Preparation method of metal antirust agent containing 1-hydroxybenzotriazol

A technology of hydroxybenzotriazole and metal antirust agent, which is applied in anticorrosion coatings, coatings, etc., can solve the problems of poor antirust performance of antirust agents, achieve extended antirust time, good compatibility, Anti-rust effect for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

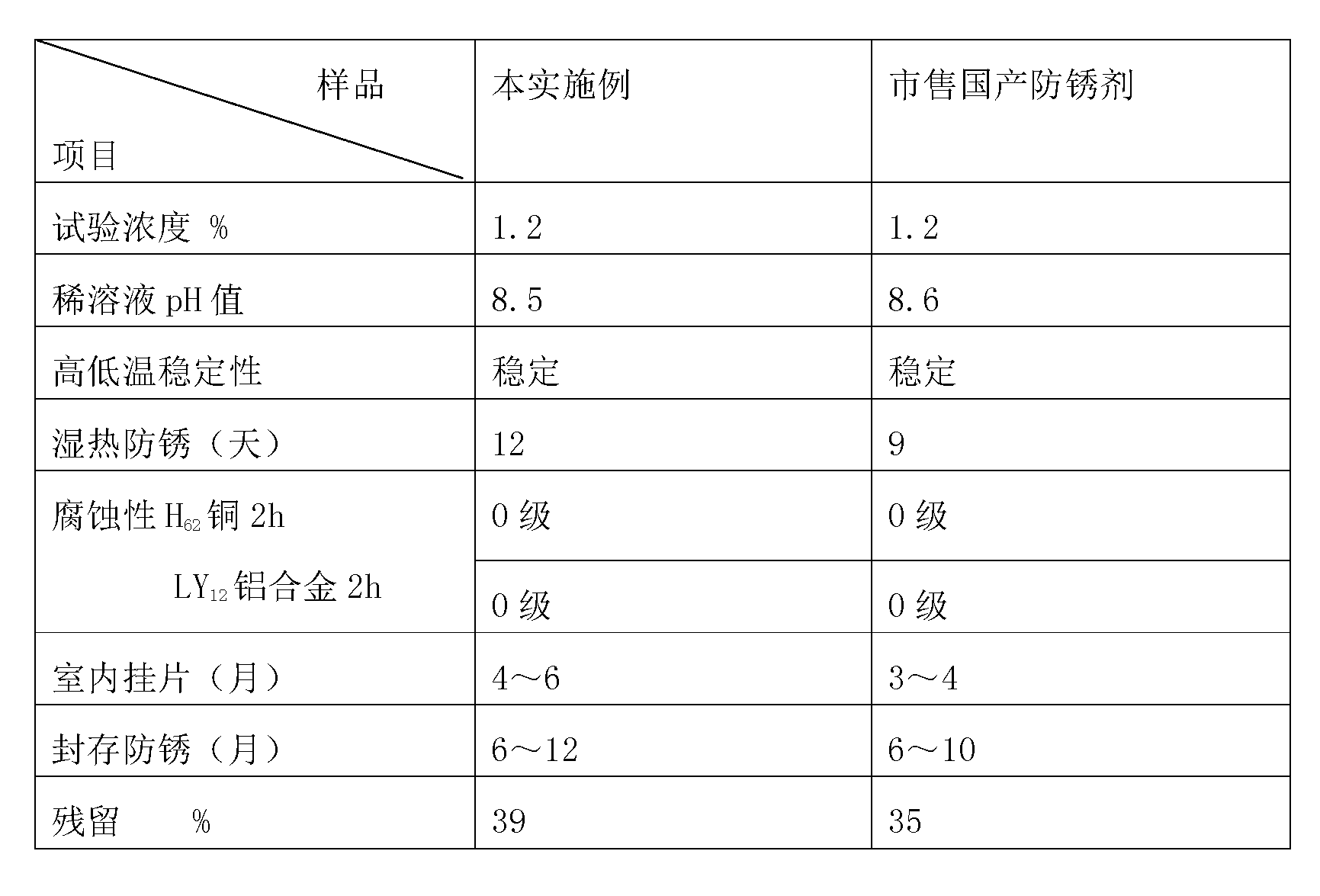

Examples

Embodiment Construction

[0014] A preparation method of a metal antirust agent containing 1-hydroxybenzotriazole, comprising the following steps:

[0015] (1) 6.1 parts by weight (kg) of liquefied paraffin, 2.9 parts by weight of acetyl citrate tris (2-ethylhexyl) ester, 3.7 parts by weight of acrylic acid, 4.2 parts by weight of epoxy linseed oil, 2 parts by weight of xylene, 5 parts by weight Add polyethylene wax in parts by weight to the reactor, heat up to 110°C, start stirring and add 3.1 parts by weight of urea, 0.3 parts by weight of potassium persulfate, 0.5 parts by weight of borax, and 0.3 parts by weight of zinc powder;

[0016] (2) Then heat up to 195°C at a rate of 60°C / hour;

[0017] (3) Stop heating after 2 hours of reaction;

[0018] (4) Add the remaining raw materials into the reaction kettle in parts by weight, mix and dissolve to obtain the product;

[0019] Described remaining raw material is the component of following parts by weight:

[0020] Polyisobutene 2.2, 2-aminoethyl he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com