Water-based coated composite environment-friendly packaging material and preparation process thereof

A packaging material and a preparation process technology, which is applied in the field of water-based coating composite environmental protection packaging materials, can solve the problems of the composite film, such as the decline of water vapor barrier oxygen barrier performance, long dissolution emission and curing time, and large emission of volatile organic compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

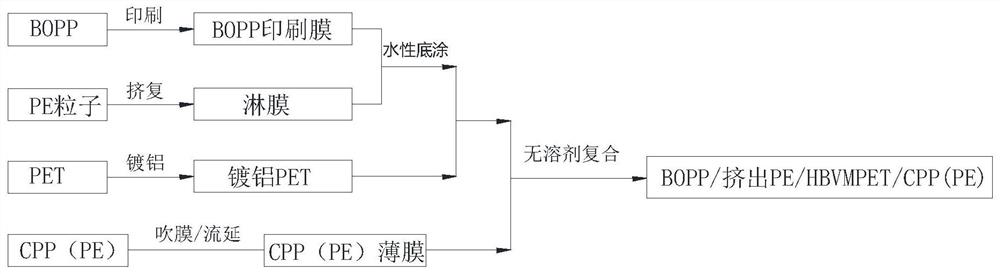

[0026] S1, the BOPP film is made BOPP printing film through flexographic printing process; Prepare PE layer raw material and take polyethylene resin and acrylic acid modified polyethylene resin and make coating film through extrusion compounding process;

[0027] S2. The BOPP printing film is bonded to the PE layer of the laminating film through the glue layer, and then the blending layer of the laminating film is bonded to the aluminized PET layer to obtain the first composite film;

[0028] S3. After the first composite film in step S2 is left statically for 24 hours, the second composite film 1 is obtained by solvent-free extrusion compounding of the adhesive layer and the polyolefin film, wherein the adhesive layer needs to be conditioned at 40-50°C. After curing for 30 hours, it needs to be cooled at room temperature for more than 18 hours to prepare the second composite film 1 .

[0029] Wherein, the ink used in the flexographic printing is an alcohol-soluble ink, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com