High-performance bi-component polyurethane adhesive and preparation method thereof

A two-component polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of affecting leveling, increasing the amount of glue, and failing to meet the peel strength requirements , lower bonding strength, etc., to achieve the effect of easy recycling, improved peel strength, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

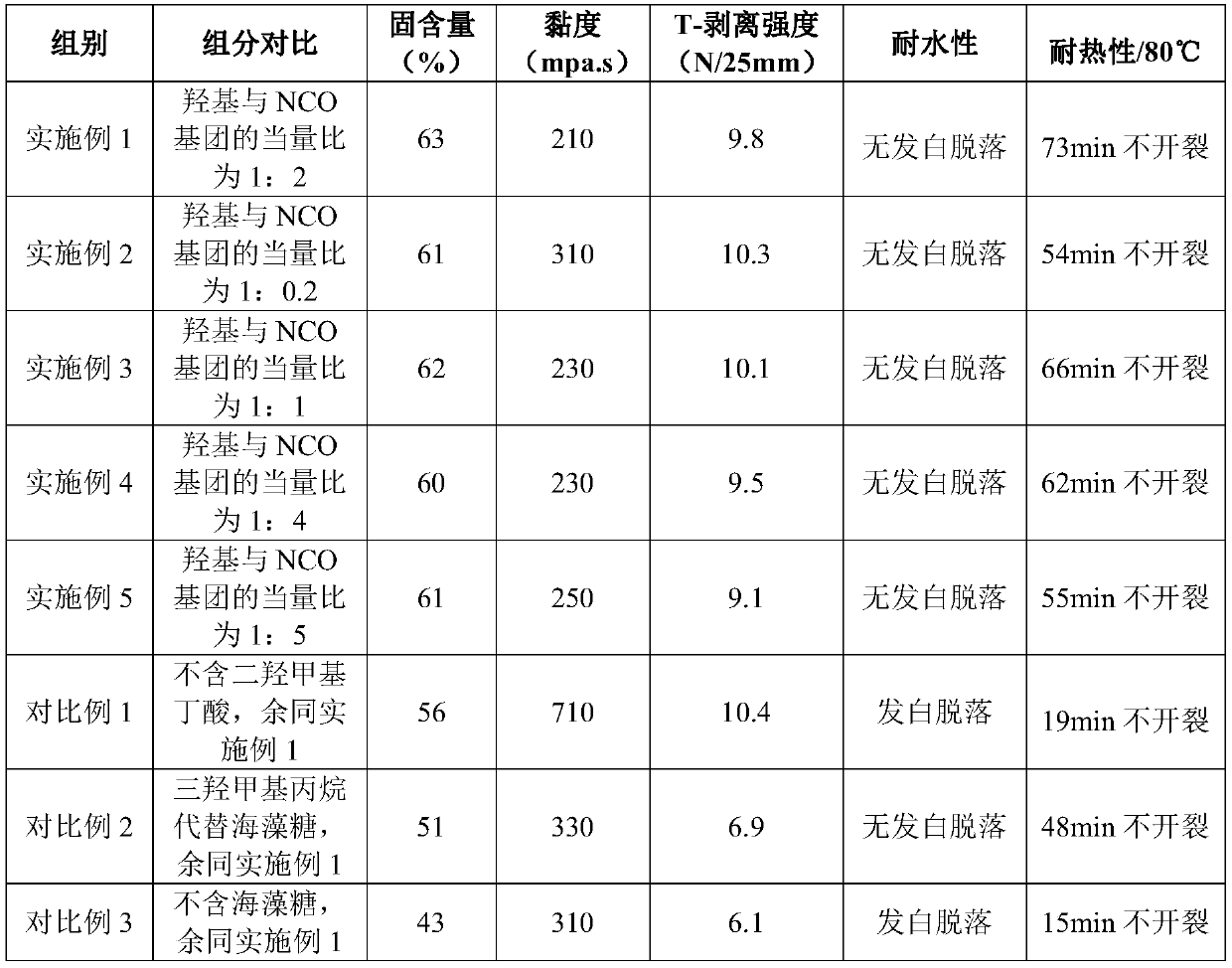

Examples

Embodiment 1

[0027] A kind of preparation method of high-performance two-component polyurethane adhesive:

[0028] (1) Weigh 25g of isophorone-diisocyanate into a reaction flask, dehydrate, then add 1g of catalyst dibutyltin dilaurate and 6g of polycaprolactone diol, and react at a constant temperature of 65°C for 1.5h; add 5g Acetone reduces viscosity, add 2g dimethylolbutyric acid to react at constant temperature for 1.5h, add 4g triethylamine to neutralize after cooling, transfer to a mixer, stir at a high speed of 17000r / min and add 1g of pre-mixed water-based anion Type polyurethane dispersion U54 and 8g deionized water, after emulsification for 15 minutes, then add 5g of ethylenediamine to extend the chain for 60 minutes, and finally evaporate the solvent under reduced pressure to obtain component A;

[0029] (2) Weigh 8g of 4,4'-dicyclohexylmethane diisocyanate, 10g of sulfonated polyether polyol and 12g of polyhexamethylene adipate into the reaction bottle, then add 5g of seaweed a...

Embodiment 2

[0032] A kind of preparation method of high-performance two-component polyurethane adhesive:

[0033] (1) Weigh 15g of isophorone-diisocyanate into a reaction flask, dehydrate, then add 0.5g of catalyst dibutyltin dilaurate and 10g of polycaprolactone diol, and react at a constant temperature of 60°C for 1h; add 4g Acetone reduces the viscosity, add 1g of dimethylolbutyric acid to react at constant temperature for 1h, add 4g of triethylamine to neutralize after cooling, transfer to a mixer, stir at a high speed of 17000r / min and add 1g of pre-mixed water-based anionic Polyurethane dispersion U54 and 8g of deionized water were emulsified for 15 minutes, then 5g of ethylenediamine was added to extend the chain for 60 minutes, and finally the solvent was distilled off under reduced pressure to obtain component A;

[0034] (2) Weigh 5g of 4,4'-dicyclohexylmethane diisocyanate, 10g of sulfonated polyether polyol and 8g of polyhexamethylene adipate into the reaction bottle, then add...

Embodiment 3

[0037] A kind of preparation method of high-performance two-component polyurethane adhesive:

[0038] (3) Weigh 30g of isophorone-diisocyanate into a reaction flask, dehydrate it, then add 3g of catalyst dibutyltin dilaurate and 10g of polycaprolactone diol, and react at a constant temperature of 70°C for 2h; add 8g of acetone Reduce the viscosity, add 3g of dimethylolbutyric acid to react at constant temperature for 2 hours, add 6g of triethylamine after cooling to neutralize, transfer to a mixer, add 1g of pre-mixed water-based anionic polyurethane dispersion at a speed of 17000r / min U54 and 10g of deionized water, after emulsification for 15min, then add 8g of ethylenediamine to extend the chain for 60min, and finally evaporate the solvent under reduced pressure to obtain component A;

[0039] (4) Weigh 15g of 4,4'-dicyclohexylmethane diisocyanate, 15g of sulfonated polyether polyol and 15g of poly-1,6-hexanediol adipate into the reaction bottle, and then add 8g of cross-li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com