Pallet having corrugated components and modular method of making same

a technology of corrugated components and pallets, applied in the field of pallets, can solve the problems of lack of compactness, large weight, environmental impact, etc., and achieve the effects of reducing space, enhancing the strength of the pallet and its resistance to collapse, and reducing the amount of spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

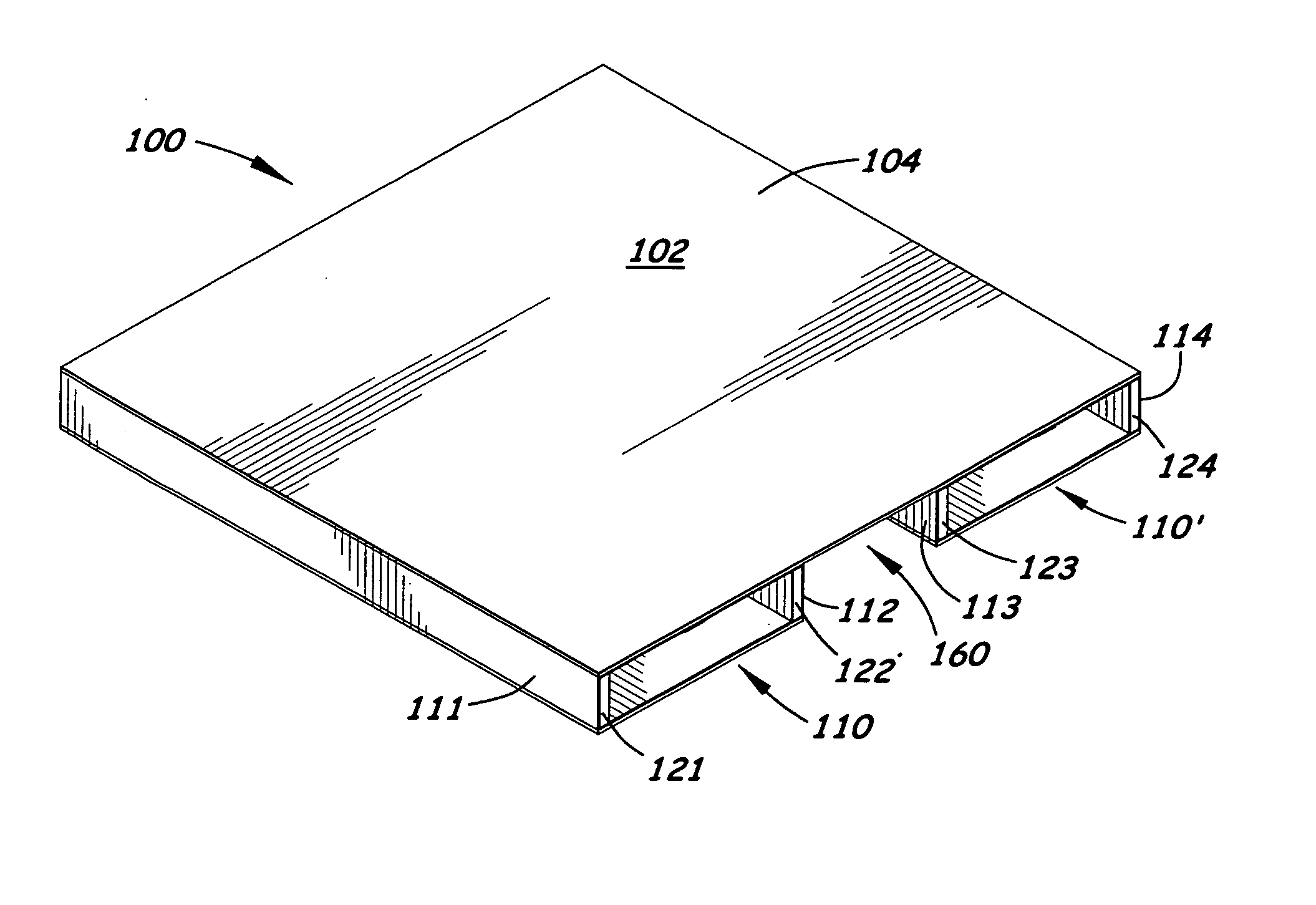

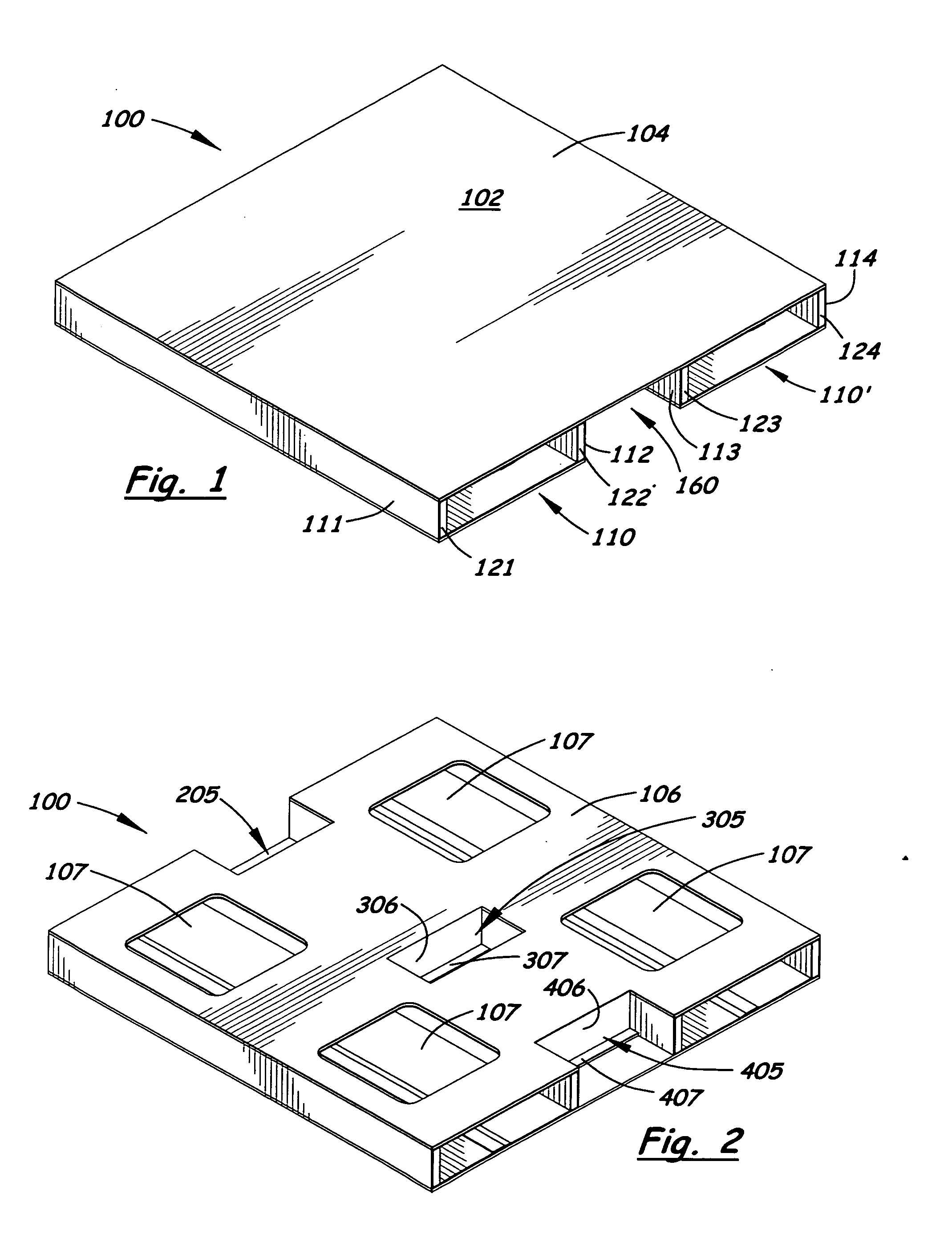

