Method for manufacturing wind power blade crossbeam mold

A wind power blade and blade technology, which is applied in the field of wind power blade girder mold production, can solve problems affecting blade service life, web top mold, girder structure damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

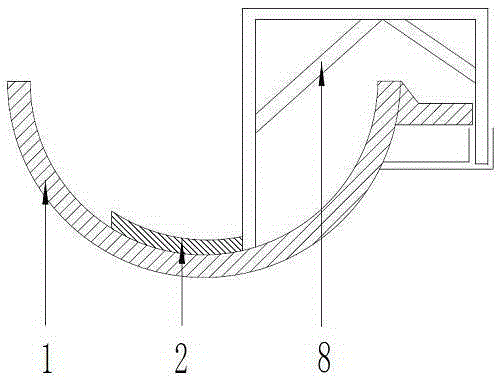

[0040] The present invention is described in conjunction with accompanying drawing and specific embodiment, and this embodiment takes the making of the male mold mold of the lee side girder of the 55.2 meter blade of lengthening type 2MW as an example;

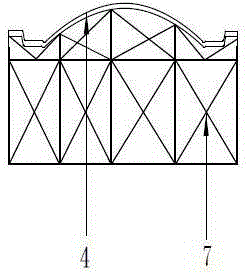

[0041] Such as figure 1 , figure 2 As shown, a method for manufacturing a wind power blade girder mold, the basic steps of making a wind power blade girder mold are to make a blade male mold, and turn the blade female mold 1 on the blade male mold; after the blade female mold 1 is manufactured , make a standard blade girder model 2 on the blade female mold 1, and then turn the blade girder male mold on the blade girder model 2; the specific manufacturing steps are:

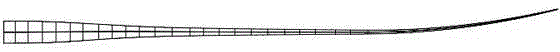

[0042] 1) Preparation of the male blade mold: According to the cross-sectional shape of each position in the electronic model of the blade, the iron profile plate of each position of the blade is obtained by laser cutting method, and the iron profile plate is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com