Method for producing PVC-B (polyvinyl chloride-board) magnetic card surface course

A technology of PVC-B and magnetic card surface layer, applied in the field of PVC-B magnetic card surface layer production, can solve the problems such as the thickness control of ultra-thin materials is not stable enough, the surface texture is not beautiful and delicate, and the production efficiency is low, etc., and saves money. The amount of glue, the surface texture is beautiful and delicate, and the production efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

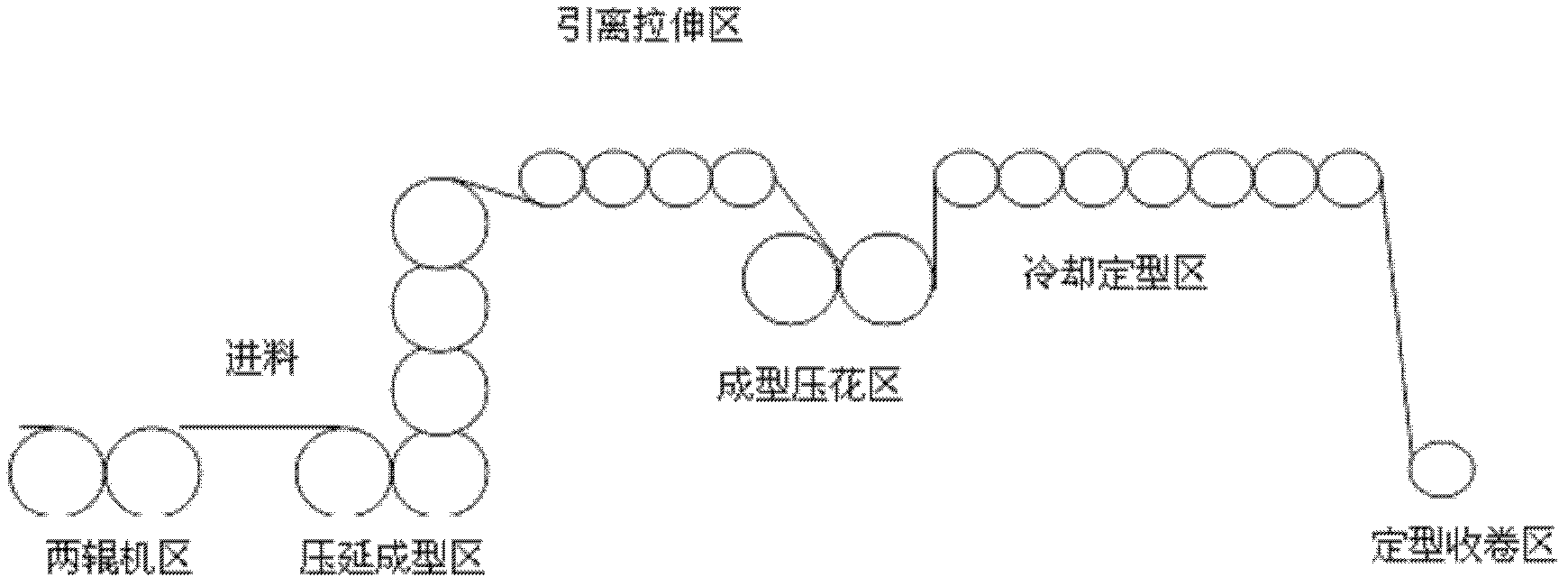

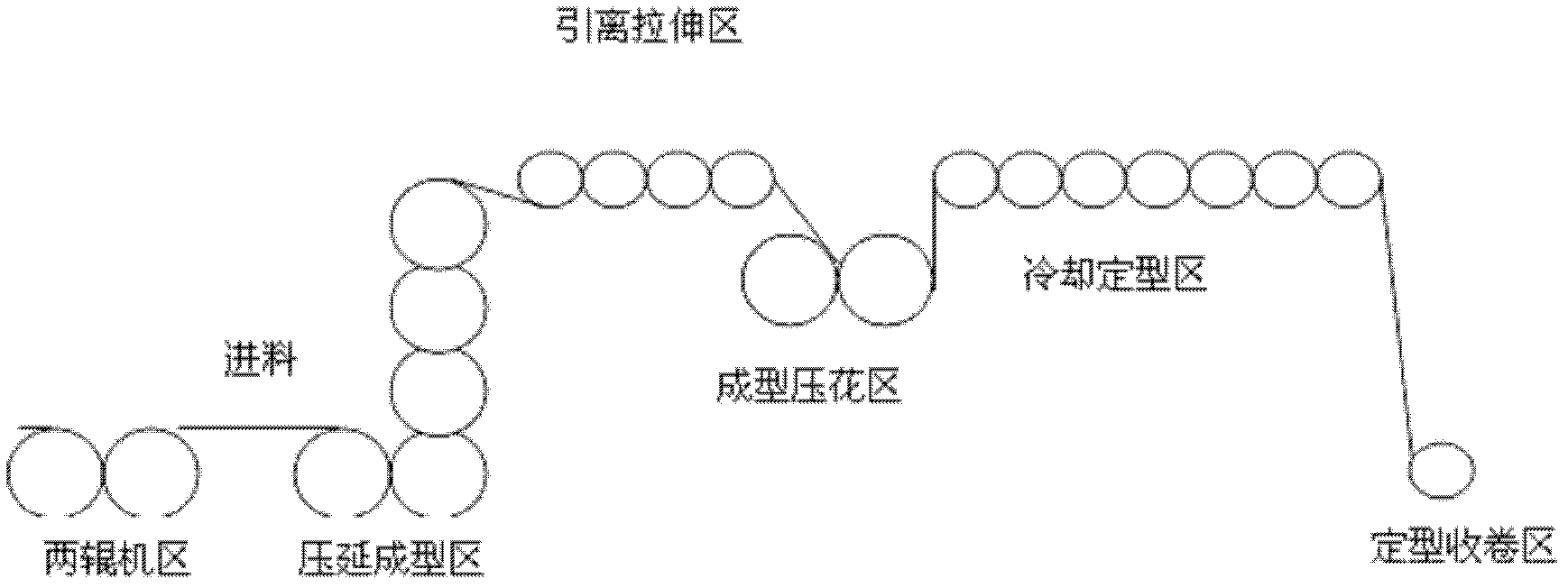

[0019] See figure 1 , the production method of PVC-B magnetic card top layer of the present invention has following production steps:

[0020] 1) Measure and mix the raw materials, put them into the extruder, the temperature of the extruder sleeve is 120-140°C, and the temperature of the die is 130-150°C; 2) The extruded material enters the two-roller machine area, so that the PVC powder is evenly plasticized, The temperature of the roller machine is 110℃~145℃, and the speed is 20m / min~30m / min; 3) Enter the calendering forming area, so that the PVC powder is initially formed into a film shape. The temperature of the calendering rubber cloth wheel is 165℃~195℃, and the speed is 12m / min. min~28m / min; 4) Enter the lead-off stretching zone to make the formed PVC film meet the required specifications. Embossing area, embossing and shaping the PVC film, the temperature of the embossing wheel is 5 ° C ~ 15 ° C, the speed is 60m / min ~ 140m / min, and the oil pressure is 2 ~ 6Kg; 6) Ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com