Antirust oil and preparation method thereof

A technology of anti-rust oil and base oil, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of users' choice of oil products and inconvenience in use, and achieve the effect of long-term anti-rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

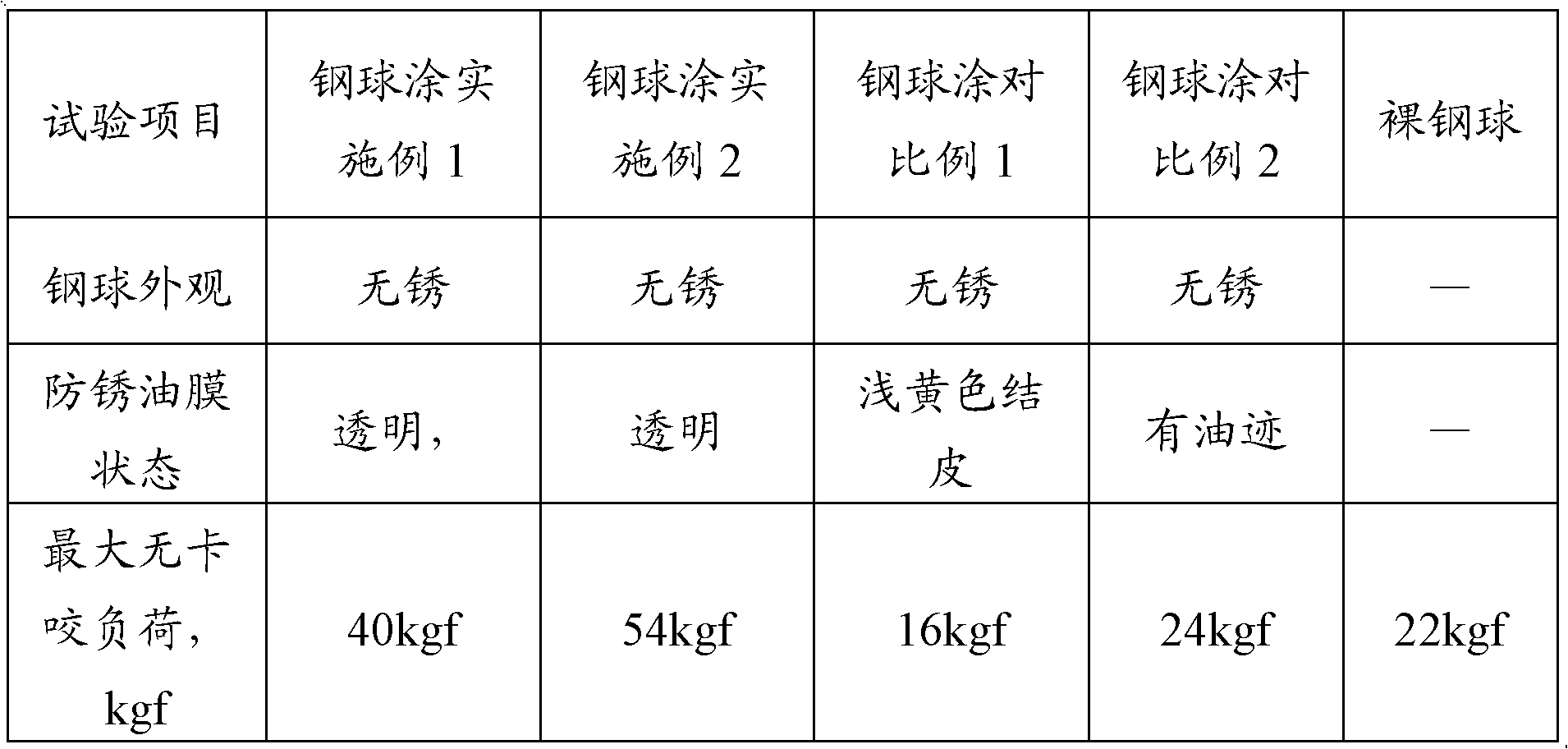

Examples

preparation example Construction

[0041] The present invention also provides a kind of preparation method of antirust oil, comprises the following steps:

[0042] a) mixing and reacting raw materials comprising polyhydric alcohols and dicarboxylic acids to generate complex esters;

[0043] b) Heat the base oil to 60°C-80°C, add barium petroleum sulfonate, barium dinonylsulfonate, dodecenylsuccinic acid, benzotriazole and di-n-butyl phthalate in sequence, and then Add the prepared complex ester, stir until the material is completely dissolved and then filter;

Embodiment 1

[0045] Add 815kg of solvent oil into the kettle, raise the temperature to 60°C, add 100kg of barium petroleum sulfonate, 30kg of barium dinonylsulfonate, 5kg of dodecenylsuccinic acid, 4.5kg of benzotriazole, and phthalic acid 45.5kg of di-n-butyl ester, 10kg complex ester, complex ester is obtained by the reaction of dipentaerythritol ester, adipic acid and neodecanoic acid with a mass ratio of 4:5:3, stirred for two hours, and filtered after the material is completely dissolved to obtain product.

Embodiment 2

[0047] Add 845kg of polyalphaolefin synthetic oil into the kettle, raise the temperature to 70°C, add 40kg of barium petroleum sulfonate, 20kg of barium dinonylsulfonate, 15kg of dodecenyl succinic acid, 4.5kg of benzotriazole, and 45.5kg of di-n-butyl phthalate, 30kg of complex ester, the complex ester is obtained by the reaction of trimethylolbutane, glutaric acid and decanol with a mass ratio of 3:4:2, stir for two hours, and wait for the material to dissolve After complete filtration, the product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com