0067] 1) Before coating, use mechanical pump and molecular pump to vacuum the coating chamber to 7×10 -4 Below Pa.

[0068] 2) Select tin oxide ceramic target, sputtering gas with Ar, O at a ratio of 19:1 2 , and select the RF power supply.

[0069] 3) Passing Ar, O 2 The mixed gas, adjust the pressure to 2Pa.

[0070] 5) Adjust t...

Embodiment 3

[0092] This embodiment is a method for preparing a perovskite solar cell. The perovskite solar cell includes a substrate layer, a dielectric layer, a metal conductive layer, a multifunctional layer, an electron transport layer, and a perovskite active layer arranged in sequence from bottom to top. , hole transport layer and back electrode layer.

[0093] The preparation process is as follows:

[0094] a) Provide 30 μm flexible foldable glass, ultrasonically clean it in absolute ethanol for 10 minutes, and blow dry;

[0095] b) On the upper surface of the cleaned flexible and foldable glass, a dielectric layer of SnO is sequentially deposited by magnetron sputtering 2 , metal Ag layer, multifunctional SnO 2 layer. Their thicknesses are 50nm, 8nm, and 50nm, respectively.

[0096] Among them, SnO 2 Layer preparation process parameters and process are as follows:

[0097] 1) Before coating, use mechanical pump and molecular pump to vacuum the coating chamber to 7×10 -4 Belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com