PVC (polyvinyl chloride) floor fitting device

A technology for laminating devices and floors, applied in the directions of lamination devices, lamination auxiliary operations, lamination, etc., can solve the problems affecting the appearance quality of products, leaving imprints on the surface of products, affecting product quality, etc., and shortening the production time. , The effect of reducing the amount of glue and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

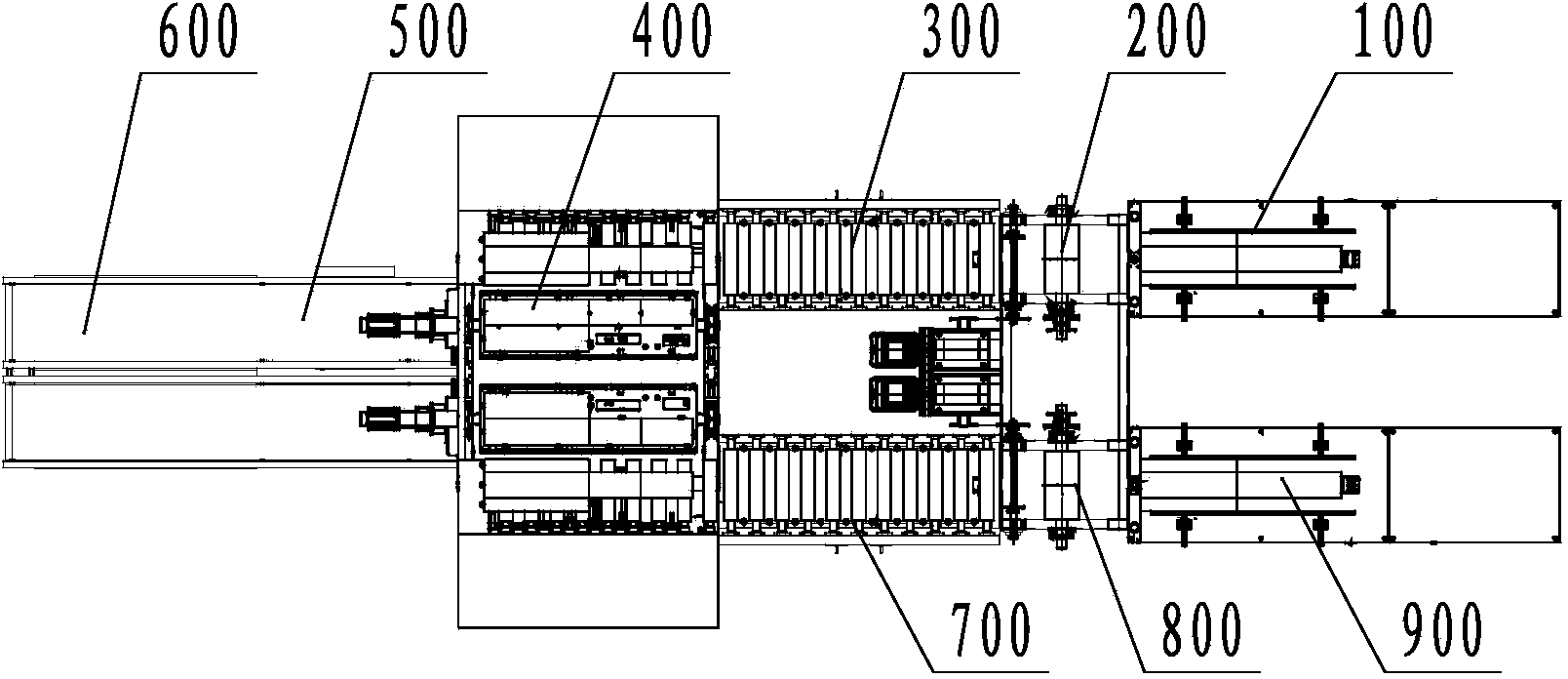

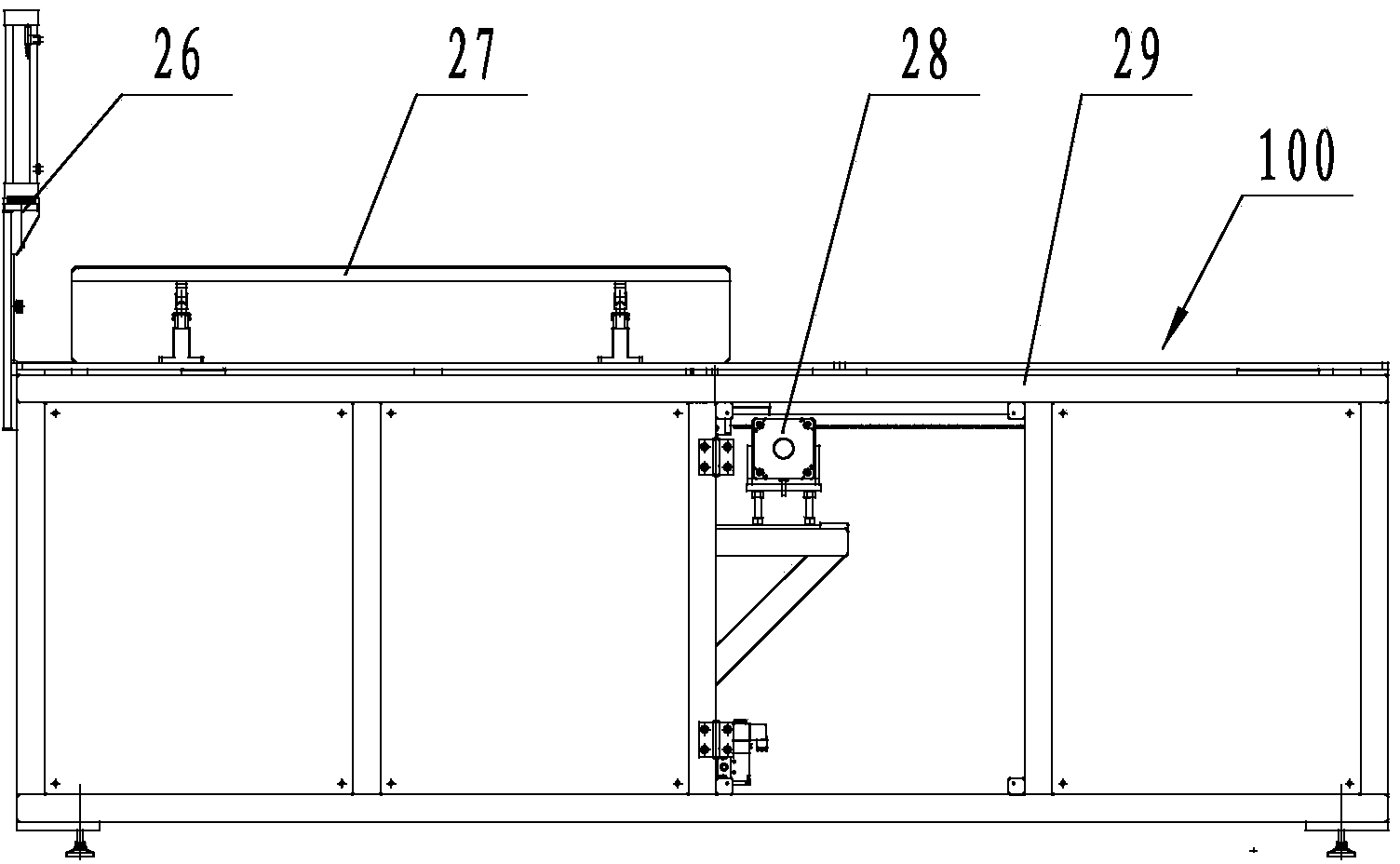

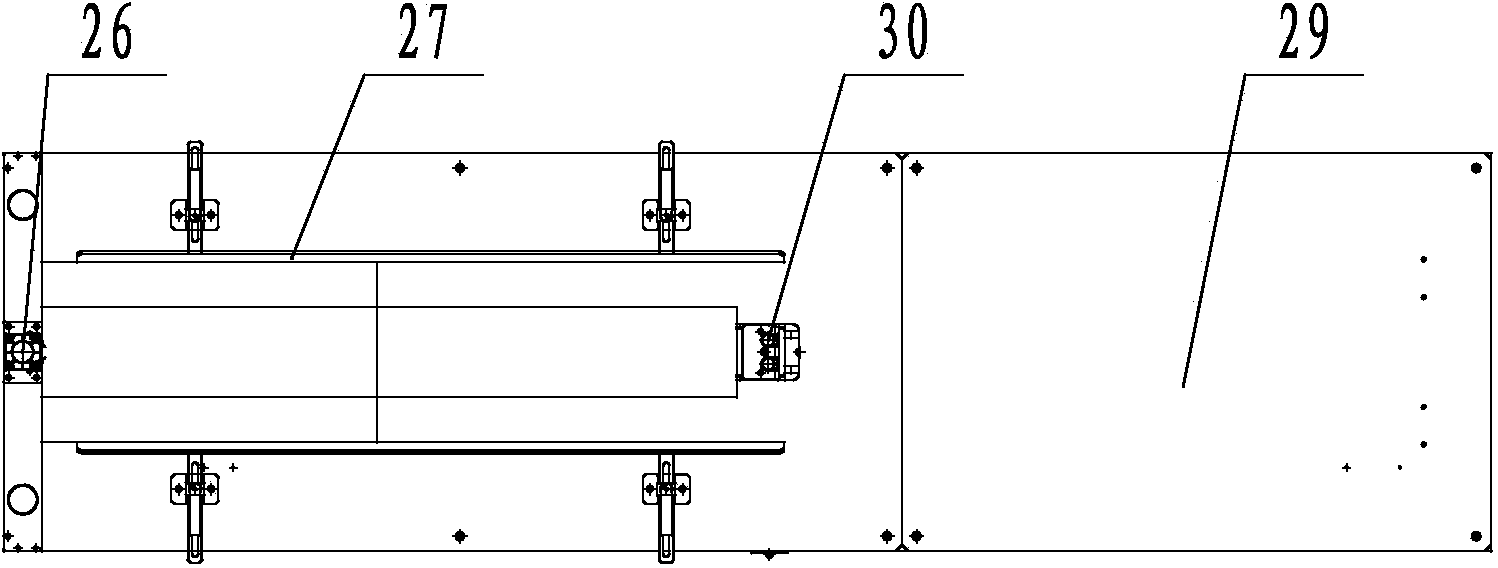

[0027] Figure 1 to Figure 10 Among them, it includes surface material feeding machine 100, surface material gluing machine 200, surface material conveyor 300, high-speed laminating machine 400, belt conveyor line 500, pressurization and holding machine 600, base material conveyor 700, base material gluing machine Machine 800, substrate feeding machine 900, surface material feeding mechanism 1, surface material conveying roller 2, surface material laminating roller 3, substrate laminating roller 4, substrate conveying roller 5, substrate feeding Mechanism 6, substrate laminating roller rotation motor 7, substrate laminating roller moving mechanism 8, surface material laminating roller rotating motor 9, surface material laminating roller moving mechanism 10, material pushing head 11, material pushing Rod 12, linear guide column 13, stepper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com