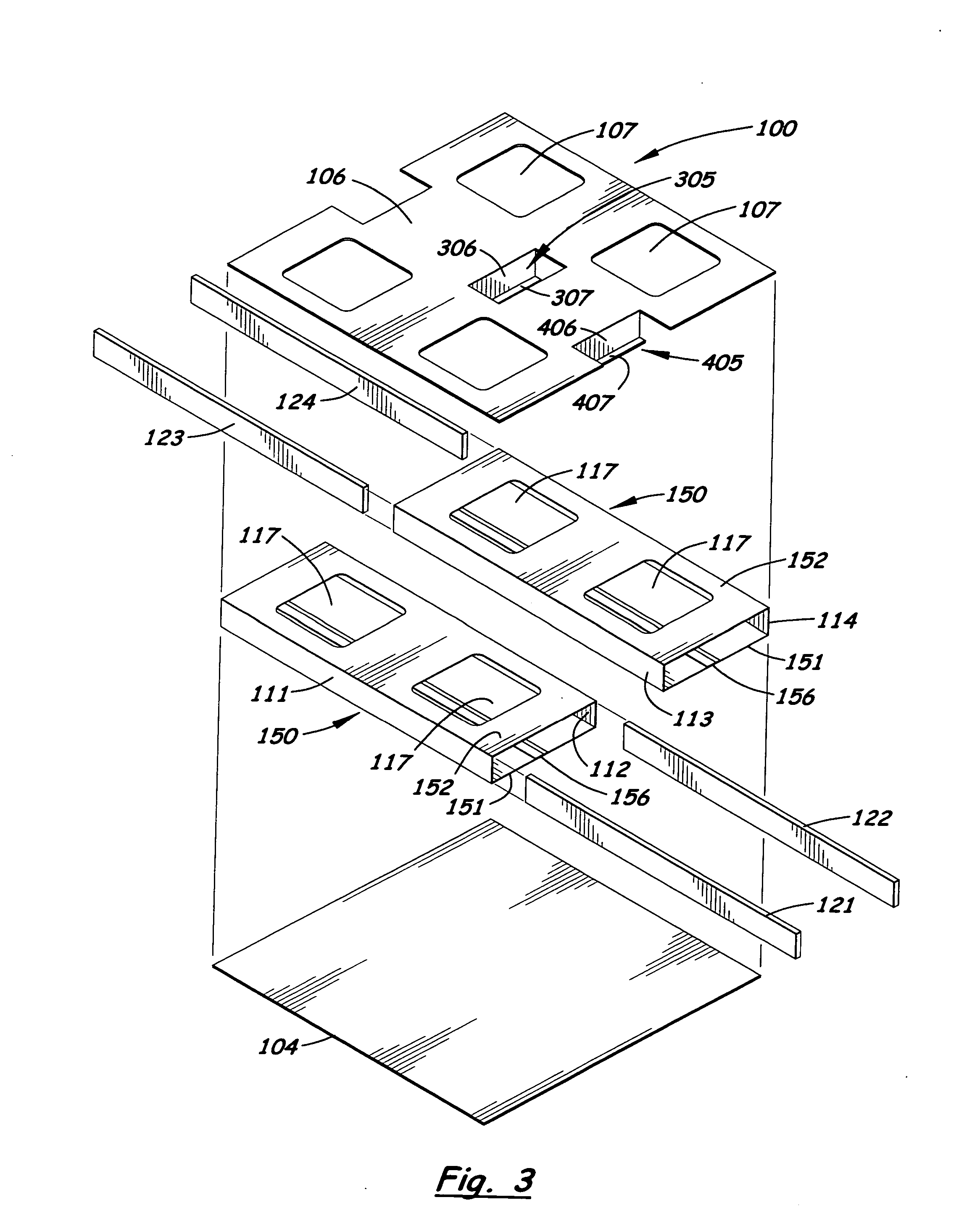

[0029] Referring to the Figures, there are shown several, but not the only, embodiments of the invented pallet. The invented pallet comprises a corrugated material and runner configuration that is particularly convenient and economical during manufacture, transport, and final assembly, and that is remarkably strong and resistant to damage from forklifts. The invented pallets are particularly effective for indoor storage and handling, however, weather-resistant coatings such as “carton coating” or covers may allow the pallets to be used outdoors at least in some climates.

[0030] The invented pallets comprise runner assemblies that run longitudinally along substantially the entire, or the entire, length of the pallet, and at least one transverse wall that extends perpendicularly to the runner assemblies, and that preferably extends between and contacts two of said runner assemblies. The preferred runner assemblies comprise housings and runner structures. The runner structures provide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com